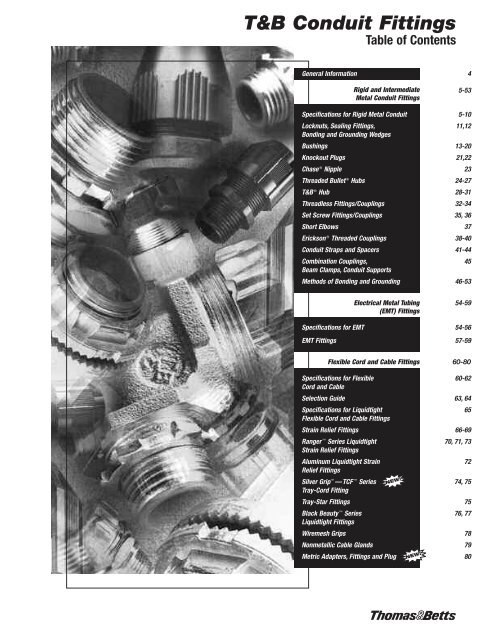

T&B Conduit Fittings

T&B Conduit Fittings

T&B Conduit Fittings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

T&B <strong>Conduit</strong> <strong>Fittings</strong>Table of ContentsGeneral Information 4Rigid and Intermediate 5-53Metal <strong>Conduit</strong> <strong>Fittings</strong>Specifications for Rigid Metal <strong>Conduit</strong> 5-10Locknuts, Sealing <strong>Fittings</strong>, 11,12Bonding and Grounding WedgesBushings 13-20Knockout Plugs 21,22Chase ® Nipple 23Threaded Bullet ® Hubs 24-27T&B ® Hub 28-31Threadless <strong>Fittings</strong>/Couplings 32-34Set Screw <strong>Fittings</strong>/Couplings 35, 36Short Elbows 37Erickson ® Threaded Couplings 38-40<strong>Conduit</strong> Straps and Spacers 41-44Combination Couplings, 45Beam Clamps, <strong>Conduit</strong> SupportsMethods of Bonding and Grounding 46-53Electrical Metal Tubing 54-59(EMT) <strong>Fittings</strong>Specifications for EMT 54-56EMT <strong>Fittings</strong> 57-59Flexible Cord and Cable <strong>Fittings</strong> 60-80Specifications for Flexible 60-62Cord and CableSelection Guide 63, 64Specifications for Liquidtight 65Flexible Cord and Cable <strong>Fittings</strong>Strain Relief <strong>Fittings</strong> 66-69Ranger Series Liquidtight 70, 71, 73Strain Relief <strong>Fittings</strong>Aluminum Liquidtight Strain 72Relief <strong>Fittings</strong>Silver Grip —TCF Series 74, 75Tray-Cord FittingTray-Star <strong>Fittings</strong> 75Black Beauty Series 76, 77Liquidtight <strong>Fittings</strong>Wiremesh Grips 78Nonmetallic Cable Glands 79Metric Adapters, <strong>Fittings</strong> and Plug 80

T&B <strong>Conduit</strong> <strong>Fittings</strong>Table of ContentsService Entrance Cable <strong>Fittings</strong> 81-85Specifications 81-83Service Entrance Cable <strong>Fittings</strong> 84, 85Liquidtight Flexible <strong>Conduit</strong> <strong>Fittings</strong> 86-108Specifications for Liquidtight 86-88Flexible Metal <strong>Conduit</strong>High Temperature Flexible 89Metal Liquidtight <strong>Fittings</strong>Liquidtight Flexible Metal 90-98, 101-104<strong>Conduit</strong> <strong>Fittings</strong>Specifications—Type A Nonmetallic 99<strong>Conduit</strong> <strong>Fittings</strong>Liquidtight Flexible Nonmetallic 100, 105<strong>Conduit</strong> <strong>Fittings</strong>ISO Metric Bullet TM Liquidtight <strong>Fittings</strong> 108Armoured Cable and Flexible 109-117Metal <strong>Conduit</strong> <strong>Fittings</strong>Specifications for Armoured 109-112Cable and Flexible Metal <strong>Conduit</strong><strong>Fittings</strong> for Armoured Cable 113-117and Flexible Metal <strong>Conduit</strong>Nonmetallic Sheathed 118-124Cable <strong>Fittings</strong>Specifications for Nonmetallic 118, 119Sheathed Cable <strong>Fittings</strong><strong>Fittings</strong> for Nonmetallic Sheathed 120-124Cable <strong>Fittings</strong>Liquatite ® Flexible <strong>Conduit</strong>Application Guide 125,126Steel 127-133, 135, 137140, 142, 143Aluminum 134, 136, 141Shielding 138, 139Nonmetallic 144, 145Corrlok ® System 146-150Engineering Information 151, 152Packaging 153<strong>Conduit</strong> Dimensional Data 154, 155<strong>Conduit</strong> Chemical Resistance Guide 156-159Alphanumeric Index 160-176

T&B <strong>Conduit</strong> <strong>Fittings</strong>General InformationThomas & Betts…The Complete Product LineSince the turn of the century, Thomas & Bettshas been a recognized leader in electricalfittings. Industry standards such as Chase ®Nipples and Erickson ® Couplings wereintroduced by Thomas & Betts and arestill registered trademarks. This leadershipcontinues. Here’s why.Innovative DesignsThe real test of product design ofelectrical fittings lies in two areas: jobsuitedinstallation and life-of-the-jobreliability. Thomas & Betts <strong>Fittings</strong>provide both because we listen. We listento problems and suggestions from thefield. Most of the products in this sectionresult from the good suggestions ofknowledgeable electrical people. Manywere customer specials to solveparticular installation and performanceproblems. You can benefit from theirexperience.High Performance ProductsQuality and performance resultwhen engineering design skills arecombined with the manufacturingtechnologies required to produce them.The Thomas & Betts <strong>Fittings</strong> in thissection are produced from manymaterials and by many manufacturingmethods, each carefully selected for itsend use suitability. This combinationgives you the reliable performance youexpect from Thomas & BettsRaceway <strong>Fittings</strong>.Lower Installed CostIt is a function of purchase cost,availability, installation advantage, andperformance. Lower installed cost comesin every carton of Thomas & BettsRaceway <strong>Fittings</strong>.Approvals and CertificationsElectrical raceways require accessoryfittings that provide the mechanicalstrength, ground continuity, andenvironmental integrity of the system.As new raceways have beenintroduced, Thomas & Betts engineershave designed fittings which meet therequirements of the Canadian electricalcode, as well as the CanadianStandards Association. You can useThomas & Betts <strong>Fittings</strong> with confidence.Note: All dimensions in this catalogue areapproximate.4

Specifications—Rigid Metal <strong>Conduit</strong>/PVC Coated Rigid Metal <strong>Conduit</strong>T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Ref. CEC Rule 12-1000Rigid Metal <strong>Conduit</strong> affords maximummechanical protection to conductorswithin the raceway. Rigid metal conduitcan be installed indoors and outdoors, indry locations or wet locations, exposed orconcealed, in all atmospheric conditionsand in hazardous locations.Galvanized rigid steel conduitinstalled in concrete does not requiresupplementary corrosion protection.Galvanized rigid steel conduit, installed incontact with soil, does not generallyrequire supplementary corrosionprotection. However, when buried incorrosive soil (corrosive soil ischaracterized by low resistivity of lessthan 2,000 ohm-centimeter) or cinders, aprotective coating of bitumastic, asphaltbasedpaint or a PVC coating is appliedto the conduit. CEC Rule 12-934requires that rigid steel conduit installed inor under permanently moist cinder fill beencased in at least two inches ofcinder-free concrete unless the conduit isat least 18 inches below the fill. Steelconduit protected from corrosion solely byenamel can only be used indoors and inoccupancies not subjected to severecorrosive influences.Rigid nonferrous metal conduit(aluminum) cannot be directlyembedded in concrete containingsoluble chlorides such as calciumchloride; unwashed beach sand,seawater, or coral bearing aggregates.However, if adequately treated by aprotective coating of bitumastic orasphalt-based paint or PVC coating, theconduit can be installed in concretecontaining chlorides.Supplementary nonmetallic coatingspresently used on ferrous rigid metal ornonferrous metal have not beeninvestigated for resistance to corrosion.CEC Rule 12-920 requires that whenconduit enters a box or fitting, a bushingmust be provided to protect wires fromabrasion unless the design of the box orfitting provides equivalent protection.According to CEC Rule 12-906where No. 4 or larger ungroundedconductors enter or leave a conduit, aninsulating bushing with a smooth wellrounded insulating surface must beprovided to protect conductors unlessthe terminating fitting is equipped with aninsulated throat, firmly secured in placeproviding equivalent protection. Theinsulating bushing or insulating materialmust have a temperature rating of not lessthan the insulation temperature rating ofinstalled conductors. When conduitbushings are constructed wholly ofinsulating material, a locknut must beinstalled both inside and outside of theenclosure to which the conduit isattached.<strong>Fittings</strong> and couplings are requiredto be of concrete-tight type whenembedded in masonry or concrete or indry locations and of the raintight typewhen installed in wet locations.In wet locations or locationswhere walls are frequently washed orwhere there are surfaces of absorbentmaterials, the entire wiring systemincluding boxes, fittings, conduit andcables must be supported suchthat there is at least 1/4 inch air spacebetween it and the supporting surface(CEC Rule 2-122).CEC Rule 12-3024 requires that theraceways be metallically joined togetherinto a continuous electric conductorand must be mechanically connected toall boxes, fittings and cabinets as toprovide effective electrical continuity.<strong>Conduit</strong> is required to be supportedadequately and conduit bends inone run are restricted to the equivalentof four quarter i.e. 360 degrees total.Listed below are some of theadvantages of rigid aluminum conduitover rigid steel conduit.1. Non-sparking—eliminates hazard inexplosive atmospheres2. Non-magnetic—reduces power lossdue to voltage drop3. Resists most corrosive atmospheresand industrial environments4. Lightweight—reduces costof handling and installation5. Attractive appearance5

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Specifications—Rigid Metal <strong>Conduit</strong>/PVC Coated Rigid Metal <strong>Conduit</strong> (continued)For further details and completeinformation please refer to the following:1. ANSI C80.1…Rigid Steel <strong>Conduit</strong>Zinc Coated, Specifications for2. ANSI C80.2…Rigid Steel <strong>Conduit</strong>,Enameled, Specifications for3. ANSI C80.5…Rigid Aluminum<strong>Conduit</strong>. Specifications for4. ANSI C80.4…<strong>Fittings</strong> for Rigid Metal<strong>Conduit</strong> and Electrical MetallicTubing, Specifications for5. WW-C-581…Federal Specification,<strong>Conduit</strong>, Metal, Rigid & Coupling,Elbow, and Nipple, Electrical<strong>Conduit</strong>, Zinc Coated6. WW-C-540…Federal Specification,<strong>Conduit</strong>, Metal, Rigid (Electrical,Aluminum)7. WW-C-571…Federal Specification,<strong>Conduit</strong>, Metal, Rigid, and Coupling,Elbow, and Nipple, Electrical<strong>Conduit</strong> Enameled8. U.L. 6…Standards for Safety. RigidMetal <strong>Conduit</strong>9. U.L. 2142…Standards for Safety.Intermediate Metal <strong>Conduit</strong>10. ANSI C33.84…Standards forSafety, Outlet Boxes and <strong>Fittings</strong>11. CEC Section 12-1100…Rigid andFlexible <strong>Conduit</strong>12. CSA C22.2 No. 45…SafetyStandards for Rigid Metal <strong>Conduit</strong>13. CSA C22.2 No. 18…SafetyStandards for Outlet Boxes,<strong>Conduit</strong> Boxes and <strong>Fittings</strong>14. NEMA FB-1…StandardsPublication. <strong>Fittings</strong> and Supportsfor <strong>Conduit</strong> and Cable Assemblies15. A-A-50553 Federal Specification.<strong>Fittings</strong> for <strong>Conduit</strong> Metal Rigid(Thickwall & Thinwall [EMT] Type)Please NoteThe excerpts and other material herein, whether relating to theCanadian Standards Association, the Underwriters Laboratories, Inc.listing, to industry practice or otherwise, is not intended toprovide all relevant information required for use and installation.Reference to original or primary source material and data ismandatory before any application or use is made of the product.6

