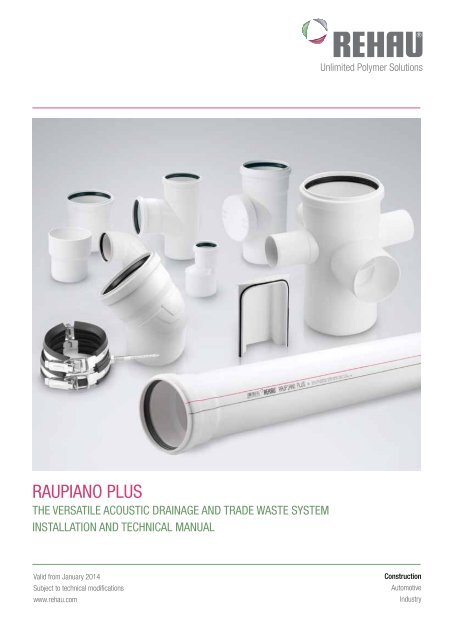

Raupiano Plus Product Book | Rehau | Reece Plumbing

Raupiano Plus Product Book | Rehau | Reece Plumbing

Raupiano Plus Product Book | Rehau | Reece Plumbing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RAUPIANO PLUSINFORMATION AND SAFETY RECOMMENDATIONS1.Notes on this technical informationApplicabilityThis technical information is applicable for Australia and New Zealand.NavigationAt the beginning of this document, you can find a detailed content pagewhich lists the individual chapters and their respective page numbers.Pictograms and logosSafety informationLegal informationImportant informationInformation on the InternetAdvantageGeneral safety measures- Observe all applicable national and international regulations oninstallation, accident prevention and safety, together with theinformation contained in this manual.- Keep the work place tidy and free of obstructions.- Ensure there is always sufficient light.- Keep children, house pets and unauthorised persons away from toolsand installation area. This is especially important in cases of renovationin occupied areas.Fire protectionObserve the applicable fire-protection regulations very carefully as wellas the codes/regulations of building practice that apply in each case,especially in relation to:- Penetrating through fire compartments.- Rooms subject to the guideline of places of assembly places.Personnel requirements- Allow only authorised and trained persons to assemble our systems.- Work on pipe components should only be performed by persons trainedand authorised for this purpose.For safe usage of RAUPIANO PLUS, please ensure you are using the latestversion of the technical information.The date of issue of your technical information is always printed at thebottom left of the cover page.The current technical information is available from your REHAU salesoffice, or as download on the Internet at www.reece.com.au orwww.rehau.com.au or www.rehau.co.nzWork clothing- Wear protective glasses, suitable work clothing, safety shoes, aprotective helmet and, if you have long hair, a hair net.- Do not wear loose clothing or jewellery. They could be caught bymoving parts.- Wear a protective helmet when performing assembly work at head levelor above your head.- Wear NBR gloves when applying lubricant by hand.- Read the safety recommendations and operating instructionscarefully and completely for your own safety and for the safety ofother people before starting with the installation.- Retain the operating instructions.- If you do not understand the safety recommendations or installationinstructions, or if they are unclear, contact your REHAU sales office.Refer to back page.Intended useThe system RAUPIANO PLUS may only be installed and operated asdescribed in this technical information. Any other use is unintended andtherefore impermissible.When assembling the system- Always read and comply with the respective operating instructions ofthe tool used.- The cutting tools have a sharp blade. The cutting tools are to be storedand handled in a safe way to prevent injuries.- When shortening pipes, maintain a safe distance between the handholding the object and the cutting tool.- Never put your hands near the area where the tool is cutting or onmoving parts.- When performing service, maintenance and alteration work and whenchanging the place of assembly, always unplug the power cable of thetool and secure it against being switched on inadvertently.5

RAUPIANO PLUSSYSTEM introduction2.ADVANTAGES2.1.1 Residential buildings- Excellent sound-insulation properties- Mineral-filled material for pipes and fitting to reduce air-borne noise- Partially thickened walls for bend fittings to improve air-borneinsulation- Special sound-dampening bracket to reduce transmission ofstructure-borne noise- Fast and easy installation- The joint is designed to absorb any thermal expansion- High quality product- Excellent impact resistance - robust for transport, storage andhandling at construction site- UV-resistance, can be stored outdoor for 1 year- Smooth yet abrasion-resistance inner layer to reduce risk of depositsand scaling- Green material, non-toxic material without halogen2.1 ApplicationRAUPIANO PLUS is a versatile system for non-pressurized drainagesystems which are installed according to AS/NZS 3500.2. It is able tocomply with the requirements of Building Code of Australia (BCA) fordifferent types of residential buildings, such as:- Double storey homes- Multi-storey apartment blocks- Condominiums- Multi storey townhousesThe sound-insulating drainage system RAUPIANO PLUS is suitablefor above & below ground installation inside and outside the buildingstructure. This is in accordance with AS/NZS 3500.2 and the NCC Volume3 as certified under Watermark WM70060 in buildings and WM71503below ground. Installation must be carried out in accordance with AS/NZS 3500.2 and the National Constructon Code. Observations of DINEN 12056, DIN EN 752, DIN 1986-100 and DIN EN 1610 are alsorecommended.2.1.2 Commercial buildingsBehaviour in fire corresponds to B2 normal combustibility according toDIN 4102 and D-S3,d0 according to EN 13501-1.The pipe connections are leak-proof up to an internal excess waterpressure of 1 bar (10 m water column). The Push-Fit Lock socketconnection allows for a higher pressure of up to 2 bar (20 m watercolumn). See section 7.14 for more information.RAUPIANO PLUS, with its special acoustic characteristics, can alsobe installed in commercial buildings that require stricter acousticrequirements such as:- Hotels- Office buildings6

- Hospitals- Shopping Centres- Supermarkets- Aged Care FacilitiesRAUPIANO PLUS meets the increasing need for peace and quiet andensures a high level of living comfort.2.1.4 Not suitable applicationsPipes and fittings may not be used for:- installation subjected to continuous operating temperature higher than90˚C (or higher than 95˚C for brief periods)- carrying waste water containing prohibited chemicals (see section 13)- exposed installation to UV radiation (e.g. sunlight) directly and indirectly2.1.3 Trade wasteIf used in cold areas, where installations are commonly done undertemperature below -10˚C, additional tests are required according toAS/NZS 7671.RAUPIANO PLUS has passed the test and therefore marked with the “icecrystal” according to AS/NZS 7671 and DIN EN 1411 and can be installedin these regions.RAUPIANO PLUS is not suitable for syphonic drainage systems. For outletof ventilation lines, use pipes suitable for outdoor installation instead ofRAUPIANO PLUS.The pipes, fittings and seals can be operated continuously at 90˚C(and up to 95°C for brief periods). They are suitable for the drainage ofchemically aggressive waste water with a pH value of 2 (acidic) to 12(basic). Please refer to chemical resistance list.RAUPIANO PLUS is ideal for drainage of greasy waste water fromcommercial kitchens up to the grease separator.For lengthy grease waste lines, the use of pipe trace heating maybe necessary. This prevents premature grease accumulation. Thetemperature of the pipe trace heating suitable for plastic pipes may notexceed 45°C. Refer to chemical resistance chart in chapter 13.Observe all applicable national and international regulations oninstallation, accident prevention and safety, together with the informationcontained in this manual.Areas of application which are not included in this technical information(special applications) require consultation with our technical department.Please contact your REHAU sales office.7

2.2 Pipe structureThe RAUPIANO PLUS multi-layer pipe construction achieves superiorproperties through the application of distinct functional layers combinedin a composite construction.Three separate layers impart unique characteristics to the pipe.The abrasion resistant, low friction inner layer ensures the easytransit of waste. The mineral filled mid-layer ensures superb sounddampening properties and also offers increased stiffness. Finally, therobust outer layer is tough enough to withstand impacts and shocks.Features:- Multi-layer pipe system:- Smooth yet abrasion-resistant inner layer made of PP- Rigid middle layer made of PP with sound-dampening minerals- Impact resistance and UV-stabilized outer layer made of PP- Built-in push-fit socket with factory-fitted sealing ring providing flexibleand vibration-resistant joints- Temperature resistance up to 95°C- Chemical resistance from pH 2 – 12. Refer to Chapter 13- High ring stiffness- 100% recyclableCombined together, the composite layers create a tough, durablepipe, with outstanding acoustic properties that gives all thefunctionality of a drainage pipe system combined with the noiseabsorption properties of lagging.Abrasion-resistant and lowfriction inner layer made of PPImpact-resistant and shockproofouter layer made of PPADVANTAGES:- State-of-the-art sound insulation technologies, no acoustic-laggingrequired- Suitable for special applications requiring high temperature andchemical resistance such as trade waste. Please refer to chemicalresistance list.- Green system due to low energy production and 100% recyclability- Simple and fast installation- 100% leak-proof connection- Flexible joint suitable for tremor-prone areas- Fracture resistant at –10˚C.- Uncompromising fire-protection solutions- Can be stored outdoors for up to 1 year.- Complete pipe, fitting, adapters and bracket rangeFig. 2-1RAUPIANO PLUS pipe structure.Highly rigid and sound-insulating middlelayer made of mineral-reinforced PPRAUPIANO's ideal characteristics are achieved thanks to the three-layerstructure of the pipe and the specialised adaptation of each individuallayer to its respective requirement:- High ring stiffness- Excellent impact strength of the outer layer at low temperature- Increased UV-resistance- Abrasion-resistant and smooth inner layer- Highly rigid and sound-insulating middle layer made of mineralreinforced PP8

