World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

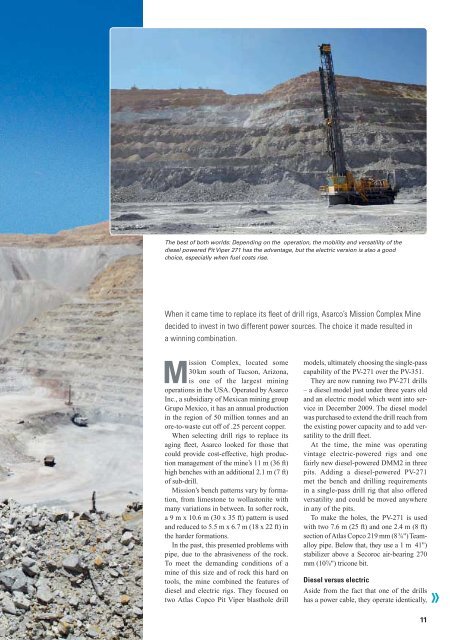

The best of both worlds: Depending on the operation, the mobility and versatility of thediesel powered Pit Viper 271 has the advantage, but the electric version is also a goodchoice, especially when fuel costs rise.When it came time to replace its fleet of drill rigs, Asarco’s Mission Complex Minedecided to invest in two different power sources. The choice it made resulted ina winning combination.Mission Complex, located some30 km south of Tucson, Arizona,is one of the largest miningoperations in the USA. Operated by AsarcoInc., a subsidiary of Mexican mining groupGrupo Mexico, it has an annual productionin the region of 50 million tonnes and anore-to-waste cut off of .25 percent copper.When selecting drill rigs to replace itsaging fleet, Asarco looked <strong>for</strong> those thatcould provide cost-effective, high productionmanagement of the mine’s 11 m (36 ft)high benches with an additional 2.1 m (7 ft)of sub-drill.Mission’s bench patterns vary by <strong>for</strong>mation,from limestone to wollastonite withmany variations in between. In softer rock,a 9 m x 10.6 m (30 x 35 ft) pattern is usedand reduced to 5.5 m x 6.7 m (18 x 22 ft) inthe harder <strong>for</strong>mations.In the past, this presented problems withpipe, due to the abrasiveness of the rock.To meet the demanding conditions of amine of this size and of rock this hard ontools, the mine combined the features ofdiesel and electric rigs. They focused ontwo <strong>Atlas</strong> <strong>Copco</strong> Pit Viper blasthole drillmodels, ultimately choosing the single-passcapability of the PV-271 over the PV-351.They are now running two PV-271 drills– a diesel model just under three years oldand an electric model which went into servicein December 2009. The diesel modelwas purchased to extend the drill reach fromthe existing power capacity and to add versatilityto the drill fleet.At the time, the mine was operatingvintage electric-powered rigs and onefairly new diesel-powered DMM2 in threepits. Adding a diesel-powered PV-271met the bench and drilling requirementsin a single-pass drill rig that also offeredversatility and could be moved anywherein any of the pits.To make the holes, the PV-271 is usedwith two 7.6 m (25 ft) and one 2.4 m (8 ft)section of <strong>Atlas</strong> <strong>Copco</strong> 219 mm (8 5 /8") Teamalloypipe. Below that, they use a 1 m 41")stabilizer above a Secoroc air-bearing 270mm (10 5 /8") tricone bit.Diesel versus electricAside from the fact that one of the drillshas a power cable, they operate identically,11