DREDGEPACK® Cutter Suction System - Hypack

DREDGEPACK® Cutter Suction System - Hypack

DREDGEPACK® Cutter Suction System - Hypack

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

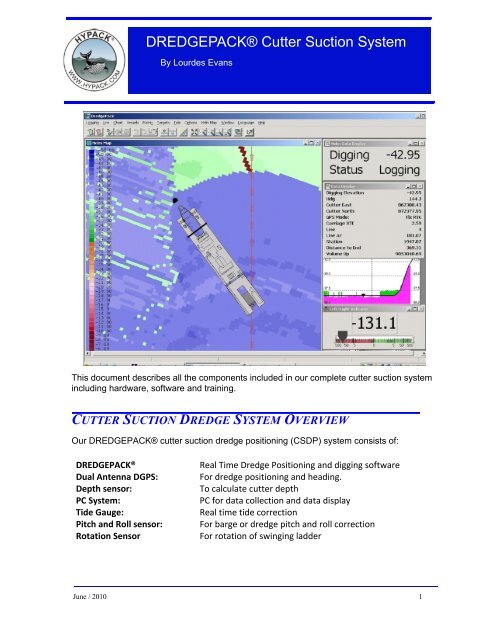

<strong>DREDGEPACK®</strong> <strong>Cutter</strong> <strong>Suction</strong> <strong>System</strong>By Lourdes EvansThis document describes all the components included in our complete cutter suction systemincluding hardware, software and training.CUTTER SUCTION DREDGE SYSTEM OVERVIEWOur <strong>DREDGEPACK®</strong> cutter suction dredge positioning (CSDP) system consists of:<strong>DREDGEPACK®</strong>Dual Antenna DGPS:Depth sensor:PC <strong>System</strong>:Tide Gauge:Pitch and Roll sensor:Rotation SensorReal Time Dredge Positioning and digging softwareFor dredge positioning and heading.To calculate cutter depthPC for data collection and data displayReal time tide correctionFor barge or dredge pitch and roll correctionFor rotation of swinging ladderJune / 2010 1

<strong>DREDGEPACK®</strong> REAL‐TIME DREDGE MANAGEMENT SYSTEM<strong>DREDGEPACK®</strong> enables you to monitor andtrack digging operations for hopper, cutter, andother dredge types. <strong>DREDGEPACK®</strong> monitorsthe position and depth of the cutting tool on theoperator's screen in real-time and re-maps thebottom based on the depth and location of thedigging tool. The color-coded depthinformation is displayed in plan and sectionalviews to show the “As Surveyed” and the “AsDredged” depths for millions of cells. Thisenables you to maximize digging efficiencywhile providing a record of digging operations.<strong>DREDGEPACK®</strong> is not meant forhydrographic surveying. It is a stand-alone product and the only requirement is to feed it withan XYZ file for the dredging area. To produce such a file you need other tools to produce ahydrographic survey. HYPACK® Max is preferred, but you can use any other surveypackage.DATA REQUIREMENTS IN DREDGEPACK ®In <strong>DREDGEPACK®</strong> there are three pieces of information we need to know:• Dredge position• Dredge heading• Depth of the digging toolDREDGE POSITION AND HEADING : DIFFERENTIAL GPSDredge position: Most dredges now operate using a differential or RTK GPS receiver.Dredge heading: There are several solutions available for vessel heading. We offer a DualAntenna GPS. A DGPS Heading and Positioning Receiver is a modular, dual-antennasystem for marine construction and hydrographic survey.2

CUTTER DEPTHFor cutter suction dredges, the preferred method to calculate the depth of the cutting tool is touse an angle sensor (also called clinometer or inclinometer) installed on the ladder. Knowingthe geometry of the ladder and the angle, we can calculate the depth of the cutter head. Mosthopper dredges use either a pressure transducer installed on the ladder near the cutter heador a series of inclinometers.ROTATION SENSOR FOR SWINGING LADDER DREDGEA rugged absolute encoder designed for heavy duty industrial is use.PITCH AND ROLL (OPTIONAL)To correct for pitch and roll in the positioning calculation from GPS antenna to <strong>Suction</strong> TubeInlet, a pitch/roll sensor must be installed. As the pitch/roll sensor is placed inside the vessel,it is not placed in a watertight housing.PC SYSTEMThe MiniPC is a computer designed for reliable operation in dirty, wet environments. Thesystem is waterproof, sealed and ideal for operation in extreme conditions. All of our sealedsystems use a unique and specialized heat pipe providing fanless cooling. A solid state driveprovides a no moving parts solution. A wide variety of configurations and I/O options areavailable.June / 2010 3

REAL-TIME WATER LEVELSA tide gauge or RTK GPS is used for real-time water elevation.ONSITE INSPECTIONOn-site Inspection is recommended prior to ordering the system. It allows a HYPACK®specialist to inspect the dredge to ensure that all needed equipment is ordered. Thetechnician can also provide guidelines for installing the equipment to ensure it will be donecorrectly. On-site inspections are usually 1 day.CALIBRATION AND TRAININGThe equipment must be installed and configured prior to the on-site calibration andtraining visit. The customer will be responsible for the mechanical parts of the installationsuch as welding and placing of the sensors, etc. HYPACK® technicians will calibrate thesystem. Calibration should take 1 day. Once the calibration has been completed, trainingwill take 3-5 days.MAINTENANCE PLANFirst-time customers receive a free, 1-year subscription to our Maintenance Plan.The HYPACK® Software Maintenance Program provides the following:• The newest versions of <strong>DREDGEPACK®</strong> software automatically upon release, at nocharge.• Access to program updates, patches and technical documentation on our support site.• Prompt, courteous and knowledgeable technical support via telephone, email, or fax. Forany technical questions, contact help@hypack.com.• Reduced registration fee to our annual HYPACK® Training Conference.PRICINGFor pricing or for additional information please contact sales@hypack.com4