2.3 FittingsRedirections in water flow at bends causes increased turbulence whichresults in greater air-borne sound transmission.RAUPIANO PLUS bends from size DN110 to DN160 consist of targetedmass optimisation zones which help to reduce sound transmission inthese areas.RAUPIANO PLUS system has been independently tested by Renzo Toninand Associates, a member of the Association of Australian AcousticalConsultants (AAAC) at the National Acoustic Laboratories (NAL). Testresults were assessed by a separate AAAC member to ensure impartialityof the report. The report found conclusively that RAUPIANO PLUS pipesystem exceeds the R w + C tr 40 requirement of the National ConstructionCode Vol.1 / Building Code of Australia, and that a stand alone RAUPIANOPLUS system is comparable, in terms of sound insulation, to a fully laggedPVC system behind a specified ceiling separation. Refer to Chapter 4Sound insulation.The acoustic test letters from the assessing acoustic engineers areavailable in the Appendix A.2.5 MarkingFig. 2-2RAUPIANO PLUS bend with reinforced impact area.Pipes and fittings are marked with the following:- Watermark- Manufacturer’s mark- Approval number- Mark of quality- Ice crystal (AS/NZS 7671 and DIN EN 1411)- Nominal diameter (DN)- Year of manufacture- <strong>Product</strong>ion line- Material- Angle specification (with elbows and branches)Fig. 2-3 Specially designed bends with increased wall thickness reduce airtransmittedsound even further.2.4 Sound insulationThe sound-insulating drainage system RAUPIANO PLUS offersquality, quietness and living comfort in important areas of a building.9

TransportationRAUPIANO PLUS proves its robustness during transport and at theconstruction site thanks to its three-layer structure and impact-resistantand shock-proof outer layer. Ensure that pipes make firm contact overtheir entire length.Storage- Protect boxes from moisture during transport and storage.- RAUPIANO PLUS and its seals can be stored outdoors for up to 1 yearWe recommend:- Protecting RAUPIANO PLUS pipes and fittings from direct sunlight andsoiling by:- storing in the box- covering them with tarpaulins (ensure proper ventilation).- Stack no more than four wooden crates on top of one another.- Ensure that the wood frames are aligned squarely when stacking.- Store pipes in such a way that no objects are placed on top of or in thesockets and male ends and that these are not deformed.RAUPIANO delivery procedureKey points to remember:- Treat RAUPIANO with care to avoid damage.- Take pipe out of bags prior to delivery to check condition. Put back inbag if possible.- Do not over tighten the ratchet on the ute.- Pipe can still be used with small indentations as long as both the maleand female ends are not damaged and the O-ring is in place.CORRECT TRANSPORTATION PROCEDUREWHAT NOT TO DOWhere possible use a truck for deliveries. Lay pipe flat on the tray Do not throw pipe into the tray Do not throw pipe off the uteKeep pipe strapped down so it doesn’t roll around and remainssupportedDo not over tighten with ratchetTake care with O-rings and ensurethey are in good conditionAlternate socket and pipe ends when loading pipeUnsupported pipes can bendKeep pipes clear of buildingdebris whilst on siteFig. 2-4Transporting of RAUPIANO PLUS10

RAUPIANO PLUSPRODUCT LIST3.PageREHAU ❄3.1 PIPES........................................................................................ 12RAUPIANO <strong>Plus</strong>3.2 FITTINGS................................................................................... 133.3 ACCESSORIES........................................................................... 2011

pipesPipesWith push-fit socket and rubber sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteD15°beODtBLREHAU ArticleREECE CodeDN/ODin mmeLength (mm)BLUnit123014 1450819 40 1.8 250 piece123024 1450820 40 1.8 500 piece123034 1450821 40 1.8 1000 piece123054 1450823 40 1.8 3000 piece120104 1450825 50 1.8 250 piece120114 1450826 50 1.8 500 piece120134 1450828 50 1.8 1000 piece120934 1450831 50 1.8 3000 piece120184 1450833 75 1.9 250 piece120194 1450834 75 1.9 500 piece120214 1450836 75 1.9 1000 piece120944 1450839 75 1.9 3000 piece120264 1450848 110 2.7 250 piece120274 1450849 110 2.7 500 piece120294 1450851 110 2.7 1000 piece120324 1450854 110 2.7 3000 piece122954 1450863 160 3.9 500 piece121664 1450864 160 3.9 1000 piece121684 1450866 160 3.9 3000 piece12

FittingsBendWith rubber sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteREHAU ArticleREECE CodeDNin mmAngleUnit123064 1450724 40 15° piece123074 1450725 40 30° piece123084 1450726 40 45° piece100255 (1) 1450972 40 87° piece121094 1450728 50 15° piece121104 1450729 50 30° piece121114 1450730 50 45° piece100276 (1) 1450973 50 87° piece121144 1450733 75 15° piece121154 1450734 75 30° piece121164 1450735 75 45° piece100278 (1) 1450974 75 87° piece123424 1450710 110 15° piece123434 1450711 110 30° piece123444 1450712 110 45° piece100259 (1) 1450971 110 87° piece124059 1450969 160 15° piece124067 1450970 160 30° piece124028 1450720 160 45° piece124029 1450721 160 87° pieceNote: (1) Swept bend13

FittingsSingle Branch junctionWith rubber sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteNote: (1) Swept angleREHAU ArticleREECE CodeDNin mmAngleUnit123104 1450902 40/40 45° piece123114 1450903 40/40 87° piece121234 1450904 50/50 45° piece121254 1450905 50/50 87° piece121264 1450906 75/50 45° piece121284 1450907 75/50 87° piece121294 1450908 75/75 45° piece121544 1450909 75/75 87° piece121304 1450916 110/50 45° piece121324 1450917 110/50 87° piece121334 1450918 110/75 45° piece121344 1450919 110/75 87° piece122984 1450920 110/110 45° piece123005 (1) 1450921 110/110 87° piece124037 1450926 160/110 45° piece124069 1450927 160/110 87° piece124038 1450930 160/160 45° piece124077 1450931 160/160 87° piecedouble Branch junctionWith rubber sealing ringsMaterial: RAU-PP (mineral reinforced)Colour: whiteREHAU ArticleREECE CodeDNin mmAngleUnit122964 1450756 110/110/110 45° piece123076 1450759 160/110/110 45° piece14

FittingsDouble SocketWith rubber sealing ringsMaterial: RAU-PP (mineral reinforced)Colour: whiteLREHAU ArticleREECE CodeDNin mmL (mm)Unit123144 1450768 40 89 piece121484 1450769 50 93 piece121584 1450770 75 111 piece121494 1450772 110 128 piece124047 1450774 160 148 pieceSlip-on SocketWith rubber sealing ringsMaterial: RAU-PP (mineral reinforced)Colour: whiteLREHAU ArticleREECE CodeDNin mmL (mm)Unit123154 1450935 40 89 piece121504 1450936 50 93 piece121574 1450937 75 111 piece121514 1450939 110 128 piece124048 1450941 160 148 pieceI.O. Access PipeWith surface-flushing insert and screwed cap and rubber sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteZ 1 Z 3REHAU ArticleREECE CodeDNin mmZ 1(mm) Z 3(mm) Unit121235 1450805 50 28 30 piece123079 1450806 75 40 43 piece121534 1450808 110 57 62 piece124049 1450810 160 83 89 piece16

FittingsLong SocketWith rubber sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteLREHAU ArticleREECE CodeDNin mmL (mm)121594 1450812 110 130 pieceUnitCloset BendWith lip sealing ringMaterial: RAU-PP (mineral reinforced)Colour: whiteREHAU ArticleREECE CodeDNin mma (mm) b (mm) Unit121624 1450744 110/90° 230 160 pieceCloset ConnectionWith lip sealing ringMaterial: RAU-PPColour: whiteLREHAU ArticleREECE CodeDNin mmLengthL (mm)Unit121634 1450746 110 150 piece121644 1450747 110 250 piece18

P-trap siphon / 110mm disconnector gullyTo be used together with DN 110 bend 45°. With rubber sealing ring and fixing eyelet.fixing eyeletREHAU ArticleREECE CodeDNin mma (mm) b (mm) Unit123039 1450870 110 142 251 pieceFloor Waste GullyWith 3x DN 50 inlets + 1 x DN75 outlet. Includes removable baffle.DN50 inlets require DN50 double socketMaterial: RAU-PP (mineral reinforced)Colour: whiteREHAU ArticleREECE CodeDNin mma (mm) b (mm) c (mm) Unit100391 1450960 50/50/50/75 222 87 105 pieceBAFFLE (spare part)Removable baffle for RAUPIANO PLUS floor gully with rubber sealing to provide air-tightnessMaterial: ABSColor: whiteREHAU ArticleREECE CodeDNin mmUnit102226 1450981 - piece19

accessoriesConnection PipeFor connection to other pipe materials. To be used together with rubber nippleMaterial: RAU-PP (mineral reinforced)Colour: whitedeLdmdiREHAU ArticleREECE CodeDNin mmMetal pipeouter d md e(mm) d i(mm) L (mm) Unit123164 1450752 40/40-30 32 - 40 40 53.7 63 piece121414 1450753 50/40-30 32 - 40 50 53.7 61 piece121424 1450754 50/50 47 - 50 50 67.2 50 pieceRubber NippleFor connection to other pipe materials. To be used together with connection pipe.Material: rubberColour: blackdaREHAU ArticleREECE CodeDNin mmd a(mm)Unit126253 1450882 50/40 55 piece121913 1450883 50/50 68 pieceRubber Nipple with BeadFor connection to other pipe materials. Replaces the pre-assembled rubber sealingring in RAUPIANO PLUS pipes or fittings.Material: rubberColour: blackdadiREHAU ArticleREECE CodeDNin mmd a(mm) d i(mm) Unit122923 1450884 40/30 40.5 32 piece122933 1450885 50/30 50.5 32 piece122943 1450886 50/40 50.5 40 piece20

Sound-dampening Support BracketMaterial: galvanised strip steelColour: BlackIncludes: Supporting and fastening clamps and headless screwApplication: 1 per stack per floor. Refer to Chapter 7REHAU ArticleREECE CodeDNin mmUnit122004 1450954 75 piece122014 1450956 110 piece122034 1450958 160 pieceGuiding ClampWith rubber lining and distance pieceMaterial: galvanised strip steelColour: Green with yellow adjustment spacersApplication: Used as a guiding clamp. Refer to Chapter 7REHAU ArticleREECE CodeDNin mmUnit122654 1450795 40 piece120534 1450796 50 piece120544 1450797 75 piece120554 1450799 110 piece121854 1450801 160 pieceApproved alternatives are available, contact <strong>Reece</strong> for further details.Fixing/Security ClampWith rubber liningMaterial: galvanised strip steelColour: BlackApplication: Fixing clamp and security clamp. Refer to Chapter 7REHAU ArticleREECE CodeDNin mmAdjustable Range(mm)122644 1450787 40 38-43 piece120504 1450788 50 50-56 piece120514 1450789 75 70-76 piece120524 1450791 110 108-116 piece121844 1450793 160 159-168 pieceUnit21

accessoriesRubber Sleeve AdaptorFor connection to different diameters cast iron or other pipe materialsMaterial: rubberColour: blackREHAU ArticleREECE CodeDNin mmUnit125024 1450894 50/53-63 piece125034 1450895 75/75-89 piece123914 1450897 110/110 pieceRubber Sealing RingFor pipe and fitting socketsMaterial: rubberColour: blackREHAU ArticleREECE CodeDNin mmUnit128243 1450887 40 piece128013 1450888 50 piece128023 1450889 75 piece128033 1450891 110 piece128053 1450893 160 pieceLubricantFor push-fit connectionsREHAU ArticleREECE CodeDNin mm128933 1450813 150 g piece128943 1450814 250 g piece128953 1450815 500 g pieceUnit22