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Suggested Specifications for Rigid Metal <strong>Conduit</strong>/PVC Coated Rigid Metal <strong>Conduit</strong>and <strong>Fittings</strong> meets 2002 CEC Rule 2-112Cat. #CP8KOPR-SHIELD** TM of Jet-Lube, Inc.Series 1451Knockout PlugCat. #AP8ALUMA-SHIELD ®Series 1470Plug, <strong>Conduit</strong>/Fitting• Rigid ferrous metal conduit or PVCcoated rigid conduit prior to coatingshall be of the hot dipped galvanizedtype adequately protected againstcorrosion inside and outside includingthreads, and conforming to thefollowing applicable specifications:-Rigid Ferrous Metal <strong>Conduit</strong> FederalSpecification WW-C-581/ANSIC80.1/U.L. 6/CSA C22.2 No. 45-PVC Coated Ferrous Metal <strong>Conduit</strong>Applicable listed under (i) and inaddition conforming to NEMAPublication No. RNI-1974 (Type A)PVC coating on conduit and associatedfittings shall have no sags,blisters, lumps or other surfacedefects and shall be free of holes.• Rigid nonferrous metal conduit shallconform to Federal SpecificationWW-C-540/ANSI C80.5/U.L. 6/CSAC22.2 No. 45.• All field cuts shall be square, reamedand deburred. <strong>Conduit</strong> threads shallbe tapered for entire length with 3 ¼4”taper per ft. <strong>Conduit</strong> threads prior toassembly shall be clean and coatedwith grease metallic type conductivecompounds such as series CP8KOPR-SHIELD for ferrous conduit orseries AP8 ALUMA-SHIELD fornonferrous(aluminum) conduit as manufacturedby Thomas & Betts.• To prevent ingress of plaster, dirt,trash or moisture in raceways, boxes,fittings and equipment during courseof construction, all open ends shallbe closed with rugged thermoplasticplugs as manufactured by Thomas &Betts, series 1470 and 1451. Plugsshall be firmly secured in place toprovide adequate seal and shall befunctionally unaffected by moisture.Thermoplastic plugs shall be rated at105°C/221°F and have a U.L.flammability rating of 94V-1.7

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Suggested Specifications for Rigid Metal <strong>Conduit</strong>/PVC Coated Rigid Metal <strong>Conduit</strong>and <strong>Fittings</strong> (continued)Series 1276<strong>Conduit</strong> StrapSeries 700Adjustable BeamClampSeries 140LocknutSeries 5302Sealing GasketSeries 485 PVCCoated ThreadedHubs (Raintight)Series 8120Threadless Coupling(Concretetight)Series 690<strong>Conduit</strong> SupportsSeries 1350<strong>Conduit</strong> SpacerSeries 106Bonding LocknutSeries 370Threaded Hub(Raintight)Series 8123Threadless Fitting(Concretetight)Series 8125Set Screw Fitting(Concretetight)• <strong>Conduit</strong> shall be securely fastened inplace, at intervals as specified by thecode, using suitable straps, hangersand other supporting assemblies asindicated on plans and asmanufactured by Thomas & Betts,series 1276, 690 and 700. All straphangers and supporting assembliesshall be of rugged constructioncapable of supporting weight with areasonable factor of safety and shallbe adequately protected againstcorrosion. Where applicable shallconform to Canadian StandardsAssociation Standard C22.2 No. 18.• In wet locations or in locations wherecorrosive conditions are present,vertical and horizontal runs of conduitshall be firmly supported so thatthere is at least 1 ¼4” air spacebetween the conduit and the wallor supporting surface. Spacers andsupporting straps shall be ofmalleable iron construction, hotdipped galvanized conforming toCanadian Standards AssociationStandard C22.2 No. 18 such asThomas & Betts series 1276 straps andseries 1350 spacers.Nonferrous metal straps and spacersmay be substituted as required.• Where threaded conduit terminatesinto a threadless opening, a locknutshall be provided both inside andoutside the box or enclosure andthe conduit end shall be fitted withan insulating bushing. In wetlocations, a suitable gasket shallbe provided between the outsidelocknut and the opening.Locknuts shall be rugged, ofhardened steel or malleable ironconstruction, electro-zinc platedand capable of cutting throughprotective coating on box orenclosure to insure positive bondsuch as Thomas & Betts series 140.• Where raceway and associatedfittings are used as part of anequipment grounding system,terminating fittings shall be equippedwith bonding typelocknuts such as Thomas & Bettsseries 106 bonding locknuts.Sealing gaskets shall beconstructed of oil resistant/moistureresistant rubber and shall be suitablyprotected by and permanentlybonded to a stainless steel retainersuch as Thomas & Betts series 5302.• Where threaded rigid metal conduit isinstalled outdoor or indoors or inlocations exposed to continuous orintermittent moisture, in dry locations, asealing hub type terminating fitting shallbe installed. Hubs shall be of malleableiron/steel construction,electro-zinc plated and equippedwith a nylon insulated throat andoil resistant/moisture resistantsealing ring as manufactured byThomas & Betts, series 370 or seriesH050-TB. Female taper hub threadsshall be adequately relieved to preventbottoming of conduit.Hubs constructed of copper-freealuminum may be substituted whenused with rigid nonferrous (aluminum)metal conduit, Thomas & Betts series370AL or H050A.For environmental conditions thatare more than normally corrosiveto exposed surfaces, hubs suitablyprotected with PVC coating suchas Thomas & Betts series 485 shallbe used.Series 8124Set Screw Fitting(Concretetight)8

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Suggested Specifications for Rigid Metal <strong>Conduit</strong>/PVC Coated Rigid Metal <strong>Conduit</strong>and <strong>Fittings</strong> (continued)Series 140LocknutSeries 3210Knockout BushingSeries 222TBInsulating BushingSeries 3870Insulated Grounding &Bonding BussingSeries 1942Insulated NippleSeries 674Threaded CouplingSeries TRIB50Threadless RigidInsulating Bushing• Where concrete-tight requirementsmust be met, or in dry locations, rigidmetal conduit or intermediate metalconduit fittings and couplings shallbe of the concrete-tight type. <strong>Fittings</strong>shall be rugged, of ferrous metalconstruction, electro-zinc platedinside and outside, and furnishedwith a nylon bushing asmanufactured by Thomas & Betts,series 8123 and 8120. Insulated setscrew type fittings such as Thomas &Betts series 8125 and 8124 may besubstituted unless otherwiseindicated on drawings.Components critical to performancesuch as set screws, split rings, andlocknuts shall be hardened oradequately designed to insurepositive bond between conduitand enclosure or conduit runs.All fittings of the system shall becapable of carrying ground faultcurrents per the following:1/2” through 1-1/2” size…10,000 ampsRMS (duration of fault current 3 cycles)2” and above…20,000 amps RMS(duration of fault current 3 cycles)• All back-to-back nippling of boxesshall be done using locknuts and nylonbushed nipples as manufactured byThomas & Betts, series 140 locknutsand series 1942 nipples. Nipples, orsuitably designed bushings such asThomas & Betts series 3210, shall alsobe used where conductors passthrough either factory or field punched,cut or drilled holes in metallicmembers.• Where neither length of threadedconduit can be rotated, couplingssuch as Thomas & Betts series 674shall be installed in conduit runs.• Where threaded or threadlessconduit terminates outside a boxor an enclosure, or where conduit isstubbed up, it shall be equipped withan insulated metallic or nonmetallicbushing such as Thomas & Betts series1222 or TRIB50.• Where code requires bonding andgrounding of single or multiple rigidmetal conduits or where positivebonding and grounding of conduit tothe box, enclosure or auxiliary gutteris required, the end of the conduitshall be equipped with an insulatedmetallic grounding and bondingbushing such as Thomas & Bettsseries 3870.Insulated metallic grounding andbonding bushing shall be approved forthe purpose. It shall be of malleableiron/steel construction adequatelyprotected against corrosion, assembledwith an insulator listed or certified for150°C/302°F application andflammability rating of 94V-0 withinsulator positively secured in place.Bonding to enclosure shall not bedependent on locknut bushing typecontact but by a positive bondingmeans such as a hardened screw orequivalent.9

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid Metal <strong>Conduit</strong> <strong>Fittings</strong>Specifications—Locknuts140 Series141AL Series106 SeriesApplication• To connect externally threadedconduit or fitting to a threadlessopening in a box or enclosure.• To effectively bond conduit orfitting to box or enclosure.Features• Hardened Steel/Malleable Iron/Copper-free Aluminum construction.• Tightens without deformation.• Locknuts specially designed to:(i) Provide extended reach forclamping on thin boxes andenclosures(ii) Cut through protective coating onbox and enclosure therebyinsuring ground continuity(iii) Permit tightening from outside(iv) Prevent loosening under vibration• 106 Series provided with a hardenedcone point screw.Standard Material140 Series & 106 Series3¼8” thru 2” Steel (hardened)2-1/2” thru 6” Malleable IronAll screws steel141AL SeriesAll copper-free aluminum(less than .4% copper)Standard FinishAll Steel and Malleable Iron locknutsincluding bonding screws..........................Electro-zinc PlatedAll Aluminum locknuts ........degreasedFor chromate coating use prefix 040Range• 3/8” through 6” conduit (all threadsstraight pipe [NPS]) (140 Series)• 1/2” through 4” conduit (106 Series& 141AL Series)ConformanceU.L. 514CSA C22.2 No. 18NEMA FB-1ANSI C80.4, ANSI C33.84Federal Specification W-F-408Federal Standard H-28 (Threads)“Case Hardened Locknuts”Case hardened locknuts make fittingsfaster and easier to install. Casehardened locknuts do not slip or turnthereby protecting the biting edge.Case hardened locknuts bite throughthe paint on the enclosure providingexcellent continuity of ground (typicalT&B/ Thomas & Betts fitting with casehardened locknuts successfully passedminimum fault current of 10,000 ampsRMS). Case hardened locknuts whenassembled in the intended mannerwill not vibrate loose thereby insuringexcellent ground continuity.10

