- Page 2 and 3:

Chapter1An Introduction toAdhesive

- Page 4 and 5:

An Introduction to Adhesives and Se

- Page 6 and 7:

An Introduction to Adhesives and Se

- Page 8 and 9:

An Introduction to Adhesives and Se

- Page 10 and 11:

An Introduction to Adhesives and Se

- Page 12 and 13:

An Introduction to Adhesives and Se

- Page 14 and 15:

An Introduction to Adhesives and Se

- Page 16 and 17:

An Introduction to Adhesives and Se

- Page 18 and 19:

An Introduction to Adhesives and Se

- Page 20 and 21:

An Introduction to Adhesives and Se

- Page 22 and 23:

21Production AspectsJoint preparati

- Page 24 and 25:

An Introduction to Adhesives and Se

- Page 26 and 27:

An Introduction to Adhesives and Se

- Page 28 and 29:

An Introduction to Adhesives and Se

- Page 30 and 31:

An Introduction to Adhesives and Se

- Page 32 and 33:

An Introduction to Adhesives and Se

- Page 34 and 35:

An Introduction to Adhesives and Se

- Page 36 and 37:

An Introduction to Adhesives and Se

- Page 38 and 39:

An Introduction to Adhesives and Se

- Page 40 and 41:

An Introduction to Adhesives and Se

- Page 42 and 43:

An Introduction to Adhesives and Se

- Page 44 and 45:

An Introduction to Adhesives and Se

- Page 46 and 47:

An Introduction to Adhesives and Se

- Page 48 and 49:

An Introduction to Adhesives and Se

- Page 50 and 51:

Chapter2Theories of Adhesion2.1 Int

- Page 52 and 53:

Theories of Adhesion 51TABLE 2.1For

- Page 54 and 55:

Theories of Adhesion 53surface ener

- Page 56 and 57:

Theories of Adhesion 551.0015Cosine

- Page 58 and 59:

Theories of Adhesion 57W Experiment

- Page 60 and 61:

Theories of Adhesion 59not result i

- Page 62 and 63:

Theories of Adhesion 61For poor wet

- Page 64 and 65:

Theories of Adhesion 63example the

- Page 66 and 67:

Theories of Adhesion 65cohesive rup

- Page 68 and 69:

Theories of Adhesion 67The result o

- Page 70 and 71:

Theories of Adhesion 69served betwe

- Page 72 and 73:

Theories of Adhesion 71Figure 2.11

- Page 74 and 75:

Theories of Adhesion 73Polyamide-Im

- Page 76 and 77:

Theories of Adhesion 75TABLE 2.3 Sh

- Page 78 and 79:

Theories of Adhesion 77Creep can oc

- Page 80 and 81:

Theories of Adhesion 79was exceeded

- Page 82 and 83:

Theories of Adhesion 81Figure 2.17

- Page 84 and 85:

Theories of Adhesion 83Favorable su

- Page 86 and 87:

Theories of Adhesion 85Figure 2.19

- Page 88 and 89:

Theories of Adhesion 87Figure 2.21

- Page 90 and 91:

Theories of Adhesion 89Figure 2.23

- Page 92:

Theories of Adhesion 9118. Perry, H

- Page 95 and 96:

94 Chapter Threebution analysis wil

- Page 97 and 98:

96 Chapter ThreeCompression loads a

- Page 99 and 100:

98 Chapter ThreeUnits of peel or cl

- Page 101 and 102:

100 Chapter Threeommended for bondi

- Page 103 and 104:

102 Chapter ThreeFigure 3.5 Effect

- Page 105 and 106:

104 Chapter ThreeFigure 3.8 Interre

- Page 107 and 108:

106 Chapter ThreeFigure 3.9Butt joi

- Page 109 and 110:

108 Chapter ThreeFigure 3.11 Shear

- Page 111 and 112:

110 Chapter ThreeFigure 3.14 Minimi

- Page 113 and 114:

112 Chapter ThreeFigure 3.16 Design

- Page 115 and 116:

