Die & Mold Handling PDF - Bushman Equipment, Inc.

Die & Mold Handling PDF - Bushman Equipment, Inc.

Die & Mold Handling PDF - Bushman Equipment, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

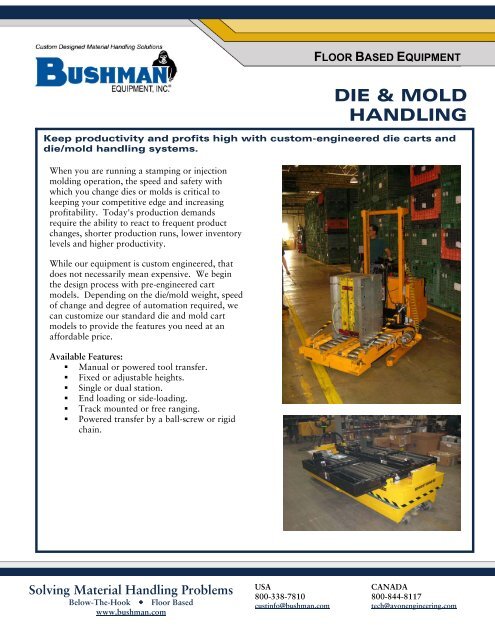

FLOOR BASED EQUIPMENTKeep productivity and profits high with custom-engineered die carts anddie/mold handling systems.When you are running a stamping or injectionmolding operation, the speed and safety withwhich you change dies or molds is critical tokeeping your competitive edge and increasingprofitability. Today's production demandsrequire the ability to react to frequent productchanges, shorter production runs, lower inventorylevels and higher productivity.While our equipment is custom engineered, thatdoes not necessarily mean expensive. We beginthe design process with pre-engineered cartmodels. Depending on the die/mold weight, speedof change and degree of automation required, wecan customize our standard die and mold cartmodels to provide the features you need at anaffordable price.Available Features:• Manual or powered tool transfer.• Fixed or adjustable heights.• Single or dual station.• End loading or side-loading.• Track mounted or free ranging.• Powered transfer by a ball-screw or rigidchain.DIE & MOLDHANDLINGSolving Material <strong>Handling</strong> ProblemsBelow-The-Hook•Floor Basedwww.bushman.comUSACANADA800-338-7810 800-844-8117custinfo@bushman.comtech@avonengineering.com

MODEL LDC – LIFT DIE CARTSDual Station Scissors Lift <strong>Mold</strong> CartBuilt for positioning dies in tight spaces, this dual deck scissors lift diecart features dual-deck, side-loading. Press bolster bridge extensions areoften included to facilitate die transfer.Model LDC Dual Station Lift <strong>Die</strong> Cart with End Pay-OffPerfect for tight spaces around presses, this scissors lift die cart includesa powered walkie drive and turntable top. The rotating tabletop allowsthe old tool to be removed and the new tool rotated into position forinsertion.Single Station Scissors Lift <strong>Mold</strong> CartThis 3,500 pound capacity Model LDC single station, end payoff carttransfers molds to/from storage racks and multiple injection moldingmachines.Dual Station Scissors Lift <strong>Mold</strong> CartThis lift die cart can handle two 10,000pound dies. Both die stations havegravity conveyors and powered moldtransfer.Model LDC Lite with <strong>Die</strong> Storage RackThis 1,000-pound capacity pushcartwith a battery powered hydraulic liftincludes a die storage rack system.Racks are built to fit your availablespace.

MAST DIE CARTSEnd Loading Mast <strong>Die</strong> CartMore maneuverable than forklifts, the <strong>Bushman</strong>mast die cart features a hydraulically operatedmast lift, roller conveyor tool deck and a manualflipper-type die stop to help ensure safetransportation throughout your facility.This <strong>Bushman</strong> mold cart substantiallyreduced the time needed to change out molds,resulting in higher plant productivity. It alsoimproves personnel safety and reduces the chancefor mold damage during mold handling.The Model MDC 1200 allows economicalpowered mold transport with powered side payoff.Designed for uninterrupted operation and quickmold changes, the dual deck mast cart facilitatesthe removal of old molds and the loading of newmolds with minimal changeover time. Dual-tierend loading maximizes productivity.

SPECIAL DIE HANDLING EQUIPMENTThis two-station, 20,000 pound capacity, fullyautomated mold cart serves a line of moldingmachines.This battery powered free ranging mold cart has two24,000 pound mold decks. The decks are raised andlowered by a scissors lift.This towable die cart can handle 100,000 pound diesthat are up to 86 inches by 94 inches.This is a 55,000 pound capacity die staging table. Ithas powered rollers and is 77 inches wide by 116inches long.USA<strong>Bushman</strong> <strong>Equipment</strong> <strong>Inc</strong>. Phone: (800) 338-7810P.O. Box 309 W133 N4960 Campbell Drive (262) 790-4200Butler, WI 53007-0309 Menomonee Falls, WI 53051 Fax: (262) 790-4202CANADAAvon Engineering Phone: (800) 844-81171680 Brampton Street (905) 689-7994Hamilton, ON L8H 3S1 Fax: (905) 689-8472