Polypropylene - Total Refining & Chemicals

Polypropylene - Total Refining & Chemicals

Polypropylene - Total Refining & Chemicals

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

At home in your world<strong>Polypropylene</strong>European product rangefor fibre applications

Architect: Samyn Partners & Co<strong>Total</strong> Petrochemicals Research FeluyBelgium

Filament & YarnThanks to its inherent set of properties (stain/chemical resistance, colourstability,…), PP is also extensively used for the production of ContinuousFilaments (CF), Bulked Continuous Filaments (BCF) and textile yarns (POY).<strong>Total</strong> Petrochemicals product range offers a wide range of fi ber grades allowingan optimized performance for each application.For BCF, our customers can select between grades such as PPH 7069 (bulk,resilience) or PPH 9069 (processability) depending on their requirements. Theyare proven to offer excellent spinning consistency and gasfading resistance.In CF, depending on required fi bre tenacity andspinning speed, products with MFI from 12 to 25 canbe selected, either with a standard or narrow MWD.Here as well, lumicene ® MR 2001 & MR 2002 havethe perfect design to reach a performance that is notachievable with conventional polypropylene grades.As shown in fi g 5, the high product regularity andvery narrow MWD of these products opens newhorizon to the very high tenacity market !TenacityPPH 4069 • lumicene ® MR 2002• lumicene ® MR 2001PPH 5069PPH 7069PPH 90695 15 25 Melt Flow Index*Fig. 5Raffia & StrappingHigh strength strapping or weaving tapes are made from polypropylene slit fi lms.They are used in various applications such as strapping, twines and ropes, bigbags or carpet backing. <strong>Total</strong> Petrochemicals offers various low melt fl ow gradesdepending on customer requirements. PPH 3060 (MFI 2) and PPH 4060 (MFI 3)are specifi cally designed for raffi a and strapping applications. The high cristallinitygrade PPH 4070 (MFI 3) is exceptionally adapted for the production of highmodulus slit fi lms.On top of its extensive homopolymer portfolio, <strong>Total</strong> Petrochemicals has alsodeveloped PPC 3666 which brings additional advantages in applications wherehigh elongation together with high tenacity are required. This can be seen in fi g 6which compares the performance of a blend of PPC 3666 and standard PPHgrade with a pure standard PPH grade.Fig. 6%4035302520151050Elongation at break.6 7 8 9 10Draw ratioPPH Standardblend with PPC 3666g/den76.565.554.5Maximal tenacity.46 7 8 9 10Draw ratioPPH Standardblend with PPC 3666

Information contained in this publication is true and accurate at the time of publication and to the best of our knowledge. Thenominal values stated herein are obtained using laboratory test specimens. Before using one of the products mentioned herein,customers and other users should take all care in determining the suitability of such product for the intended use. Unless specifi callyindicated, the products mentioned herein are not suitable for applications in the pharmaceutical or medical sector.The Companies within <strong>Total</strong> Petrochemicals do not accept any liability whatsoever arising from the use of this information or theuse, application or processing of any product described herein. No information contained in this publication can be considered asa suggestion to infringe patents. The Companies disclaim any liability that may be claimed for infringement or alleged infringementof patents.Marketing and SalesTOTAL PETROCHEMICALSRue de l’Industrie, 52, NijverheidstraatB-1040 Brussels - BelgiumPhone : +32 (0) 2 288 33 40Fax : +32 (0) 2 288 35 36Technical AssistanceTOTAL PETROCHEMICALS RESEARCH FELUY saZone Industrielle CB-7181 Feluy - BelgiumPhone : +32 (0) 64 40 05Fax : +32 (0) 64 46 50 : polypropylene@total.com : www.totalpetrochemicals.comwww.entercom.be : 10-2010 H7601 Photo Collection <strong>Total</strong> Petrochemicals/Michel Clinckemaille/Entercom

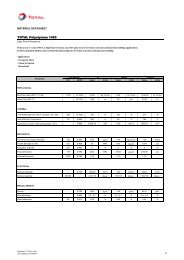

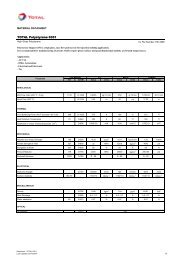

Spunbond MFI RemarkPPH 7089 12 AGF* - High tenacityPPH 9069 25 AGF - High elongationPPH 9089 25 AGFPPH 9099 25 AGFPPH 10099 35 AGFlumicene MR 2001 25 AGF - metallocenelumicene MR 2002 15 AGF - metalloceneFilament MFI RemarkPPH 7069 12 Yarn - AGFPPH 8069 18 BCF - AGFPPH 9059 25 BCF - AGFPPH 9069 25 BCF - AGFMR 2001 25 High tenacity yarn, metallocenelumicene ®lumicene ®MR 2002 15 High tenacity yarn, metalloceneStapleNonwovenMFIRemarkPPH 4069 4 Superior tenacityPPH 5069 6 High tenacity, short spinPPH 7059 12 AGF, long spinPPH 7069 12 AGF, short spinPPH 8069 18 AGFPPH 9069 25 AGFlumicene MR 2001 25 AGF - metallocenelumicene MR 2002 15 AGF - metalloceneRaffia /StrappingMFIRemarkPPH 3060 1.8 High tenacityPPH 4060 3.0 Raffi aPPH 4070 3.0 High crystalinityPPC 3666 1.5 Superior tenacity/elongation* AGF = Anti Gas Fading