Compliance Monitoring Report for Mines and Quarries - National ...

Compliance Monitoring Report for Mines and Quarries - National ...

Compliance Monitoring Report for Mines and Quarries - National ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

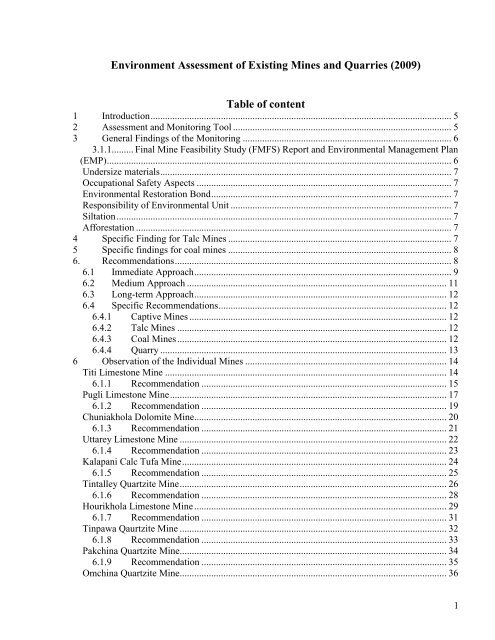

6.1.10 Recommendation ..................................................................................................... 377 Talc <strong>Mines</strong> ........................................................................................................................... 38Kharipakha (Kharikhola) Talc Mine ............................................................................................ 387.1.1 Recommendation ..................................................................................................... 39Kharipakha East ........................................................................................................................... 417.1.2 Recommendation ..................................................................................................... 42Lower Kharipakha Talc Mine ...................................................................................................... 437.1.3 Recommendation ..................................................................................................... 44Mowater Talc Mine...................................................................................................................... 457.1.4 Recommendation ..................................................................................................... 467.1.5 Simanadara Talc Mine ............................................................................................. 477.1.6 Recommendation ..................................................................................................... 48Sadhumardhu Talc Mine .............................................................................................................. 497.1.7 Recommendation ..................................................................................................... 50Upper Sukrety Talc Mine (Closed) .............................................................................................. 517.1.8 Recommendations .................................................................................................... 52Sukrety Talc Mine (Closed) ......................................................................................................... 537.1.9 Recommendations .................................................................................................... 54Bahundara Talc Mine (Closed) .................................................................................................... 557.1.10 Recommendation ..................................................................................................... 56Lower Sukrety Talc Mine (Suspended) ....................................................................................... 577.1.11 Recommendation ..................................................................................................... 57Sukreti Phase VIII Talc Mine ...................................................................................................... 597.1.12 Recommendation ..................................................................................................... 60Thumkey Talc Mine ..................................................................................................................... 627.1.13 Recommendation ..................................................................................................... 63Dipujhora Talc Mine .................................................................................................................... 647.1.14 Recommendation ..................................................................................................... 65Soilaykhola Talc Mine (Lease expired) ....................................................................................... 667.1.15 Recommendation ..................................................................................................... 67Allaypakha (Closed) .................................................................................................................... 687.1.16 Recommendation ..................................................................................................... 69Pitsu Talc Mine ............................................................................................................................ 708 Quarry .................................................................................................................................. 71Lampathey Quartzite Mine .......................................................................................................... 71Gidaphug Marble Mine ................................................................................................................ 738.1.1 Recommendation ..................................................................................................... 74Hasilo Marble Mine ..................................................................................................................... 75Khariphu Limestone Mine ........................................................................................................... 768.1.2 Recommendation ..................................................................................................... 77Reshore coal mine ........................................................................................................................ 788.1.3 Recommendation ..................................................................................................... 79Reshore coal mine no 5. ............................................................................................................... 808.1.4 Recommendation ..................................................................................................... 81Khotakpa Gypsum mine .............................................................................................................. 828.1.5 Recommendation ..................................................................................................... 832

