Download PDF-Brochure - Van der Molen GmbH

Download PDF-Brochure - Van der Molen GmbH

Download PDF-Brochure - Van der Molen GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

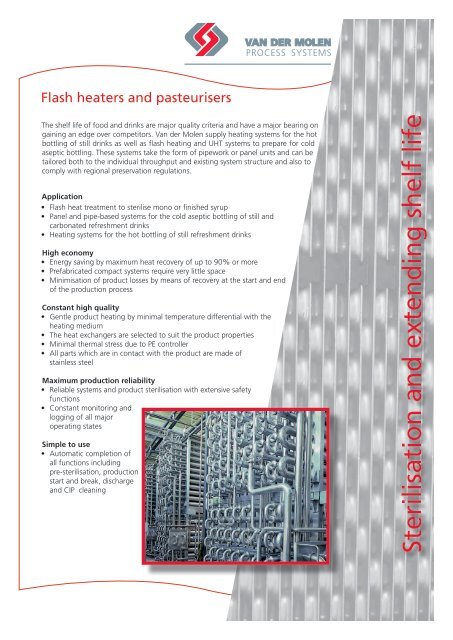

Flash heaters and pasteurisers<br />

The shelf life of food and drinks are major quality criteria and have a major bearing on<br />

gaining an edge over competitors. <strong>Van</strong> <strong>der</strong> <strong>Molen</strong> supply heating systems for the hot<br />

bottling of still drinks as well as flash heating and UHT systems to prepare for cold<br />

aseptic bottling. These systems take the form of pipework or panel units and can be<br />

tailored both to the individual throughput and existing system structure and also to<br />

comply with regional preservation regulations.<br />

Application<br />

• Flash heat treatment to sterilise mono or finished syrup<br />

• Panel and pipe-based systems for the cold aseptic bottling of still and<br />

carbonated refreshment drinks<br />

• Heating systems for the hot bottling of still refreshment drinks<br />

High economy<br />

• Energy saving by maximum heat recovery of up to 90% or more<br />

• Prefabricated compact systems require very little space<br />

• Minimisation of product losses by means of recovery at the start and end<br />

of the production process<br />

Constant high quality<br />

• Gentle product heating by minimal temperature differential with the<br />

heating medium<br />

• The heat exchangers are selected to suit the product properties<br />

• Minimal thermal stress due to PE controller<br />

• All parts which are in contact with the product are made of<br />

stainless steel<br />

Maximum production reliability<br />

• Reliable systems and product sterilisation with extensive safety<br />

functions<br />

• Constant monitoring and<br />

logging of all major<br />

operating states<br />

Simple to use<br />

• Automatic completion of<br />

all functions including<br />

pre-sterilisation, production<br />

start and break, discharge<br />

and CIP cleaning<br />

Sterilisation and extending shelf life

DSKZE EN 01<br />

Flash heaters and pasteurisers<br />

Technical data<br />

Capacity 2,000 – 40,000 l/h<br />

Heating 85 – 140 °C<br />

Holding at high temperature 20 to 85°C, 2 seconds to 2 minutes<br />

Pressure range 10/16 bar<br />

Design Panel heat exchanger,<br />

free-flow or pipe pasteuriser<br />

Options<br />

• Pressure monitoring and control system for the product<br />

• Capacity monitoring and control<br />

• Vacuum ventilation with aroma recovery<br />

• Homogeniser<br />

• Fault buffer tank to avoid multiple pasteurisation<br />

Controller<br />

• Siemens S7 with operator panel (PC visualisation to or<strong>der</strong>)<br />

• Other controllers available to or<strong>der</strong><br />

<strong>Van</strong> <strong>der</strong> <strong>Molen</strong> <strong>GmbH</strong><br />

Industriestraße 34a, D-86438 Kissing, Germany<br />

T +49 8233 79270, F +49 8233 20847<br />

www.van-<strong>der</strong>-molen.com, info@van-<strong>der</strong>-molen.com<br />

Sterilisation and extending shelf life