PDF PDF.

PDF PDF.

PDF PDF.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

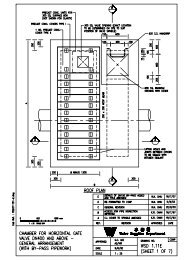

- 22 pipe arising from the internal pressure of the pipeline or the flow of waterhitting bends, tapers and closed or partially closed valves. The size of a thrustblock is dependent upon the deflection of the flow and the head of water insidethe pipe. Refer to “Guidance Note on the Design of Thrust Blocks forBuried Pipelines” in designing thrust blocks. Typical details of thrust blocks,including horizontal and vertical bend blocks, tee block, taper block and endblock, are shown in Standard Drawing WSD 1.4.(i)For Flexibly Joined PipesThrust blocks are essential on flexibly joined pipelines where any pipemovement would open up the joints in the line and cause water leakage.They should be provided to all bends, branches and tapers and pipe endsto take the full thrust unless special design is provided. However, theyshould not rely on lateral soil pressure for their stability because in HongKong situation, there is a high risk that the soil is removed by otherparties without notifying WSD.(ii)For Steel Pipes with Welded JointsFor buried steel pipes of diameter 1200 mm and under and subject to aworking head of less than 100 m, there is no need to provide any thrustblocks for bends of less than 45 o . For bends of 45 o and greater, it issufficient to design thrust blocks to resist 50% of the thrust. However,in both cases, there must be no loose joint (such as bolted collars orthose joints normally used for valve installations) within 30 m on eitherside of the bend; otherwise the full thrust must be resisted by thrustblocks.Unless it is known that the full thrust is being resisted by a thrust block,repairs, connections and branches to an existing steel main within 30mfrom a bend, if unavoidable, should be effected without introducing aloose joint (e.g. by using welded collars or harnessed couplings).Similarly valves should not be inserted within this distance unlessharnessed flange adaptors are used or additional thrust blocks areprovided to take the full thrust.For steel pipes of diameter larger than 1200 mm or for pipes subject tomore than 100 m working head, design of thrust blocks needs individualconsideration to provide a higher safety factor. Thrust blocks must beprovided for all bends on exposed steel pipes to resist the full thrustregardless of the diameter of the pipe.