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>(B) ThicknessSteel or malleable iron (steel thru 2”)or Aluminum 624Many of the T&B standard conduit and cablefittings are furnished with “case hardenedlocknuts”. This exclusive feature means thelocknut tightens up against the box withoutdeforming; the locknut bites into the boxproviding a positive ground; the fitting canbe tightened from outside the box.LocknutsCat. No.Dimensions (in.)Stl. or M.I. Alum. Size A B139* † — 1/4” 27/32 5/32140* — 3/8” 15/16 5/32141** 141AL 1/2” 1-7/64 5/32142-TB** 142AL 3/4” 1-3/8 3/16143 143AL 1” 1-11/16 13/64144 144AL 1-1/4” 2-5/32 13/64145 145AL 1-1/2” 2-1/2 13/64146-TB 146AL 2” 3 7/32147 147AL 2-1/2” 3-9/16 13/32148 148AL 3” 4-3/16 13/32149 149AL 3-1/2” 4-13/16 15/32150 150AL 4” 5-5/16 15/32151 151AL 4-1/2” 5-15/16 17/32152 152AL 5” 6 -1/2 17/32153 153AL 6” 7-3/4 17/32* Hex shape** Case hardened locknutsAluminum locknuts comply with federal standard of copper-free aluminum; less than .4% copper.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.† Not UL or CSA certified(B)ThicknessSteel or malleable iron (steel thru 2”).Use anywhere an ordinary locknut is installed toinsure positive bonding of conduit to box andprevent loosening due to vibration. Also can beused for Service Entrance applications inconformance with Code. T&B rigid conduit andE.M.T. (thinwall) fittings comply with FederalSpecification WF 408c.Bonding LocknutsDimensions (in.)Cat. No. Size Screw Sizes A B106 † 1/2” 8-32x 7/16” 1-3/8 .125107 † 3/4” 8-32x 7/16” 1-5/8 .140108 1” 8-32x 7/16” 1-15/16 .170109 1-1/4” 8-32x 7/16” 2-5/32 .170110-TB 1-1/2” 8-32x 7/16” 2-1/2 .170111 2” 8-32x 7/16” 3 .187112-TB † 2-1/2” 1/4-20x 5/8” 3-13/32 .375113-TB † 3” 1/4-20x 5/8” 4-13/16 .375114 † 3-1/2” 1/4-20x 5/8” 4-29/32 .438115-TB † 4” 1/4-20x 5/8” 5-7/16 .438†Not CSA certified.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Steel finish: zinc platedMolded Santoprene SealColor: BlueProvides positive seal against water and oil. Foruse with rigid and intermediate metal conduits,or fittings to provide watertight or raintight sealat all enclosures. NPS threads.Sealing <strong>Fittings</strong>Dimensions (in.)Cat. No. Size A B C141SL 1/2 1.140 1/8 1/4142SL 3/4 1.420 5/32 9/32143SL 1 1.770 11/64 9/32144SL 1-1/4 2.281 11/64 5/16145SL 1-1/2 2.598 11/64 9/32146SL 2 3.175 3/16 19/64Steel finish: zinc plated11

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>B ASealing Ring-SantopreneThermoplastic RubberThese sealing rings provide a liquid tight, dusttight, seal of fitting at enclosures.Sealing Rings with Stainless Steel Retainer<strong>Conduit</strong>Dimensions (in.)Cat. No. Size A B ± 1¼645302 1/2” 1-11/64 3/45303 3/4” 1-1/2 15/165304 1” 1-3/4 1-11/645305 1-1/4” 2-9/64 1-1/25306 1-1/2” 2-27/64 1-3/45307 2” 2-59/64 2-15/645308 2-1/2” 3-7/16 2-43/645309 3” 4-5/64 3-19/645311 4” 5-9/32 4-19/64NEMA 3R, 4, 6 and 13Series 3650Bonding & Grounding WedgesApplicationTo effectively bond terminating fitting orconduit to a box or enclosure.Features• Sizes 3/4” thru 6” equipped with anadditional bonding screw to installbonding jumper where required.• Can be added to an existing installationwithout disconnecting conductors.Standard Material/Finish1/2” size ............Steel/Electro-zinc Plated3/4” thru 6” size..........Bronze/Tin PlatedRange1/2” thru 6” conduitConformityU.L. 467C.S.A. C22.2 No. 41NFPA70-1987 (ANSI)Federal Specification A-A-50552Series 3651Bonding and Grounding WedgesEspecially suited for grounding old work, butequally convenient for new, grounding wedgesprovide grounding without a jumper except inconcentric knockouts. When a jumper is required, itfits under a set screw in the grounding wedge.Update existing installations to meet coderequirements for bonding (CEC Section (10-806)without disconnecting wiring. Use on newwiring also.1. Loosen bushing and position wedge.2. Tighten bushing and bonding screw.Cat. No.Size3650 1/2”3651 3/4”3652 1”3653 1-1/4”3654 1-1/2”3655 2”3656 2-1/2”3657 3”3658 3-1/2”3659 4”3661 5”3662 6”12

Blackjack —<strong>Conduit</strong> Grounding BushingsT&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Mountingscrew withnylon lockingpatch has acone point tolock bushingsecurely inplace.Insulator surfacefeatures a roundeddesign to reducedrag and preventabrasion duringwire pulling.Integral groundinglug enhancesground continuity.Added groundwire range takingreduces inventory.Accepts copper oraluminum groundwires.Insulating nylonsurface is 150°Crated and coverstop of bushing,including lugcorners.Angle of lugscrew improvesaccessibilitywhen securinggrounding wire.Cast “threads”opposite themounting screwtighten the fitduring installation.Innovative design makes installationquicker, easier.The Blackjack ® Grounding Bushingnever has to be threaded onto aconduit. It is simply placed in position oneither a threaded or non-threaded rigid orIMC conduit, with the grounding lug inperfect position to accept the groundingwire. Even in tight installations.It’s as simple as one, two, three.Compare the installation withconventional bushings that must bethreaded onto the conduit. In tightareas, you may have to remove thegrounding lug, keep up with the looseparts, and then reattach the lug.Then you still have to twist and turnthe bushing to get the lug in positionto accept the grounding wire.The Blackjack bushing does away withthese needless delays for good,making it the ideal grounding bushing.And the only logical choice for smallspaces, corners, and multiple conduitruns. And, because the grounding lugis an integral part of the bushing, it isdesigned not to fall off or get lost.Innovative design improvesperformance.The Blackjack ® bushing providessuperior ground continuity.The design of the Blackjack bushinghas an integral, cast-on grounding lugfor better ground continuity. Thismeans that the Blackjack bushingstands up to intense loads.Secure gripforms lastingbond.The Blackjackbushing’s conepointmountingscrew bitessecurely into boththreaded andnon-threaded rigid conduits. And theBlackjack bushing’s nylon locking patchis designed to prevent the screw fromloosening due to vibration.Reduce inventory.Because the Blackjack GroundingBushing is designed for threaded andnon-threaded conduits, and the groundlugs are designed to handle anextended range, the number of parts ininventory is reduced by up to two-thirdswithout losing any application coverage.Blackjack ® – <strong>Conduit</strong> Grounding BushingLug Screw:14-4: Slotted14-2/0: Slotted6-4/0: Internal Hex DriveStandard Material/FinishBody: Malleable Iron or AluminumMounting Screw: (1/2"-2") StainlessSteel, (2-1/2"-6") BrassLug Screw: Stainless SteelFinish: Zinc Plated or MechanicalGalvanizedRange<strong>Conduit</strong>: 1/2 thru 6" threaded orthreadless rigid/IMCWire Range: #14 AWG to 4/0 AWGCU/ALConformityU.L. 514B & U.L. 467CSA C22.2 No. 18 & CSA C22.2 No. 4113

ttT&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Blackjack —<strong>Conduit</strong> Grounding BushingsCat No. Cat No.Zinc <strong>Conduit</strong> Dim.Plated Size ØA ØB ØC ØD E WireMalleable Iron Aluminum in. Max. Max. Max. Max. Max. RangeBG050-14-20 BGA050-14-20 1/2 1.251 .569 1.181 2.134 .696 14-2/0BG050-14-4 BGA050-14-4 1/2 1.251 .569 1.027 1.940 .696 14-4BG075-14-20 BGA075-14-20 3/4 1.533 .772 1.221 2.414 .696 14-2/0BG075-14-4 BGA075-14-4 3/4 1.533 .772 1.030 2.168 .696 14-4BG100-14-20 BGA100-14-20 1 1.783 .993 1.181 2.581 .696 14-2/0BG100-14-4 BGA100-14-4 1 1.783 .993 1.027 2.368 .696 14-4BG125-14-20 BGA125-14-20 1-1/4 2.220 1.319 1.181 2.987 .759 14-2/0BG150-14-20 BGA150-14-20 1-1/2 2.470 1.553 1.181 3.236 .696 14-2/0BG200-14-20 BGA200-14-20 2 2.830 2.010 1.181 3.766 .696 14-2/0BG250-14-20 BGA250-14-20 2-1/2 3.148 2.412 1.181 4.341 .978 14-2/0BG250-6-40 BGA250-6-40 2-1/2 3.148 2.412 1.524 4.526 .978 6-4/0BG300-14-20 BGA300-14-20 3 4.042 3.022 1.181 4.966 .978 14-2/0BG300-6-40 BGA300-6-40 3 4.042 3.022 1.524 5.139 .978 6-4/0BG350-14-20 BGA350-14-20 3-1/2 4.542 3.491 1.181 5.467 .978 14-2/0BG350-6-40 BGA350-6-40 3-1/2 4.542 3.491 1.524 5.639 .978 6-4/0BG400-14-20 BGA400-14-20 4 5.042 3.975 1.181 5.966 .978 14-2/0BG400-6-40 BGA400-6-40 4 5.042 3.975 1.524 6.139 .978 6-4/0BG500-14-20 BGA500-14-20 5 6.136 4.991 1.181 7.045 .978 14-2/0BG500-6-40 BGA500-6-40 5 6.136 4.991 1.524 7.207 .978 6-4/0BG600-14-20 BGA600-14-20 6 7.199 6.009 1.181 8.087 .978 14-2/0BG600-6-40 BGAT600-6-40 6 7.199 6.009 1.524 8.409 .978 6-4/0Suggested SpecificationsInsulated grounding and bonding bushing(Series BG050-BG600)Where code requires bonding and grounding of single or multiple metal conduits, or positive bonding and grounding of metal conduit to thebox, enclosure or auxiliary gutter, the end of the conduit shall be equipped with an insulated metallic grounding and bonding bushing seriesBG050-14-20 as manufactured by Thomas & Betts.Grounding and bonding bushings used shall be approved for the purpose and(i) Shall be of malleable iron/steel/aluminum construction adequately protected against corrosion.(ii) Bushing insulator shall be listed or certified for 150°C/302°F application with a flammability rating of 94V-O. Insulator must be positivelylocked in place.* Mechanical galvanization is available in the 3870 Series; add suffix MG to Cat. No.Nylon Insulator (150 o C)Mounting ScrewLug Screw14-4: Slotted14-2/0: Slotted6-4/0: Internal hex drivetttØAtEtCtDttØBThroat I.D.For Threaded & Threadless Rigid & IMC <strong>Conduit</strong>.14