RAUPIANO PLUSSOUND INSULATION4.4.1 BasicsAir-borne noiseIn every area of building construction, especially the construction ofmulti-storey apartment blocks, hospitals and rehabilitation homes, soundinsulation plays an increasingly important role. One of the most significantsources of sound within buildings is the sanitation set-up and theaccompanying drainage water pipe system.Typical sources of sound include:- Fitting noises- Filling noises- Draining noises- Inlet noises- Impact noises- TurbulanceAir-borne noise is present if the noises of a sound source are transferreddirectly through the air to human ears.Structure-borne noiseWith structure-borne noise, the sound transfer first occurs through a solidbody. This body vibrates and passes the vibrations on to human ears asairborne noise.Unsuitable drainage pipe system and type of brackets are considerablecontributors to disturbing noise. RAUPIANO PLUS, a system-tested,versatile sound-insulating drainage water system, puts things right.Airborne noiseStructure-borne noiseA differentiation is made between air-borne noise and structure-bornenoise.Fig. 4-1Air-borne and structure-borne noise.23

RAUPIANO PLUSSOUND INSULATION4.2 Sound insulation requirements for AustraliaSound insulation requirements differ from country to country and fromone building type to another. In Australia the NCC / BCA Volume One PartF5 outlines the requirements for sound insulation:- F5.6 Sound insulation rating of servicesFor the Northern Territory:- R w 45 if the adjacent room is habitable (other than a kitchen); or- R w 30 if the adjacent room is a kitchen or non-habitableWeighted sound reduction index (R w ) is the number used to rate theeffectiveness of a system as a noise insulator. An increase in one Rw unitapproximately equals a reduction of one decibel in noise level.NCC/BCA Acoustic requirementThe NCC / BCA specifies that if a pipe that is located in a wall or floorcavity, serves or passes through more than one sole-occupancy unit, thepipe must be separated from the rooms by construction with an R w+C tr of:Weighted sound reduction index plus spectrum adaptation term (R w +C tr )takes into account the lower frequency noise. C tr is a negative number, soR w +C tr value will always be lower than Rw value.- 40 if the adjacent room is habitable (other than a kitchen); or- 25 if the adjacent room is a kitchen or non-habitableKitchenBathroomBedroomSeperation between the noise source (water/waste) and the habitable room must have asound reduction level of R w + C tr 40 accordingto NCC/BCA Volume 1 Class F5.6 for servicesR w + C tr 25passing through habitable rooms. For theNorthern Territory a sound reduction level ofR w + C tr 40R w 45 is required.KitchenBathroomBedroomFig. 4-2NCC/BCA Acoustic requirement.24

4.3 Sound reduction with RAUPIANO PLUSUNPROTECTED PIPEWORKBoth structure-borne and air-borne noises occur in drainage pipesystems. The wall of the pipe vibrates due to water currents and flownoises. The type and intensity of these pipe vibrations depend on a varietyof factors, such as the mass of the pipe, the pipe material, its inner sounddampening material and installation method.123The pipe vibrations are emitted directly from the pipe as air-borne noiseand are transferred as structure-borne noise via the pipe brackets to thewall.4When developing a sound-insulating drainage water system, both types ofnoise distribution must be taken into account.Airborne noise insulation with RAUPIANO PLUSFig. 4-4Sound distribution with sewer pipe systems.1 Structure-borne noise2 Standard drainage pipe3 Standard bracket (pipe clamp with/without rubber ply)4 Airborne noiseAirborne noise is reduced by RAUPIANO PLUS due to special materials,sound-dampening minerals and increased weight of the pipe system.Targeted mass optimisation in sound-sensitive areas of fitting elbows ofnominal diameter DN 110 to DN 160 provides further improvement atredirection points.Structure-borne noise insulation with RAUPIANO PLUSThe transmission of structure-borne noise to the wall is reduced withRAUPIANO PLUS with the use of patented, sound dampening brackets:- A supporting clamp with loose gap in the pipe is fastened to the wall- A fastening clamp rests onto the supporting clamp, keeping the pipe inpositionThis extensive physical decoupling of the pipe, bracket and wall meansthat the transmission of structure-borne noise is eliminated to a highdegree (see Chapter 7 for installation details).PROTECTED PIPEWORK5Fig. 4-5Sound insulation with RAUPIANO PLUS.1 Reduction of structure-borne noise2 RAUPIANO PLUS pipe with sound-dampening fillers3 RAUPIANO PLUS bracket, patented sound-dampeningsupport bracket4 Reduction of airborne noise5 Reduced overall noise level142325

RAUPIANO PLUSSOUND INSULATION4.4 Laboratory testing of sound-insulation behaviour4.4.2 Acoustic test results4.4.1 Acoustic testingAcknowledging the different installation practices and the effects onacoustic level reading in the building, REHAU engaged several acousticconsultants to perform extensive acoustic tests on RAUPIANO PLUSdrainage system under different configurations. The acoustic tests wereperformed in:In Australia and New Zealand, buildings can be classified intotwo categories:- For buildings regulated by NCC/BCA- For buildings not regulated by NCC/BCAOur extensive acoustic test results provide the necessary data for bothcategories.- National Acoustic Laboratory (NAL) by Renzo Tonin & Associates- McLay Industries Facility (MIF) by ASK Consulting Engineers- Technical and Further Education South Australia (TAFE SA) by AECOMRAUPIANO PLUS pipe system has been independently tested using anestablished acoustic industry test based on ISO 140 testing methodologyand independently rated to ISO 717, then assessed in accordance withthe requirements of NCC/BCA.Buildings regulated by NCC/BCABased on the acoustic test done in NAL, RAUPIANO PLUS system can beinstalled without acoustic lagging for the following requirements:- R w + C tr 40- R w 45To ensure close proximity to real-life noise, full-toilet flush was usedduring measurement. Full-toilet flush represents the worst-case scenarioin domestic drainage environment. The water swirling and turbulence fromtoilet flush, and therefore the noise created by them, cannot be replicatedby any other noise source such as continuous water flow.RAUPIANO PLUS system tested with industry standard suspended ceilingachieved R w + C tr 42 (R w 49), which means RAUPIANO PLUS exceedsBCA’s acoustic requirements in habitable areas without acoustic lagging.Minimum BCArequirement forhabitable areasMinimum BCArequirement fornon- habitable areasPVC PIPEno lagging*R w + C tr28PVC PIPEwith laggingR w + C tr42RAUPIANO PLUSno laggingR w + C tr42(R w 49, C tr -7)0 5 10 15 20 25 30 35 40 45Rw + C trFig. 4-6Acoustic testing.* Boral Selector + Feb 2009 - System WP13, 13mm std core plasterboard with insulation (Graeme E Harding & Associates)26

To ensure full compliance to the NCC/BCA acoustic requirements, the following configurations are recommended:R w + C tr 25 (non-habitable areas)Approved fire collar*R w + C tr 40 (habitable areas)Approved fire retardant mastic orcaulking material*10mm standard plasterboardR1.5, 75mm Glass wool Insulation13mm standard plasterboardFig 4-7Recommended suspended ceiling configurations to comply with NCC/BCA acoustic requirements* The above schematic shows a general example and is not intended to satisfy the installation requirements for any particular project. Specificfire protection measures may or may not be required depending on building class and design, check with fire engineer and refer to the NationalConstruction Code for detailed information.Buildings not regulated by NCC/BCAThe acoustic requirements of buildings outside of NCC/BCA’s scopetend to be different. The rooms are normally classified differently, andtherefore have different noise level requirements. The LAmax and theLAeq values are more of important values than Rw+Ctr.- RAUPIANO PLUS produces noise levels within 3 dB(A) compared tolagged PVC and lagged HDPE when the suspended ceiling is installedwithout insulation batt. This noise difference is not noticeable byhuman earRAUPIANO PLUS has gone through extensive acoustic testing withdifferent ceilings, ranging from flush plasterboard to Rondo ceiling gridsystem with lay in tiles, and with different plasterboard thicknesses.- RAUPIANO PLUS produces lower noise level compared to laggedPVC and lagged HDPE when the suspended ceiling is installed withinsulation batt- RAUPIANO PLUS produces lower noise level compared to laggedPVC when it is installed in wall cavity (vertical stack pipe), when thewall cavity is installed with insulation batt.The acoustic assessment letters from the acoustic consultants (RenzoTonin & Associates, ASK Consulting Engineers, and AECOM) can be foundin the website’s download section under www.rehau.com.au/raupianoand www.rehau.co.nz/raupiano. The complete test reports can beprovided upon request.27