Cherung Ri Gypsum mine ........................................................................................................... 848.1.6 Recommendation ..................................................................................................... 85Ngabephu Stone Quarry ............................................................................................................... 868.1.7 Recommendation ..................................................................................................... 87Geerza <strong>and</strong> Dojim Stone Quarry .................................................................................................. 888.1.8 Recommendation ..................................................................................................... 89Tenzin Stone Quarry, Drakarpo ................................................................................................... 918.1.9 Recommendation ..................................................................................................... 92TW Stone Quarry ......................................................................................................................... 938.1.10 Recommendation ..................................................................................................... 94Langukha Stone Quarry ............................................................................................................... 958.1.11 Recommendation ..................................................................................................... 96Lomekha Stone Quarry ................................................................................................................ 978.1.12 Recommendation ..................................................................................................... 98Dalukha Stone Quarry.................................................................................................................. 99Gidaphug Stone Quarry ............................................................................................................. 1008.1.13 Recommendation ................................................................................................... 101Kilikhar Stone Quarry ................................................................................................................ 1028.1.14 Recommendation ................................................................................................... 103Riju Stone Surface Collection .................................................................................................... 1048.1.15 Recommendation ................................................................................................... 105Ghatak Stone Quarry.................................................................................................................. 1068.1.16 Recommendation ................................................................................................... 107Dhur Stone Quarry ..................................................................................................................... 1088.1.17 Recommendation ................................................................................................... 109Lamegonpa Stone Quarry .......................................................................................................... 1108.1.18 Recommendation ................................................................................................... 111Pachhulum Stone Quarry ........................................................................................................... 1128.1.19 Recommendation ................................................................................................... 113Thongtimo Stone Quarry ........................................................................................................... 114Taksha Stone Quarry.................................................................................................................. 1158.1.20 Recommendation ................................................................................................... 116Baychu Stone Quarry ................................................................................................................. 1178.1.21 Recommendation ................................................................................................... 118Lamishawa Stone Quarry ........................................................................................................... 1198.1.22 Recommendation ................................................................................................... 120Tshachugang Quartize Quarry ................................................................................................... 1218.1.23 Recommendation ................................................................................................... 122Jungomlo stone Quarry .............................................................................................................. 1238.1.24 Recommendation ................................................................................................... 124Sha Ngwang Granite Quarry ...................................................................................................... 1258.1.25 Recommendation ................................................................................................... 126Wangchena stone Quarry ........................................................................................................... 1279 The List of <strong>Mines</strong> <strong>and</strong> <strong>Quarries</strong> ......................................................................................... 12910 Conclusion ......................................................................................................................... 13311 Agreed timeframe <strong>for</strong> implementation of Recommendations ........................................... 1333

Environment Assessment of Existing <strong>Mines</strong> <strong>and</strong> <strong>Quarries</strong>1 IntroductionThe <strong>National</strong> Environment Commission Secretariat (NECS) conducted environmental monitoringof existing mines <strong>and</strong> quarries in the country, from March to May 2009. A total of 63 mines <strong>and</strong>quarries were monitored. The monitoring was carried out as it is required under section 14 of theRegulation <strong>for</strong> the Environmental Clearance of Projects 2002.It is an accepted fact that mining causes disturbance <strong>and</strong> damage to the environment. Themagnitude of impact on the environment depends upon the geological <strong>for</strong>mation of the mining area<strong>and</strong> the method of mining operation. All mines in the country are of open-cast type, which couldaffect the environment by changing the l<strong>and</strong>scape, Ph medium of soil <strong>and</strong> water, flora <strong>and</strong> fauna,<strong>and</strong> socio- economic aspects.In order to address the environmental issues, many countries have paid attention to restoration ofmines <strong>and</strong> alternative use of restored areas. However, in Bhutan, most of the mines are still active.Some mines may exhaust their deposits in few years from now, which will have to be restored.There<strong>for</strong>e, it is important to start planning from now how to effectively restore the mined outareas.In general, the mines in Bhutan can be grouped into the following categories:Captive <strong>Mines</strong>Talc <strong>Mines</strong>Quarry2 Assessment <strong>and</strong> <strong>Monitoring</strong> ToolThe NECS has conducted the compliance monitoring using the following general checklists:1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong> SafetyPersonnel Protective GearsWater <strong>and</strong> Sanitation FacilitiesFirst Aid Kit3. Waste <strong>and</strong> Overburden ManagementSanitary WasteOverburden/interburden <strong>and</strong> undersize/rejectTopsoilMechanism of Dumping <strong>and</strong> ArrestingPit slope Angle, Bench Height <strong>and</strong> Width5

