World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

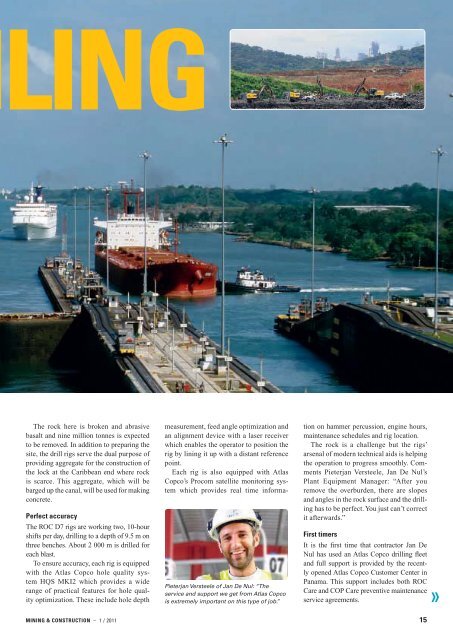

The rock here is broken and abrasivebasalt and nine million tonnes is expectedto be removed. In addition to preparing thesite, the drill rigs serve the dual purpose ofproviding aggregate <strong>for</strong> the construction ofthe lock at the Caribbean end where rockis scarce. This aggregate, which will bebarged up the canal, will be used <strong>for</strong> makingconcrete.Perfect accuracyThe ROC D7 rigs are working two, 10-hourshifts per day, drilling to a depth of 9.5 m onthree benches. About 2 000 m is drilled <strong>for</strong>each blast.To ensure accuracy, each rig is equippedwith the <strong>Atlas</strong> <strong>Copco</strong> hole quality systemHQS MKI2 which provides a widerange of practical features <strong>for</strong> hole qualityoptimization. These include hole depthPieterjan Versteele of Jan De Nul: “Theservice and support we get from <strong>Atlas</strong> <strong>Copco</strong>is extremely important on this type of job.”measurement, feed angle optimization andan alignment device with a laser receiverwhich enables the operator to position therig by lining it up with a distant referencepoint.Each rig is also equipped with <strong>Atlas</strong><strong>Copco</strong>’s Procom satellite monitoring systemwhich provides real time in<strong>for</strong>mationon hammer percussion, engine hours,maintenance schedules and rig location.The rock is a challenge but the rigs’arsenal of modern technical aids is helpingthe operation to progress smoothly. CommentsPieterjan Versteele, Jan De Nul’sPlant Equipment Manager: “After youremove the overburden, there are slopesand angles in the rock surface and the drillinghas to be perfect. You just can’t correctit afterwards.”First timersIt is the first time that contractor Jan DeNul has used an <strong>Atlas</strong> <strong>Copco</strong> drilling fleetand full support is provided by the recentlyopened <strong>Atlas</strong> <strong>Copco</strong> Customer Center inPanama. This support includes both ROCCare and COP Care preventive maintenanceservice agreements.MINING & CONSTRUCTION – 1 / 2011 15