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Threaded Insulated Grounding BushingApplication• For quick installation of bondingjumper to multiple metal conduits(Rigid and IMC).• Designed to bush conductors andprevent insulation damage.Standard Material / FinishBody: Electro-zinc platedLay-in lug: Aluminum/tin platedInsulator: Thermoplastic150°C/302°FApplication with 94V-0 flammability.Features• Ease of installation, lay in lug design.• Cast malleable iron body designed tolock insulator in place within bodyreducing common assembly problemresulting in dislodging of insulator.• Insulator rated for 150°C/302°Fapplication.WireClamping ScrewInsulatorSet-Screw(one)Lay-In*LugBushingCastingThreaded Insulated Grounding BushingWireRange<strong>Conduit</strong> Bushing Throat Lug Swing Bushing AWGCat. No. Size Dia. Dia. Length Radius Height CU/AL3870-TB 1/2 1.125 .560 1.310 1.212 .657 14-43861 1/2 1.125 .560 1.675 1.402 .657 8-2/03871-TB 3/4 1.420 .742 1.310 1.360 .660 14-43862 3/4 1.420 .742 1.675 1.550 .660 8-2/03872 1 1.770 .944 1.310 1.535 .735 14-43882 1 1.770 .944 1.675 1.725 .735 8-2/03873 1-1/4 2.190 1.242 1.310 1.745 .735 14-43883 1-1/4 2.190 1.242 1.675 1.935 .735 8-2/03874 1-1/2 2.468 1.449 1.310 1.884 .770 14-43884 1-1/2 2.468 1.449 1.675 2.074 .770 8-2/03875 2 3.031 1.860 1.310 2.165 .770 14-43889 2 3.031 1.860 1.675 2.355 .770 8-2/03876 2-1/2 3.516 2.222 1.310 2.408 .940 14-43886 2-1/2 3.516 2.222 1.675 2.598 .940 8-2/03993 2-1/2 3.516 2.222 2.230 2.928 .940 6-4/03877 3 4.234 2.761 1.310 2.767 .975 14-43887 3 4.234 2.761 1.675 2.957 .975 8-2/03994 3 4.234 2.761 2.230 3.287 .975 6-4/03878 3-1/2 4.781 3.193 1.310 3.040 .975 14-43863 3-1/2 4.781 3.193 1.675 3.230 .975 8-2/03995 3-1/2 4.781 3.193 2.230 3.560 .975 6-4/03879 4 5.328 3.623 1.310 3.314 .980 14-43864 4 5.328 3.623 1.675 3.504 .980 8-2/03996 4 5.328 3.623 2.230 3.834 .980 6-4/03880 5 6.328 4.542 1.310 3.814 .985 14-43865 5 6.328 4.542 1.675 4.000 .985 8-2/03998 5 6.328 4.542 2.230 4.334 .985 6-4/03881 6 7.406 5.458 1.310 4.353 1.200 14-43866 6 7.406 5.458 1.675 4.543 1.200 8-2/03999 6 7.406 5.458 2.230 4.875 1.200 6-4/0Temperature rating 150°C.Meets Coast Guard Regulation CG293For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Available in Mechanically Galvanized malleable iron; add MG suffix to cat. no.*Contact customer service for copper lay in lug15

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Nylon insulatedmetallic bushingsSteel or malleable iron (Steel thru 1-1/2”).The canadian electric Code 10-906 (2) calls forprotection of ungrounded conductors by meansof smoothly rounded insulating surfaces at theentrance to raceways, pull boxes, junction boxes,etc. T&B insulated throat fittings, recognizableby the distinctive trademarked blue insulatingliner in the throat, meet and surpass this Coderequirement. In addition, T&B insulated fittingsalso reduce wire pulling effort by as much as50%. Temperature rating 105°C.Insulated Throat <strong>Fittings</strong>Dimensions (in.)Cat. No. Size A B1222 1/2” 1-1/32 29/641223 3/4” 1-9/32 31/641224 1” 1-19/32 19/321225 1-1/4” 1-15/16 21/321226 1-1/2” 2-3/16 23/321227 2” 2-11/16 7/81228 2-1/2” 3-3/16 31/321229 3” 3-27/32 15/161230 3-1/2” 4-7/16 1-1/161231 4” 4-7/8 1-3/321232 † 4-1/2” 5-7/16 1-15/64586 5” 5-31/32 1-9/32587 6” 7-3/16 1-11/32†Not CSA CertifiedCatalogue series 1222 thru 1232, 586 and 587 are available in aluminum. Add suffix AL toCat. No. The aluminum series are not CSA certified.Patented.Aluminum, steel or malleable iron(steel thru 1-1/2”).Smoothly rounded shoulder covers end ofconduit; broad flange covers knockout hole.High ribs make tightening easy with fingers orwith wrench. 1/2”-1-1/2” sizes, formed in steel,have extra smooth shoulders. Locknut-typebase gives improved bonding and resistsloosening under conditions of vibration.Metallic BushingsCat. No.Dimension (in.)Stl. or M.I. Alum. Size A B122 122AL 1/2” 1-1/32 13/32123 123AL* 3/4” 1-9/32 13/32124 124AL 1” 1-19/32 1/2125-TB 125AL 1-1/4” 1-15/16 9/16126 126AL 1-1/2” 2-3/16 9/16127 127AL 2” 2-11/16 19/32128 128AL 2-1/2” 3-3/16 13/16129 129AL 3” 3-27/32 13/16130-TB 130AL 3-1/2” 4-7/16 15/16131-TB 131AL 4” 4-7/8 1132-TB — 4-1/2” 5-7/16 1-5/64133-TB 133AL 5” 6-1/16 1-1/16134-TB 134AL 6” 7-3/16 1-1/16* Not U.L. Listed or CSA CertifiedFor Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.16

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>ABAll Plastic Insulating BushingsImpact-resistant plastic insulation. Thesebushings have ribs for gripping when installing.Perfect threads for easy thread on. U.L. Listed105°C. NPT threaded.Plastic Insulating BushingsDimensions (in.)Cat. No. Size A B222-TB 1/2” 1-1/16 3/8223-TB 3/4” 1-9/32 13/32224 1” 1-37/64 9/16225-TB 1-1/4” 2-1/32 9/16226 1-1/2” 2-15/64 9/16227 2” 2-25/32 5/8228-TB 2-1/2” 3-13/32 3/4229-TB 3” 4-3/32 3/4230-TB 3-1/2” 4-5/8 7/8231 4” 5-3/16 7/8232 4-1/2” 5-5/8 7/8233 5” 6-3/8 1234 6” 7-7/16 1Flame retardant. U.L. Rated 94V-1.17

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Insulating BushingTRIB50 Series(For Threadless Rigid <strong>Conduit</strong> and Intermediate Metal <strong>Conduit</strong>)Application• When assembled to the end of athreadless conduit, provides a wellrounded insulating surface overwhich conductors may be pulledor on which conductors may bearwhile in service.Standard MaterialHigh impact thermoplastic listed for105°C (221°F) application.Flammability Classification 94V-1.Standard FinishAs molded.1. Cut conduit end squarely. Remove sharp edgesand burrs on inside and outside diameters byreaming or filing.2. Slip the pop-on bushing over the end of theconduit.Features• Designed to be popped onto, andbush, conduit end.• Fast easy installation without screws.• High impact thermoplasticconstruction.Range1/2” through 4” conduitConformityU.L. 514ANSI C80.4, ANSI C33.84NFPA 70-1978 (ANSI)3. Using the flat surface of any standard utility toolsuch as an electricians pliers (or a hammer witha block of wood, for the larger sizes), strike thebushing on its top surface using a series of lightblows until the end of the conduit rests againstthe bushing throat and conduit stop.Insulated Metallic BushingDimensions (in.)Cat. No. Size A B CTRIB-50 1/2” 19/32 1-9/32 1-1/16TRIB-75 3/4” 25/32 1-25/64 1-1/4TRIB-100 1” 1 1-1/2 1-9/16TRIB-125 1-1/4” 1-5/16 1-5/8 1-59/64TRIB-150 1-1/2” 1-17/32 1-21/32 2-11/64TRIB-200 2” 1-31/32 1-13/16 2-11/16TRIB-250 2-1/2” 2-23/64 2 3-1/4TRIB-300 3” 2-59/64 2-7/32 3-29/32TRIB-350 3-1/2” 3-3/8 2-5/16 4-29/64TRIB-400 4” 3-27/32 2-13/32 5I.M.C. sizes 1/2” thru 4”U.L. Rated flame retardant 94V-1.ABC18

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Knockout Bushings3210 SeriesApplication• To bush knockout openings in metalboxes or enclosures.Features• One piece construction designedto snap in place.• High impact strength selfextinguishing nondripping (per U.L.94) thermoplastic construction.Standard MaterialThermoplastic rated for 105°C (221°F)application.Standard FinishAs molded.Range• .875” through 2.469” nominal diameterknockout opening (1/2” through 2”trade size knockouts).• Wall thickness of box or enclosure.095” max. up to 1” trade size..140” max. 1-1/4” through 2” trade size.ConformityU.L. 514CSA C22.2 No. 18ANSI C33.84NFPA 70-1978 (ANSI)Knockout BushingFor useWallTrade in KO* ThicknessCat. No. Size +.032/-.016 A B of Elec. Box C D3210 1/2” .875 1.000 .725 .095 MAX .360 .1803211 3/4” 1.109 1.215 .940 .095 MAX .360 .1803212 1” 1.375 1.500 1.200 .095 MAX .360 .1803213 1-1/4” 1.734 1.865 1.550 .140 MAx .400 .2103214 1-1/2” 1.984 2.240 1.760 .140 MAX .530 .3103215 2” 2.469 2.740 2.245 .140 MAx .530 .310One-piece knockout bushing quickly snaps intooutlet box, switch box, or other enclosure leftvacant by wiring modifications or maintenancechanges. Provides smooth, rounded insulationsurface for easy wire pulling. Easily installed byhand, they are available to fit 1/2” through 2”knockouts. U.L. Listed 105°C. High impactthermoplastic.* Per U.L. and NEMA standards.Material: ThermoplasticFlammability classification of 94V-1 Per UL 94Service temperature: -40°C to 105°C.19

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Capped BushingsDimension (in.)Cat. No. Size A B1460 1/2” 1-1/32 13/321461 3/4” 1-9/32 7/161462 1” 1-19/32 1/21463 1-1/4” 1-15/16 9/161464 1-1/2” 2-3/16 19/321465 2” 2 -21/32 5/8For aluminum, add suffix AL to Cat. No.Makes a workmanlike seal against grit,plaster, and mischief. Removable with pliers. Asshown 1/2” through 1-1/4” in steel; 1-1/2” and2” in malleable iron.Slip over wires—insertinto bushing—snapsinto placeHigh dielectric nylon, 105°C.An insuliner sleeve snapped into a regularbushing makes a CSA. Listed insulated bushing.For standard rigid conduit, E.M.T. (thinwallconduit) or any standard bushed outlet.Especially suitable for use with flexible metallicconduit.Converts ordinary bushing to code approvedinsulated bushing without disturbing wiring.INSULINER ® SleevesDimension (in.)Cat. No. Size A B422 1/2” 5/8 .022423 3-3/4” 11/16 .025424 1” 7/8 .040425 1-1/4” 1 .040426-TB 1-1/2” 1 .050427-TB 2” 1-1/8 .050428-TB 2-1/2” 1-1/4 .035429 3” 1-1/2 .035430-TB 3-1/2” 1-25/32 .035431 4” 2-1/32 .035433 5” 2-1/2 .035434 6” 2-1/2 .035Oxygen index >28°20

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Knockout Plugs1451 SeriesApplication• To bush knockout openings in metalboxes or enclosures.Features• One piece construction designedto snap in place.• High impact strength selfextinguishing nondripping (per U.L.94) thermoplastic construction.Standard MaterialThermoplastic rated for 105°C(221°F) application.Standard FinishAs molded.Range• .875” through 2.469” nominal diameterknockout opening ( 1 ¼2” through 2”trade size knockouts).• Wall thickness of box or enclosure.095” max. up to 1” trade size..140” max. 1-1/4” through 2” trade size.ConformityU.L. 514CSA C22.2 No. 18ANSI C33.84NFPA 70-1978 (ANSI)Knockout PlugsDimensions (in.)Cat. No. Size A B1451 1/2” 1.060 .4001452 3/4” 1.300 .4001453 1” 1.590 .4001454 1-1/4” 1.860 .4501455 1-1/2” 2.240 .5701456 2” 2.740 .570105°C rated by U.L. Made from flame retardant,non-dripping thermoplastic.Wall thickness of electrical box .095 max.Meets Coast Guard Regulation CB293.21

