LOCTITE 4305™ - Loctite HF

LOCTITE 4305™ - Loctite HF

LOCTITE 4305™ - Loctite HF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

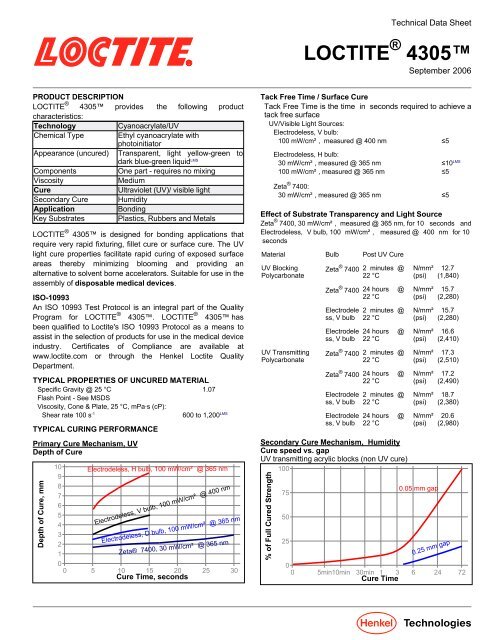

Technical Data Sheet<strong>LOCTITE</strong> ® 4305September-2006PRODUCT DESCRIPTION<strong>LOCTITE</strong> ® 4305 provides the following productcharacteristics:TechnologyCyanoacrylate/UVChemical Type Ethyl cyanoacrylate withphotoinitiatorAppearance (uncured) Transparent, light yellow-green todark blue-green liquid LMSComponentsOne part - requires no mixingViscosityMediumCureUltraviolet (UV)/ visible lightSecondary Cure HumidityApplicationBondingKey Substrates Plastics, Rubbers and Metals<strong>LOCTITE</strong> ® 4305 is designed for bonding applications thatrequire very rapid fixturing, fillet cure or surface cure. The UVlight cure properties facilitate rapid curing of exposed surfaceareas thereby minimizing blooming and providing analternative to solvent borne accelerators. Suitable for use in theassembly of disposable medical devices.ISO-10993An ISO 10993 Test Protocol is an integral part of the QualityProgram for <strong>LOCTITE</strong> ® 4305. <strong>LOCTITE</strong> ® 4305 hasbeen qualified to <strong>Loctite</strong>'s ISO 10993 Protocol as a means toassist in the selection of products for use in the medical deviceindustry. Certificates of Compliance are available atwww.loctite.com or through the Henkel <strong>Loctite</strong> QualityDepartment.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity @ 25 °C 1.07Flash Point - See MSDSViscosity, Cone & Plate, 25 °C, mPa·s (cP):Shear rate 100 s -1600 to 1,200 LMSTYPICAL CURING PERFORMANCEPrimary Cure Mechanism, UVDepth of CureDepth of Cure, mm1098765432100 5 10 15 20 25 30Electrodeless, H bulb, 100 mW/cm² @ 365 nmElectrodeless, V bulb, 100 mW/cm² @ 400 nmElectrodeless, D bulb, 100 mW/cm² @ 365 nmZeta® 7400, 30 mW/cm² @ 365 nmCure Time, secondsTack Free Time / Surface CureTack Free Time is the time in seconds required to achieve atack free surfaceUV/Visible Light Sources:Electrodeless, V bulb:100 mW/cm², measured @ 400 nm ≤5Electrodeless, H bulb:30 mW/cm², measured @ 365 nm ≤10 LMS100 mW/cm², measured @ 365 nm ≤5Zeta ® 7400:30 mW/cm², measured @ 365 nm ≤5Effect of Substrate Transparency and Light SourceZeta ® 7400, 30 mW/cm², measured @ 365 nm, for 10 seconds andElectrodeless, V bulb, 100 mW/cm², measured @ 400 nm for 10secondsMaterial Bulb Post UV CureUV BlockingPolycarbonateUV TransmittingPolycarbonateZeta ® 7400 2 minutes @22 °CZeta ® 7400 24 hours22 °CElectrodeless, V bulbElectrodeless, V bulb@2 minutes @22 °C24 hours @22 °CZeta ® 7400 2 minutes @22 °CZeta ® 7400 24 hours22 °CElectrodeless, V bulbElectrodeless, V bulb@2 minutes @22 °C24 hours @22 °CSecondary Cure Mechanism, HumidityCure speed vs. gapUV transmitting acrylic blocks (non UV cure)100% of Full Cured Strength755025Cure TimeN/mm² 12.7(psi) (1,840)N/mm² 15.7(psi) (2,280)N/mm² 15.7(psi) (2,280)N/mm² 16.6(psi) (2,410)N/mm² 17.3(psi) (2,510)N/mm² 17.2(psi) (2,490)N/mm² 18.7(psi) (2,380)N/mm² 20.6(psi) (2,980)0.05 mm gap0.25 mm gap00 5min10min 30min 1 3 6 24 72