RAUPIANO PLUSSYSTEM DESIGN6.6.1 General Drainage Requirements6.3 SpecificationThe design and installation of RAUPIANO PLUS drainage system shallcomply to AS/NZS 3500.2.The goal is to ensure intended functioning of the universal drainagesystem RAUPIANO PLUS, i.e.- Back siphoning and leaking of water seal column must be prevented- Ventilation of the drainage system must be ensured- Nominal diameter larger than those calculated are not to be used toensure effective drainage- Sewage must drain with little noise- Anaerobic digestion is to be prevented- Gas emissions are to be lead out without harmful effects via the mainventilation system6.2 Equivalent pipe sizesPipe sizing chartPVCRAUPIANO PLUSDNOD(mm)DNOD(mm)40 43 40 4050 56 50 5065 69 75 75100 110 110 110150 160 160 160GeneralRAUPIANO PLUS system is suitable for acoustic drainage, acousticstormwater and trade waste application. It can be installed inside thebuilding and below ground.StandardsNCC/BCA National Construction Code / Building Code ofAustraliaNZBCNew Zealand Building CodeAS/NZS 3500.2 <strong>Plumbing</strong> and drainage – Sanitary plumbing anddrainageAS/NZS 7671 Plastic piping systems for soil and waste drainage (lowand high temperature) inside buildings - Polypropylene(PP)AS/NZS 5065 Polyethylene and polypropylene pipes and fittings fordrainage and sewerage applicationsApproval in Australia and New ZealandPipes and fittings are certified under Watermark Certificates WM70060,WM71501 and WM 71502 for sizes DN 40 to DN 200 and also underWM 71503 for sizes DN110 to DN200. System shall have BRANZapproval in New Zealand.System design and performanceTable 6-1Equivalent pipe sizes.Planning, installation and commissioning are to comply with AS/NZS3500.2 and RAUPIANO PLUS - THE VERSATILE ACOUSTIC DRAINAGEAND TRADE WASTE SYSTEM - INSTALLATION AND TECHNICAL MANUAL.When connecting RAUPIANO PLUS directly to PVC systems, somedimensions require connection adapters. Refer to chapter 9 for details.System component – Pipes and FittingsPipe materials shall be composite polypropylene RAU-PP, consisting ofpolypropylene inner layer, mineral-filled polypropylene middle layer andUV-stabilised polypropylene outer layer, complying with AS/NZS 7671for gravity drainage and stormwater drainage system in residential andcommercial applications.29

Fitting materials shall be mineral-filled polypropylene for acousticperformance enhancement, complying with AS/NZS 7671 for gravitydrainage and stormwater drainage system in residential and commercialapplications.Pipes and fittings shall be designed for an operating temperature of 90°Cand shall temporarily withstand temperatures of up to 95°C and markedwith ice crystal to indicate suitability for installations under extreme lowtemperatures up to -10°C. They shall have excellent chemical resistanceand withstand acidity level from pH 2 - 12. The packing shall be done toreduce the effect of UV radiation on the pipe and fitting material and toprotect them from dirt and other foreign materials.System component - Sound-dampening bracketAcoustic behaviourSystem acoustic performance shall have been demonstrated to meetthe BCA/NCC requirements for Sound Transmission and Insulation (BCA/NCC Volume 1 Part F5), F5.6 - Sound insulation rating of services whentested to ISO 140 methodology and sound insulation performance ratedaccording to ISO 717.When rated in accordance to ISO 717 the system shall meet or exceedthe BCA/NCC requirements of R w +C tr = 25 when adjacent to nonhabitableareas, and R w +C tr = 40 (for NT R w = 45) when adjacentto habitable rooms, without the use of acoustic lagging material.Recommended ceiling constructions are as follows:- 75mm R1.5 glass wool acoustic insulation batts- 13mm standard plasterboardSound-dampening bracket shall be rubber-lined with vibration-decouplingsystem to reduce the structure-borne noise transmitted from theRAUPIANO PLUS system.System component - Floor Waste GullyREVIT files, CAD 2D and 3D files and latest Specification Texts areavailable for download from www.rehau.com.au/raupiano under thedownloads link.Floor Waste Gully material shall be polypropylene RAU-PP. The Floor WasteGully shall have 1 main inlet in dimension DN (OD) 110mm with socketand 3 additional inlets in dimension DN (OD) 50mm. The outlet shall beof dimension DN (OD) 75mm. Floor Waste Gully shall have a removableinserted baffle. The total height shall be 222 mm.ConnectionsThe connections between the polypropylene pipes and fittings shall beof leak-proof push-fit socket connection with Styrene Butadiene Rubber(SBR) sealing ring. The connections shall be able to withstand internalpressure of up to 100 kPa and accommodate thermal expansion.30

RAUPIANO PLUSinstallation7.7.2 Pipe AssemblyAll schematic show general examples only and are not intended to satisfythe installation requirements for any particular project. For the installationof RAUPIANO PLUS waste water piping system, national and local codes,rules and regulations, as well as local conditions and the demands of theend use customer need to be considered.Like other materials at low temperatures, the mineral-reinforced pipematerial RAU-PP becomes brittle and thus more sensitive to impacts.7.1 Cutting and Chamfering1. Clean dirt from sealing ring, socket interior and pipe end.2. Use small amount of RAUPIANO lubricant (eg. a 10mm drop) tomoisten male end and O-ring and slide into the socket until itstops.3. Mark inserted male end in this position at the socket edge witha pencil, pen etc.4. With longer pipes (> 500 mm), pull the male end out anadditional 10 mm from the socket to create an expansion jointfor heat-related expansion.5. With short pipes (≤ 500 mm) and fittings, insert the male endsfully into the socket.ca. 10 mmFig. 7-1Pulling out pipe ends for expansion joints.1. Cut the pipes with common pipe cutters or a fine-toothed saw.2. Make a cut at 90° angle from the pipe axis.3. De-burr the inner diameter of the pipe.4. For connections to push-fit socket pipe systems, taper the pipeends with a tapering tool (i.e. Rothenberger Rocut cutter andchamferring tool 55020 for pipes DN40 to DN110. <strong>Reece</strong> Code:7705255) or a coarse file at an angle of approximately 15°.By pulling out the male ends from the socket, the changes in length ofthe pipe caused by temperature fluctuations are absorbed in the push-fitsockets.Each RAUPIANO PLUS pipe socket can accept the changes in lengthof a waste pipe up to 3 m in length (coefficient of linear expansion inaccordance with DIN 53752 averages 0.09 mm/(m·K) at 0°C to 70°C).Fittings must not be cut.When the pipe is installed in ground it is not required to pull the male endout by 10mm to provide an expansion joint.31

7.3 Handling cut lengths7.4 Installation of additional fittingsCut lengths (pipes with smooth ends) can be handled with double socketsand slip-on socket up to a maximum pipe length of 3 m.The installation of additional fittings in an existing pipeline is possible withslip-on socket:Pipe stopperDouble socketSlip-on socketIf pipe sections with fittings or short pipes are formed:- Prevent the pipe components from sliding apart with fixing brackets.- Secure socket plug from being pushed out by installing securing clip.1. Cut out a sufficiently long section of pipe from the pipeline:fitting length + 2 x pipe outer diameter2. De-burr pipe ends.3. Slide slip-on socket all the way onto one end of the pipe.4. Slide fitting onto the other end of the pipe.5. Fit adapter into the remaining space of the pipe and de-burr.6. Slide second slip-on socket all the way onto the adapter.7. Insert adapter and close both gaps by sliding the slip-on socket.Use REHAU lubricant liberally here.Fig. 7-3Installing fitting.1 slip-on socket d a Pipe outer diameter2 Adapter1 5 331 5max. 10xODmax. 10xODmax. 10xOD42 4 55 4 2 4max. 10xODmax. 10xODmax. 10xODFig. 7-2Using double sockets and slip-on socket in vertical stacksFig 7-4Using double sockets and slip-on socket in horizontal installations1 Double socket2 Slip-on socket3 Guiding clamp (green)4 Guiding clamp (green) at 15-20mmdistance to the slip-on socket5 Sound-dampening bracket6 Sound-dampening bracketat 15-20mm distance to theslip-on socket1 Double socket2 Slip-on socket3 Guiding clamp (green)4 Guiding clamp (green) at 15-20mmdistance to the slip-on socket5 Fixing clamp (black)32

7.5 Bracketing7.5.1 Bracketing plan for horizontal pipesGA plan for effective bracketing of a horizontal sound-insulating pipe withRAUPIANO PLUS is displayed graphically (refer to images on and the nextpage).Fig. 7-5Guiding clampsSound-dampening support brackets are not required for horizontalpipe installations.• Allows for thermal expansion of the pipe• Always loose on pipe (has spacer)• Fix to ceiling on horizontal pipes• Fix to wall on vertical stackFixing clamps hold pipe in place. Guiding clamps allow for thermalexpansion in one direction.SFF2mGDN110GFGuiding clamp (loose)FFixing clamp (tight)Fig. 7-8Bracketing plan for horizontal pipesFig. 7-6Fixing/security clamp• Always tight on pipe• When used as fixing clamp on horizontal pipes: fix to ceiling• When used as security clamp in vertical stacks: never fix to wallSD• Don’t use sound-dampening bracket on horizontal lines.• Install fixing clamp at socket end followed by guiding clamps until nextjoint.• Install fixing clamp downstream, as near as possible to the socket end.• Max bracket spacing can be increased for smaller pipes sizes, seeTable 7.1 for recommendation.• If more than 3 fittings are joined together in the same line, ensure thegroup of fittings are sufficiently supported to avoid sagging, twistingand to prevent the connections from sliding apart.Fig. 7-7Sound-dampening bracket• Minimizes transmission of vibrations from pipe through fixinginto wall.• Consists of loose and tight bracket:- lower clamp (loose) attaches to wall and de-couples pipe vibrationsfrom wall fixing.- upper clamp (tight) supports pipe.- attach to vertical stack only 1 required per floor, per stack33

7.5.2 Vertical stackTo achieve optimum acoustic insulation, use only RAUPIANO PLUS sounddampening brackets during assembly.3. Open supporting clamp, insert pipe with fastening clamp and closesupporting clamp.RAUPIANO PLUS drainage pipes must be installed tension-free.7.5.2.1 Assembly of Sound Dampening BracketThe patented sound-dampening support bracket consists of a supportingclamp (loose) and a fastening clamp (tight, sits above supporting clamp).One sound-dampening support bracket per storey is sufficient.1. Fit fastening clamp around the pipe and close it.Fig. 7-16Closing supporting clamp.After installation, the fastening clamp fully lies on the supporting clamp.This achieves optimum sound decoupling.Fig. 7-14Fastening clamp, secured around pipe2. Assemble supporting clamp on masonry.Fig. 7-17Fully installed sound-dampening bracket.Fig. 7-15Supporting clamp assembled, opened.A spacer is attached at the closure of the support clamp to prevent theclamp being closed completely. This ensures minimum transmission ofstructure-borne noise to the wall.35