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Plug, <strong>Conduit</strong>, <strong>Fittings</strong> (Push Penny Plugs)Application• To plug open end of conduit orfitting in order to prevent ingressof trash, dirt or moisture duringconstruction and remodeling.Features• Wide range of application; can beused with rigid metal conduit,intermediate metal conduit, electricalmetallic tubing, all connnectorsand all bushings.• Designed to stand up to normalhandling and is functionallyunaffected by moisture.Standard MaterialPolyethyleneStandard FinishAs molded.ConformityCSA C22.2 No. 18ANSI C80.4NFPA 70-1987 (ANSI)NEMA FB-1CEC Rule: 12-3026“Unused openings in boxes, cabinetsand fittings shall be effectively closed byplugs or plates affording protectionsubstantially equivalent to that of thewall of the box, cabinet or fittings.”Fig. 1Material: Steel bushing, plastic capPush-Penny ® PlugsSizeAssembly ofCat. No. Bushing Push-penny A Fig.1460 1/2” 122 1470 1-1/32” 11461 3/4” 123 1471 1-9/32” 11462 1” 124 1472 1-19/32” 11463 1-1/4” 125 1473 1-15/16” 11464 1-1/2” 126 1474 2-3/16” 11465 2” 127 1475 2-21/32” 2Available in AluminumAdd suffix AL to Cat. No.Fig. 2Material: Malleable iron bushing, plastic capA penny under a bushing will seal the end of theconduit during construction. Made to fit anybushing. Completely salvageable.Pennies—SteelCat. No.815-TB 1/2”816 3/4”817 1”818 1-1/4”819 1-1/2”820 2”821 2-1/2”822 3”824 3-1/2”823 4”U.L. not applicableSize22

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>CHASE ® NippleNPSThreads1942 Series842AL Series (Non Insulated)Application• To effectively bush factory orfield-punched, cut, or drilled holes inmetal boxes or enclosures.• To couple boxes back-to-back.Features• Rugged construction.•Insulator curled over to: Bushconductors entering/leaving at anyangle. Reduce wire pull effort.Protect threads against damagein handling.Standard Material1942 SeriesBody 1/2”-Steel3/8”, 3/4” through 6”-Malleable IronInsulator Nylon842AL SeriesAll Copper-free Aluminum(less than .4% copper)Standard Finish1942 Series Electro-zinc Plated& Chromate Coated842AL Series DegreasedRange 1942 & 842AL Series1¼2” through 6”All hub threads straight pipe (NPS).ConformityU.L. 514CSA C22.2 No. 18Federal Specification W-F-408ANSI C80.4, ANSI C33.84NFPA 70-1978 (ANSI)NEMA FB-1Federal Standard H-28 (Threads)Steel, malleable iron or aluminum.CHASE ® NipplesCat. No.Dimensions (in.)Stl. or M.I. Alum. Size A B841TB — 3/8” 13/16 7/16842TB 842ALTB † 1/2” 15/16 11/32843TB 843ALTB 3/4” 1-3/16 11/32844 844AL † 1” 1-7/16 21/32845 845AL † 1-1/4” 1-3/4 3/4846 846AL 1-1/2” 2-1/16 13/16847 847AL 2” 2-1/2 31/32848 848AL 2-1/2” 3-1/16 1-1/16849 849AL 3” 3-13/16 1-3/16850 850AL 3-1/2” 4-3/8 1-5/16851 851AL 4” 4-3/4 1-5/16853 853AL 5” 5-7/8 1-5/16854 854AL 6” 6-15/16 1-3/8†Not U.L. ListedFor Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Steel or malleable ironCHASE ® Nipples—Nylon InsulatedSizeDimensions (in.)Cat. No. in. A B C1942 1/2 15/16 1/2 19/321943 3/4 1-3/16 17/32 23/321944 1 1-7/16 21/32 7/81945 1-1/4 1-3/4 25/32 1-1/321946 1-1/2 2-1/16 13/16 1-3/321947 2 2-9/16 31/32 1-11/321948 2-1/2 3-1/16 1-1/16 1-7/161949 3 3-13/16 1-3/16 1-19/321950 3-1/2 4-3/8 1-5/16 1-25/321951 4 4-5/8 1-5/16 1-13/161953 5 5-29/32 1-5/16 1-13/161954 6 6-13/16 1-3/8 1-7/823

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>(B)(C)(E)370 Series370AL Series(A)PredeterminedCompression(D)Threaded Hubs (Bullet ® Hubs)(For Threaded Rigid Metal <strong>Conduit</strong>/IMC/PVC Coated Rigid Metal <strong>Conduit</strong>)Application• To connect threaded metal conduit(ferrous rigid/nonferrous rigid/PVCcoated/or intermediate metal) toa threadless opening in a box orenclosure in outdoors or indoorlocation exposed to continuousor intermittent moisture.• Suitable for hazardous location useper following:(i) Class II, Division 1 Groups E, F, G,CEC Rule 18-202Class II, Division 2 Groups E, F, G,CEC Rule 18-252Class III, Division 1 Rule 18-302Class III, Division 2 Rule 18-352(B)(C)(E)(G)(A)(F)(D)(G)• To positively bond conduit to boxor enclosure.Features• Rugged steel/malleable iron/copperfreealuminum construction.• Tapered internal threads forwatertight/dust tight union (A).• Threads relieved to preventbottoming of conduit ensuring soundassembly (B).• Recessed sealing ring at box end.Captive sealing ring (C).• PVC coated 485 Series(i) Protects fitting from extremelycorrosive surroundings withoutaffecting integrity of electricalgrounding path (F).(ii) Provided with overlapping sleevefor additional seal (G).Canadian Electric Code Rule 10-602states that, “Dissimilar metals wheredissimilar metals cannot be avoided atbonding connections as indicated inRule 2-112 (2). Connections shall bemade using methods or material thatwill minimize deterioration fromgalvanic action”.485 Series• Hardened steel/malleable iron/copper-free aluminum locknutsdesigned to provide high qualityground continuity; extended reach oflocknut permits clamping on thinboxes and enclosures (D).• Insulated throat protects conductors,prevents abrasion and thinning ofconductor insulation, reduces wirepull effort (E).Joint Industrial Council (JIC) ElectricalStandards also forbid dissimilar metalsin contact for the same reason andrequire that the fittings for metal conduitbe of malleable iron or ductile iron andhave impact strength comparable tothat of the conduit.“Copper-free Aluminum”• Copper-free aluminum castingsfor fittings have a maximum of 0.4%copper. The most detrimental effect ofhigher percentage of copper onaluminum base alloy is its decrease incorrosion resistance.24

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Threaded Hubs (Bullet Hubs)—continued(For Threaded Rigid Metal <strong>Conduit</strong>/IMC/PVC Coated Rigid Metal <strong>Conduit</strong>)Standard Material370-485 Series 370ALBody 1/2” thru 1” Steel All Copper-Free Aluminum1-1/4” thru 6” Malleable IronLocknut 1/2” thru 2” Steel (hardened) 1/2” thru 2” Steel (hardened)2-1/2” thru 6” Malleable Iron 2-1/2” thru 4” Copper-freeAluminumScrews Steel (hardened)‘O’ Ring Buna NInsulator NylonCoating PVCStandard Finish370 Series 370AL Series 485 SeriesHub Electro-zinc Plated As Cast PVC—Outside.Chromate Coated. Electro-zincLocknuts All Ferrous locknuts Plated ChromateElectro-Zinc PlatedCoated Inside.and Chromate Coated.Screws All Electro-Zinc Plated& Chromate Coated.Range370 Series 1/2” thru 6” <strong>Conduit</strong>370AL & 485 Series 1/2” thru 4” <strong>Conduit</strong>All hub threads—straight pipeAll female threads—taper pipe(NPT)ConformityU.L. 514CSA 22.2 No. 18ANSI C80.4; ANSI C33.84NFPA 70-1978 (ANSI)NEMA FB-1JIC EGP1; JIC EMP 1Federal Specification W-F-408Federal Standard H-28 (Threads)25

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Nylon insulated.Aluminum, steel, or malleable iron (steelthrough 1”). With Neoprene “O” Ring provides awatertight threaded hub on enclosures. U.L.Listed 105°C.Steel/Malleable Iron and Aluminum Hub <strong>Fittings</strong>* †Cat. No. Size Dimensions (in.) Wall Thk.Stl. or M.I. Alum.** A B C (max.)in.370 370AL 1/2 1-3/8 1-5/16 3/4 5/16371 371AL 3/4 1-5/8 1-3/8 7/8 5/16372 372AL 1 2-3/32 1-23/32 1-7/32 5/16373 373AL 1-1/4 2-9/16 2 1-11/32 5/16374 374AL 1-1/2 3-3/32 2 1-11/32 5/16375 375AL 2 3-5/8 1-31/32 1-11/32 5/16376 — 2-1/2 4-1/8 2-21/32 1-15/16 5/16377 — 3 5 2-31/32 2 1/2378 — 3-1/2 5-9/16 3-1/8 2-1/8 1/2379-TB — 4 6-9/16 3-1/8 2-1/8 1/2381-TB — 5 8 4 2-3/16 1/2382-TB — 6 9-3/16 4 2-3/16 1/2* General purpose equipment is specifically permitted per CEC 18-050.** Aluminum not available with insulated throat.†U.L. Listed raintight and CSA Certified watertight and dust tight.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Bullet ® Hub <strong>Fittings</strong> with Bonding Locknut —Nylon InsulatedCat. No. Size (in.) Description401 1/2402 3/4403-TB 1 Available in steel or malleable iron404-TB 1-1/4 (steel through 1 inch.).405-TB 1-1/2 Used with a neoprene “O” ring to provide406-TB 2 a watertight* threaded hub on enclosures.407 2-1/2 Supplied with 106 series bonding nut.408 3 Temperature rating: 105° C.409 3-1/2410-TB 4CSA certified watertight and dust tight.26

