Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

emoving the hinge pins, which each<br />

weighed over 400kg and had been in place<br />

eleven years, we had only half an hour to<br />

release them using hydraulic jacks.”<br />

Planning for the project took six<br />

months, including using a simulation tool<br />

to build a 3D animation of the job. The<br />

actual operation took place in September<br />

2007, using a crew of 25 specialists from<br />

around the world. “The trickiest part was<br />

the handling of the submerged pontoon,”<br />

says Jimmerfors. “It’s so big and<br />

asymmetric in form – it weighs 150<br />

tonnes – and we had to bring it through<br />

the surface of the water, which<br />

completely changed its stability.”<br />

Once this huge job had been<br />

completed, the team took the barge to<br />

Harwich and did it all over again! The<br />

barge, by now absolutely fully loaded –<br />

Lundberg says the linkspans overhung the<br />

barge by 5m on each side – was towed to<br />

Belfast, fortunately in good weather. Once<br />

the barge reached the Harland and Wolff<br />

shipyard, the team used one of the<br />

company’s two giant cranes to lift the<br />

linkspans off the barge, and put them<br />

into storage for the winter. During April<br />

of 2008, the team will reconvene in<br />

Belfast and install one of the linkspans in<br />

the new Victoria Terminal Four.<br />

“There are more HSS linkspans that<br />

need attention – Lloyd’s Register says<br />

that they need docking at least every 20<br />

years,” says Lundberg. “What is important<br />

is that we have come up with a method<br />

that can be used to move other<br />

linkspans. There are other shore-sea<br />

interfaces where we could apply the<br />

same method.”<br />

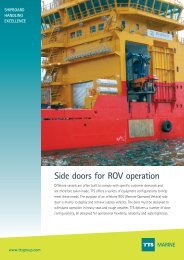

A new generation of translifters for port handling<br />

Anew generation of translifters<br />

for both RoRo and industrial<br />

operations is to be launched by<br />

<strong>TTS</strong> Liftec. The RoRo 2008 exhibition in<br />

Gothenburg on 20–22 May will see the<br />

unveiling of a series of seven different<br />

models, with payloads ranging from 50-<br />

130 tonnes.<br />

The new models include several<br />

improvements. In the translifter control<br />

systems, sensors have been improved in<br />

terms of reliability, and reduced in<br />

number. “Parallel lifting sensors are now<br />

available in the translifter, so additional<br />

sensor assembly is no longer needed in<br />

the tugmaster,” says Tatu Miikkulainen,<br />

managing director of <strong>TTS</strong> Liftec.<br />

One of the pre-launch translifter models<br />

Extensive use of modular wire<br />

harnesses has also contributed to<br />

increased reliability and modularity, and<br />

the introduction of load-sensing<br />

hydropneumatic suspension for bogies<br />

means that the translifters adapt<br />

automatically to different load conditions,<br />

assuring the best possible suspension.<br />

“We’ve also improved the user interface,<br />

adding new features such as ‘Teach in’<br />

calibration, and the ability to adjust<br />

Linkspans on route to Belfast<br />

Translifters<br />

different features,” adds Miikkulainen.<br />

Among the optional features is a<br />

newly developed lifting gooseneck, which<br />

improves the stability of the tugmaster<br />

and control of the lifting function. The<br />

gooseneck has been tested in operation<br />

for a year and is now available for all<br />

translifter models. Further options<br />

include xenon work lights, CAN bus<br />

connection to the tugmaster, and a<br />

remote service interface.<br />

<strong>TTS</strong> <strong>Review</strong> • April 2008 5

![2012.MasterPresentation_final [Compatibility Mode] - TTS Group ASA](https://img.yumpu.com/4612021/1/190x146/2012masterpresentation-final-compatibility-mode-tts-group-asa.jpg?quality=85)