You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Linkspans<br />

The Stena Line relocation project<br />

Specialists from <strong>TTS</strong> Port Equipment are close to completing one of the most extraordinary<br />

relocation projects in the history of the marine industry<br />

Technical manager Mikael<br />

Jimmerfors takes us through the<br />

story. “Eleven or twelve years ago,<br />

while working for a different company,<br />

we designed six linkspans for Stena Line’s<br />

HSS fast ferry services. These linkspans<br />

form an integrated part of the vessel, and<br />

are designed to minimise turnaround<br />

times and reduce fuel consumption. The<br />

linkspan concept has been a great<br />

success – Stena is able to load or unload<br />

1,500 passengers, as well as cars and<br />

buses, in 15 minutes.”<br />

The linkspans, which are semisubmersible,<br />

measure 40m long by 40m<br />

wide and weigh over 1,000 tonnes, were<br />

installed at the terminals for Stena’s<br />

Holyhead–Dun Laoghaire, Belfast–<br />

Stranraer and Harwich–Hoek van Holland<br />

routes. However, Stena recently decided<br />

to close down the latter service and came<br />

to Jimmerfors and his colleague, project<br />

manager Klaes Lundberg, now working<br />

for <strong>TTS</strong>, for help with the linkspan.<br />

“The linkspans installed in Harwich<br />

and Hoek van Holland were newer, and of<br />

an upgraded design,” says Lundberg. “So<br />

Stena simply asked us if we could move<br />

them to Scotland and Northern Ireland<br />

for use on the Belfast–Stranraer route.”<br />

This was a challenge. When the<br />

linkspans were originally installed, giant<br />

floating cranes were used to lift them<br />

into place. These particular cranes,<br />

though, are now deployed elsewhere<br />

around the world. “To lift them with<br />

cranes wasn’t practical, because the best<br />

window the crane company could give us<br />

was ‘The first or second half of the year.’<br />

But we only had a one or two week<br />

window to do the work!” says<br />

Jimmerfors.<br />

4 <strong>TTS</strong> <strong>Review</strong> • April 2008<br />

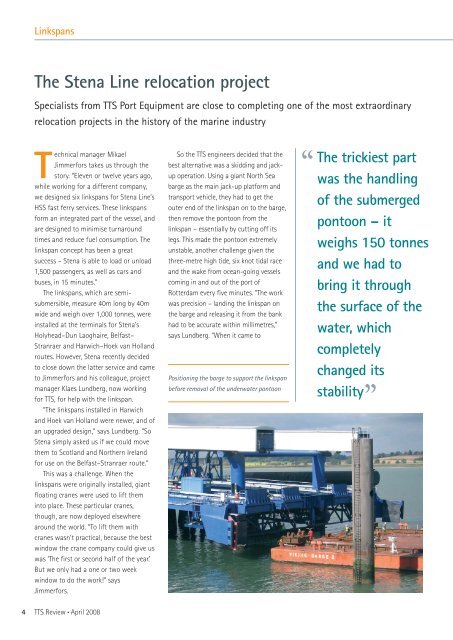

So the <strong>TTS</strong> engineers decided that the<br />

best alternative was a skidding and jackup<br />

operation. Using a giant North Sea<br />

barge as the main jack-up platform and<br />

transport vehicle, they had to get the<br />

outer end of the linkspan on to the barge,<br />

then remove the pontoon from the<br />

linkspan – essentially by cutting off its<br />

legs. This made the pontoon extremely<br />

unstable, another challenge given the<br />

three-metre high tide, six knot tidal race<br />

and the wake from ocean-going vessels<br />

coming in and out of the port of<br />

Rotterdam every five minutes. “The work<br />

was precision – landing the linkspan on<br />

the barge and releasing it from the bank<br />

had to be accurate within millimetres,”<br />

says Lundberg. “When it came to<br />

Positioning the barge to support the linkspan<br />

before removal of the underwater pontoon<br />

“<br />

The trickiest part<br />

was the handling<br />

of the submerged<br />

pontoon – it<br />

weighs 150 tonnes<br />

and we had to<br />

bring it through<br />

the surface of the<br />

water, which<br />

completely<br />

changed its<br />

stability<br />

”

![2012.MasterPresentation_final [Compatibility Mode] - TTS Group ASA](https://img.yumpu.com/4612021/1/190x146/2012masterpresentation-final-compatibility-mode-tts-group-asa.jpg?quality=85)