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Steel or malleable iron (steel thru 1-1/4”).LOCKNUTNFS THREADBPLASTICCOATINGPVC Coated Hub for Rigid <strong>Conduit</strong>Dimensions (in.)Cat. No. <strong>Conduit</strong> Size A B C485 1/2” 1-21/64 2-1/8 1-7/8486 3/4” 1-19/32 2-3/8 2-1/8487 1” 1-27/32 2-3/4 2-3/8488 1-1/4” 2-15/32 3-3/8 3-1/8489 1-1/2” 2-29/32 3-5/8 3-1/2490 2” 3-3/8 3-3/4 4491 2-1/2” 3-27/32 4 4-1/2492 3” 4-21/32 4-5/8 5-3/8493 3-1/2” 5-9/64 4-13/16 5-7/8494 4” 5-3/4 4-9/16 6-7/16CA*485 Series are CSA Certified Watertight and Dustight for Ordinary Locations.INSULATORSEALING RINGSpacing Chart for Bullet ® HubsCenter to Center SpacingMin. Space from<strong>Conduit</strong> Sizes Center of KOBullet ® Hub to Diameters1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 Wall of Box (min.)1/2 1-7/16 1-5/8 1-3/4 2-1/8 2-3/8 2-5/8 2-7/8 3-5/16 3-1/2 3-7/8 3/4 7/83/4 — 1-3/4 1-7/8 2-1/4 2-1/2 2-3/4 3 3-1/2 3-3/4 4-1/8 7/8 1-1/81 — — 2 2-3/8 2-5/8 2-7/8 3-1/8 3-5/8 3-7/8 4-1/4 1-1/8 1-3/81-1/4 — — — 2-11/16 2-15/16 3-1/4 3-1/2 4 4-1/4 4-1/2 1-3/8 1-3/41-1/2 — — — — 3-1/8 3-1/2 3-3/4 4-1/8 4-3/8 4-3/4 1-5/8 22 — — — — — 3-3/4 4 4-1/2 4-3/4 5 1-7/8 2-1/22-1/2 — — — — — — 4-1/4 4-3/4 5 5-3/8 2-1/8 33 — — — — — — — 5-1/8 5-3/8 5-3/4 2-5/8 3-5/83-1/2 — — — — — — — — 5-5/8 6 2-7/8 4-1/84 — — — — — — — — — 6-1/4 3-1/4 4-5/8T&B Hub Centerline Spacing Chart<strong>Conduit</strong>Trade Size 1/2” 3/4” 1” 1-1/4” 1-1/2” 2” 2-1/2” 3” 3-1/2” 4” 5” 6”inc.1/2” 1-9/163/4” 1-43/64 1-25/321” 1-27/32 1-61/64 2-1/81-1/4” 2-1/32 2-9/64 2-5/16 2-1/21-1/2” 2-7/32 2-21/64 2-1/2 2-11/16 2-7/82” 2-15/32 2-37/64 2-3/4 2-15/16 3-1/8 3-3/82-1/2” 2-23/32 2-53/64 3 3-3/16 3-3/8 3-5/8 3-7/83” 3-1/32 3-9/64 3-5/16 3-1/2 3-11/16 3-15/16 4-3/16 4-1/23-1/2” 3-11/32 3-21/64 3-5/8 3-13/16 4 4-1/4 4-1/2 4-13/16 5-1/84” 3-19/32 3} 3-7/8 4-1/16 4-1/4 4-1/2 4-3/4 5-1/16 5-3/8 5-5/85” 4-9/32 3-25/64 4-9/16 4-3/4 4-15/16 5-3/16 5-7/16 5-3/4 6-1/16 6-5/16 76” 4-11/16 4-51/64 4-31/32 5-5/32 5-11/32 5-19/32 5-27/32 6-5/32 6-15/32 6-23/32 7-13/32 7-13/16Nearest obstruction to center of hub.27/32 61/64 1-1/8 1-5/16 1-1/2 1-3/4 2 2-5/16 2-5/8 2-7/8 2-9/16 3-31/3227

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>THE T&B ® HubNever before has a single hub fit like this one. Designed for unequalled performance. The innovative engineering of theT&B ®Hub will, quite simply, raise your performance expectations for threaded hubs. The revolution in hub design is here,and the fate of our competition is sealed.Figure 1 Figure 2 Figure 31. Sealing ring and groove withinnovative profile outperformsstandard 'O' ring design. Sealingring is captive before installationand resists buckling or slipping duringinstallation. The seal groove isdesigned for optimum compression ofthe sealing ring. The sealing ring isdesigned to provide a complete 360°seal, even when the conduit is notperpendicular with the enclosure. (SeeFigure 1)Throat Dia. E2. Locknut design with peripheralslots and a hexagonal/angledspline spaced every 30° enableseasy application of torque withwrench or hammer and screwdriver.(SeeFigures2&3)3. Sharper and deeper teeth onlocknut and body designed for amore penetrating bite for improvedbonding to the enclosure.T&B ® Hub4. Hexagonal / splined body designfor fast, easy installation withwrench or hammer and screwdriver.5. Precision machined taperedthreads designed to create watertightunion.6. Insulated throat molded from105°C rated thermoplastic with aflammability rating of 94 V-O.Trade Max. Panel ThroatCat. Size Dia. Thickness Dia.No. (in.) A B C D EH050-TB 1/2 1-7/16 1-9/16 7/8 3/16 19/32H075-TB 3/4 1-21/32 1-19/32 29/32 3/16 25/32H100-TB 1 2 1-13/16 1-1/16 1/4 1H125-TB 1-1/4 2-3/8 1-7/8 1-1/16 1/4 1-5/16H150-TB 1-1/2 2-3/4 1-7/8 1-1/16 1/4 1-17/32H200-TB 2 3-1/4 1-15/16 1-5/32 1/4 1-31/32H250-TB 2-1/2 3-3/4 2-9/16 1-9/16 1/4 2-13/32H300-TB 3 4-3/8 2-21/32 1-19/32 1/4 2-31/32H350-TB 3-1/2 5 2-23/32 1-5/8 1/4 3-13/32H400-TB 4 5-1/2 2-23/32 1-5/8 1/4 3-7/8H500-TB 5 6-7/8 3-1/32 1-15/16 1/4 4-15/16H600-TB 6 7-11/16 3-5/32 2 1/4 6BDACMaterial – Hub and Locknut: zinc or copper free aluminumInsulating Throat: thermoplastic temp. rating – 105°C, Flammability Rating: – 94V-0Sealing Ring Nitrile (BUNA “N”)For Aluminum Hubs add suffix A (i.e. H050A). For Chrome Plated Hubs add suffix CP (i.e. H050CP).Meets NEMA sealing requirements for NEMA 3R, 4 & 13 enclosures.U.L. Listed and CSA Certified. CSA Certified for hazardous locations Class II Groups E, F, G Class III.Chrome Plated Hubs (suffix-“CP”) are rated NEMA 4X.28

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>T&B Grounding HubDimensions (in.)A B C D ETrade Max. Panel ThroatCat. No. Size Dia. Thickness Dia.H050GR-C 1/2 17/16 19/16 7/8 3/16 19/32H075GR-C 3/4 12-1/32 1-19/32 29/32 3/16 25/32H100GR-C 1 2 1-13/16 1-1/16 1/4 1H125GR-C 1-1/4 2-3/8 1-7/8 1-1/16 1/4 1-5/16H150GR-C 1-1/2 2-3/4 1-7/8 1-1/16 1/4 1-17/32H200GR-C 2 3-1/4 1-15/16 1-15/32 1/4 1-31/32H250GR-C 2-1/2 3-3/4 2-9/16 1-9/16 1/4 2-13/32H300GR-C 3 4-3/8 2-21/32 1-19/32 1/4 2-31/32H350GR-C 3-1/2 5 2-23/32 1-5/8 1/4 3-13/32H400GR-C 4 5-1/2 2-23/32 1-5/8 1/4 3-7/8H500GR-C 5 6-7/8 3-1/32 1-15/16 1/4 4-15/16H600GR-C 6 7-11/16 3-5/32 2 5/16 6BEThroat Dia.ACMaterial—Hub and Locknut: zinc or copper-free aluminum.Insulating Throat: thermoplastic temp. rating—105°C;flammability rating:—94V-0.Sealing Ring: Nitrile (BUNA “N”)For Aluminum Grounding Hubs add suffix A (i.e. H050GRA-C).For Chrome Plated Hubs add suffix CP (i.e. H050GRCP).For 316 Stainless Steel Hubs add suffix SST (i.e. H050GRSST).For PVC coating add suffix PVC (i.e. H050GRPVC-C).Meets NEMA sealing requirements for NEMA 3R, 4 & 13 enclosures.U.L. Listed and CSA Certified.CSA approved for use in hazardous locations: Class I, Division 2, Class II, Divisions 1& 2, Groups E, F & G, Class III and type 4 enclosures.T&B Grounding and Bonding LocknutMax.Trade A B Ground ConductorCat. No. Size Dia. Height Screw SizeL050GR-C 1/2 1-1/2 13/32 #10-32 x 1/4” #10L075GR-C 3/4 1-11/16 13/32 #10-32 x 1/4” #10L100GR-C 1 2 13/32 #10-32 x 1/4” #10L125GR-C 1-1/4 2-3/8 15/32 1¼4-20 x 1/4” #10L150GR-C 1-1/2 2-3/4 15/32 1¼4-20 x 5/16” #8L200GR-C 2 3-1/4 15/32 1¼4-20 x 5/16” #8L250GR-C 2-1/2 3-3/4 11/16 1¼4-20 x 5/16” #6L300GR-C 3 4-3/8 23/32 1¼4-20 x 5/16” #6L350GR-C 3-1/2 5 23/32 1¼4-20 x 5/16” #6L400GR-C 4 5-1/2 23/32 1¼4-20 x 5/16” #4L500GR-C 5 6-5/8 23/32 3¼8-16 x 3/8” #2L600GR-C 6 7-11/16 23/32 3¼8-16 x 3/8” #1Material—Locknut: zinc or copper-free aluminumFor Aluminum Locknuts add suffix A. (i.e. L050GRA-C)For Chrome Plated Locknuts add suffix CP. (i.e. L050GR-CP)For 316 Stainless Steel Locknuts add suffix SST (i.e. L050GRSST).Grounding Locknut for Hubs29

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>T&B Bulkhead <strong>Fittings</strong>ThreadAcross FlatsDiameterNipple NutNot IncludedBulkhead FittingCat. No.TradeSizeH050BHD 1/2”H075BHD 3/4”H100BHD 1”H125BHD 1-1/4”H150BHD 1-1/2”H200BHD 2”H250BHD 2-1/2”H300BHD 3”H350BHD 3-1/2H400BHD 4”H500BHD 5”H600BHD 6”Thru Bulkhead FittingTradeCat. No.SizeHeightH050TBF 1/2”H075TBF 3/4”H100TBF 1”H125TBF 1-1/4”H150TBF 1-1/2”H200TBF 2”Thru Bulkhead HubTradeCat. No.SizeH050TBH 1/2”H075TBH 3/4”H100TBH 1”H125TBH 1-1/4”H150TBH 1-1/2”H200TBH 2”TradeAcrossSize Thread Height Diameter Flats A B1/2” 1/2”-14 1-13/32 1-7/16 1 3/4 1/23/4” 3/4”-14 1-15/32 1-11/16 1-1/4 25/32 17/321” 1”-11-1/2 1-11/16 2 1-17/32 29/32 19/321/4” 1-1/4”-11-1/2 1-25/32 2-3/8 1-27/32 29/32 21/321-1/2” 1-1/2”-11-1/2 1-13/16 2-3/4 1-1/8 29/32 21/322” 2”-1-1/2 1-27/32 3-1/4 2-5/8 15/16 21/322-1/2” 2-1/2”-8 29/32 3-3/4 3-1/8 17/32 7/83” 3”-8 2-9/16 4-3/8 3-25/32 15/16 29/323-1/2” 3-1/2”-8 2-9/16 5 4-9/32 1-3/8 7/84” 4”-8 2-9/16 5-1/2 4-27/32 1-3/8 7/85” 5”-8 2-23/32 6-5/8 5-29/32 1-15/32 7/86” 6”-8 3 7-11/16 7-1/32 1-1/2 31/32Material—Hub, Body and Locknut: zinc or copper-free aluminumInsulating Throat: thermoplastic temp. rating—105°C; Flammability rating:—94V-0Sealing Ring: Nitrile (BUNA “N”)For Aluminum Bulkhead add suffix A.For Chrome Plated Bulkhead add suffix CP.30

