CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

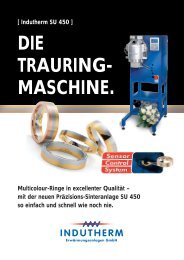

An effective solution for wedding ring production<strong>The</strong>se machines aredesigned…• for the production ofmulti-colour ringsin accordance with thediffusion bonding process• for solid bondingof every kind of metal38Sintering is the optimum process for producingmulti-coloured rings, mostly sold aswedding rings. Metals are processed underpressure and at temperatures below the solidificationpoint. <strong>The</strong> pressure is generatedpneumatically and not mechanically via athreaded spindle. This means that there is norisk of graphite parts breaking as a result ofheat expansion. <strong>The</strong> fusion between layershas the same durability as the metal itself.Pre-manufactured rings can be easily resized(7 sizes and more).Benefits of the <strong>Indutherm</strong> sinteringprocess:• With the sintering unit processes can takeplace under a vacuum, which is importantfor alloys with a manganese component• Processes can take place under inert gas• Straightforward installation/removal of therings• Approximate duration of process: 5 minutes• Depending on the thickness of the rings, upto 6 rings can be processed simultaneously<strong>Indutherm</strong> offers different methods ofsintering:<strong>The</strong> special sintering machines (SU series) orthe sintering kit for installation into existingcasting or continuous casting machines.Sintering Machine SU 300With the SU 300, the temperature andpressure are controlled manually. Exceptionalresults can be produced using this machineafter just a brief introductory period.Sintering Machine SU 450<strong>The</strong> new SU 450 is equipped with a highlysensitive sensor system, which permanentlycontrols the reduction of the rings andprovides real-time information about thereduction values on the display. <strong>The</strong> temperaturemay be regulated very precisely close tothe solidus temperature, right until the reductionbegins.As soon as the pre-defined reduction valuehas been reached, the process stops automaticallythus preventing too much deformation(depending on the composition and alloy thepre-defined reduction value varies between0.1 mm and 0.3 mm). <strong>The</strong> “Sensor-Control-System” considerably reduces the time andmaterial required for production for twomajor reasons: firstly because the processparameters can be defined quickly andwithout making lots of test rings; andsecondly because the quality of the sinteringprocess is constantly very high. <strong>The</strong>refore thefinishing effort is reduced, as well as the lossof material, which occurs during subsequentdiamond dressing or turning.Benefits of the SU 450:• <strong>program</strong> control for 100 different processcycles• sintering protocol after every cycle• LCD display• sensor control system for permanentprocess control and real-time display of thereduction• no long-winded preliminary tests• less finishing effort and loss of metal<strong>The</strong> Sintering Kit<strong>The</strong> sintering kit can be installed into existingVC 200 to VC 650 V type casting machinesand in all continuous casting machines. <strong>The</strong>kit is ideal for the occasional diffusionbonding job and for smaller seriesproduction. Only a few minutes are neededto install/remove the sintering kit.<strong>The</strong> sintering kit can be used for occasionaldiffusion bonding and for small seriesproduction. For larger production quantitieswe recommend our sintering machinesSU 300 and SU 450.