Sirius_en_cn_042012 - Savio SPA

Sirius_en_cn_042012 - Savio SPA

Sirius_en_cn_042012 - Savio SPA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

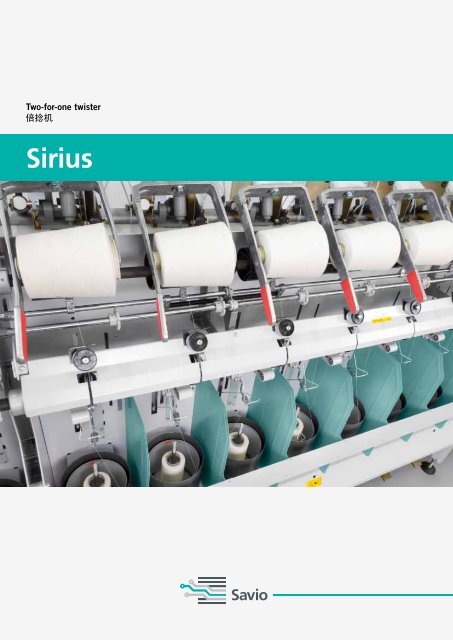

<strong>Sirius</strong><strong>Sirius</strong> Thinking Global, Acting localMiddle and Far East countries, that constitute the key Markets for Two for one Twisters, are today showing requirem<strong>en</strong>ts thatuntil now have characterized the “Traditional” western markets.The new needs are diverse, not only among each Market area, but also throughout a single Market.The main requirem<strong>en</strong>t is to reduce workforce, which is becoming, day by day, more and more difficult to find, ev<strong>en</strong> if its costsare still strongly competitive if compared with the western markets.Moreover, apart from the need to reduce the initial investm<strong>en</strong>t costs as well as power consumption, a great number ofCompanies keep asking for products which can grant low maint<strong>en</strong>ance times and costs.To meet those new requests, sometimes in contradiction one with each other, <strong>Savio</strong> has developed its brand new Two for OneTwisters g<strong>en</strong>eration, <strong>Sirius</strong>, that is able to solve all the problems m<strong>en</strong>tioned above.The main features of our new machine are:• An high structural standardization for all the diverse models.• A wide range both for feeding and spindle dim<strong>en</strong>sions for every yarn type and count.• A great optional offer, available for all the differ<strong>en</strong>t machine versions.• “Electronic” solutions and simplified maint<strong>en</strong>ance to reduce the workforce needed for each machine.In other words, with its new Two for One Twister, <strong>Sirius</strong>, <strong>Savio</strong> met the objective to put together needs that, until today, appearedto be alternative, offering a competitive global machine, that can, at the same time, be fitted according the local needs of eachsingle market and cli<strong>en</strong>t, finding a “Third Way” melting global and local approach.2 3

<strong>Sirius</strong>The spindle<strong>Sirius</strong> has be<strong>en</strong> realized tosupport the <strong>en</strong>tire <strong>Savio</strong> spindlerange.The main objective ofthe innovative spindlemanufacturing way is tooptimize its integration withinthe machine structure.The main features of spindlesare:• Life lubricated top bearings,with special dustproofprotection.• Bigger whorl diameter, forB & C spindles types, toreduce belt load on thespindle bearings; this systemguarantees twist ev<strong>en</strong>ness.• Stainless steel plate andcomp<strong>en</strong>sating pulley inaluminum with a ceramiccoating, with optimized shapethat guarantees less powerabsorption and maximumfeeding cont<strong>en</strong>t.• Yarn t<strong>en</strong>sioning withinterchangeable springpistons for differ<strong>en</strong>t countsand materials.• T<strong>en</strong>sion can be adjusted with6 differ<strong>en</strong>t positions.• High flexibility thanks to quicktransformation from free tocontrolled balloon.ARR AR A BR B C4 5

<strong>Sirius</strong>Compact tang<strong>en</strong>tial driveEncased tang<strong>en</strong>tial drive andmotorisation system to reduc<strong>en</strong>oise, keeping free from dustand lint.Headstock gears Twist control• Twist variation by means ofdrive pulleys positioned at thefront for easy access.• Mechanical change of S/Ztwist variation.Control unit with display for:• Spindle speed• Twists number• Take-up speed• Motor power absorption(Ampere)• Time counter• Yarn l<strong>en</strong>gth meter forprogrammed machine stopGearbox• Mechanical modulation,by means of gear pairs, forantiribboning effect.• Cross winding angle variationby means of gear pairs.• Oil lubricated top gearboxwith oil level indicatorand pilot light to check oilcirculation pump operation.6 7

