Next* Magazine, Issue 4 - Chevron

Next* Magazine, Issue 4 - Chevron

Next* Magazine, Issue 4 - Chevron

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

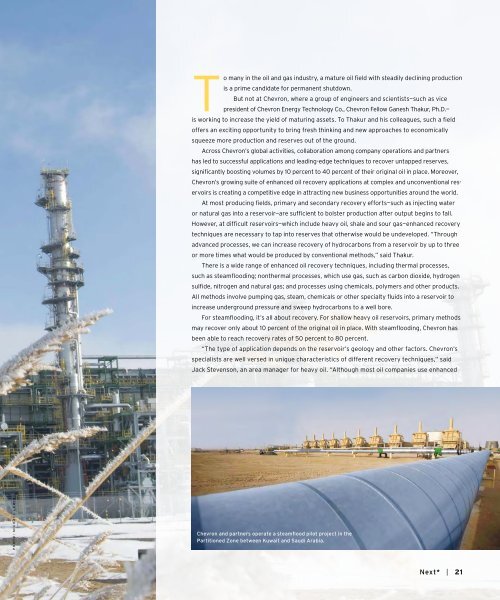

To many in the oil and gas industry, a mature oil field with steadily declining productionis a prime candidate for permanent shutdown.But not at <strong>Chevron</strong>, where a group of engineers and scientists—such as vicepresident of <strong>Chevron</strong> Energy Technology Co., <strong>Chevron</strong> Fellow Ganesh Thakur, Ph.D.—is working to increase the yield of maturing assets. To Thakur and his colleagues, such a fieldoffers an exciting opportunity to bring fresh thinking and new approaches to economicallysqueeze more production and reserves out of the ground.Across <strong>Chevron</strong>’s global activities, collaboration among company operations and partnershas led to successful applications and leading-edge techniques to recover untapped reserves,significantly boosting volumes by 10 percent to 40 percent of their original oil in place. Moreover,<strong>Chevron</strong>’s growing suite of enhanced oil recovery applications at complex and unconventional reservoirsis creating a competitive edge in attracting new business opportunities around the world.At most producing fields, primary and secondary recovery efforts—such as injecting wateror natural gas into a reservoir—are sufficient to bolster production after output begins to fall.However, at difficult reservoirs—which include heavy oil, shale and sour gas—enhanced recoverytechniques are necessary to tap into reserves that otherwise would be undeveloped. “Throughadvanced processes, we can increase recovery of hydrocarbons from a reservoir by up to threeor more times what would be produced by conventional methods,” said Thakur.There is a wide range of enhanced oil recovery techniques, including thermal processes,such as steamflooding; nonthermal processes, which use gas, such as carbon dioxide, hydrogensulfide, nitrogen and natural gas; and processes using chemicals, polymers and other products.All methods involve pumping gas, steam, chemicals or other specialty fluids into a reservoir toincrease underground pressure and sweep hydrocarbons to a well bore.For steamflooding, it’s all about recovery. For shallow heavy oil reservoirs, primary methodsmay recover only about 10 percent of the original oil in place. With steamflooding, <strong>Chevron</strong> hasbeen able to reach recovery rates of 50 percent to 80 percent.“The type of application depends on the reservoir’s geology and other factors. <strong>Chevron</strong>’sspecialists are well versed in unique characteristics of different recovery techniques,” saidJack Stevenson, an area manager for heavy oil. “Although most oil companies use enhancedphoto: MICHAEL LEWIS<strong>Chevron</strong> and partners operate a steamflood pilot project in thePartitioned Zone between Kuwait and Saudi Arabia.<strong>Next*</strong> | 21