7.6 Floor waste gully installationRAUPIANO PLUS Floor waste gully includes:• 3-way riser (DN 110 floor inlet, 3 x DN50 inlets, DN75 outlet).• Removable insert that creates a water sealing column for the “trap”.• The same push-fit joining method applies for all the inlets and outlet.Floor grateLeak controlflange1. Drill hole for required inlets using 44 mm hole sawDN75 fixing clampFloor waste gullyDN50 fixing clampFig. 7-22 Bracketing of floor Waste Gully (General example only)3. Install floor waste gully beneath slab by inserting over DN110 penetrationDN110 riser pipe must be chamfered and have no internal burr.4. Install socket of DN75 pipe over outletFig. 7-19 Floor waste gully2. Assemble double socket over DN50 inlets5. Install DN50 waste pipe into socket of inlets6. Secure floor gully by installing fixed brackets on DN75 outlet and oppositeDN50 inlet.7. Recommended to use a leak control flange with rubber finsDN50 double socketart no: 1214847.7 P-trap siphon / 110mm disconnector gullyFig. 7-20 Floor waste gully with double sockets on inletsBuilt in support holefor hanging supportFig. 7-23RAUPIANO PLUS P-trap siphonRAUPIANO PLUS P-trap siphon provides 50 mm water seal to prevent foulodour from coming out of the drainage lines. The P-trap siphon is to beused together with DN 110 bend 45°.When installing this P-trap, it is important to install the pipe supportproperly to ensure safe operation of the drainage system.Fig. 7-21 Removing the BaffleThe P-trap siphon can be supported by attaching a hook into the built-inhole.37

7.8 Cleaning the waste pipe systemFig. 7-26 RAUPIANO PLUS securing clip.Fig. 7-24RAUPIANO PLUS I.O. access pipe.The socket plug can be used to plug-off the pipe ends if they are notin use. The socket plug is to be used together with the securing clip toensure a safe and tight jointing.Installing access pipes enables mechanical cleaning of the waste pipesystem.7.10 Installing pipes in masonryRAUPIANO PLUS access pipe is supplied with insert to ensure flushingsurface for smooth and uninterrupted water flow.Place the insert into the access opening and tighten the screw cap withrubber seal inserted.Do not use sharp cleaning devices for mechanical cleaning.7.9 Socket plugObserve the applicable national regulations for recesses and slots in themasonry.- Make wall chases and penetrations in such a way that the pipeline canbe laid without tension.- Avoid sound bridges between the masonry and the pipe.If the pipes will be plastered directly without using a plaster board:- Fully wrap pipes and fittings with flexible materials such asmineral or glass wool, to prevent sound bridges between the pipe andplaster or masonry.- In locations where temperatures above 90°C may be reached dueto external heat sources, protect pipes and fittings with appropriatemeasures to avoid excessive heat.Fig. 7-25 RAUPIANO PLUS socket plug.38

7.11 Installing pipes in concreteWhen installing in concrete, fully wrap pipes and fittings with flexiblemoisture-proof and sound-insulating materials, to prevent sound bridgesbetween the pipe and the concrete.- Fix pipes appropriately to prevent movement during concreteapplication.- Ensure sufficient expansion joints when installing the pipe.- Seal off socket gap with adhesive strips to prevent the penetration ofconcrete.- Seal off pipe openings with socket plugs before concrete application.Fig. 7-27 Typical ceiling penetration through non-fire rated building elements(General example only)7.13 Installation as stormwater pipingThere is a risk of condensation on pipes installed as stormwater pipingwithin the building.CAUTIONDanger of damage to property!Damage to the pipelines!- Avoid placing the weight of the concrete on the pipelines by makingprovisions for dissipating the load, e.g. by using:- Spacers in the case of reinforcing steels- Carrying boxes- Brackets- Avoid walking on the pipes during concrete application.7.12 Ceiling penetrationsCeiling penetrations must be constructed to be moisture-proof andsound-insulating as per BCA requirements. Fire-protection measurementsare necessary if pipes penetrate through fire-rated building elements.Refer to chapter 5 for details.If mastic asphalt is to be applied to the floor:Protect exposed pipeline components with ceiling liner, protective sleevesor by wrapping them with heat-insulating materials.Condensation appears when the temperature of the pipe walls dropsbelow the dew point temperature of the ambient air due to cold rain water,for example. Humidity from the ambient air then condenses on the pipesurface.It is recommended to wrap all pipework where condensation could occurwith closed-cell insulation materials.Fixing of stormwater pipingTo prevent the pipelines from sliding apart, a security clamp is to beattached to the pipe directly below the sound-dampening bracket. (oneper stack, per floor)SDSDSFig. 7-28 Fixing of stormwater pipingSDSSound-dampening bracketSecurity Clamp (not to be fixed to wall)39

7.14 RAUPIANO Push-Fit LockThe RAUPIANO Push-Fit Lock increases the socket joint integrity bypreventing the pipe from being pulled-out of the socket at higher load.Push-Fit Lock Application1. Stormwater Downpipe installed inside buildings up to a maximumpressure of 2 bar (20 m).2. Connection of Pump stations up to a maximum pressure of 2 bar3. As an alternative solution, the Push-Fit Lock can be used to securethe socket plug, it would be used in replacement of using a securingclip.For Pump station application, it is recommended to install the Push-FitLock around all sockets in horizontal and vertical pipework where theapplied pump pressure may exceed 1 bar.In stormwater applications it is recommended to install the Push-Fit Lockaround all sockets in horizontal and vertical pipework in buildings of morethan 10m in height.In addition, the Push-Fit Lock can also be used to prevent the pipe fromsliding apart during installation phase.It is easily installed and dismantled. The auto-locking assemblymechanism prevents it from falling off the pipe, even when the Push-FitLock has not been tightened yet.Installation is simple, fast and secure. The necessary bolts and nuts aresupplied together with the Push-Fit Lock.Fig. 7-29 Push-Fit Lock assembled on a socket40

<strong>Raupiano</strong> plusINSTALLATION BELOW GROUND8.RAUPIANO PLUS is suitable for installations both above and below ground,inside and outside the building structure. The installation is to be carriedout in accordance with the static requirements.*8.2 Pipe trench123Other applicable standards/test certificates4The following standards are to be observed when installing510RAUPIANO PLUS:- National Construction Code- New Zealand Building Code- AS/NZS 5065- AS/NZS 35006789a b c11OD1213- AS/NZS 2566.28.1 GeneralGenerally applicable pipeline construction rules are to be followed.Careful and professional handling of the pipes and fittings duringtransport, storage and laying must be ensured.Only plumbers who carry a recognised plumbing certificate for Australiaor New Zealand should be installing the pipeworkObserve the following:- Accident prevention regulations of the employers' liability insurance- Road traffic regulations- Any special project-dependent regulations- Applicable requirements contained in the regulations or technicalregulationsFig. 8-1 Schematic structure of pipe trenches1 Surface 10 Covering height2 Bottom edge of street 11 Thick beddingor sliding construction 12 Thick embedment(if present)13 Trench depth3 Trench walls a Thick lower inter-4 Main filling mediate bedding layer5 Cover b Thick top bedding6 Side filling layer7 Top bedding layer c Thick cover8 Bottom bedding layer OD Outer diameter pipe9 Trench bottomPipe trenches must comply with AS/NZS 3500.2 and AS/NZS 2566.2.Note:- Ensure the structural integrity of the trench either via suitable shoring(joists) or other suitable measures.- Prepare trench bottom according to the required gradient.- Make suitable recesses in the bottom pipe bed layer at the pipeconnection points or in the trench bottom so that the entire length ofthe pipe makes contact.- Ensure a consistently level lie of the pipelines.- Protect trench bottom from the effects of frost.- In high altitude and cold climates, do not use snow, ice or frozensoil above or below the pipelines.- Remove trench shoring materials according to the static calculationsso that the pipeline is neither damaged nor repositioned.* Static calculations must be conducted in order to quantify that mechanical loading on the RAUPIANO PLUS pipe will be avoided at all times. Drainsconstructed with less than minimum cover shall comply with Clause 3.7 of AS/NZS 3500.2.41

8.3 EmbedmentThe embedment of the pipe installed in ground is comprised of the:- Pipe bedding- Side support- Pipe overlay- BackfillAS/NZS 3500.2 - Section 5.4 Bedding of Drains and Backfilling must becomplied to. The following are the manufacturers recommendations forRAUPIANO PLUS pipes installed below ground.LocationSubject to heavy vehicular trafficMinimum depth of cover(mm)N/ASubject to light vehicular traffic 500*Ensure that the embedment is created carefully, as it is the maindetermining factor in the supportive capacity of the pipe.Bedding, sidefilling and initial backfilling shall be carried out inaccordance with the design and specification. The embedment shouldbe protected against any foreseeable change of its load bearing capacity,stability or position that could be caused by removal of sheeting,groundwater influences or other excavation work. When parts of a pipelineneed anchoring or strengthening, this shall be done before placement ofthe embedment. During placement of the embedment special attentionshould be given to the following:- avoidance of displacement of the pipeline from line and level;- care for placement of upper bedding to ensure that the voids under thepipe are filled with compacted material.8.3.1 Bedding MaterialsEmbedment materials must comply with the design specifications. Thiscan also be the excavated soil, whose suitability has been checked.When selecting embedment materials and their grain size, observe thefollowing:- Pipe diameter- Pipe material- Pipe wall thickness- Soil characteristicsEmbedment materials must comply with requirements stated in AS/NZS3500.2 - Clause 5.4 and AS/NZS 2566.2.8.3.2 Pipe beddingThe pipe bedding is comprised of a bottom bedding layer, a pipe sidesupport layer and a top bedding layer. The width of the pipe bedding mustmatch the trench width.Table 8-1BackfillCompacted pipeoverlayCompacted pipeside supportCompacted pipebeddingB min. = D+ 200Fig. 8-2Elsewhere 300*Minimum depth of cover for RAUPIANO PLUSExistingsurface100 min. D 100 min.B min.Ground levelRecommended bedding of drainsSee table 8.175 min.Special pipe bedding or support construction typeAny localized quantity of soft ground below trench bottom shall beremoved and replaced with suitable bedding material. If more extensivequantities are encountered a re-evaluation of the structural design shouldbe undertaken.NOTE:Very soft or expansive clays, irregular or fragmented rock, and saturatedsoils, are unsuitable pipe beddings and should be avoided. Whereavoidance is impracticable, most of these situations may usually beovercome by adequate drainage of ground water, and removing theunsuitable material and replacing it with compacted embedment material.D75 min.BackfillPipe overlayPipe side supportBed zone* Static calculations must be conducted in order to quantify that mechanical loading on the RAUPIANO PLUS pipe will be avoided at all times. Drainsconstructed with less than minimum cover will be required to fulfill Clause 3.7 of AS/NZS 3500.2.42

