Download... - Emuge UK

Download... - Emuge UK

Download... - Emuge UK

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

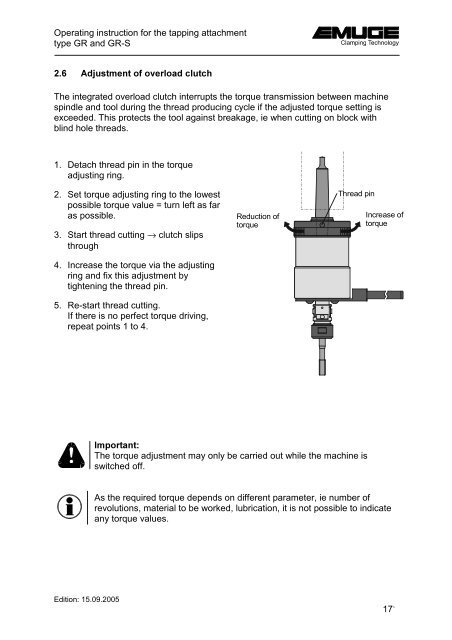

Operating instruction for the tapping attachmenttype GR and GR-S$GMXVWPHQWRIRYHUORDGFOXWFKThe integrated overload clutch interrupts the torque transmission between machinespindle and tool during the thread producing cycle if the adjusted torque setting isexceeded. This protects the tool against breakage, ie when cutting on block withblind hole threads.1. Detach thread pin in the torqueadjusting ring.2. Set torque adjusting ring to the lowestpossible torque value = turn left as faras possible.3. Start thread cutting → clutch slipsthrough4. Increase the torque via the adjustingring and fix this adjustment bytightening the thread pin.5. Re-start thread cutting.If there is no perfect torque driving,repeat points 1 to 4.Reduction oftorqueThread pinIncrease oftorque,PSRUWDQWThe torque adjustment may only be carried out while the machine isswitched off.As the required torque depends on different parameter, ie number ofrevolutions, material to be worked, lubrication, it is not possible to indicateany torque values.Edition: 15.09.200517`