4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong> Progressive RestorationRestorationEnvironmental Bond7. Others3 General Findings of the <strong>Monitoring</strong>All the mines in the country are of open-cast type, causing serious visual impact. Most of themineral deposits occur in the southern Dzongkhag in geologically fragile zone. The currentlocations of mines are done on an ad-hoc basis. The mineral development policy undertaken by theDepartment of Geology <strong>and</strong> <strong>Mines</strong> (DGM) should revisit the present mining practices <strong>and</strong> come upwith clear direction <strong>for</strong> holistic mineral development in the country.3.1 Final Mine Feasibility Study (FMFS) <strong>Report</strong> <strong>and</strong> EnvironmentalManagement Plan (EMP)As per the <strong>Mines</strong> <strong>and</strong> Mineral Management Act 1995 <strong>and</strong> its Regulation 2002, the FMFS report<strong>and</strong> EMP are prerequisites as they contain details of mining operation. Based on the report, thefollowing are the observation in most mines:Operation of some mines are not in line with the approved Pit PlansNo proper bench height <strong>and</strong> width length as required by the mine plan is maintained inmost minesTop soil, an important material, that will be required <strong>for</strong> restoration works were not storedseparately as required under the mine planThe environmental restoration works carried out is limited mostly to construction of checkdamsonly. The check-dams are built only after the operation of the mine, which in-fact hasto be other way round. Also the damaged check-dams during monsoon are not repairedOverburden is disposed directly downhill, which has resulted in the removal of vegetation<strong>and</strong> widening of the gorge, causing l<strong>and</strong> slide during monsoonThe erection of demarcation pillar, which is crucial in maintaining the mine boundary, isdifferent from one mine to anotherPersonnel Protective Gears provided are limited to safety helmets onlyThere is poor water management in the minesThe copy of FMFS report <strong>and</strong> EMP were not available at the site6

3.2 Undersize materialsDuring the operation of the mine, substantial quantity of undersized materials <strong>and</strong> fines aregenerated. These materials are disposed off along with the overburden.3.3 Occupational Safety AspectsIn the mining, overall safety of the workers is very important. Incidences of accidents in the minescan be avoided by following simple safety measures. Awareness both among the workers <strong>and</strong> themanagers is lacking. For instance, some of the workers did not underst<strong>and</strong> the benefit of wearingprotective gears. The protective gears provided are limited to safety helmet only in most cases.3.4 Environmental Restoration BondCurrently most of the mines are still active <strong>and</strong> only few are either closed down or not in operation.No restorations have been undertaken <strong>for</strong> the mines, which are closed <strong>and</strong> <strong>for</strong> those mines nearingclosure do not have restoration plan as yet.The amount collected <strong>for</strong> environmental restoration bond is calculated based on the tonnagesystem, which is predetermined in the FMFS report <strong>and</strong> EMP. It can be said that the amountcollected as environmental bond <strong>and</strong> the restoration works that will be required to be carried outmay not match. The amount collected may not be adequate <strong>for</strong> mine restoration.3.5 Responsibility of Environmental UnitThe Regulation <strong>for</strong> the Environmental Clearance of Projects 2002 requires establishment ofenvironmental unit or designation of environmental focal person by the proponent. It was seen thatthe above requirement was poorly implemented.3.6 SiltationIn general, mines in Bhutan are located on the hills. During monsoon, improperly managedoverburden is washed down causing siltation. Further, since the mining is open-cast type, most ofthe areas are exposed to soil erosions.3.7 Af<strong>for</strong>estationFew mines have carried out af<strong>for</strong>estation at the periphery of the mine, at the overburden dumpyard<strong>and</strong> mined out areas. Un<strong>for</strong>tunately, the survival rate of the seedlings planted is poor becauseonce planted is not maintained properly.Specific Finding <strong>for</strong> Talc <strong>Mines</strong>Most of the Talc <strong>Mines</strong> are located at the foothills in Samtse Dzongkhag. The operation ofthe mines is seasonal due to its geological <strong>for</strong>mation. Generally, these mines generate huge7