8.3.3 FillingTo prevent surface settling, side and main filling are to be put in placein accordance with the design requirements.8.3.4 CompactingThe degree of compacting must correspond to the requirements for thepipeline according to the static calculation. The degree of backfillingmust comply with AS/NZS 3500.2 - Section 5.58.4 Connections to pipes and manholesConnections to pipes and manholes shall be made by using prefabricatedelements. Compatible junctions, connection fittings or saddle fittings maybe used. The connection shall be made in accordance with the installationinstructions of the manufacturer of the prefabricated elements, and shallbe leaktight.8.5 Expansion joints in ground- If necessary, compacting of the cover must be carried out by handdirectly over the pipe.- Mechanical compacting of the main filling cannot be carried out untila layer that is at least 30 cm thick is in place over the pipe apex.- Selection of the compacting equipment, the number of compactingruns and the layer thickness to be compacted must be appropriate forto the material to be compacted and the pipeline.- Compacting the main or side filling via silting is only permissible inexceptional cases with suitable cohesionless ground.For pipes installed in ground it is not required to pull the pipe end out by10mm to provide an expansion joint, refer to chapter 7.2.43

RAUPIANO PLUSADAPTATION TO DRAINAGE SYSTEMS9.9.1 PVC drainage to RAUPIANO PLUSIf it is necessary to adapt to PVC systems which are manufactured according to AS/NZS 1260, the simple adaptor from RAUPIANO PLUS to PVC systemis available. To install these adaptors, please adhere the following steps:- apply primer and solvent cement to the PVC side of the adaptor- insert the solvent-cemented portion into a female socket of PVC fitting- apply REHAU lubricant to the other portion of the adaptor and insert into RAUPIANO PLUS socketThese adaptors are made of PVC and available for the following sizes:PVCFromToadaptorRAUPIANO PLUS OD (mm) PVC system OD (mm)DN 40/43 DN 40 40 DN 40 43DN 50/56 DN 50 50 DN 50 56DN 75/69 DN 75 75 DN 65 69Table 9-1 Available adaptor sizes from RAUPIANO PLUS to PVC systemDN 40 DN 50 DN 65 DN 100, DN 150DN 40 PVC fitting (female socket)DN 50 PVC fitting (female socket)DN 65 PVC fitting (female socket)DN 100 / DN 150PVC adaptorDN 40/40 PVC adaptor(Art. No. 123009)(<strong>Reece</strong> code 1450706)DN 50/50 PVC adaptor(Art. No. 123012)(<strong>Reece</strong> code 1450707)DN 65/75 PVC adaptor(Art. No. 123016)(<strong>Reece</strong> code 1450708)DN 40 RAUPIANO PLUS pipe orfitting15°DN 50 RAUPIANO PLUS pipe orfittingDN 75 RAUPIANO PLUS pipe orfittingDN 110 / DN 160 RAUPIANO PLUSpipe or fittingTable 9-2PVC to RAUPIANO PLUS adaptiond eeed e15°bed e15°bed e15°bIt is not necessary to adapt from RAUPIANO PLUS DN 110 to PVC system DN 100 as they have exactly the same outer diameter of 110 mm. It ispossible to insert DN 100 PVC pipe into DN 110 RAUPIANO PLUS socket after chamferring the pipe and applying REHAU lubricant.44

15°b15°9.2 Drainage fittings to RAUPIANO PLUSThere are several options for connecting plumbing fixture drainage fittingsor other pipe materials to RAUPIANO plus drainage pipes or fittings:- RAUPIANO PLUS connection pipe- RAUPIANO PLUS connection bend- RAUPIANO PLUS fitting with beaded rubber nippleRAUPIANO PLUS connection pipe1. Insert rubber nipple in the socket of the connection pipe.2. Apply REHAU lubricant on the sealing lips of the rubber nipple.3. Insert male end of drain fitting of plumbing fixture into the rubbernipple.Fig. 9-1RAUPIANO PLUS connection pipe with rubber nipple.Fixture trapDN 40 DN 50 DN 50OD 32 - 40 mmmetal pipeOD 32 - 40 mmmetal pipeOD 47 - 50 mmmetal pipeDN 50/40rubber nipple(Art. No. 126253)(REECE code 1450882)DN 50/40rubber nipple(Art. No. 126253)(REECE code 1450882)DN 50/50rubber nipple(Art. No. 121913)(REECE code 1450883)DN 40/40connection pipe(Art. No. 123164)(REECE code 1450752)DN 50/40-30connection pipe(Art. No. 121414)(REECE code 1450753)DN 50/50connection pipe(Art. No. 121424)(REECE code 1450754)DN 40 RAUPIANOPLUS pipe or fittingDN 50 RAUPIANOPLUS pipe or fittingDN 50 RAUPIANOPLUS pipe or fittinged eed ebed e15°b45

15°RAUPIANO PLUS fitting with beaded rubber nipple1. Remove the installed sealing rubber from the pipe or fitting socket.2. Insert rubber nipple with bead into the fitting socket.3. Insert male end of the drain fitting of plumbing fixture into the rubber nipple.Fixture trapDN 40 DN 50 DN 50OD 32 mmmetal pipeOD 32 mmmetal pipeOD 32 mmmetal pipeDN 40/30 rubbernipple with bead(Art. No. 122923)(REECE code 1450884)DN 50/30 rubbernipple with bead(Art. No. 122933)(REECE code 1450885)DN 50/30 rubbernipple with bead(Art. No. 122933)(REECE code 1450885)DN 40 RAUPIANOPLUS pipe or fitting(without rubber ring)DN 50 RAUPIANOPLUS pipe or fitting(without rubber ring)DN 50 RAUPIANOPLUS pipe or fitting(without rubber ring)Table 9-3ed eDrainage fittings to RAUPIANO PLUS adaptionb15°15°ed ebed eb9.3 Rubber sleeve adaptor for Cast Iron pipe or other materialsFor transition from RAUPIANO PLUS pipes to Cast Iron pipes or othermaterials for drainage systems, rubber sleeve adaptors can be used.These rubber sleeves come with rubber seal that is attached to the pipeends and two stainless-steel worm-gear clamps. These rubber sleeveadaptors can be used in new construction or renovation works.Fig. 9-3Rubber sleeve for same or different outer diameters.Below are the properties of the rubber sleeve adaptor.MaterialRubberTightening deviceStainless-steel worm-gear clampsRecommended tightening torque 3 Nm (Newton metres)Pressure resistance1 barChemical resistance pH 2 - 12Table 9-4 Properties of rubber sleeve adaptor.46

Installation steps:1. Insert RAUPIANO PLUS pipe end into one end of the rubber sleeveadaptor.2. Insert Cast Iron / other material pipe end into the other end of therubber sleeve adaptor.3. Tighten the worm-gear clamps on both ends of the rubber sleeveadaptor without exceeding the maximum tightening torque.The rubber sleeve adaptor can be installed on most Cast Iron and othermaterials pipe sizes, the table below specifies the suitable dimensions ofCast Iron or other pipe materials.OD 40 mm pipe (plastic/metal)OD 53 - 63 mm pipe (plastic/metal)OD 75 - 89 mm pipe (plastic/metal)OD 100 - 115 mm pipe(plastic/metal)OD 40-56mmmetal pipeFrom metalor otherplastic pipeDN 50/40 rubber adaptor(REECE code: 1430720)DN 50/53-63 rubber sleeveadaptor(Art. No. 125024)(REECE code 1450894)DN 75/75-89 rubber sleeveadaptor(Art. No. 125034)(REECE code 1450895)DN 110/110 rubber sleeveadaptor(Art. No. 123914)(REECE code 1450897)Reducing Adaptor40-56mm (REECE code1430938)DN 50 RAUPIANO PLUS pipe(plain)DN 50 RAUPIANO PLUS pipe(plain)DN 75 RAUPIANO PLUS pipe(plain)DN 110 RAUPIANO PLUSpipe (plain)DN 110 RAUPIANO PLUSpipe plainTable 9-5Metal and other pipe to RAUPIANO PLUS adaption9.4 Closet connection and bendRAUPIANO PLUScloset bend= ...mmRAUPIANO PLUS closet connectionRAUPIANO PLUS closet bendRAUPIANO PLUScloset connection• For connection to toilet bowls, RAUPIANO PLUS offers a straightconnection or 90° bend connection.• The rubber connection allows leak-proof push-fit connection to commontoilet pan outlet sizes.RAUPIANO PLUS installation withcloset bendRAUPIANO PLUS installation withcloset connectionInstall closet connection flush withslab surface47

RAUPIANO PLUSLEAK TEST10.10.2 Air TestThe leak test must be carried out in accordance with AS/NZS 3500.2For pipes installed below ground, testing shall be conducted prior to theplacement of the trench fill (backfill).10.1 Hydrostatic testWhere there are water restrictions or the network provider has a watermanagement strategy, hydrostatic testing may not be permitted, in whichcase an air or vacuum seal test must be conducted. In accordance withsection 13 of AS/NZS 3500.2The sanitary plumbing and sanitary drainage shall be filled with water -(a) in the case of sanitary drainage, to a height of not less than 1mabove the pipe soffit level at the highest point of the section being tested;(b) in the case of sanitary plumbing, to the spill level of the highestfixture or to the flood level of the lowest sanitary fixture, whichever ishigher; and(c) in the case of pipe installed below ground, to a height not lessthan 2 m (or 20 kPa ) above the pipe soffit level at the highest point ofthe section being tested or 2 m (or 20 kPa ) above ground water table,whichever is the greater.Alternatively, the test can be carried out with air.The air test is carried out with:- Test pressure 15 kPa1. Ensure firm and sealed seating of plugs.2. Pressurise the system and stabilize for a minimum of 3 minuteswhile checking for leaks3. After pressure is stabilized commence the test by allowing thepressure to reduce to 10 kPa4. Start test time and record drop in pressure during the test time5. The section of sanitary plumbing or sanitary drainage being testedshall not have a drop in pressure greater than 3 kPa over theminimum test duration specified in Table 10.1Test Length (m)Pipe size50 100 150 120 250 300DNMinimum test duration, min110 2 2 2 2 3 3160 3 3 3 6 6 6Table 10-1 Minimum test duration for Air Test in minutesThe pressure shall be maintained without leakage for at least 15 min.The source of any leak shall then be ascertained and any defectsrepaired. The section under test shall then be retested.48

