World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

World record for raiseboring - Atlas Copco

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

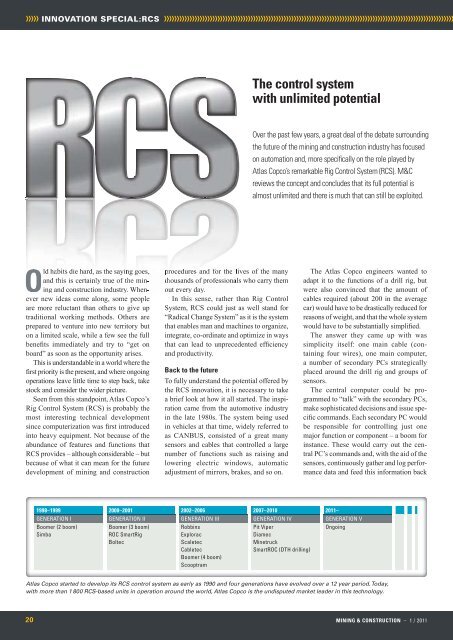

INNOVATION SPECIAL:RCS >>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>The control systemwith unlimited potentialOver the past few years, a great deal of the debate surroundingthe future of the mining and construction industry has focusedon automation and, more specifically on the role played by<strong>Atlas</strong> <strong>Copco</strong>’s remarkable Rig Control System (RCS). M&Creviews the concept and concludes that its full potential isalmost unlimited and there is much that can still be exploited.Old habits die hard, as the saying goes,are more reluctant than others to give uptraditional working methods. Others areprepared to venture into new territory buton a limited scale, while a few see the full board” as soon as the opportunity arises.This is understandable in a world where theoperations leave little time to step back, takestock and consider the wider picture.Seen from this standpoint, <strong>Atlas</strong> <strong>Copco</strong>’sRig Control System (RCS) is probably themost interesting technical developmentinto heavy equipment. Not because of theabundance of features and functions thatRCS provides – although considerable – butbecause of what it can mean <strong>for</strong> the futuredevelopment of mining and constructionprocedures and <strong>for</strong> the lives of the manySystem, RCS could just as well stand <strong>for</strong>that enables man and machines to organize,integrate, co-ordinate and optimize in ways and productivity.Back to the futureTo fully understand the potential offered bythe RCS innovation, it is necessary to takea brief look at how it all started. The inspirationcame from the automotive industryin the late 1980s. The system being usedin vehicles at that time, widely referred toas CANBUS, consisted of a great manysensors and cables that controlled a largenumber of functions such as raising andlowering electric windows, automaticadjustment of mirrors, brakes, and so on.The <strong>Atlas</strong> <strong>Copco</strong> engineers wanted toadapt it to the functions of a drill rig, butwere also convinced that the amount ofcables required (about 200 in the averagecar) would have to be drastically reduced <strong>for</strong>reasons of weight, and that the whole systemThe answer they came up with wassimplicity itself: one main cable (containingfour wires), one main computer,a number of secondary PCs strategicallyplaced around the drill rig and groups ofsensors.The central computer could be pro-make sophisticated decisions and issue spe-be responsible <strong>for</strong> controlling just onemajor function or component – a boom <strong>for</strong>instance. These would carry out the centralPC’s commands and, with the aid of thesensors, continuously gather and log per<strong>for</strong>mancedata and feed this in<strong>for</strong>mation back1998–1999 2000–2001 2002–2006 2007–2010 2011–GENERATION I GENERATION II GENERATION III GENERATION IV GENERATION VBoomer (2 boom) Boomer (3 boom) Robbins Pit Viper OngoingSimba ROC SmartRig Explorac DiamecBoltec Scaletec MinetruckCabletecSmartROC (DTH drilling)Boomer (4 boom)Scooptram<strong>Atlas</strong> <strong>Copco</strong> started to develop its RCS control system as early as 1990 and four generations have evolved over a 12 year period. Today,with more than 1 800 RCS-based units in operation around the world, <strong>Atlas</strong> <strong>Copco</strong> is the undisputed market leader in this technology.20 MINING & CONSTRUCTION – 1 / 2011