quantity of waste materials (overburden <strong>and</strong> other waste). Most of these wastes are washeddownhill during heavy monsoonIn most of these mines, because of the geological <strong>for</strong>mation, maintenance of final Pit slopeof 45 0 , <strong>and</strong> bench height <strong>and</strong> width of 5 meters <strong>and</strong> 2.5 meters each is not possibleGenerally the mines are leased <strong>for</strong> a maximum period of three years. The environmentalrestoration bond collected is based on reserve, which is predetermined <strong>and</strong> not on the basisof actual mineral deposit <strong>and</strong> environmental damage/degradation caused. The amountcollected may be less since mineable reserve estimated is comparatively small compared tothat of captive minesThe majority of the mines are located at the foothill of Sukrety <strong>and</strong> Kharipakha underSamtse, which may affect the settlements lying at the top of the mines. Some miningoperation have been carried out in private l<strong>and</strong>, which have been bought by the proponentsSamtse Dzongkhag has constructed a farm road to connect the resettlement areas <strong>and</strong> othervillages. The take-off point of the road is from Sukrety <strong>and</strong> passes below the Talc mines inKharipakha area. There is a potential risk to the road if the mine is not managed properly<strong>and</strong> restoredSpecific findings <strong>for</strong> coal minesIn case of Rishore coal mines, the demarcation pillars 4, 5, 6 <strong>and</strong> 7 are just next to the crest of theultimate pit slope maintained at a gradient of 70º, which is too steep <strong>and</strong> may cause instability ofthe area. The pillars (4,5,6 <strong>and</strong> 7) located above need to be shifted further by 30 to 80 meteres <strong>for</strong><strong>for</strong>mation of benches <strong>and</strong> to stabilize the slope. The crest of the top bench at piller No. 5 wasobserved to be a thin ridge. On the other side, it was found to be sloping downwards falling in theprivate l<strong>and</strong> which is being acquired by the company. Once acquired, benches can be developed bythe company from top down <strong>and</strong> the steep dead end can be reduced in height by atleast 15 meters<strong>and</strong> the slope made more gentle.Rishore Mine No. 5 was abondoned. Though the ultimate pit slope was maintained at a steeperangle, it was observed that there was no sign of instability. The scope of further advancement to<strong>for</strong>m proper benches <strong>and</strong> reduce the slope to restore the mine was restricted by private l<strong>and</strong>situated just above it. The management has built a check dam to arrest the overburden rolling downthe hill. However, there were two rows of benches maintained at the top of the mine followed by anumber of benches along the lateral side of the mined area.There are 34 registered households <strong>and</strong> about 28 thram holders in the village located on thenorthern side of the mine. Out of the above mention registered households, 15 of them are close tothe mine area. However, no immediate threat to the settlement above is observed.6. RecommendationsThe recommendations are further segregated into immediate, medium <strong>and</strong> long-term approach tocarry out environmentally sound mining operation.8

6.1 Immediate Approach6.1.1 FMFS <strong>and</strong> EMPThe DGM should ensure that the mining operations are carried out strictly asper the approved FMFS report <strong>and</strong> EMPThe NECS should ensure that the mining operations are carried out as per theapproved EMP <strong>and</strong> the terms <strong>and</strong> conditions of the Environmental Clearance.This requires frequent visits to the mine, which at times is restricted bybudgetary constraintsThe proponents have to ensure that the copy of FMFS report, EMP <strong>and</strong>environmental clearance is kept at the site at all timesThe proponents must be aware of all requirements contained under the approvedFMFS report <strong>and</strong> EMP, Environmental Clearance, <strong>Mines</strong> <strong>and</strong> MineralsManagement Act 1995, <strong>National</strong> Environmental Protection Act 2007 <strong>and</strong>Environmental Assessment Act 2000The proponents must ensure that the top soil is preserved <strong>and</strong> used <strong>for</strong>restoration works in the futureThe DGM should st<strong>and</strong>ardize demarcation pillars <strong>for</strong> all mines <strong>and</strong> demarcatethe mine boundaryThe proponents must ensure that there is proper water management system inplace. The objective should be to channel <strong>and</strong> drain the surface water to thedesired location to prevent soil erosionThe pit plans in the FMFS report should be practical. The proponents shouldthere<strong>for</strong>e ensure that mining/quarrying activities are done strictly as per the yearwise pit plans including the number <strong>and</strong> sizes of benches as reflected in theFMFS report <strong>and</strong> EMP6.1.2 Occupational Safety AspectsThe proponent has to develop an internal safety rules <strong>for</strong> the workers <strong>and</strong>implement it. Conduct awareness programs among the workers on theimportance of safety applications <strong>and</strong> its benefits. In addition, the managementhas to ensure that other protective gears such as gloves, breathing masks <strong>and</strong>protective shoes are provided to the workers, besides safety helmets onlyThe NECS has been in<strong>for</strong>med by the Ministry of Labour <strong>and</strong> Human Resources onthe General Rules <strong>and</strong> Regulation on Occupational Health <strong>and</strong> Safety 2006. As perthe rules <strong>and</strong> regulation, the Ministry of labour <strong>and</strong> Human Resources is responsible<strong>for</strong> implementation of occupational health <strong>and</strong> safety requirements6.1.3 Environmental Restoration BondThe <strong>for</strong>mula used <strong>for</strong> calculating the amount of environmental restoration bond needs to be reassessed.The assessment should incorporate parameters such as environment damage/degradation,9