<strong>Raupiano</strong> plusCERTIFICATIONS AND TEST REPORTS11.AustraliaNew ZealandRAUPIANO PLUS and other REHAU product Watermark Certificates areavailable for download from www.rehau.com.au/raupiano Please beadvised that the REHAU PVC Adaptors have Best Environmental PracticeCertification and the certificate is available for download from the abovelink.49

RAUPIANO PLUSTECHNICAL SPECIFICATIONS12.MaterialPP-MD mineral-reinforced (pipes and fittings)Size range DN 40 – DN 160Area of applicationWaste water pipes in buildings and laid below ground inside and outside the building structureChemical resistance Polypropylene basis in accordance with DIN 8078No waste water containing benzeneSeals made of SBR DIN 4060, DIN EN 681-1Application Waste water with ph value 2 – 12Waste water temperature up to 95°C (brief periods) or 90°C (continuous load)Maximum head pressure 1 bar (10m) respectively 2 bar (20m) when using Push-fit Lock.Design Service Life 50 years within these application parameteres.Density Pipes 1.9 g/cm 3Fittings 1.1 – 1.9 g/cm 3Coefficient of thermal expansion 0.09 mm/m·K DIN 53752Ring stiffness > 4 kN/m 2 DIN EN ISO 9969Tensile strength > 16 N/mm 2 DIN EN ISO 527-3Elongation before breaking Approx. 150 % DIN EN ISO 527-3Modulus of elasticity Approx. 2,700 N/mm 2 DIN EN ISO 527-2MFR 190/5 Approx. 1.7 g/10 min. DIN EN ISO 1133MFR 230/2,16 Approx. 0,82 g/10 min. DIN EN ISO 1133Pipe structurePipes features innovative three-layer structure- Impact-resistant and shock-proof PP outer layer- Highly rigid middle layer made of mineral-reinforced PP- Abrasion-resistant and very slick inner layerFittings- Mass optimisation in redirection area for increased sound insulation DN 110 – DN 160Halogen contents Halogen-free (no F, Cl, Br, J)ConnectionPush-fit socket with factory-installed lip sealing ringFire behaviour B2 (normally inflammable) In accordance with DIN 4102D,S3-dO In accordance with EN 13501-1System compatibilityAdapters to PVC system and other pipe materials are availableStandards and approval System test according to:- AS/NZS 7671, WM70060- AS/NZS 2887, WM71501- AS/NZS 1260, WM71502- AS/NZS 5065, WM71503System assessed according to:- BRANZ Appraisal No. 809- Best Environmental Practice PVC to AS/NZS 1260Sound insulation Tested to ISO 140 methodology. Sound insulation performance rated according to ISO 717.Fulfils BCA/NCC requirement of Rw + Ctr 40 for habitable rooms without acoustic lagging.Independent monitoring Süddeutsches Kunststoffzentrum (SKZ), GermanyFire loadThe RAUPIANO PLUS fire load was determined by MPA. It is- 14,992 kJ/kgTransferred to a DN 110 RAUPIANO PLUS pipe:- 7.9 kWh/m- 28,464.8 kJ/mTab. 11-1 Technical specifications.50

RAUPIANO PLUSCHEMICAL RESISTANCE13.Pipe and fittingThe specifications below are used as a general guidance as to thechemical resistance of the material and cannot simply be applied toall applications. They shall not be used as a guidance to determine thepossible affects on the reagent. Mechanical behaviour can be impaired incases where tension and the presence of chemicals occur simultaneously(tension-fracture corrosion).Rubber sealing ringThe types of rubber used generally exhibit high chemical resistance,but components of esters, ketones and aromatic and chlorinatedhydrocarbons in sewer water can lead to swelling of the material, whichcan influence the tightness of the connection.If in doubt, we recommend testing the suitability of the pipe, fitting andseal material in existing systems or have them checked in a laboratory.Contact REHAU if necessary.Table legendr = resistantcr = conditionally resistantnr = not resistant– = not testedReagent Concentr. Temp. RAUPP% °C2-Propen-1-ol 96 20 r96 60 rAcetaldehyde + acetic acid 90/10 20 –Acetaldehyde, aqueous 40 40 rAcetaldehyde, concentrated 100 20 –Acetate ether 100 20 –Acetic acid, aqueous up to 25 40 rup to 25 60 r25–60 60 r80 40 rAcetic acid, concentrated 95 40 –Acetic anhydride 100 20 r100 40 cr100 60 crAcetone 100 20 r100 60 rAcetone, aqueous traces 20 rAcronal dispersions com. avail. 20 –Acronal solutions com. avail. 20 –Acrylic acid ethyl ester 100 20 –Adipic acid, aqueous saturated 20 rsaturated 60 –Aluminium chloride diluted 40 rdiluted 60 rsaturated 60 rReagent Concentr. Temp. RAUPP% °CAluminium sulfate, aqueous diluted 40 rdiluted 60 rsaturated 60 rAlums, aqueous diluted 40 rdiluted 60 rsaturated 60 rAmmonia, gas 100 60 rAmmonia, liquid 100 20 rAmmonium chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rAmmonium fluoride, aqueous up to 20 20 rup to 20 60 rAmmonium hydroxide warm sat. 40 rwarm sat. 60 rAmmonium nitrate, aqueous diluted 40 rdiluted 60 rsaturated 60 rAmmonium sulfate, aqueous diluted 40 rdiluted 60 rsaturated 60 rAmmonium sulfide, aqueous diluted 40 rdiluted 60 rsaturated 60 rAniline hydrochloride, aqueous saturated 20 rsaturatedr 60 r51

Reagent Concentr. Temp. RAUPP% °CAniline, aqueous saturated 20 rsaturated 60 rAniline, pure 100 20 r100 60 rAnimal glue custom. conc. 20 rcustom. conc. 60 rAnthraquinonesulfonic acid, aqueous suspension 30 rAntiformin, aqueous 2 20 –Antimony chloride, aqueous 90 20 rArsenic acid, aqueous diluted 40 rdiluted 60 r80 40 r80 60 rBeef tallow emulsion, sulphonated com. avail. 20 –Beer com. avail. 20 rBeer colouring agent com. avail. 60 rBenzaldehyde, aqueous 0,1 60 –Benzene 100 20 crBenzoic acid, aqueous any 20 rany 40 rany 60 rBisulphite solution, w/ SO 2 warm sat. 50 rBleaching liquour, usage conc. 40 –containing 12.5 % active chlorine usage conc. 60 crBorax, aqueous diluted 40 rdiluted 60 rsaturated 60 rBoric acid, aqueous diluted 40 rdiluted 60 rsaturated 60 rBrandy com. avail. 20 rBromine fumes minimal 20 nrBromine, liquid 100 20 nrButadiene 100 60 –Butane, gaseous 50 20 rButanediol up to 100 20 –Butanediol, aqueous up to 10 20 rup to 10 40 rup to 10 60 rButanol up to 100 20 rup to 100 40 rup to 100 60 crButyl acetate 100 20 crReagent Concentr. Temp. RAUPP% °CButylene, liquid 100 20 –Butylphenol 100 20 rButynediol up to100 40 –Butyric acid, aqueous 20 20 rconcentr. 20 rCalcium chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rCalcium nitrate, aqueous 50 40 rCarbolineum, aqueous usage conc. 20 –Carbon dioxide, aqueous under saturated 20 –8 atmospheric pressuresCarbon dioxide, dry 100 60 rCarbon dioxide, moist any 40 rany 60 rCarbon disulfide 100 20 crCarbon tetrachloride, technical 100 20 nrCaustic potash solution, aqueous up to 40 40 rup to 40 60 r50/60 60 rCaustic soda, aqueous up to 40 40 rup to 40 60 r50/60 60 rChloramine, aqueous diluted 20 –Chloric acid, aqueous 1 40 –1 60 –10 40 –10 60 –20 40 –20 60 –Chlorine water saturated 20 crChlorine, gaseous, dry 100 20 nrChlorine, gaseous, moist 0,5 20 nr1 20 nr5 20 nrChlormethyl 100 20 –Chloroacetic acid (mono) 100 40 r100 60 –Chloroacetic acid (mono) aqueous 85 20 rChlorosulfonic acid 100 20 nrChromic acid, aqueous up to 50 40 –up to 50 60 cr52

Reagent Concentr. Temp. RAUPP% °CChromic acid/Sulphuric acid/Water 50/15/35 40 nr50/15/35 60 nrCider com. avail. 20 rCitric acid, aqueous up to 10 40 rup to 10 60 rsaturated 60 rClophene com. avail. 20 –com. avail. 60 –Coconut fat alcohol 100 20 r100 60 crCopper fluoride, aqueous 2 50 rCopper sulfate, aqueous diluted 40 rdiluted 60 rsaturated 60 rCresol, aqueous up to 90 45 –Crotonaldehyde 100 20 rCyclohexanol 100 20 rCyclohexanone 100 20 rCyclohexanone 100 20 rDensodrin W com. avail. 60 –Dextrin, aqueous saturated 20 r18 60 rDiethylether 100 20 crDiglycol acid, aqueous 30 60 rsaturated 20 rDimethyl sulfate, aqueous up to 50 20 rup to 50 40 r100 40 –100 60 –Dimethylamine, liquid 100 30 –Disulfuric acid 10 20 nrEthanol (fermentation mash) common 40 rcommon 60 –Ethanol, aqueous any 20 r96 60 rEthanol, denatured (with 2 % tolulene) 96 20 crEthanol+ acetic acid common 20 r(fermentation mash)Ethyl acetate 100 20 cr100 60 nrEthylene chloride 100 20 nrReagent Concentr. Temp. RAUPP% °CEthylene oxide, liquid 100 20 –Exhaust gas, w/ H 2 CO 3 any 60 rExhaust gas, w/ HF traces 60 rExhaust gas, w/ NOX traces 60 rhigher 60 –Exhaust gases, w/ H 2 S 2 O7 lower 20 –higher 20 nrExhaust gases, w/ H 2 SO 4 , moist any 60 rExhaust gases, w/ HCl any 60 rExhaust gases, w/ SO 2 lower 60 r50 50 –Fatty acids 100 60 crFerric chloride, aqueous up to 10 40 rup to 10 60 rsaturated 60 rFertilizer salts, aqueous up to 10 40 rup to 10 60 rsaturated 60 rFluorsilicic acid, aqueous up to 32 60 –Formaldehyde, aqueous diluted 40 rdiluted 60 r40 30 rFormic acid 100 20 r100 60 crFormic acid, aqueous up to 50 40 r50 60 rFrigen 100 20 crFruit pulp custom. conc. 20 rGlucose, aqueous saturated 20 rsaturated 60 rGlycerine, aqueous any 60 rGlycine, aqueous 10 40 rGlycol, aqueous com. avail. 60 rGlycolic acid, aqueous 37 20 rHexantriol com. avail. 60 rHydrobromic acid, aqueous up to 10 40 rup to 10 60 r48 60 rHydrochloric acid, aqueous up to 30 40 rup to 30 60 rover 30 20 rover 30 60 r53