TDS <strong>LOCTITE</strong> ® 4305, September-2006Cure Speed vs. SubstrateThe rate of cure will depend on the substrate used. The tablebelow shows the fixture time achieved on different materials at22 °C / 50 % relative humidity. This is defined as the time todevelop a shear strength of 0.1 N/mm². Fixture timemeasurements relate to non-UV cure.Fixture Time, seconds:ABS 5 to 10Acrylic 10 to 20Aluminum (etched)≤5Neoprene≤5Phenolic 105 to 150Polycarbonate 20 to 30Polyethylene≥300Polyethylene (Primer 770)≤5Polypropylene≥300Polypropylene (Primer 770)≤5PVC 105 to 120Steel (grit blasted) 30 to 45TYPICAL PROPERTIES OF CURED MATERIALCured @ 100 mW/cm², measured @ 400 nm for 10 seconds perside, using an Electrodeless system, V bulb, plus 24 hours post cure@ 22 °CPhysical Properties:Coefficient of Thermal Expansion, ISO 11359-2, K -1 74.7×10 -6Glass Transition Temperature, ASTM E 228, °C 106Volume Shrinkage, ASTM D 792, % 12.8Shore Hardness, ISO 868, Durometer D 77Elongation, at break, ISO 527-3, % 5.5Tensile Strength, at break, ISO 527-3 N/mm² 42(psi) (6,090)Tensile Modulus, ISO 527-3 N/mm² 1,700(psi) (246,565)Cured @ 100 mW/cm², measured @ 365 nm, for 10 secondsperside using an Electrodeless system, V bulb plus 24 hours @ 22 °C,(Cured sheets 0.63 mm thick)Electrical Properties:Volume Resistivity, IEC 60093, Ω·cm 7.43×10 15Surface Resistivity, IEC 60093, Ω 1.38×10 15Dielectric Breakdown Strength, IEC 60243-1, kV/mm 33.5Dielectric Constant / Dissipation Factor, IEC 60250:0.1-kHz 3.95 / 0.0411-kHz 3.67 / 0.04110-kHz 3.52 / 0.037TYPICAL PERFORMANCE OF CURED MATERIALAdhesive PropertiesCured for 72 hours @ 22 °C (non-UV cure)Block Shear Strength, ISO 13445:ABS N/mm² 35.7(psi) (5,170)Acrylic N/mm² 14.1(psi) (2,050)Aluminum (etched) N/mm² 17.9(psi) (2,600)Neoprene N/mm² 0.8(psi) (115)Phenolic N/mm² 8.2(psi) (1,190)Polycarbonate N/mm² 14.1(psi) (2,050)Polyethylene N/mm² 0.4(psi) (60)Polypropylene N/mm² 0.3(psi) (45)PVC N/mm² 32.7(psi) (4,740)Steel (grit blasted) N/mm² 22.5(psi) (3,265)Cured @ 30 mW/cm², measured @ 365 nm, for 10 secondsBlock Shear Strength, ISO 13445:Polycarbonate N/mm² ≥9 LMS(psi) (≥1,305)TYPICAL ENVIRONMENTAL RESISTANCECured @ 30 mW/cm², measured @ 365 nm, for 10 seconds using aZeta ® 7400 light source plus 24 hours post cure @ 22 °CBlock Shear Strength, ISO 13445:PolycarbonateHot StrengthTested at temperature100% Strength @ 22 °C75502500 20 40 60 80 100 120Temperature, °CHeat AgingAged at temperature indicated and tested @ 22 °C% Initial strength, at RT12510075502500 24 170 340Exposure Time, hoursChemical/Solvent ResistanceAged under conditions indicated and tested @ 22 °C.% of initial strength80 °C100 °CEnvironment °C 24 h 170 h 500 hMotor oil (MIL-L-46152) 22 100 105 115Water 22 95 105 100Isopropanol 22 95 100 120Humidity, 100% RH 40 105 105 105Henkel <strong>Loctite</strong> Americas+860.571.5100Henkel <strong>Loctite</strong> Europe+49.89.9268.0Henkel <strong>Loctite</strong> Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com