cost of the restoration <strong>and</strong> others. There is a need to institute a proper system of reporting on theamount of environmental restoration bond collected. The amount collected should be high enoughto oblige the miners to restore the exhausted area.6.1.4 Responsibility of Environmental unit/Focal personAll mining companies must nominate an environmental focal person. Once nominated, he/sheshould attend a short-term training conducted by NEC <strong>and</strong> MOEA etc.6.1.5 Environmental Restoration PlanAll mining companies should be required to prepare <strong>and</strong> submit Environmental Restoration Plan<strong>for</strong> approval by the NECS <strong>and</strong> DGM.6.1.6 Overall Environmental AwarenessThe overall environment awareness amongst the workers is lacking. There is a need <strong>for</strong> themanagement to introduce a system of environment awareness. This could be done throughorganization of events, such as Celebration of World Environment Day <strong>and</strong> observation of a SafetyDay, with an objective of emphasizing on the importance of environment <strong>and</strong> safety aspects.6.1.7 <strong>Compliance</strong> monitoringThe NECS has to develop its own competence in the mining sector <strong>and</strong> <strong>for</strong>m a strong monitoringteam to ensure proper compliance. This would directly result in preventing or reducingenvironmental damages <strong>and</strong> timely rectification.6.1.8 En<strong>for</strong>cement of environmental terms <strong>and</strong> conditionsSince DGM has their mining inspectors at sites, they should ensure strict implementation of FMFSreport <strong>and</strong> EMP <strong>and</strong> en<strong>for</strong>cement of the environmental terms <strong>and</strong> conditions. This will be furthersupported by NECS.6.1.9 Corporate Social ResponsibilityAs a country known to the outside world as an environmentally conscious nation, every Bhutaneseshould be responsible <strong>for</strong> maintaining such recognition at all times. In this regard, even thoughcorporate profit motive of companies is indispensable <strong>for</strong> their business sustainability, they shouldalso realize that ensuring environmental sustainability is their social responsibility. Hence,concerned companies/agencies should instill the sense of corporate social responsibility in theirrespective companies.6.1.10 Operation within the Demarcated areaThe mine operators/proponents have the notion that once the area is demarcated <strong>and</strong> leased out tothem they have the liberty to cut the area till the exact demarcated boundary. Doing so is likely to10