Reagent Concentr. Temp. RAUPP% °CHydrofluoric acid, aqueous up to 40 20 r40 60 r60 20 r70 20 rHydrogen 100 60 rHydrogen peroxide, aqueous up to 30 20 rup to 20 50 rHydrogen phosphide 100 20 –Hydrogen sulfide, dry 100 60 rHydrogen sulfide, aqueous warm sat. 40 rwarm sat. 60 rHydrosulfite, aqueous up to 10 40 rup to 10 60 rHydroxylamine sulfate, aqueous up to 12 35 rLactic acid, aqueous up to 10 40 rup to 10 60 r90 60 rLead acetate, aqueous warm sat. 50 rdiluted 40 rdiluted 60 rsaturated 60 rLead tetraethyl 100 20 rMagnesium chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rMagnesium sulfate, aqueous diluted 40 rdiluted 60 rsaturated 60 rMaleic acid, aqueous saturated 40 rsaturated 60 r35 40 rMalic acid, aqueous 1 20 rMersol D custom. conc. 40 –Methanol 100 40 r100 60 rMethyl amine 32 20 rMethylene chloride 100 20 nrMilk com. avail. 20 rReagent Concentr. Temp. RAUPP% °CMixed acid 48/49/3 20 nr(Sulfuric acid/Nitric acid/Water) 48/49/3 40 nr50/50/0 20 nr50/50/0 40 nr10/20/70 50 cr10/87/3 20 nr50/31/19 30 nrMolasses custom. conc. 20 rcustom. conc. 60 rMolasses wort custom. conc. 60 rMowilith D com. avail. 20 –Nekal, BX, aqueous diluted 40 –diluted 60 –Nickel sulfate, aqueous diluted 40 rdiluted 60 rsaturated 60 rNicotine compounds, aqueous usage conc. 20 –Nicotine, aqueous usage conc. 20 –Nitric acid, aqueous up to 30 50 r30/50 50 nr98 20 nr98 60 nrNitrous gasses concentr. 20 rconcentr. 60 –Oils and greases com. avail. 60 crOleic acid com. avail. 60 crOleum vapour lower 20 crhigher 20 nrOxalic acid, aqueous diluted 40 rdiluted 60 rsaturated 60 rOxygen any 60 –Ozone 100 20 cr10 30 rPalm kernel oil acid 100 60 –Paraffin emulsions com. avail. 20 –com. avail. 40 –Perchloric acid, aqueous up to 10 40 rup to 10 60 rsaturated 60 –Petrol 100 60 nr54

Reagent Concentr. Temp. RAUPP% °CPetrol-benzene mixture 80/20 20 crPhenol, aqueous up to 90 45 r1 20 –Phenylhydrazine 100 20 cr100 60 –Phenylhydrazine hydrochloride, aqueous saturated 20 –saturated 60 –Phosgene, aqueous 100 20 nrPhosgene, gaseous 100 20 cr100 60 crPhosphoric acid, aqueous up to 30 40 rup to 30 60 r40 60 r80 20 r80 60 rPhosphorous pentoxide 100 20 rPhosphorous trichloride 100 20 rPhotographic developers com. avail. 40 rPhotographic emulsions any 40 –Photographic fixers com. avail. 40 rPicric acid, aqueous 1 20 rPotash, aqueous saturated 40 –Potassium borate, aqueous 1 40 r1 60 rPotassium bromate, aqueous up to 10 40 rup to 10 60 rPotassium bromide, aqueous diluted 40 rdiluted 60 rsaturated 60 rPotassium chlorate, aqueous 1 40 r1 60 rPotassium chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rPotassium chromate, aqueous 40 20 rPotassium cyanide, aqueous up to 10 40 rup to 10 60 rsaturated 60 rPotassium dichromate, aqueous 40 20 rPotassium ferrocyanide diluted 40 rPotassium ferrocyanide, aqueous diluted 60 rsaturated 60 rReagent Concentr. Temp. RAUPP% °CPotassium nitrate, aqueous diluted 40 rdiluted 60 rsaturated 60 rPotassium permanganate, aqueous up to 6 20 rup to 6 40 rup to 6 60 rup to 18 40 –Potassium persulfate, aqueous diluted 40 rdiluted 60 rsaturated 40 rsaturated 60 rPropane, gaseous 100 20 –Propane, liquid 100 20 –Propargyl alcohol, aqueous 7 60 rPure acetic acid 100 20 r100 40 rRamasite com. avail. 20 –com. avail. 40 –Roaster gases, dry any 60 rSeawater – 40 r– 60 rSilicic acid, aqueous any 60 rSilver nitrate, aqueous up to 8 40 rup to 8 60 rSoap solution, aqueous concentrated 20 rconcentrated 60 rSoda, aqueous diluted 40 rdiluted 60 rsaturated 60 rSodium benzoate, aqueous up to 10 40 rup to 10 60 r36 60 rSodium chlorate, aqueous up to 10 40 rup to 10 60 rsaturated 60 rSodium chlorite, aqueous 50 20 rdiluted 60 nrSodium hydrosulfite, aqueous diluted 40 rdiluted 60 rsaturated 60 rSodium hypochlorite, aqueous diluted 20 r55

Reagent Concentr. Temp. RAUPP% °CSodium sulfide, aqueous diluted 40 rdiluted 60 rsaturated 60 rSpirits com. avail. 20 rStarch syrup custom. conc. 60 rStarch, aqueous any 40 rany 60 rStearic acid 100 60 crSulphur dioxide, aqueous under saturated 20 –8 atmospheric pressuresSulphur dioxide, liquid 100 –10 –100 20 r100 60 rSulphur dioxide, moist and aqueous any 40 r50 50 rany 60 rSulphur dixode, dry any 60 rSulphuric acid, aqueous up to 40 40 rup to 40 60 r70 20 r70 60 cr80–90 40 cr96 20 r96 60 nrTable salt, aqueous diluted 40 rdiluted 60 rsaturated 60 rTallow 100 20 r100 60 rTanigan extra A, aqueous any 20 –Tanigan extra B, aqueous any 20 –Tanigan extra D, aqueous saturated 40 –saturated 60 –Tanigan F, aqueous saturated 60 –Tanigan U, aqueous saturated 40 –saturated 60 –Tanning extracts, cellul. common 20 rTanning extracts, natural common 20 rReagent Concentr. Temp. RAUPP% °CTartaric acid, aqueous up to 10 40 rup to 10 60 rsaturated 60 rThionyl chloride 100 20 nrTin (II) chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rToluene 100 20 nrTrichloroethylene 100 20 nrTriethanolamine 100 20 rTrilone com. avail. 60 –Trimethylolpropane, aqueous up to 10 40 –up to 10 60 –com. avail. 40 rcom. avail. 60 rUrea, aqueous up to 10 40 rup to 10 60 r33 60 rUrine normal 40 rnormal 60 rVinegar (wine vinegar) com. avail. 40 rcom. avail. 50 rcom. avail. 60 rVinyl acetate 100 20 rWater 100 r100 rWax alcohol 100 60 crWine, red and white com. avail. 20 rXylene 100 20 nrYeast wort custom. conc. 40 rcustom. conc. 60 rZinc chloride, aqueous diluted 40 rdiluted 60 rsaturated 60 rZinc sulphate, aqueous diluted 40 rdiluted 60 rsaturated 60 r56

RAUPIANO PLUSSTANDARDS, REGULATIONS AND GUIDELINES14.AS 1530.4Method for fire tests on building materials, components and structuresPart 4: Fire-resistance test of elements of constructionAS 2887Plastic waste fittingsDIN 4102Fire behaviour of building materials and elementsDIN 4124Excavations and trenches – Slopes, planking and strutting, breadths ofworking spacesAS/NZS 1260PVC-U pipes and fittings for drain, waste and vent applicationAS/NZS 2566.2Buried flexible pipelines - Part 2: InstallationAS/NZS 3500.2<strong>Plumbing</strong> and drainagePart 2: Sanitary plumbing and drainageAS/NZS 5065Polyethylene and polypropylene pipes and fittings for drainage andsewerage applicationsAS/NZS 7671Plastic piping systems for soil and waste drainage (low and hightemperature) inside buildings - Polypropylene (PP)DIN EN 476General requirements for components used in discharge pipes, drainsand sewers for gravity systemsDIN EN 681Elastomeric sealsMaterial requirements for pipe joint seals used in water and drainageapplicationsDIN EN 752Drain and sewer systems outside buildingsDIN EN 1610Construction and testing of drains and sewersDIN EN 12056Gravity drainage systems inside buildingsDIN 1054Ground – Verification of the safety of earthworks and foundationsDIN 1055 Part 2Design loads for buildings; soil characteristics; specific weight, angle offriction, cohesion, angle of wall frictionGeneral building construction approval from the GermanInstitute of Building Technology (DIBt)Approval Z-42.1-223RAUPIANO PLUS waste pipes and fittingsDIN 1986Drainage systems on private groundDIN 4060Pipe joint assemblies with elastomer seals for use in drains and sewers,requirements and tests57

APPENDIX ARAUPIANO PLUS ACOUSTIC PERFORMANCE SUMMARYRENZO TONIN ACOUSTIC LETTER58