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Offset ReducersCTradeDimensions (in.)Cat. No. Size Height Dia. (Ø) A B C D EBAHeightH150-075ORGR-TB 1-1/2”-3/4” 1-21/32 2-3/4 15/16 23/32 1-29/32 1-9/32 11/32H150-100ORGR-TB 1-1/2”-1” 1-25/32 2-3/4 1-1/16 23/32 1-29/32 1-9/16 7/32H150-125ORGR-TB 1-1/2”-1-1/4” 1-25/32 2-3/4 1-1/16 23/32 1-29/32 1-7/8 1/32H250-200ORGR-TB 2-1/2”-2” 2-1/8 3-3/4 1-3/16 15/16 2-29/32 2-21/32 3/32Dia. (Ø)Dia. (0)Material—Offset Reducer and Locknut: zinc or copper-free aluminumInsulating Throat: thermoplastic temp. rating—105°C; Flammability rating—94V-0Sealing Ring: Nitrile (BUNA “N”)For Aluminum Offset Reducer add suffix A. (i.e. H150-125ORGRA-TB)For Chrome Plated Offset Reducer add suffix CP. (i.e. H150-125ORGRCP-TB)ECapoffsBTradeDimensions (in.)Cat. No. Size Height Diameter A B CDia.ACCapoffHeightH050CAP 1/2” 1-13/32 1-7/16 19/32 27/32 3/16H075CAP 3/4” 1-15/32 1-11/16 19/32 1-1/16 3/16H100CAP 1” 1-11/16 2 11/16 1-5/16 1/4H125CAP 1-1/4” 1-25/32 2-3/8 23/32 1-21/32 1/4H150CAP 1-1/2” 1-13/16 2-3/4 23/32 1-29/32 1/4H200CAP 2” 1-27/32 3-1/4 23/32 2-3/8 1/4H250CAP 2-1/2” 2-9/32 3-3/4 7/8 2-29/32 1/4H300CAP 3” 2-9/16 4-3/8 7/8 3-1/32 11/32H350CAP 3-1/2” 2-9/16 5 29/32 4-1/32 11/32H400CAP 4” 2-9/16 5-1/2 29/32 4-1/2 11/32H500CAP 5” 2-23/32 6-5/8 29/32 5-9/16 11/32H600CAP 6” 3 7-5/8 31/32 6-5/8 11/32Material—Capoff and Locknut: zinc or copper-free aluminumInsulating Throat: thermoplastic temp. rating—105°C; flammability rating—94V-0Sealing Ring: Nitrile (BUNA “N”)For Aluminum Capoff add suffix A. (i.e. H050CAPA)For Chrome Plated Capoff add suffix CP. (i.e. H050CAPCP)31

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Threadless <strong>Fittings</strong>/Couplings(For Threadless Rigid Metal <strong>Conduit</strong> and Intermediate Metal <strong>Conduit</strong>)8123 Series8130 Series8120 SeriesApplication• To connect and effectively bondthreadless rigid metalconduit/intermediate metal conduit toa box or enclosure, or to couple endsof threadless conduit.Features• Steel/Malleable Iron Construction.• Case hardened ring bites intoconduit for high quality continuity andgrip.• Nylon insulator firmly secured in placeprotects conductors and reduceswire pulling effort by as much as50%; prevents thread damage inhandling.• Case hardened steel locknut ormalleable iron locknut designedto provide a positive bond.• Suitable for concretetight application.• Raintight application.• Capable of carrying ground faultcurrents up to 10,000 amps RMS(1/2" through 1-1/2” size) and 20,000amps RMS (2” and above sizes)duration of current 3 cycles.Standard MaterialNut, Gland 1/2” to 1” Steel—1-1/4”to 4” Malleable IronBody All Malleable IronRing Steel (case hardened)Insulator NylonLocknut 1/2” thru 2” Steel(hardened) 2” thru 4”Malleable IronStandard FinishElectro Zinc Plated & ChromateCoatedRange• 8123 & 8120 Series 1/2” through 4”Size <strong>Conduit</strong>• 8130 Series 1/2” and 3/4”Size <strong>Conduit</strong>• All hub threadsStraight Pipe(NPS)ConformityU.L. 514CSA C22.2 No. 18ANSI C80.4; ANSI C33.84NFPA 70-1978 (ANSI)NEMA FB-1Federal Specification W-F-408Federal Standard H-28 (Threads)32

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Nylon Insulated Threadless <strong>Fittings</strong>Cat. No. <strong>Conduit</strong> Dimensions (in.)Nylon Insul. Non-Insul. Size A B C8123 8121 1/2” 1-11/32 1-15/16 3/48223 8221 3/4” 1-5/8 2 3/48323 8321 1” 1-7/8 2-7/16 7/88423 8421 1-1/4” 2-3/8 2-9/16 11/168523 8521 1-1/2” 2-5/8 2-3/4 3/48623 8621 2” 3-1/4 2-15/16 27/328723-TB 8721 2-1/2” 3-15/16 3-15/16 1-1/88823-TB 8821 3” 4-11/16 4-1/8 1-7/328853 8851 3-1/2” 5-3/16 4-1/4 1-1/88973 8971 4” 5-11/16 5 1-1/8For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.A split steel ring with diagonal serrations grips theconduit and bites into it for positive ground.Makes a permanent connection and eliminatesthe need for cutting a thread on the conduit.Insulation helps to guarantee continuity ofservice with protection of the conductor at thecritical point—the fitting bushing. Malleable ironconstruction.Threadless CouplingsDimensions (in.)Cat. No. Size A B8120 1/2” 1-9/32 28220 3/4” 1-19/32 2-5/168320 1” 1-7/8 2-11/168420 1-1/4” 2-3/8 2-13/168520 1-1/2” 2-5/8 3-5/88620 2” 3-1/4 3-13/168720 2-1/2” 3-15/16 5-3/88820 3” 4-11/16 5-1/28850 3-1/2” 5-3/16 5-1/28970 4” 5-11/16 5-1/2For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Eliminate conduit threading. When tightenedwith a wrench they make a U.L. Listed and CSACertified concrete-tight connection.Malleable iron.33

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Threadless Short Elbows—Nylon InsulatedDimensions (in.)Cat. No. Size A B C8130 1/2” 1-11/32 1-1/2 1/28131 3/4” 1-5/8 1-3/4 9/168132 1” 1-7/8 1-15/16 11/168134 1-1/2” 2-23/32 3-1/8 13/16For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Ideal for entering enclosure or conduit body at rightangles. Eliminates need to thread conduit. As withstraight couplings, this fitting makes a concretetightconnection. Malleable iron.34

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Specifications—Set Screw Fitting/Coupling(For Threadless Rigid Metal <strong>Conduit</strong> and Intermediate Metal <strong>Conduit</strong>)Application• To connect and effectively bond threadless rigid metal conduit or intermediatemetal conduit to a box or enclosure or to couple ends of threadless conduit.8125 SeriesFeatures• Thickwall steel or malleable iron body.• Hardened hex head cup point screw to provide high quality bond.• Captive screw, will not vibrate loose.8124 Series• Nylon insulated throat meets and exceeds all codes requirements for bushing:(i) Prevents thinning of insulation.(ii) Reduces installation effort.(iii) Prevents first thread damage.• Coupling provided with positive center stop.• Suitable for concretetight application.• Capable of carrying ground fault currents up to 10,000 amps RMS(1¼2 through 1-1/2” size) and 20,000 amps RMS (2” and above sizes).Standard MaterialBody1/2” thru 2” Steel2-1/2” thru 4” Malleable IronLocknut 1/2” thru 2” Steel (hardened)2-1/2” thru 4” Malleable IronScrewSteel (hardened)Insulator NylonStandard FinishElectro Zinc Plated & Chromate Coated.ConformityU.L. 514CSA C22.2 No. 18ANSI C80.4; ANSI C33.84NFPA 70-2002 (ANSI)NEMA FB-1Federal Specification W-F-408Federal Standard H-28 (Threads)35

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Insulated Set-Screw Fitting<strong>Conduit</strong>Dimensions (in.)Cat. No. Size A B8125 1/2” 1-3/8 13/328225 3/4” 1-1/2 7/168325 1” 1-13/16 35/658425 1-1/4” 2 5/88525-TB 1-1/2” 2-5/16 5/88625 2” 2-7/16 11/168725-TB 2-1/2” 3-3/8 18825 3” 3-7/16 18855 3-1/2 3-7/8 1-1/168975 4” 4-3/16 1-1/8Sizes 1/2”-2” made of steel. Sizes 2-1/2”-4” are malleable iron.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Eliminate conduit threading with these setscrew fittings. Captive hex head screws tightendown onto conduit for positive holding strengthand ground. The fittings are furnished withinsulated throats reducing wire pulling effort byas much as 50%. Approved concrete-tight.Set Screw Coupling<strong>Conduit</strong>Dimensions (in.)Cat. No. Size A8124 1/2” 2-1/28224-TB 3/4” 2-11/168324-TB 1” 2-27/328424 1-1/4” 38524 1-1/2” 3-3/88624 2” 3-5/88724-TB 2-1/2” 3-7/88824-TB 3” 4-1/48854 3-1/2 4-15/168974 4” 5-3/8Sizes 1/2”-2” made of steel; sizes 2-1/2”-4” are malleable iron.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Eliminate the need for threading conduit endswhen joining rigid conduit with these set screwcouplings. Captive hex head screws providepositive holding strength and ground continuity.Approved concrete-tight.36

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Bushed ElbowsDimensions (in.)Cat. No. Size A B C460TB 1/2” 1-13/16 1-1/8 5/8461TB 3/4” 2-1/4 1-1/2 9/16462 1” 2-23/32 1-23/32 11/16463 1-1/4” 3-1/8 2-1/16 25/32The noninsulated elbow has smoothly roundedshoulders to protect conductor insulation.Malleable iron.For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.The integral insulation of the insulated elbow isa guarantee that the bushing of every fitting willbe smooth. Malleable iron.Short Elbows—Nylon InsulatedDimensions (in.)Cat. No. Size A B C4290 1/2” 1-7/32 1-1/4 1/24291 3/4” 1-7/16 1-5/16 9/164292 1” 1-23/32 1-9/16 11/164293 1-1/4” 2-7/32 2-1/16 13/164294 1-1/2” 2-15/32 2-3/16 13/164295 2” 3 2-9/16 13/16For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Not U.L. ListedWhen an insulated elbow is not desired, theNoninsulated short elbow should be used.Malleable iron.Short ElbowsDimensions (in.)Cat. No. Size A B C4250 1/2” 1-5/16 1-1/4 7/164251 3/4” 1-17/32 1-5/16 1/24252 1” 1-13/16 1-9/16 5/84253 1-1/4” 2-9/32 2-1/16 11/164254 1-1/2” 2-9/16 2-3/16 11/164255 2” 3-3/32 2-9/16 11/16For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.37

