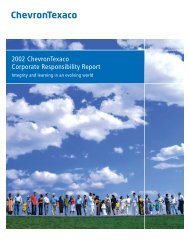

(continued from page 15)back pressure and significant costs; the northern route, which was ultimately selected, savedinstallation costs and improved operability because of the shorter pipeline length.The Gorgon natural gas development on BarrowIsland will occupy 741 acres (300 ha) of unclearedland, some of which will be just south of the WesternAustralia oil terminal tanks, above.Expanding the boundaries of technologyWhile the LNG facilities on Barrow Island will appear typical, the scale and complexity at thislocation will be unprecedented.Con Kalimeris, a senior LNG process engineer with <strong>Chevron</strong> Energy Technology Co. (ETC)who works on Gorgon in Perth, Western Australia, explained, “One complication will be waterin the well-stream fluids that are directed to shore. Water introduces the possibility of hydrateformation, which may lead to operating problems. We will inject monoethylene glycol (MEG) intothe well-stream fluids to prevent hydrates from forming,” said Kalimeris.“While this won’t be the first MEG system associated with an LNG plant, the size of thesystem and importance of preventing feed disruptions to the onshore plant require extensivedesign efforts and proper management during operation.”Additionally, to significantly reduce environmental impact to the island, many of the componentswill be prefabricated and assembled offsite into transportable parts. Other plants havebeen redesigned to enable modularization in expansion phases, but Gorgon is one of the onlyLNG projects in the world for which modularized construction was designed from the outset.(continued on page 19)World’s largest commercial-scale CO 2-injection projectGorgon will position Australia as a world leaderin commercial-scale carbon dioxide–injectiontechnology.CO 2Gas ProductPHOTO: ROBERT GARVEY1Natural gas is fed from thereservoir to the plant.CO 2is separated from the2 natural gas.3CO 2is compressed and injectedmore than 1.6 miles (2.5 km)underground into the DupuyFormation beneath Barrow Island.16 | <strong>Next*</strong>

The World’s Largest Commercial-Scale CO 2 -Injection ProjectAs the search for new sources of natural gaswhich must be separated before liquefaction.CO 2 in brine-filled rock, the thermal effectspushes farther and deeper than ever before,Depending on the final, ultimately recover-of injecting cooler CO 2 into hot rocks andextraction becomes more difficult and moreable volumes, the cumulative volume ofthe tendency of CO 2 to vaporize connatecomplex. And the responsibility to protectreservoir CO 2 to be disposed of during thewater—water that was trapped in the rockthe environment becomes more critical.operating life of the project is expected to bepores when the rock was formed—in theOne of the most successful advancementsabout 2 trillion cubic feet.region near the well bore.ILLUSTRATION: AMY KWONG/CHEVRON INFORMATION DESIGN AND COMMUNICATIONSin improving efficiencies and minimizing environmentalimpact is carbon sequestration,used to varying degrees on projects aroundthe world.Now, in a remote corner of Australia, aspart of the Gorgon Project, <strong>Chevron</strong> is planningthe largest project for carbon dioxide(CO 2 ) injection developed to date, fourtimes the size of the largest existing operation.CO 2 injection is expected to reduceGorgon’s overall emissions by approximately40 percent, or 3.4 million metrictons of CO 2 per year.Raw gas from the Greater Gorgon Areafields contains up to 14 percent of CO 2 ,The destination for this CO 2 is almost8,200 feet (2,500 m) below the surfaceof Barrow Island, within the DupuyFormation, a sand-rich reservoir with theproperties required for a saline aquiferCO 2 -injection project.Donna Parker, Gorgon’s CO 2 -injection projectmanager, clearly understands the scaleand complexity of the task ahead. “This will bethe largest project of its kind and will position<strong>Chevron</strong> as a world leader in commercial-scaleinjection technology,” she said. “We will bedoing something never achieved before. Itwill be within a designated nature reserve;the technical robustness of this project hastherefore been exhaustive, and our modelingof the reservoir has been long and iterative.”Gorgon will be capable of an averageIn addition to these factors is the massbalanceeffect of injecting large volumes ofa new substance into an aquifer. The pressuremanagement system was designed topartially offset the pressure increase frominjection. The hot formation water fromthe four water-production wells will bereinjected into a shallower aquifer, whichwill also minimize the environmentalimpact on Barrow Island.“The use of nine injection wells will helpspread the CO 2 and result in lower concentrationswithin the injection interval,” saidTrupp. “This will help with long-term residualgas and CO 2 trapping. Seismic surveys, surveillancewells and surface-soil gas mappingwill monitor and verify CO 2 movement.”Drilling is expected to start in 2012,CO 2 -injection rate of 220 million standardwith 17 wells in the initial project plans. LNGcubic feet per day via nine injection wellsproduction of Greater Gorgon Area gas isspread over three drill centers. The projectexpected to begin in 2014 with the startup ofalso includes four water-production wellsthe Gorgon CO 2 -injection project.outside the expected CO 2 injection area inThe Australian government has committedorder to maintain reservoir pressure withinAU$60 million to the Gorgon CO 2 -injectionaccepted limits.project as part of the Low Emissions Tech-Mark Trupp, the project’s subsurfacenology Demonstration Fund, which supportsteam lead, explained that at this depth, CO 2the commercialization of technologies thathas a viscosity of a gas but a volume andcan reduce greenhouse gas emissions on adensity closer to a liquid.large scale.“CO 2 -injection rates are established bya complex interplay of factors,” said Trupp,Learn how <strong>Chevron</strong> is addressing climate4Movement of the CO 2underground ismonitored by repeated seismic surveysand in surveillance wells.“starting with the maximum bottom-holepressure required to avoid fracturing theformation.” Injectivity, he explained, is alsoaffected by the relative permeability ofchange through carbon capture and storageat <strong>Chevron</strong>.com/Next/CO2.<strong>Next*</strong> | 17