PDF Download Issue 2-2013 - Bilfinger

PDF Download Issue 2-2013 - Bilfinger

PDF Download Issue 2-2013 - Bilfinger

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

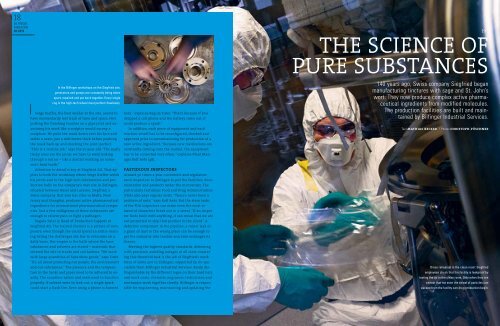

10BILFINGERMAGAZINE02.<strong>2013</strong>11Özlem Güler coordinates the subcontractors.Her work starts months prior to the shutdown.Turnaroundsmade by <strong>Bilfinger</strong>IN 2012 THE COMPANIESFROM BILFINGER INDUSTRIALSERVICES WERE ALREADYINVOLVED IN A TURN-AROUND RIGHT NEXT TOTHE KPE REFINERY: AT BP INROTTERDAM. IN ADDITION,THEY WERE OPERATING INNORDIC COUNTRIES IN PAR-TICULAR, FOR THE LIKES OFAKZONOBEL, FOR YARA ORSTATOIL. APART FROM THEMEGA-SHUTDOWN ATKUWAIT PETROLEUM EURO -POORT, <strong>2013</strong> WILL ALSO SEELARGE TURNAROUNDSUNDERTAKEN AT BASF INLUDWIGSHAFEN AND ATBOREALIS, THE PLASTICSAND CHEMICAL GROUP INLINZ, AUSTRIA.Rainer Gross (right) and Jens Teichmann (center)have been managing major turnarounds togetherfor KPE for the last six years.high platform from where you have a view of the entireplant and the oil tankers behind anchoring in theworld’s third-largest port.INTERNATIONAL COMPETENCETeichmann tracks his outstretched arm across the site:on the left the towering fractionating columns whichdistill the heated crude oil into various products. Nextto them the huge fans in the air coolers. There you havethe heat exchangers. One of the largest exchangers,slightly to one side, on its own, looks like new. And it istoo: “We completely modernized that one only lastyear.” It was number 6304C on the operation chart forthe 2012 turnaround. And the figure’s stuck in Teichmann’shead even to this day.From up here you only see a handful of people. Now,in early March, apart from the refinery staff, there areonly three dozen <strong>Bilfinger</strong> specialists in the plantpreparing everything for the large “showdown” at theshutdown. They come from four different <strong>Bilfinger</strong>companies with different areas of expertise. Later in theyear they will be joined by colleagues from three otherinternational <strong>Bilfinger</strong> units – plus twenty to thirty externalcompanies which Jens Teichmann and his colleagueswill also coordinate.October 7. That’s the day towards which they are allworking here – day one of the shutdown. They will thenhave six weeks to get the plant into shape for the nextfive years. “That’s when it’ll be just teaming with specialistson the site,” says Rainer Gross, Head of Turnaroundsat <strong>Bilfinger</strong>, “a veritable army of metalworkers,electricians, material testers, insulators, scaffolders,bricklayers.” Huge tents are being set up on the edge ofthe plant to cope with this massive influx of people.Even now, with still months to go, the work is alreadygetting underway. Gross tries to come up with somethingcomparable that gives an idea of the size: “Try toimagine the Oktoberfest in Munich.” Some of the tentswill be used as gigantic changing rooms, with showercabins and two lockers per person, one for their personalclothes and another for their work gear. Others willaccommodate canteen facilities. “Naturally, we’ll haveto stagger the lunch breaks for the work groups, otherwiseit’d be total chaos.”A turnaround is an exceptional situation in many respects:a mass event and a high-speed event at one andthe same time. A turnaround, says Rainer Gross smiling,entails “the largest manageable form of chaos, whichrequires some sort of order. And it’s precisely that that Ilove about my job.” He and Jens Teichmann have beenmanaging the KPE turnarounds since 2006. This experiencegives them a sense of composure even if thepreparations for this year’s major shutdown are reallyextensive.DIGITAL BACKBONEIf Gross is the theater manager and Teichmann the directorof the turnaround, Özlem Güler, 33, Junior Consultantat <strong>Bilfinger</strong> Industrial Services, is the assistantdirector. The mechanical engineer coordinates the waythe subcontractors mesh together. Or, as she says withsomewhat of an understatement: “I ensure that thecleaners are in the right place at the right time.” Forthree weeks Özlem Güler has been in Rotterdam to getup to speed on the coordination software.The program is the digital backbone of the turnaround,linking the project managers with all the relevantinformation – and providing the <strong>Bilfinger</strong> coordinatorsand the customer with an insight into theproject progress in real time. That is an invaluable