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Threaded Coupling (ERICKSON ® Couplings)(For Threaded Rigid Metal <strong>Conduit</strong> and Intermediate Metal <strong>Conduit</strong>)674 Series675AL SeriesApplication• To couple and effectively bondthreaded ends of rigid metal conduit/intermediate metal conduit whereneither length of conduit can berotated.Features• Malleable Iron/Steel/Copper-freeAluminum Construction.• Free fitting threads insure easyassembly.• Permits conduit coupling withoutrotating either conduit.• Provides rigid in-line coupling withhigh quality grounding; will not loosenunder vibration.• Suitable for concrete-tight application.• Capable of carrying ground faultcurrents up to 10,000 amps RMS(1/2” through 1-1/2” size) and up to20,000 amps RMS (2” and above)(duration of fault current 3 cycles)(674 series tested).Standard Material674 SeriesBushing and BodyRing675AL SeriesBushing and BodyRingMalleable IronSteel up to 2” orMalleable IronAluminumAluminumStandard Finish674 Series: Electro Zinc Plated &Chromate Coated675AL Series: DegreasedRange• 674 Series: 3/8” thru 6” <strong>Conduit</strong>• 675AL Series: 1/2” thru 6” <strong>Conduit</strong>• All straight pipe threads (NPS)ConformityU.L. 514CSA C22.2 No. 18NEMA FB1ANSI C80.4, ANSI C33.84NFPA 70-2002 (ANSI)Federal Specification W-F-408Federal Standard H-28 (Threads)With an Erickson coupling, a conduit run may becompleted when neither conduit can be turned.A conduit run may also be broken without takingdown the whole run. <strong>Conduit</strong> joined withErickson Couplings is rigid and in line andvibration will not loosen the connections.ERICKSON ® CouplingsCat. No.Dimensions (in.)Mal. Iron Alum.* Size A B674 — 3/8” 1-1/8 1-1/8675 675AL 1/2” 1-15/32 1-1/4676 676AL 3/4” 1-9/16 1-13/32677 677AL 1” 1-29/32 1-5/8678 678AL 1-1/4” 2-3/8 1-13/16679 679AL 1-1/2” 2-5/8 1-31/32680-TB 680AL 2” 3-7/32 2-7/32681 681AL 2-1/2” 3-3/32 2-11/16682 682AL 3” 4-7/16 2-29/32683 683AL 3-1/2” 5 3684 684AL 4” 5-1/2 3-3/16685 685AL † 4-1/2” 6-1/4 3-15/32686 686AL 5” 6-25/32 3-3/4687 687AL 6” 8 4-1/32* Copper-free Aluminum (less than .4% Copper).U.L. Listed and CSA Certified concrete-tight.†Not CSA Certified.38

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>Panel Fitting ExtensionsDimensions (in.)Cat. No. Size A B C1440 1/2” 1-1/4 1-3/16 1-7/81441 3/4” 1-1/4 1-13/32 1-15/161442 1” 1-3/16 1-21/32 1-15/161443 1-1/4” 1-1/4 2-1/8 2Ideal when longer thread length is needed. Willcombine with any fitting having a male thread.Male thread of panel fitting extension is 1” long.Malleable iron.Male Enlargers*Dimensions (in.)Cat. No. Size A B C1245 1/2” to 3/4” 1-1/4 1-5/32 1/21246 3/4” to 1” 1-17/32 1-9/32 15/321244 1” to 1-1/4” 1-7/8 1-7/16 17/321247 1-1/4” to 1-1/2” 2-3/16 1-15/32 19/32For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.Adapt an outlet hole to the next larger size ofconduit. Rough ends of conduit carefully coveredby built-in bushing. Malleable iron.Adapt any outlet to the next smaller size ofconduit. Hex shoulder makes wrench tighteningconvenient. Malleable iron.Female Reducers*Dimensions (in.)Cat. No. Size A B C1250-TB 3/4” to 1/2” 1-1/8 5/8 3/161261 1” to 1/2” 1-7/16 1-7/16 3/161251 1” to 3/4” 1-3/8 11/16 3/161262 1-1/4” to 1/2” 1-13/16 21/32 3/161263 1-1/4” to 3/4” 1-13/16 23/32 3/161252 1-1/4” to 1” 1-3/4 25/32 7/321253 1-1/2” to 1-1/4” 2 13/16 1/41254 2” to 1-1/2” 2-3/8 1-3/16 9/321255 2-1/2” to 2” 3 1-1/4 3/81256 3” to 2-1/2” 3-5/8 1-1/2 1/21257 3-1/2” to 3” 4-1/8 1-9/16 1/21258 4” to 3-1/2” 4-5/8 1-3/16 1/2For Dura-Plate finish, add prefix 040- to Cat. No. Consult Customer Service for details.39

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>For reducing the threaded opening in conduitbodies or any female threaded fitting. Smooth,built-in bushing completely covers rough endsof conduit. Iron or steel construction. Steel from600-TB thru 606-TB, also 614 & 615.Threaded ReducersCat. No.Dimensions (in.)Stl. or M.I. Alum. Size A600-TB 600AL-TB 1/2” to 3/8” 5/8601-TB 601AL-TB 3/4” to 1/2” 19/32602-TB 602AL-TB 1” to 1/2” 19/32603-TB 603AL-TB 1” to 3/4” 19/32604-TB 604AL-TB 1-1/4” to 1/2” 19/32605-TB 605AL 1-1/4” to 3/4” 19/32606-TB 606AL 1-1/4” to 1” 11/16607 607AL 1-1/2” to 1/2” 15/16608 608AL 1-1/2” to 3/4” 15/16609 609AL 1-1/2” to 1” 1-3/32610 610AL 1-1/2” to 1-1/4” 27/32611-TB 611AL 2” to 1/2” 23/32612 612AL 2” to 3/4” 1-1/16613 613AL 2” to 1” 1-1/16614-TB 614AL 2” to 1-1/4” 1-1/16615-TB 615AL 2” to 1-1/2” 27/32Washers reduce knockout hole in outlet box.Newly designed of galvanized steel. Thesewashers, used in pairs, interlock and form a ribwhich centers the washers and conduit in theknockout.Reducing WashersDimensions (in.)Cat. No. Size A B3700 3/4” to 3/8” 1-3/8 45/643701 3/4” to 1/2” 1-3/8 7/83702 1” to 3/8” 1-5/8 45/643703 1” to 1/2” 1-5/8 7/83704 1” to 3/4” 1-5/8 1-3/323705-TB 1-1/4” to 3/8” 2 45/643706 1-1/4” to 1/2” 2 7/83707 1-1/4” to 3/4” 2 1-3/323708 1-1/4” to 1” 2 1-23/643709 1-1/2” to 3/8” 2-1/4 45/643710 1-1/2” to 1/2” 2-1/4 7/83711 1-1/2” to 3/4” 2-1/4 1-3/323712 1-1/2” to 1” 2-1/4 1-23/643713 1-1/2” to 1-1/4” 2-1/4 1-23/323714 2” to 1/2” 2-3/4 7/83715-TB 2” to 3/4” 2-3/4 1-3/323716 2” to 1” 2-3/4 1-23/643717 2” to 1-1/4” 2-3/4 1-23/323718 2” to 1-1/2” 2-3/4 1-31/3240

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong><strong>Conduit</strong> Straps(For Rigid Metal <strong>Conduit</strong> and Intermediate Metal <strong>Conduit</strong>)1275 Series1276AL Series<strong>Conduit</strong>Strap<strong>Conduit</strong><strong>Conduit</strong>SpacerSupportingWallApplication• To support and securely fasten rigidmetal conduit and intermediate metalto the supporting surface.Features• Rugged malleable iron/copper-freealuminum construction—snugly fitson the conduit.• Designed to prevent accumulation ofmoisture and start of corrosion onvertical run of conduit (A).Standard Material1275 SeriesMalleable Iron1976AL SeriesAll copper-freealuminumStandard Finish1275 SeriesHot Dipped Galvanized1276AL SeriesAs CastRange• 1275 Series3/8” through 6” conduit• 1276AL Series1/2” through 6” conduitConformityCSA C22.2 No. 18ANSI C80.4NFPA 70-2002 (ANSI)ADesigned to fit each size of conduit snugly. Highreinforcing ribs on each side increase strength,reduce weight. Hot-dipped galvanized finish.CBPipe Straps—Malleable Iron or AluminumCat. No. Dimensions (in.) ScrewMal. Iron Alum. Size A B C Size1275 † 1275AL 3/8” 1-15/16” 19/32” 1/4” 1/4”1276 † 1276AL † 1/2” 2-11/32” 23/32” 1/2” 1/4”1277 † 1277AL † 3/4” 2-11/16” 21/32” 5/8” 1/4”1278 † 1278AL † 1” 3-3/32” 11/16” 13/16” 1/4”1279 † 1279AL † 1-1/4” 4-1/8” 13/16” 29/32” 5/16”1280 † 1280AL 1-1/2” 4-1/2” 15/16” 1-17/32” 3/8”1281 1281AL 2” 5-3/16” 1-1/8” 1-1/4” 7/16”1282* 1282AL 2-1/2” 5 -15/16” 1-1/2” 1-3/4” 1/2”1283* 1283AL 3” 6-11/16” 1-5/8” 2-3/16” 1/2”1284 1284AL 3-1/2” 7-19/32” 1-3/4” 2-3/4” 5/8”1285* 1285AL 4” 8-5/16” 1-7/8” 2-13/16” 5/8”1286** 1286AL** 4-1/2” 9-3/16” 1-15/16” 2-15/16” 5/8”1287 1287AL 5” 9-15/16” 2” 3-1/4” 5/8”1288 1288AL 6” 11-1/2” 2-7/16” 4-1/8” 5/8”* May be used with EMT of same size.†Not snap on type.U.L. not applicable.** Not CSA Certified41

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong>CAElongated bolt hole makes alignment easy, evenwhen holes in mounting surface are off center.Snap on features. Steel. Zinc platedBPipe Straps—Steel<strong>Conduit</strong> Dimensions (in.) ScrewCat. No. Size A B C Size1210C † 3/8” 1-15/32 3/4 11/16 1/4”1211C 1/2” 2 3/4 15/16 1/4”1212C 3/4” 2-5/16 3/4 1” 1/4”1213C 1” 3-13/16 3/4 1-17/64 1/4”1214TB* 1-1/4” 2-31/32 1-9/16 1-9/16 3/8”1215TB* 1-1/2” 3-23/32 1-13/16 1-13/16 3/8”1216TB* 2” 4-7/16 2-5/16 2-5/16 3/8”†Not snap on type.U.L. not applicable.* Not CSA Certified.ABMalleable iron. Designed to fit each size ofconduit snugly. High reinforcing ribs on eachside increase strength, reduce weight.CCorrosion Resistant PVC Coated Rigid <strong>Conduit</strong> StrapsBoltDimensions (in.)Cat. No. Size Size A B C1275CR 3/8” 1/4” 2 21/32 1/41276CR 1/2” 1/4” 2-13/32 25/32 1/21277CR 3/4” 1/4” 2-3/4 23/32 5/81278CR 1” 1/4” 3-5/32 3/4 13/161279CR 1-1/4” 3/8” 4-5/32 25/32 7/81280CR 1-1/2” 3/8” 4-9/16 1 1-7/321281CR 2” 1/2” 5-1/4 1-3/16 1-1/4U.L. not applicable.42

T&B <strong>Conduit</strong> <strong>Fittings</strong>Rigid and Intermediate Metal <strong>Conduit</strong> <strong>Fittings</strong><strong>Conduit</strong> Spacers(For Rigid Metal <strong>Conduit</strong>, Intermediate Metal <strong>Conduit</strong> and Electrical Metallic Tubing)1350 Series1350AL SeriesApplication• Provides mounting surface forconduit where installation requiresair space between conduit andsupporting surface.Features• Prevents conduit rusting from wallcondensation.• Spacers can be stacked one atopthe other facilitating installation andeliminating expensive conduit offsetting (A).• Designed to cover wide range;marked with accurate size markingfor proper positioning (B).Standard Material1350 SeriesMalleable Iron1350AL SeriesCopper-free aluminumStandard Finish1350 SeriesHot Dipped Galvanized1350AL SeriesAs CastRange1/2” through 6” conduitConformityCSA C22.2 No. 18ANSI C80.4NFPA 70-2002 (ANSI)43