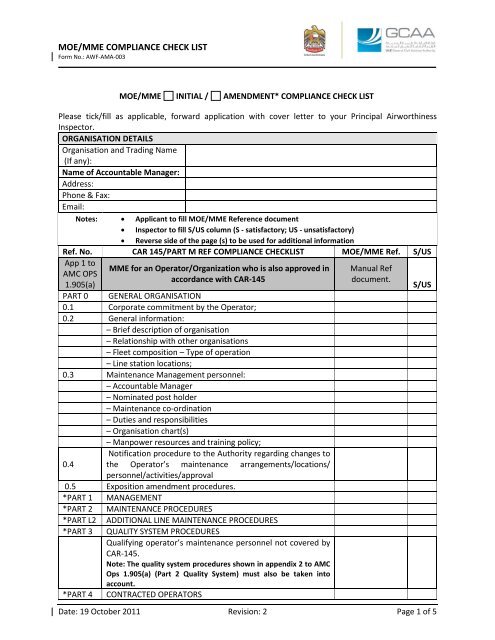

MOE/MME COMPLIANCE CHECK LIST

MOE/MME COMPLIANCE CHECK LIST

MOE/MME COMPLIANCE CHECK LIST

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

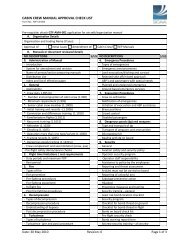

<strong>MOE</strong>/<strong>MME</strong> <strong>COMPLIANCE</strong> <strong>CHECK</strong> <strong>LIST</strong>Form No.: AWF-AMA-003APPENDICES (Sample of Documents)*PART 5 (*) These Parts comprise the Exposition of the CAR-145approved maintenance organisation.PART 6 CAR-OPS Maintenance Procedures6.1 Aircraft technical log utilisation and MEL application;6.2Aircraft maintenance programme – Development and6.3amendment;Time and maintenance records, Responsibilities, Retention,Access;6.4 Accomplishment and control of Airworthiness Directives;6.5 Analysis of the effectiveness of the maintenance programme;6.6 Non-mandatory modification embodiment policy;6.7 Major modification standards;6.8 Defect reports:6.9 – Analysis– Liaison with manufacturers and Regulatory Authorities– Deferred defect policy;Engineering activity;6.10 Reliability programmes– Airframe– Propulsion– Components;6.11 Pre-flight Inspection:– Preparation of aircraft for flight– Sub-contracted Ground Handling functions– Security of Cargo and Baggage loading– Control of refuelling, Quantity/Quality– Control of snow, ice, dust and sand contamination to anapproved standard;6.12 Aircraft weighing;6.13 Flight test procedures; **6.14 Sample of documents, Tags and Forms used;(**) could be covered in Part 2, Maintenance Procedures.App 1 toAMC OPS1.905(a)PART 0PART 1<strong>MME</strong> for an Operator who is NOT approved in accordancewith CAR-145General Organisation (as in Appendix 1 to IEM OPS 1.905(a))CAR-OPS Maintenance Procedures (as in Appendix 1, Part 6entitled – CAR-OPS Maintenance procedures)2 Quality System2.1 Maintenance quality policy, plan and audit procedures;2.2 Monitoring of maintenance management activities;2.3Monitoring the effectiveness of the maintenanceprogramme;2.4Monitoring that all maintenance is carried out by anappropriate CAR-145 organisation:– Aeroplane maintenanceDate: 19 October 2011 Revision: 2 Page 2 of 5

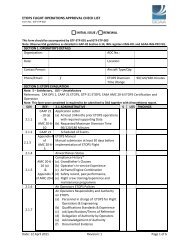

<strong>MOE</strong>/<strong>MME</strong> <strong>COMPLIANCE</strong> <strong>CHECK</strong> <strong>LIST</strong>Form No.: AWF-AMA-003– Engines– Components;Monitoring that all contracted maintenance is carried out in2.5 accordance with the contract, including sub-contractors usedby the maintenance contractor;2.6 Quality audit personnel.PART 3 Contracted Maintenance3.1 Maintenance contractor selection procedure;3.2 Detailed list of maintenance contractors;3.3Relevant technical procedures identified in the maintenancecontract(s).Appendix 1 to AMC OPS 1.910(a) & (b) GeneralrequirementsType/model and registration number of the aeroplane,1.1.1 engines and, where applicable, auxiliary power units andpropellers.1.1.2 Name and address of the operator.1.1.3Operator’s reference identification of the programmedocument; the date of issue and issue number.A statement signed by the operator to the effect that the1.1.4specified aeroplanes will be maintained to the programmeand that the programme will be reviewed and updated asrequired by paragraph 5.1.1.5 Contents/list of effective pages of the document.Check periods which reflect the anticipated utilisation of the1.1.6aeroplane. Such utilisation should be stated and include atolerance of not more than 25%. Where utilisation cannot beanticipated, calendar time limits should also be included.1.1.7Procedures for the escalation of established check periods,where applicable and acceptable to the Authority.1.1.8Provision to record date and reference to approvedamendments incorporated in the programme.Details of pre-flight maintenance tasks which are1.1.9 accomplished by maintenance staff and not included in theOperations Manual for action by flight crew.The tasks and the periods (intervals/frequencies) at whicheach part of the aeroplane, engines, APU’s, propellers,1.1.10components, accessories, equipment, instruments, electricaland radio apparatus, and associated systems and installationsshould be inspected, together with the type and degree ofinspection.The periods at which items as appropriate, should be1.1.11 checked, cleaned, lubricated, replenished, adjusted andtested.1.1.12Details of applicable ageing aeroplane systems requirementstogether with any specified sampling programs.1.1.13 Details of specific structural maintenance programs whereDate: 19 October 2011 Revision: 2 Page 3 of 5

