CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

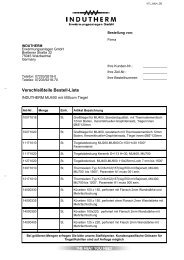

TF 4000Ingot Casting MachineVC 400Pellet Casting MachineVC 400 BBar Casting Machine<strong>The</strong> demands on casting and smelting plants differ considerably inthe field of analysis and recycling. Sometimes only a few grams haveto be molten for sampling, sometimes large quantities have to bemolten. Often a certain shape or size is required, such as ingots orpellets.Moreover, the metals and alloys themselves require different handling:alloys containing copper, for example, should be molten in avacuum or inert gas atmosphere as they tend towards strong oxideformation. For other metals or alloys, in turn, open plants are recommendedas fumes have to be drawn off, for example.<strong>The</strong> overview shown on the left page is intended to give you an insightinto the versatile possibilities of our <strong>program</strong>. <strong>The</strong> ideal solutionfor your application is best determined by discussion or by trialcasts. Just ask us!TF 4 000 Ingot Casting Machine<strong>The</strong> ingot moulds are located in a movable slide which locks intoplace precisely at the casting point, thus ensuring safe filling ofthe individual moulds.VC 400 Pellet Casting MachineThis machine has been developed for casting alloys or productionleftovers into pellets with a pre-defined weight or size.A hydraulic ejector allows the pellets to be collected easily.<strong>The</strong> machine is based on the VC 400 model.VC 400 B Bar Casting MachineThis machine is especially suitable for melting and casting definedquantities of metal such as one kilogram ingots. During the meltingprocess, the crucible chamber is flooded with inert gas.At a glance: all ourmachines for metalrecyclingtemperature max.capacitymostly used forvacuum/inert gaspageVTC V series2,000°C25 - 600 ccmingots■14MU/TF series1,400° - 2,000° C50 - 12,000 ccmingots–26-31VC 400 Pellet Casting1,400°C170 ccmpellets■see aboveVC 400 B1,300°C170 ccmingots■see above33