Part # 12176799 97-03 F-150 AirBar - Air Ride Technologies

Part # 12176799 97-03 F-150 AirBar - Air Ride Technologies

Part # 12176799 97-03 F-150 AirBar - Air Ride Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

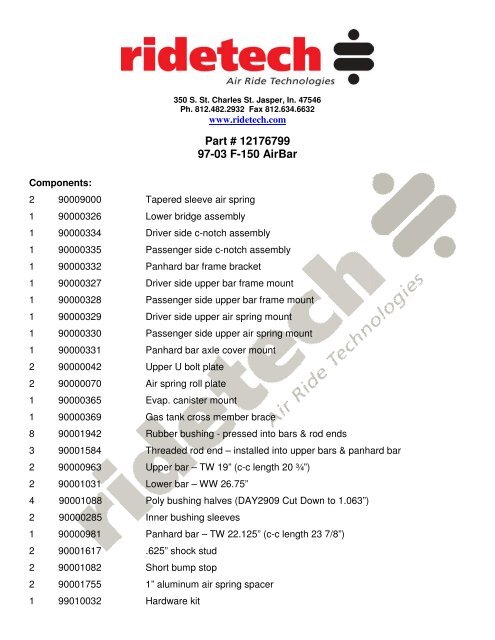

Components:<br />

350 S. St. Charles St. Jasper, In. 47546<br />

Ph. 812.482.2932 Fax 812.634.6632<br />

www.ridetech.com<br />

<strong>Part</strong> # <strong>12176799</strong><br />

<strong>97</strong>-<strong>03</strong> F-<strong>150</strong> <strong><strong>Air</strong>Bar</strong><br />

2 90009000 Tapered sleeve air spring<br />

1 9000<strong>03</strong>26 Lower bridge assembly<br />

1 9000<strong>03</strong>34 Driver side c-notch assembly<br />

1 9000<strong>03</strong>35 Passenger side c-notch assembly<br />

1 9000<strong>03</strong>32 Panhard bar frame bracket<br />

1 9000<strong>03</strong>27 Driver side upper bar frame mount<br />

1 9000<strong>03</strong>28 Passenger side upper bar frame mount<br />

1 9000<strong>03</strong>29 Driver side upper air spring mount<br />

1 9000<strong>03</strong>30 Passenger side upper air spring mount<br />

1 9000<strong>03</strong>31 Panhard bar axle cover mount<br />

2 90000042 Upper U bolt plate<br />

2 90000070 <strong>Air</strong> spring roll plate<br />

1 9000<strong>03</strong>65 Evap. canister mount<br />

1 9000<strong>03</strong>69 Gas tank cross member brace<br />

8 90001942 Rubber bushing - pressed into bars & rod ends<br />

3 90001584 Threaded rod end – installed into upper bars & panhard bar<br />

2 90000963 Upper bar – TW 19” (c-c length 20 ¾”)<br />

2 90001<strong>03</strong>1 Lower bar – WW 26.75”<br />

4 90001088 Poly bushing halves (DAY2909 Cut Down to 1.063”)<br />

2 90000285 Inner bushing sleeves<br />

1 90000981 Panhard bar – TW 22.125” (c-c length 23 7/8”)<br />

2 90001617 .625” shock stud<br />

2 90001082 Short bump stop<br />

2 90001755 1” aluminum air spring spacer<br />

1 99010<strong>03</strong>2 Hardware kit

350 S. St. Charles St. Jasper, In. 47546<br />

Ph. 812.482.2932 Fax 812.634.6632<br />

www.ridetech.com<br />

<strong>Part</strong> # 99010<strong>03</strong>2 Hardware Kit<br />

Note: front lower bar utilizes oem spring hanger bolt<br />

8 5/8 x 6 sae bolts grade 8 bridge to axle assembly<br />

16 5/8 sae flat washers grade 8 bridge to axle assembly<br />

8 5/8 sae nyloc nuts grade 8 bridge to axle assembly<br />

8 5/8 x 2 ¾ sae bolts grade 8 rod ends<br />

8 5/8 sae nyloc jam nuts rod ends<br />

2 ½ x 2 ½ uss bolts lower shock mounting<br />

10 ½ uss nyloc nuts 2=lower shock mounting / 8=upper front bar mount<br />

8 ½ x 1 ½ uss bolts front upper bar mount<br />

16 ½ uss flat washers front upper bar mount<br />

33 7/16 x 1 ½ uss bolts c-notch to frame<br />

66 7/16 uss flat washers c-notch to frame<br />

33 7/16 uss nyloc nuts c-notch to frame<br />

2 3/8 x 1 ¾” USS bolt lower air spring mount<br />

6 3/8 x 1 uss bolts airspring mounting / gas tank x-member<br />

6 3/8 lock washers airspring mounting<br />

10 3/8 sae flat washers airspring mounting / gas tank x-member<br />

2 3/8 uss nyloc nuts gas tank x-member<br />

2 3/8 x 1 ¼ uss bolts upper airspring mount<br />

2 3/8 x 1 ½ uss bolts upper airspring mount<br />

4 3/8 x ¾ uss bolts upper airspring mount<br />

4 7/16 uss flat washers upper airspring mount<br />

4 3/8 uss nyloc nuts upper airspring mount<br />

12 3/8 sae flat washers upper airspring mount<br />

4 3/8 lock washers upper airspring mount<br />

3 5/16 x 1 uss bolts axle cover bracket<br />

3 5/16 sae flat washers axle cover bracket<br />

3 5/16 lock washers axle cover bracket<br />

3 ¼ x 1 uss bolts evap. canister<br />

6 ¼ uss flat washers evap. canister<br />

3 ¼ uss nyloc nuts evap. canister<br />

<strong>97</strong> to Present Ford F<strong>150</strong> <strong>Air</strong>bar