<strong>Sirius</strong>Package cradleThe package cradle, specificallydesigned to perform a simplemanual package doffing, isequipped with:• Mechanical counterweightwith 4 adjustm<strong>en</strong>t possibilities(1 spring, 1 OPT). Settingrequires no tools.• Antivibration device (anadjustable friction disk) tooptimize package formationand eliminate packagevibration ev<strong>en</strong> at high take-upspeed.Mechanical counterweighingDamping device8 9

<strong>Sirius</strong>The Duo Pot system / Twin-ThreadingThe true direct twisting frame.All-in-one assembling andtwistingDirect feeding with standardconical packages 2x1°30’ -2x3°30’ - 2x4°20’ -2x5°57’The main characteristics ofthe new system is the separatedirections of the two yarns thatonly join at the point of controlof the t<strong>en</strong>sion.AdvantagesFormat standardisation. Thesystem uses standard packages1°30’ - 3°30’ - 4°20’ - 5°57 witha 152 mm traverse. Minimumdiameter on tube nose is 28mm.Production increaseHigher speed.Reduced breaks.Reduced yarn waste.Improved qualitySeparate unwinding of the two<strong>en</strong>ds.T<strong>en</strong>sion ev<strong>en</strong>ness.No knots, tangles or ravels.FlexibilityUse of yarns which differ incount, material and colour.Upper and lower yarn packagebrakeA pat<strong>en</strong>ted device brakes theunwinding of the lower packagein case of upper yarn break.This avoids that single lowerpackage yarn continues to betwisted.Like the traditional system, it involvesa few simple operations, and, thanks toits pedal control, pneumatic threadingis extremely fast.10 11

<strong>Sirius</strong><strong>Sirius</strong> Electronic Drive SystemThe two for one twisters markets are more and more asking for a strong reduction in work force, especially in those areas, likeChina and other Far East countries, still characterized by competitive labor costs.To meet customers’ requirem<strong>en</strong>ts, <strong>Savio</strong> has developed <strong>Sirius</strong> Electronic Drive System, the innovative system available on ourbrand new two for one Twister <strong>Sirius</strong>.<strong>Sirius</strong> Electronic Drive System allows customers to set all the working parameters via PC.The main impact of this innovation is to decrease strongly the machine set-up time, thus reducing the number of operators foreach machine, while introducing a simple and direct way to change any setting.Moreover, the new system allows to change settings continuously and not “step by step”, as in the mechanical version, allowingcustomers to try any parameters combination, in order to obtain the best results.<strong>Sirius</strong> Electronic Drive System springs out from our great R&D activity, melted with the requirem<strong>en</strong>ts and issues of all ourcustomers in every working field.14 15

<strong>Sirius</strong>The innovative technologyThe Electronic Drive Systemuses 3 indep<strong>en</strong>d<strong>en</strong>t motors todrive, respectively:• Spindles• Take-Up (overfeed and drums)• Thread-guideAn electrical control links thespeed ratio among the variousmotors, guaranteeing, in anymom<strong>en</strong>t, the twists ev<strong>en</strong>ess,both during normal runningconditions and start/stop phases.• The main motor exclusivelydrives the spindles, and is theb<strong>en</strong>chmark for the other twomotors• A brushless motor controlsdrums and overfeed• Another brushless motordrives the tread-guideThe link among all the motors ismaintained also in brown out /black out cases.Wh<strong>en</strong> such cases occur,the spindle motor works asg<strong>en</strong>erator, supplying the powerneeded to feed the take-up andthread-guide motors, reducingprogressively their speed untilthe complete stop.The twist ev<strong>en</strong>ess is, thus,granted also in case of brownout / black out.16 17

