CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

CATALOGUE: The complete Indutherm program PDF 8,0 MB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

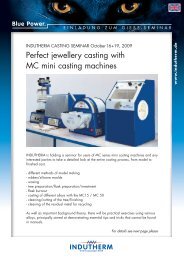

NEWWhy did we not just make one of the triedand tested machines in the VC range smaller?<strong>The</strong>re are actually machines on the market inwhich the construction principle of largermachines has been miniaturised, and whichtherefore work with a sealing rod system. Weprefer the tilting casting system for thefollowing reasons:• Small crucibles with sealing rods are hard tofill. Generally only granulate or some otherground material can be poured in; thesealing rod gets in the way with largerpieces such as manufacturing residues,sprue etc.• Naturally the pouring-off opening is also verysmall with small crucibles. This makes viscousalloys hard to pour out, leading to the formationof incrustations and consequently leakage.This makes the service lives of expensiveconsumables extremely short. <strong>The</strong> crucibles inour MC machines are not only cheaper – theycan also be used for a substantially longertime. Pouring off into the mould is extremelysimple.• <strong>The</strong> number of mechanically moving partsand seals – so all wearing parts – is substantiallysmaller with our tilting principle,reducing your running costs.• <strong>The</strong> viewing glass and open design enableyou to keep an eye on the melting andcasting process and control it perfectly.MC 15+, the fast all-rounder for anymetal• For individual pieces or multiple smalljewellery parts• Minimum material use for the sprue• Shortest combustion times for the flaskin the oven – approx. 1 hr with a speedinvestment material• With graphite crucible for gold and silver;ceramic crucible for platinum, palladium,steel• Maximum temperature 2,000°C.MC 60, the larger capacity version forgold and silver casting• Largely the same technology as with theMC 15+, but designed for a temperaturerange up to 1,300°C• Hence larger capacity for gold and silvercasting• For flasks up to 80 mm x 120 mm,optionally up to 100 mm x 120 mm.A significant factor for theeconomic efficiency is the lowquantity of metal that must becalculated for button.9