<strong>MOE</strong>/<strong>MME</strong> <strong>COMPLIANCE</strong> <strong>CHECK</strong> <strong>LIST</strong>Form No.: AWF-AMA-0031.1.141.1.151.1.161.1.171.1.181.1.191.1.20issued by the Type Certificate Holder including but not limitedto:- Maintenance of Structural Integrity by Damage Toleranceand Supplemental Structural Inspection Programs (SSID)- Structural maintenance programs resulting from the ServiceBulletin review performed by the Type Certificate holder- Corrosion Prevention and Control- Repair Assessment- Widespread Fatigue DamageStatement of the limit of validity in terms of total flightcycles/calendar data/flight hours for the structural programin 1.1.13.The periods and procedures for the collection of enginehealth monitoring dataThe periods at which overhauls and/or replacements by newor overhauled parts should be made.A cross-reference to other documents approved by theAuthority which contain the details of maintenance tasksrelated to mandatory life limitations, CertificationMaintenance Requirements (CMR’s) and AirworthinessDirectives (AD’s).Details of, or cross-reference to, any required ReliabilityProgramme or statistical methods of continuous Surveillance.A statement that practices and procedures to satisfy theProgramme should be to the standards specified in the TypeCertificate Holder’s Maintenance Instructions. Whenpractices and procedures are included in a customisedOperator’s Maintenance Manual approved by the Authority,the statement should refer to this Manual.Each maintenance task quoted should be defined in adefinition section of the Programme.2 Programme basis2.12.2Operator’s Aeroplane Maintenance programmes shouldnormally be based upon the Maintenance Review BoardReport, where available, and the Type Certificate holder’sMaintenance Planning Document or Chapter 5 of theMaintenance Manual, (i.e. the Manufacturer’s recommendedMaintenance Programme). The structure and format of thesemaintenance recommendations may be re-written by theoperator to better suit his operation and control of theparticular maintenance programme.For a newly type-certificated aeroplane, where no previouslyapproved Maintenance Programme exists, it will be necessaryfor the operator to comprehensively appraise themanufacturer’s recommendations (and the MRB Reportwhere applicable), together with other airworthinessinformation, in order to produce a realistic Programme forDate: 19 October 2011 Revision: 2 Page 4 of 5

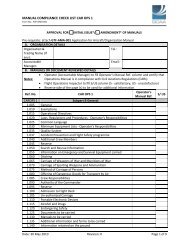

<strong>MOE</strong>/<strong>MME</strong> <strong>COMPLIANCE</strong> <strong>CHECK</strong> <strong>LIST</strong>Form No.: AWF-AMA-003approval.For existing aeroplane types it is permissible for the operatorto make comparisons with maintenance programmespreviously approved. It should not be assumed that aProgramme approved for another operator will automaticallybe approved for the operator. Evaluation is to be made ofaircraft/fleet utilisation, landing rate, equipment fit and, inparticular, the experience of the maintenance organisation2.3must be assessed. Where the Authority is not satisfied thatthe proposed maintenance programme can be used as is bythe Operator, the Authority should request the Operator tointroduce appropriate changes to it, such as additionalmaintenance tasks or de-escalation of check frequencies, orto develop the aeroplane initial maintenance programmebased upon the Manufacturer’s recommendations.3 3. Amendments3.1 Amendments (revisions) to the approved Programmeshould be raised by the operator, to reflect changes in thetype certificate holder’s recommendations, modifications,3.1service experience, or as required by the Authority. Reliabilityprogrammes form one important method of updatingapproved programmes.4 4. Permitted variations to maintenance periods4.1 The Operator may only vary the periods prescribed by the4.1Programme with the approval of the Authority.This is to certify that the Manual content has been cross-referenced with the UAE CARs and foundto be in compliance.Name of Accountable Manager:Date:Signature:GCAA USE ONLYName of GCAA AW Inspector:Date:Signature:Date: 19 October 2011 Revision: 2 Page 5 of 5