Hole Master Technology - Air Liquide Welding

Hole Master Technology - Air Liquide Welding

Hole Master Technology - Air Liquide Welding

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

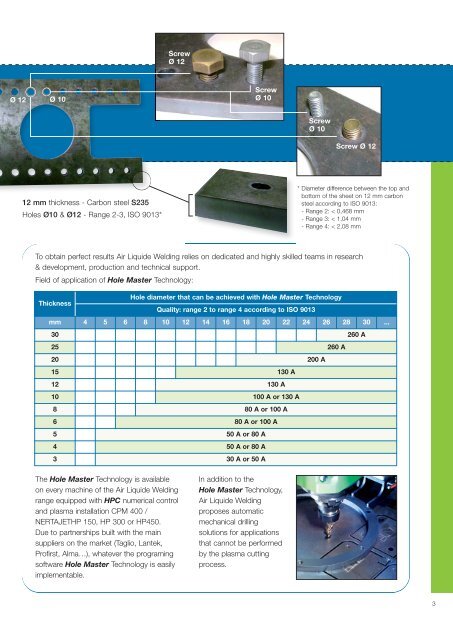

ScrewØ 12Ø 12 Ø 10ScrewØ 10ScrewØ 10Screw Ø 1212 mm thickness - Carbon steel S235<strong>Hole</strong>s Ø10 & Ø12 - Range 2-3, ISO 9013** Diameter difference between the top andbottom of the sheet on 12 mm carbonsteel according to ISO 9013:- Range 2: < 0,468 mm- Range 3: < 1,04 mm- Range 4: < 2,08 mmTo obtain perfect results <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> relies on dedicated and highly skilled teams in research& development, production and technical support.Field of application of <strong>Hole</strong> <strong>Master</strong> <strong>Technology</strong>:Thickness<strong>Hole</strong> diameter that can be achieved with <strong>Hole</strong> <strong>Master</strong> <strong>Technology</strong>Quality: range 2 to range 4 according to ISO 9013mm 4 5 6 8 10 12 14 16 18 20 22 24 26 28 30 ...30 260 A25 260 A20 200 A15 130 A12 130 A10 100 A or 130 A8 80 A or 100 A6 80 A or 100 A5 50 A or 80 A4 50 A or 80 A3 30 A or 50 AThe <strong>Hole</strong> <strong>Master</strong> <strong>Technology</strong> is availableon every machine of the <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong>range equipped with HPC numerical controland plasma installation CPM 400 /NERTAJETHP 150, HP 300 or HP450.Due to partnerships built with the mainsuppliers on the market (Taglio, Lantek,Profirst, Alma…), whatever the programingsoftware <strong>Hole</strong> <strong>Master</strong> <strong>Technology</strong> is easilyimplementable.In addition to the<strong>Hole</strong> <strong>Master</strong> <strong>Technology</strong>,<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong>proposes automaticmechanical drillingsolutions for applicationsthat cannot be performedby the plasma cuttingprocess.3