Installation instructions<br />

1. Raise vehicle to a comfortable working height and support the frame with jackstands ahead of the leafspring<br />

hangar and also behind the axle center.<br />

2. Remove wheels and tires.<br />

3. Remove bed.<br />

4. The C notch framerail section will be<br />

installed first. Use the C notch as the<br />

template. Line up the bumpstop positions<br />

on the new C notch and the OEM<br />

framerail to determine exact position of<br />

C notch. Then scribe the outline of the<br />

notch onto the framerail and cut out that<br />

section using a sawzall, cutoff wheel or<br />

other appropriate tool. NOTE: Using a<br />

torch make a huge mess and increases<br />

that chance of fire or other accident. BE<br />

CAREFUL!<br />

5. After the framerail is cut, slide the C<br />

notch over the frame and use it as a<br />

template to mark and drill the attachment<br />

holes. The C notch will be a snug fit and<br />

may require a few light taps to get<br />

positioned properly.<br />

6. Install the upper bar frame brackets. This will<br />

require removal of 2 of the attachment rivets on the<br />

OEM leafspring hangar. The new frame bracket will<br />

index off of these two points. You will need to drill<br />

the remaining attachment holes using the bracket as<br />

the template.

7. Install the axle bracket bridge assembly. This assembly is installed underneath the axle and is<br />

indexed off the bottom of the OEM leafspring pads. The upper bar axle mounts are then set on top of<br />

the OEM leafspring pads and the entire assembly is bolted together with the supplied grade 8 bolts,<br />

washers and nuts. A second set of hands is helpful during this procedure. NOTE: At some point<br />

during the installation the OEM tailpipe will need to be removed for clearance. A custom tailpipe or a<br />

turndown out of the muffler will be necessary to properly complete the <strong><strong>Air</strong>Bar</strong> installation. If you let the<br />

exhaust blow back on the ailines and airsprings, damage will certainly result.<br />

8. Remove the 3 bolts in the right hand corner of the axle cover. Bolt on the panhard bar axle mount.<br />

The other side will bolt to the frame bracket.

9. The bracket shown<br />

to the left was there to<br />

locate the spare tire. It<br />

will be removed as<br />

shown to the right to<br />

provide room for the<br />

upper airspring mount.<br />

8. Install the 4 link bars into the frame<br />

and axle brackets. The long bars will go<br />

into the bottom brackets. The adjustable<br />

end should go into the frame brackets.<br />

The bars are pre-adjusted to length at<br />

the factory, but double check that they<br />

are indeed the same length from side to<br />

side.

10. The emissions canister will also need to be<br />

modified slightly as shown to accept new mounting<br />

bracketry.<br />

NOTE: Not all models will have this configuration of<br />

the emissions canister.<br />

11. The photo to the left shows the new<br />

drivers side emissions canister mounting<br />

[provided] that is necessary to clear the new<br />

upper airspring mounts. This also shows the<br />

upper airspring mount attachment through<br />

the OEM shock mount and 2 other existing<br />

holes.<br />

12. Passenger side bottom view of the<br />

upper airspring mount. Hidden is the ear<br />

that attaches to the C notch. There will be 2<br />

bolts that are installed from the top into a<br />

threaded bung on the airspring mount and<br />

an ear that is bolted to the C notch. The<br />

fourth hole should line up with the OEM<br />

upper shock mount<br />

13. The airsprings can now be installed. Be sure to use Teflon tape or paste on the airline fitting threads to<br />

avoid air leaks. Also be sure to use the provided plate under the airsprings for proper support.

14. Install the provided shocks into the<br />

upper and lower shock mounts. If using a<br />

shock other than ours, be sure the shock<br />

does not bottom out but will capture the<br />

suspension before overextending the<br />

airspring. [note possible location for air<br />

tank]<br />

15. The fuel tank crossmember must be sectioned for driveshaft clearance at full drop. The<br />

photo on the left shos the OEM crossmember with the marks for cutting. Use a sawzall or cutoff<br />

wheel to cut out a section approx. 5” wide The photo on the right shows the cut crossmember .<br />

The fuel tank strap bolt must be repositioned approx. 1.25” outboard and the muffler heat shield<br />

must be trimmed approx. 1”<br />

16. Install the provided fuel tank crossmember support onto the top of the crossmember to restore the strength<br />

to the modified crossmember.<br />

NOTE: WHEN LIFTING THE VEHICLE BY THE FRAME, BE SURE TO DEFLATE THE AIRSPRINGS AT<br />

LEAST PARTIALLY TO MINIMIZE STRESS ON THE EXTENDED AIRSPRING.<br />

NOTE: IT IS THE FINAL RESPONSIBILITY OF THE INSTALLER TO ENSURE THAT THE<br />

AIRSPRING DOES NOT RUB ON ANYTHING! ABRASION WILL CAUSE IMMEDIATE AND FATAL<br />

DAMAGE TO THE AIRSPRING!!!