114 Chapter Three3.5.5 Plastic and

- Page 117 and 118:

116 Chapter ThreeFigure 3.20 End jo

- Page 119 and 120:

118 Chapter Threewill go into tensi

- Page 121 and 122:

120 Chapter ThreeA parabolic stress

- Page 123 and 124:

122 Chapter ThreeFigure 3.27 Moveme

- Page 125 and 126:

124 Chapter ThreeFigure 3.29 Compou

- Page 128 and 129:

Chapter4Standard Test Methods4.1 In

- Page 130 and 131:

Standard Test Methods 129standards

- Page 132 and 133:

Standard Test Methods 131TABLE 4.1

- Page 134 and 135:

Standard Test Methods 133TABLE 4.1

- Page 136 and 137:

Standard Test Methods 135TABLE 4.1

- Page 138 and 139:

Standard Test Methods 137TABLE 4.2

- Page 140 and 141:

Standard Test Methods 139Figure 4.1

- Page 142 and 143:

Standard Test Methods 141Tackiness

- Page 144 and 145:

Standard Test Methods 143A simple,

- Page 146 and 147:

Standard Test Methods 1454.4 Standa

- Page 148 and 149:

Standard Test Methods 147Figure 4.2

- Page 150 and 151:

Standard Test Methods 149Generally,

- Page 152 and 153:

Standard Test Methods 151Figure 4.5

- Page 154 and 155:

Standard Test Methods 153Figure 4.8

- Page 156 and 157:

Standard Test Methods 155Figure 4.1

- Page 158 and 159:

Standard Test Methods 157Figure 4.1

- Page 160 and 161:

Standard Test Methods 159Figure 4.1

- Page 162 and 163:

Standard Test Methods 161Figure 4.1

- Page 164 and 165:

Standard Test Methods 163Test Fixtu

- Page 166 and 167:

Standard Test Methods 165rate of 0.

- Page 168 and 169:

Standard Test Methods 167TABLE 4.6

- Page 170 and 171:

Standard Test Methods 169Figure 4.2

- Page 172 and 173:

Standard Test Methods 171Figure 4.2

- Page 174 and 175:

Standard Test Methods 173TABLE 4.7

- Page 176:

Standard Test Methods 175References

- Page 179 and 180:

178 Chapter Fivemeans to prevent pr

- Page 181 and 182:

180 Chapter FiveConformance to a sp

- Page 183 and 184:

182 Chapter Fivedatory. Checks shou

- Page 185 and 186:

184 Chapter Fivepart will be loaded

- Page 187 and 188:

186 Chapter FiveTABLE 5.3Visual Ins

- Page 189 and 190:

188 Chapter Five Contact through tr

- Page 191 and 192:

190 Chapter FiveThis method is appl

- Page 193 and 194:

192TABLE 5.5 Correlation of NDT Res

- Page 195 and 196:

194 Chapter Fivetion it is sometime

- Page 197 and 198:

196 Chapter Fiveanalysis is relativ

- Page 199 and 200:

198 Chapter Sixsurface with the com

- Page 201 and 202:

200 Chapter SixFigure 6.1 In an ide

- Page 203 and 204:

202 Chapter Sixcould also be proces

- Page 205 and 206:

204 Chapter Sixresulting bond stren

- Page 207 and 208:

206 Chapter Sixrelease films, such

- Page 209 and 210:

208 Chapter SixTABLE 6.1Effect of S

- Page 211 and 212:

210 Chapter Sixpreparations can ran

- Page 213 and 214:

212 Chapter SixTABLE 6.4 Surface Tr

- Page 215 and 216:

214 Chapter SixOn many nonporous su

- Page 217 and 218:

216 Chapter SixTABLE 6.6 Maximum Al

- Page 219 and 220:

218 Chapter Sixvents for cleaning s

- Page 221 and 222:

220 Chapter SixFigure 6.7 Represent

- Page 223 and 224:

222 Chapter Sixgallon of tap water

- Page 225 and 226:

224 Chapter SixDry abrasive blast c

- Page 227 and 228:

226 Chapter Sixtypes of grits are a

- Page 229 and 230:

228 Chapter SixTABLE 6.12Common Act

- Page 231 and 232:

230Receive AdherendsQuality Control

- Page 233 and 234:

232 Chapter Six6.5.1.1 Chemical tre

- Page 235 and 236:

234 Chapter Sixtablishing how much

- Page 237 and 238:

236 Chapter Sixthe adhesive is a po

- Page 239 and 240:

238 Chapter SixFigure 6.10 Basic ar

- Page 241 and 242:

240 Chapter Sixsurface. Molecular c

- Page 243 and 244:

242 Chapter Six6.13. Certain polyme

- Page 245 and 246:

244TABLE 6.13 Effect of Plasma Expo

- Page 247 and 248:

246 Chapter Sixtadiene elastomers.

- Page 249 and 250:

248TABLE 6.15 Comparison of Surface

- Page 251 and 252:

250 Chapter Six6.6.5 Other adherend

- Page 254 and 255:

Chapter7Primers and Adhesion Promot

- Page 256 and 257:

Primers and Adhesion Promoters 255s

- Page 258 and 259:

Primers and Adhesion Promoters 257s

- Page 260 and 261:

Primers and Adhesion Promoters 259p

- Page 262 and 263:

Primers and Adhesion Promoters 261F

- Page 264 and 265:

Primers and Adhesion Promoters 263E

- Page 266 and 267:

Primers and Adhesion Promoters 265m

- Page 268 and 269:

Primers and Adhesion Promoters 267a

- Page 270 and 271:

Primers and Adhesion Promoters 269a

- Page 272 and 273:

Primers and Adhesion Promoters 271T

- Page 274 and 275:

Primers and Adhesion Promoters 273I

- Page 276 and 277:

275Titanate orApplications/Zirconat

- Page 278 and 279:

Primers and Adhesion Promoters 277m

- Page 280 and 281:

Chapter8Adhesive Classifications8.1

- Page 282 and 283:

Adhesive Classifications 281cals. H

- Page 284 and 285:

Adhesive Classifications 283Figure

- Page 286 and 287:

Adhesive Classifications 285tempera

- Page 288 and 289:

Adhesive Classifications 287CTBN Di

- Page 290 and 291:

Adhesive Classifications 289charact

- Page 292 and 293:

Adhesive Classifications 291are the

- Page 294 and 295:

293TABLE 8.4b Properties of the Fiv

- Page 296 and 297:

Adhesive Classifications 295Figure

- Page 298 and 299:

Adhesive Classifications 297toiniti

- Page 300 and 301:

Adhesive Classifications 299Figure

- Page 302 and 303:

Adhesive Classifications 301removed

- Page 304 and 305:

303TABLE 8.7 Properties and Charact

- Page 306 and 307:

Adhesive Classifications 305only a

- Page 308 and 309:

Adhesive Classifications 307ness of

- Page 310 and 311:

Adhesive Classifications 309 One pa

- Page 312 and 313:

Adhesive Classifications 311strengt

- Page 314 and 315:

Adhesive Classifications 313the art

- Page 316 and 317:

Adhesive Classifications 3158.2.4.4

- Page 318:

Adhesive Classifications 3178. Davi

- Page 321 and 322:

320 Chapter Ninewithout the additio

- Page 323 and 324:

322 Chapter NineAn ingredient added

- Page 325 and 326:

324 Chapter Nineformulation, plasti

- Page 327 and 328:

326 Chapter Ninethe properties that

- Page 329 and 330:

328 Chapter NineTABLE 9.3Thixotropi

- Page 331 and 332:

330 Chapter Nineproperties in the c

- Page 333 and 334:

332 Chapter NineFigure 9.3 Lap shea

- Page 335 and 336:

334 Chapter NineFigure 9.4 The coef

- Page 337 and 338:

336 Chapter Ninewhereas the base po

- Page 339 and 340:

338 Chapter Ninetivity drops drasti

- Page 341 and 342:

340 Chapter Ninebefore he can make

- Page 344 and 345:

Chapter10Adhesives Families10.1 Int

- Page 346 and 347:

345Elastomeric resinsNatural rubber

- Page 348 and 349:

347Epoxy Two-part liquid orpaste; o

- Page 350 and 351:

349Polyvinyl acetals Solvent soluti

- Page 352 and 353:

351StyrenebutadieneSolvent solution

- Page 354 and 355:

353Vinyl-phenolic Solvent solutions

- Page 356 and 357:

Adhesives Families 355Elastomeric a

- Page 358 and 359:

357TABLE 10.6 Properties of Selecte

- Page 360 and 361:

Adhesives Families 359Figure 10.1 C

- Page 362 and 363:

Adhesives Families 361Cycloaliphati

- Page 364 and 365:

363TABLE 10.8 Characteristics of Cu

- Page 366 and 367:

Adhesives Families 365Epoxy Ring -

- Page 368 and 369:

Adhesives Families 367Properties an

- Page 370 and 371:

Adhesives Families 369TABLE 10.10Si

- Page 372 and 373:

Adhesives Families 371caulking comp

- Page 374 and 375:

Adhesives Families 373mulation. Tem

- Page 376 and 377:

Adhesives Families 375applied as a

- Page 378 and 379:

Adhesives Families 377properties, n

- Page 380 and 381:

379TABLE 10.14 Suppliers of Selecte

- Page 382 and 383:

Adhesives Families 381BMI adhesives

- Page 384 and 385:

Adhesives Families 383(TDI) or meth

- Page 386 and 387:

Adhesives Families 385tics. Since t

- Page 388 and 389:

387Polyurethane22005 Swift 1 part;m

- Page 390 and 391:

Adhesives Families 389They have goo

- Page 392 and 393:

Adhesives Families 391TABLE 10.17 T

- Page 394 and 395:

Adhesives Families 393applications

- Page 396 and 397:

Adhesives Families 395truly non-str

- Page 398 and 399:

Adhesives Families 397an additive f

- Page 400 and 401:

Adhesives Families 399tained in the

- Page 402 and 403:

Adhesives Families 401TABLE 10.19 E

- Page 404 and 405:

Adhesives Families 403metal foil. T

- Page 406 and 407:

Adhesives Families 405TABLE 10.21 A

- Page 408 and 409:

Adhesives Families 407by crosslinki

- Page 410 and 411:

Adhesives Families 409perature rang

- Page 412 and 413:

Adhesives Families 411ature and set

- Page 414 and 415:

Adhesives Families 4132. Hull, C. G

- Page 416 and 417:

Chapter11Selection of Adhesives11.1

- Page 418 and 419:

Selection of Adhesives 417of these

- Page 420 and 421:

Selection of Adhesives 419can also

- Page 422 and 423:

Selection of Adhesives 421 Inflamma

- Page 424 and 425:

Selection of Adhesives 423with the

- Page 426 and 427:

Selection of Adhesives 425dimension

- Page 428 and 429:

427Phenol formaldehyde .......... 2

- Page 430 and 431:

Selection of Adhesives 429Such stre

- Page 432 and 433:

431TABLE 11.2 Properties of Structu

- Page 434 and 435:

Selection of Adhesives 433TABLE 11.

- Page 436 and 437:

Selection of Adhesives 435more diff

- Page 438 and 439:

Selection of Adhesives 43711.4.4.2

- Page 440 and 441:

Selection of Adhesives 439ness, or

- Page 442 and 443:

Selection of Adhesives 44111.6.1 Na

- Page 444 and 445:

44320. Vinyl vinylidene ...........

- Page 446 and 447:

Selection of Adhesives 445 The degr

- Page 448 and 449:

Selection of Adhesives 447organic a

- Page 450:

Selection of Adhesives 449ture, tem

- Page 453 and 454:

452 Chapter Twelvesealant materials

- Page 455 and 456:

454TABLE 12.2 Hardening Sealants, N

- Page 457 and 458:

456 Chapter Twelvecapability in cer

- Page 459 and 460:

458 Chapter Twelveused in high volu

- Page 461 and 462:

460 Chapter TwelveTABLE 12.4 Typica

- Page 463 and 464:

462TABLE 12.5 Application Character

- Page 465 and 466:

464 Chapter TwelveTABLE 12.6Sealant

- Page 467 and 468:

466 Chapter Twelve12.3.2 SolventsSo

- Page 469 and 470:

468 Chapter Twelveresins and mercap

- Page 471 and 472:

470 Chapter TwelveTABLE 12.9 Proper

- Page 473 and 474:

472 Chapter Twelve12.4.2 Performanc

- Page 475 and 476:

474 Chapter Twelvestructural glazin

- Page 477 and 478:

476 Chapter ThirteenTABLE 13.1 Char

- Page 479 and 480:

478TABLE 13.2 Summary of Sealant Pr

- Page 481 and 482:

480TABLE 13.3 Summary of Sealant Pr

- Page 483 and 484:

482 Chapter Thirteen13.2.2 Asphalti

- Page 485 and 486:

484 Chapter Thirteenpounds. They ha

- Page 487 and 488:

486 Chapter ThirteenPolyisobutylene

- Page 489 and 490:

488 Chapter ThirteenThey are often

- Page 491 and 492:

490 Chapter Thirteennents is critic

- Page 493 and 494:

492 Chapter ThirteenTABLE 13.7 Cons

- Page 495 and 496:

494 Chapter ThirteenTABLE 13.8 Typi

- Page 497 and 498:

496 Chapter Thirteentions in buildi

- Page 499 and 500:

498 Chapter Thirteenas a hot melt,

- Page 502 and 503:

Chapter14Selecting and Using Sealan

- Page 504 and 505:

Selecting and Using Sealants 503Typ

- Page 506 and 507:

Selecting and Using Sealants 505 In

- Page 508 and 509:

Selecting and Using Sealants 507Fig

- Page 510 and 511:

Selecting and Using Sealants 509Fig

- Page 512 and 513:

Selecting and Using Sealants 511ket

- Page 514 and 515:

Selecting and Using Sealants 513TAB

- Page 516 and 517:

Selecting and Using Sealants 515may

- Page 518 and 519:

Selecting and Using Sealants 517eth

- Page 520 and 521:

Selecting and Using Sealants 51914.

- Page 522 and 523:

Selecting and Using Sealants 521Fig

- Page 524 and 525:

Selecting and Using Sealants 523acc

- Page 526 and 527:

Selecting and Using Sealants 525pli

- Page 528 and 529:

527TABLE 14.5 Comparison of Various

- Page 530 and 531:

Selecting and Using Sealants 529TAB

- Page 532 and 533:

Selecting and Using Sealants 531aft

- Page 534 and 535:

Selecting and Using Sealants 533TAB

- Page 536:

Selecting and Using Sealants 535pro

- Page 539 and 540:

538 Chapter Fifteencesses in indust

- Page 541 and 542:

540 Chapter FifteenTABLE 15.1 Typic

- Page 543 and 544:

542 Chapter FifteenTABLE 15.2 Typic

- Page 545 and 546:

544TABLE 15.3 Assembly Methods for

- Page 547 and 548:

546TABLE 15.4 Bonding or Joining Pl

- Page 549 and 550:

548TABLE 15.4 Bonding or Joining Pl

- Page 551 and 552:

550 Chapter FifteenThis method is o

- Page 553 and 554:

552 Chapter FifteenTABLE 15.5 Hot P

- Page 555 and 556:

554 Chapter FifteenFigure 15.2 Hot

- Page 557 and 558:

556 Chapter FifteenFigure 15.4 Conv

- Page 559 and 560:

558 Chapter FifteenLike hot plate w

- Page 561 and 562:

560 Chapter Fifteenable precautions

- Page 563 and 564:

562 Chapter FifteenFigure 15.6 Sche

- Page 565 and 566:

564 Chapter Fifteen Heat damage, di

- Page 567 and 568:

566 Chapter Fifteen15.6 Friction We

- Page 569 and 570:

568 Chapter Fifteenwill see higher

- Page 571 and 572:

570 Chapter FifteenFigure 15.9 Stag

- Page 573 and 574:

572 Chapter FifteenTABLE 15.9 Compa

- Page 575 and 576:

574 Chapter FifteenFigure 15.12 Ult

- Page 577 and 578:

576 Chapter Fifteenwelded. Vibratio

- Page 579 and 580:

578 Chapter Fifteenvent diffuses in

- Page 581 and 582:

580 Chapter Fifteenmay be immersed

- Page 583 and 584:

582 Chapter FifteenFigure 15.15 Mec

- Page 585 and 586:

584 Chapter Fifteenfor the body of

- Page 587 and 588:

586 Chapter FifteenFigure 15.18 Pus

- Page 589 and 590:

588 Chapter Fifteentemperature cycl

- Page 591 and 592:

590 Chapter Fifteenvibration weldin

- Page 594 and 595:

Chapter16Bonding and SealingSpecifi

- Page 596 and 597:

Bonding and Sealing Specific Substr

- Page 598 and 599:

Bonding and Sealing Specific Substr

- Page 600 and 601:

Bonding and Sealing Specific Substr

- Page 602 and 603:

601TABLE 16.1 Effect of Surface Tre

- Page 604 and 605:

Bonding and Sealing Specific Substr

- Page 606 and 607:

Bonding and Sealing Specific Substr

- Page 608 and 609:

Bonding and Sealing Specific Substr

- Page 610 and 611:

Bonding and Sealing Specific Substr

- Page 612 and 613:

Bonding and Sealing Specific Substr

- Page 614 and 615:

Bonding and Sealing Specific Substr

- Page 616 and 617:

Bonding and Sealing Specific Substr

- Page 618 and 619:

Bonding and Sealing Specific Substr

- Page 620 and 621:

Bonding and Sealing Specific Substr

- Page 622 and 623:

Bonding and Sealing Specific Substr

- Page 624 and 625:

Bonding and Sealing Specific Substr

- Page 626 and 627:

Bonding and Sealing Specific Substr

- Page 628 and 629:

Bonding and Sealing Specific Substr

- Page 630 and 631:

629TABLE 16.3 The Effect of Thermal

- Page 632 and 633:

Bonding and Sealing Specific Substr

- Page 634 and 635:

Bonding and Sealing Specific Substr

- Page 636 and 637:

Bonding and Sealing Specific Substr

- Page 638 and 639: Bonding and Sealing Specific Substr

- Page 640 and 641: Bonding and Sealing Specific Substr

- Page 642 and 643: Bonding and Sealing Specific Substr

- Page 644 and 645: 643EA913 .... ... X X PartB 100:12

- Page 646 and 647: 645TABLE 16.10 Tensile Strength of

- Page 648 and 649: Bonding and Sealing Specific Substr

- Page 650 and 651: Bonding and Sealing Specific Substr

- Page 652 and 653: Bonding and Sealing Specific Substr

- Page 654 and 655: Bonding and Sealing Specific Substr

- Page 656 and 657: Bonding and Sealing Specific Substr

- Page 658 and 659: Bonding and Sealing Specific Substr

- Page 660 and 661: 659TABLE 16.17 Common Adhesives tha

- Page 662 and 663: Bonding and Sealing Specific Substr

- Page 664 and 665: Bonding and Sealing Specific Substr

- Page 666 and 667: Bonding and Sealing Specific Substr

- Page 668 and 669: 667TABLE 16.20 ASTM Designation of

- Page 670 and 671: Bonding and Sealing Specific Substr

- Page 672 and 673: Bonding and Sealing Specific Substr

- Page 674 and 675: Bonding and Sealing Specific Substr

- Page 676 and 677: 675TABLE 16.22 Description and Use

- Page 678 and 679: Bonding and Sealing Specific Substr

- Page 680 and 681: Bonding and Sealing Specific Substr

- Page 682 and 683: Bonding and Sealing Specific Substr

- Page 684: Bonding and Sealing Specific Substr

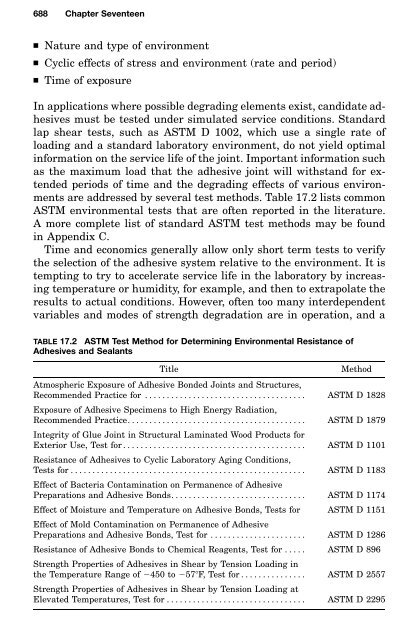

- Page 687: 686TABLE 17.1 Relative Resistance o

- Page 691 and 692: 690 Chapter Seventeenlowered by ele

- Page 693 and 694: 692 Chapter Seventeenof oxidation b

- Page 695 and 696: 694TABLE 17.4 Properties of High Te

- Page 697 and 698: 696 Chapter SeventeenFigure 17.3 Co

- Page 699 and 700: 698 Chapter Seventeenhesives lose m

- Page 701 and 702: 700 Chapter Seventeenderivative, FM

- Page 703 and 704: 702 Chapter Seventeentemperatures a

- Page 705 and 706: 704 Chapter Seventeensuch as 40F to

- Page 707 and 708: 706 Chapter SeventeenCommercially a

- Page 709 and 710: 708 Chapter SeventeenTABLE 17.6 Per

- Page 711 and 712: 710 Chapter SeventeenFigure 17.7 Hy

- Page 713 and 714: 712 Chapter Seventeendisplacing the

- Page 715 and 716: 714 Chapter SeventeenThis effect wa

- Page 717 and 718: 716TABLE 17.10 Comparison of Long T

- Page 719 and 720: 718 Chapter SeventeenFigure 17.12 E

- Page 721 and 722: 720 Chapter SeventeenTABLE 17.13 Ef

- Page 723 and 724: 722 Chapter Seventeen4. Acetic acid

- Page 725 and 726: 724 Chapter SeventeenFigure 17.14do

- Page 727 and 728: 726 Chapter Seventeen34. Minford, J

- Page 729 and 730: 728 Chapter Eighteenity. The simple

- Page 731 and 732: 730 Chapter EighteenFigure 18.2 Inc

- Page 733 and 734: 732 Chapter Eighteen18.3 Preparing

- Page 735 and 736: 734 Chapter EighteenFigure 18.4 Sev

- Page 737 and 738: 736 Chapter Eighteendriven mixer. F

- Page 739 and 740:

738 Chapter Eighteenhead to rise an

- Page 741 and 742:

740TABLE 18.1 Characteristics of Va

- Page 743 and 744:

742 Chapter Eighteenreaching areas

- Page 745 and 746:

744 Chapter EighteenKiss Roll Coate

- Page 747 and 748:

746 Chapter Eighteen18.4.2 Pastes a

- Page 749 and 750:

748 Chapter EighteenFilm material c

- Page 751 and 752:

750 Chapter Eighteen Solvent reacti

- Page 753 and 754:

752 Chapter Eighteen Ease of pressu

- Page 755 and 756:

754 Chapter EighteenFigure 18.13 Le

- Page 757 and 758:

756 Chapter Eighteenibility, and th

- Page 760 and 761:

Chapter19Information Technology19.1

- Page 762 and 763:

Information Technology 761sion trad

- Page 764 and 765:

Information Technology 763The user