<strong>Sirius</strong>AdvantagesThe new Electronic DriveSystem allows to set via PC anyworking parameter, introducingan important flexibility elem<strong>en</strong>t,that will drastically reduce bothset-up times and labor forcerequirem<strong>en</strong>ts.In particular, is possible to set:• Spindle Speed• Twist number and direction(S/Z)• Winding angle• Modulation (antiribboning)• Thread-guide traverse• Axial displacem<strong>en</strong>t• Variable bunching l<strong>en</strong>gthMoreover the thread-guideelectronic control allows to setnot only traverse and windingangle, but also the yarndistribution over the package,thus improving design andformation, optimizing all thedownstream processes.Electronic Drive System allowscustomers to choose, among thediverse package shape:• Standard packages• “Pineapple” packages• Rounded-edge packagesThis system includes axialdisplacem<strong>en</strong>t, realized by theelectronic thread-guide control,that allows the yarn distributionover package edges, to obtain a“Customized” Package design.The bunching l<strong>en</strong>gth is settableby the PC, as well as its positionon the package tube.The working parameters canbe varied continuously and notany more “step by step”, thusallowing our customers to obtainthe best results, both in termsof working speed and packageformation.As consequ<strong>en</strong>ce, maint<strong>en</strong>ance isdrastically reduced if comparedwith standard version.18 19

<strong>Sirius</strong>Possible working rangeFeedingRecom<strong>en</strong>ded working rangePossible working rangeSpindle ARRF / ARRFcotton /201ARRFcotton/polyester-polyester-bl<strong>en</strong>ds /201ARRFwool /201ARRFacrylic /201ARRFNe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Spindle A / Acotton /201-251 A202-252 A251 AF252 AFcotton/polyester-polyester-bl<strong>en</strong>ds /251 AF252 AFwool /201-251 A202-252 Aacrylic /201-251 A202-252 ANe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Spindle B / Bcotton /251-301 B252-302 B254-304 Bcotton/polyester-polyester-bl<strong>en</strong>ds /301 BF302 BFwool /251-301 B252-302 B254-304 Bacrylic /251-301 B252-302 B254-304 BNe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Spindle AR / ARcotton /201ARwool /201ARacrylic /201ARcotton/polyester-polyester-bl<strong>en</strong>ds /251 ARFNe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Spindle BR / BRcotton /201 BR202 BR251 BRFcotton/polyester-polyester-bl<strong>en</strong>ds /251 BRFwool /201 BR202 BRacrylic /201 BR202 BRNe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Spindle C / Ccotton /252-302 C254-304 Ccotton/polyester-polyester-bl<strong>en</strong>ds /302 CFwool /252-302 C253-303 C254-304 Cacrylic /252-302 C253-303 C254-304 CNe /2 0 10 20 30 40 50 60 70 80 90 100 110 1202/ Nm0 10 20 30 40 50 60 70 80 90 100110120 130 140150160170180190 200Gauge Spindles Baskets200250250LOW300300LOWFeeding - Machine model -Double Superimposed Duo Pot system Controlled balloon Free balloonARR 1 155x94 201ARRFAR 1 155x125 201ARABR1 155x141 2x85x140 201A2178x141200x1412x110x145202A1 155x151 201BR2178x151200x1512x110x155202BRAR 1 155x125 251AR 251ARFABRB1 155x141 2X85x140 251A 251AF2178x141200x1412x110x145 252A 252AF1 155x151 251BR 251BRF2178x151200x1512x110x155252BR1 155x162 2x85x165 251B2C 2B 4CB178x162200x162178x185200x1852x110x1652x110x1852x4°20’x1602x5°57’x160252B252C254B3 2x150x185 253C42x4°20’x1852x5°57’x1851 155x162 2x85x165 301B 301BF2C 2B 4C178x162200x162178x185200x185254C2x110x165 302B 302BF2x110x185 302C 302CF2x4°20’x1602x5°57’x160304B304BF (pns)3 2x150x185 303C 303CF (pns)42x4°20’x1852x5°57’x185304C304CF (pns)20 21