TDS <strong>LOCTITE</strong> ® 4305, September-2006Effects of SterilizationIn general, products similiar in composition to <strong>LOCTITE</strong> ®4305 subjected to standard sterilization methods, such asEtO and Gamma Radiation (25 to 50 kiloGrays cumulative)show excellent bond strength retention. <strong>LOCTITE</strong> ® 4305maintains bond strength after 1 cycle of steam autoclave. It isrecommended that customers test specific parts aftersubjecting them to the perferred sterilization method. Consultwith <strong>Loctite</strong> ® for a product recommendation if your device willsee more than 3 sterilization cycles.GENERAL INFORMATIONThis product is not recommended for use in pure oxygenand/or oxygen rich systems and should not be selected asa sealant for chlorine or other strong oxidizing materials.For safe handling information on this product, consult theMaterial Safety Data Sheet (MSDS).Directions for use1. This product is light sensitive; exposure to daylight, UVlight and artificial lighting should be kept to a minimumduring storage and handling.2. For best performance bond surfaces should be clean andfree from grease.3. This product performs best in thin bond gaps (0.05 mm).4. Excess adhesive can be dissolved with <strong>Loctite</strong> cleanupsolvents, nitromethane or acetone.<strong>Loctite</strong> Material Specification LMSLMS dated November-17, 2004. Test reports for each batchare available for the indicated properties. LMS test reportsinclude selected QC test parameters considered appropriate tospecifications for customer use. Additionally, comprehensivecontrols are in place to assure product quality andconsistency. Special customer specification requirements maybe coordinated through Henkel Quality.StorageStore product in the unopened container in a dry location.Storage information may be indicated on the product containerlabeling.Optimal Storage: 2 °C to 8 °C. Storage below 2 °C orgreater than 8 °C can adversely affect product properties.Material removed from containers may be contaminated duringuse. Do not return product to the original container. HenkelCorporation cannot assume responsibility for product whichhas been contaminated or stored under conditions other thanthose previously indicated. If additional information is required,please contact your local Technical Service Center orCustomer Service Representative.Conversions(°C x 1.8) + 32 = °FkV/mm x 25.4 = V/milmm / 25.4 = inchesµm / 25.4 = milN x 0.225 = lbN/mm x 5.71 = lb/inN/mm² x 145 = psiMPa x 145 = psiN·m x 8.851 = lb·inN·m x 0.738 = lb·ftN·mm x 0.142 = oz·inmPa·s = cPNoteThe data contained herein are furnished for information onlyand are believed to be reliable. We cannot assumeresponsibility for the results obtained by others over whosemethods we have no control. It is the user's responsibility todetermine suitability for the user's purpose of any productionmethods mentioned herein and to adopt such precautions asmay be advisable for the protection of property and of personsagainst any hazards that may be involved in the handling anduse thereof. In light of the foregoing, Henkel Corporationspecifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for aparticular purpose, arising from sale or use of HenkelCorporation’s products. Henkel Corporation specificallydisclaims any liability for consequential or incidentaldamages of any kind, including lost profits. The discussionherein of various processes or compositions is not to beinterpreted as representation that they are free fromdomination of patents owned by others or as a license underany Henkel Corporation patents that may cover suchprocesses or compositions. We recommend that eachprospective user test his proposed application before repetitiveuse, using this data as a guide. This product may be coveredby one or more United States or foreign patents or patentapplications.Trademark usageExcept as otherwise noted, all trademarks in this documentare trademarks of Henkel Corporation in the U.S. andelsewhere.® denotes a trademark registered in the U.S.Patent and Trademark Office.Reference 1.4Henkel <strong>Loctite</strong> Americas+860.571.5100Henkel <strong>Loctite</strong> Europe+49.89.9268.0Henkel <strong>Loctite</strong> Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com