<strong>Sirius</strong>Overall dim<strong>en</strong>sions and installation layoutMECHANICAL HEADSTOCKVERSION WITH 1 MOTOREDS HEADSTOCKVERSION WITH 2 MOTORSEDS SHORT HEADSTOCKVERSIONS WITH 1 MOTOR652652652464770 DuoPot464770 DuoPot464770 DuoPot2616 2616 26162632 2632 26001512 1479684 684 684151241739451344785060522506058506056051511511512003 (1803 Sc. 300)MachinE L<strong>en</strong>gth /2003 (1803 Sc. 300)2036 (1836 Sc. 300)MachinE L<strong>en</strong>gth /2003 (1803 Sc. 300)2036 (1836 Sc. 300)2250 2036 (1836 Sc. 300) 2036 (1836 Sc. 300) 3212036 (1836 Sc. 300)2036 (1836 Sc. 300)2036 (1836 Sc. 300)665336127660 132336363 363904706123706665 6841512665928 (DuoPot) 2178 928 (DuoPot)2178928 (DuoPot)2178MachinE L<strong>en</strong>gth / (mm)Gauge 200 mm - Gauge 250 mm - Gauge 300 mm -SectionsARF - AFSpindles ARRFSpindlesSpindlesBRBRF 4 B 2 C 3/4 CAR - A1/2 BB C1 20 4.607 4.607 16 4.607 4.607 4.607 4.607 12 4.407 4.4072 40 6.643 6.643 32 6.643 6.643 6.643 6.643 24 6.243 6.2433 60 8.679 8.679 48 8.679 8.679 8.679 8.679 36 8.079 8.0794 80 10.715 10.715 64 10.715 10.715 10.715 10.715 48 9.915 9.9155 100 12.751 12.751 80 12.751 12.751 12.751 12.751 60 11.751 11.7516 120 14.787 14.787 96 14.787 14.787 14.787 14.787 72 13.587 13.5877 140 16.823 16.823 112 16.823 16.823 16.823 16.823 84 15.423 15.4238 160 18.859 18.859 128 18.859 18.859 18.859 18.859 96 17.259 17.2599 180 20.895 20.895 144 20.895 20.895 20.895 20.895 108 19.095 19.09510 200 22.931 22.931 160 22.931 22.931 23.514 22.931 120 20.931 20.93111 220 24.967 25.550 176 24.967 24.967 25.550 25.550 132 22.767 22.76712 240 27.003 27.586 192 27.003 27.586 27.586 27.586 144 24.603 24.60313 260 29.622 29.622 208 29.622 29.622 29.622 29.622 156 26.439 27.02214 280 31.658 31.658 224 31.658 31.658 31.658 31.658 168 28.275 28.85815 300 33.694 33.694 240 33.694 33.694 33.694 33.694 180 30.111 30.69416 320 35.730 35.730 256 35.730 35.730 192 31.947 32.53017 340 37.766 37.766 272 37.766 37.766 204 33.783 34.366MECHANICAL HEADSTOCK VERSION WITH 1 MOTOR -EDS SHORT HEADSTOCK VERSIONS WITH 1 MOTOR -EDS HEADSTOCK VERSION WITH 2 MOTORS -= -460 mm17902036 (1836 Sc. 300)2036 (1836 Sc. 300)321MachinE L<strong>en</strong>gth /22 23

<strong>Sirius</strong><strong>Sirius</strong><strong>Savio</strong> Macchine Tessili S.p.A.33170 PORDENONE (Italy)Via Udine, 105Tel. +39 0434 3971Fax +39 0434 397599E-mail: order@saviospa.itwww.saviospa.itSAVIO (Shandong)Textile Machinery Co., Ltd.No.6 Torch Industry Park, No. 2166Chongw<strong>en</strong> Dadao,High&New Tech IndustryDevelopm<strong>en</strong>t Zone, Jining,Shandong, P.R. China 272000Tel. +86 0537 2395206/101Fax +86 0537 2395216E-mail: info@saviochina.comSAVIO INDIA LTD.Nallattipalayam, Tamaraikulam - PostPollachi, Coimbatore - 642109Tamil Nadu, IndiaTel. +91 4259 304555Fax +91 4259304567E-mail: mail@savioindia.inwww.savioindia.in<strong>Savio</strong> Advertising Dpt. - Foto: Riccardo Maria Moretti - PN - Edizione 04/2012 - inglese-cineseWe reserve the right to modify the characteristics of the machines described herein without prior notice. The data giv<strong>en</strong> in this brochure are not int<strong>en</strong>ded asa guarantee. <strong>Savio</strong> machines are equipped with safety devices in compliance with existing regulations.24