lead to encroachment <strong>and</strong> may lead to serious problem during restoration works if /l<strong>and</strong>scapeneeds to be improved by cutting further. Hence there is a need to keep a provision of a st<strong>and</strong>arddistance between the last cutting point <strong>and</strong> the demarcation boundary to avoid encroachments <strong>and</strong>l<strong>and</strong>/soil erosion.6.1.11 St<strong>and</strong>ardization of Environmental ClearanceThere is a need to harmonize <strong>and</strong> st<strong>and</strong>ardize the environmental terms <strong>and</strong> conditions of theenvironmental clearance. For instance, an environmental clearance issued by DGM is a one-pageletter <strong>and</strong> the other issued by NECS is 1-3 pages. Accordingly, there is likelihood of dilution of theenvironmental terms <strong>and</strong> conditions. The NECS <strong>and</strong> DGM are in consultation to work on this <strong>for</strong>better harmonization.6.2 Medium Approach6.2.1 Undersized materialsThe proponent should look <strong>for</strong> alternative use of undersized materials instead of disposing themdownhill. If an alternative use of undersized materials is found, it has some benefits such asreducing the volume of overburden generated <strong>and</strong> there is also an opportunity to generate someadditional income by sale of such materials.6.2.2 Progressive restorationOn the progressive restoration of the mine, the management has to explore alternatives other thanjust constructing check-dams. The management has to carry out progressive restoration works inmined areas, simultaneously. Af<strong>for</strong>estation program must be carried out in consultation with theDepartment of Forest (DoF) instead of leaving it to natural regeneration only. After af<strong>for</strong>estationprogram has been carried out, the area has to be monitored to ensure that the success rate of theplantation is more than 50 percent.6.2.3 SiltationThe DGM has to include in the Rules regarding ore to waste ratio factor in determining thefeasibility of mining operation which could play a crucial role in reducing the damage to theenvironment <strong>and</strong> siltation problem.6.2.4 Af<strong>for</strong>estationA st<strong>and</strong>ard methodology needs to be developed to carry out the af<strong>for</strong>estation activities of themined areas or exhausted mines in consultation with DoF.6.2.5 Environmental award/Certificate of ExcellenceThe NECS strongly feels that in-order to encourage mining companies to adopt the state of arttechnology <strong>and</strong> best practices, there should be a system of recognition. The government should11

ecognize the initiatives <strong>and</strong> ef<strong>for</strong>ts undertaken by companies to reduce pollution, promote cleanertechnology, practicing scientific mining <strong>and</strong> improve environmental management by introducing asystem to present environmental award or a certificate of excellence on an annual basis.6.2.6 EmploymentIn order to alleviate unemployment problem in the country, it is advisable to employ nationals asfar as possible <strong>and</strong> preference be given to the local people. The management has to emphasize inemploying <strong>and</strong> providing opportunity <strong>for</strong> national workers instead of non-nationals. Further, inorder to improve productivity <strong>and</strong> encourage Bhutanese youths to join mining/quarrying jobs,companies should consider mechanizing the operation of mines.6.3 Long-term Approach6.3.1 Environmental Restoration BondRestoration of mined areas is most important not only <strong>for</strong> environmental consideration but also tomake the area gainfully useable in the future. The DGM has introduced the environmentalrestoration bond since 2002 in consultation with the NECS <strong>and</strong> as per the requirements under the<strong>Mines</strong> <strong>and</strong> Minerals Management Regulation 2002. The DGM should make it m<strong>and</strong>atory <strong>for</strong> allminers to develop a comprehensive Mine Restoration Plan along with the budget estimate twoyears prior to closure of the mine. For those few mines, which are already closed down, the DGMin consultation with the NECS must take strong action if they do not restore them.6.4 Specific Recommendations6.4.1 Captive <strong>Mines</strong>Most of the check-dams are constructed of gabion walls without proper foundation. Themanagement has to explore the idea or possibility of constructing the check dam, which couldbe a combination of rein<strong>for</strong>ced cement concrete <strong>and</strong> gabion walls. This is suggested since thegabion walls have not been able to withst<strong>and</strong> the monsoon in most cases.6.4.2 Talc <strong>Mines</strong>Considering the huge environmental damages being caused by Talc mines vis-a- vis smallrevenue generation, it is vital <strong>for</strong> the Government to carry out proper environmental cost <strong>and</strong>benefit analysis <strong>for</strong> all Talc mines be<strong>for</strong>e they are leased out <strong>for</strong> operation. Most of these minesare located in geographically fragile area in the southern belt.6.4.3 Coal <strong>Mines</strong>Regarding Rishore cola mine, in order to provide scope <strong>for</strong> the company to restore <strong>and</strong>stabilize the unstable slope, issuance of environment clearance is recommended based on the12

FMFS report submitted by them. However, the management has been instructed to startrestoration of the ab<strong>and</strong>oned pit by carrying out the following works:To level all the overburden <strong>and</strong> plant fast growing species in consultation with DoFTo carry out plantation on the benches <strong>and</strong> other possible areasTo build two more checkdams using the depression below the dump site6.4.4 QuarryIt was observed that some of the mineral grade deposits are being extracted <strong>for</strong> purposes other thanuse by the industries. The DGM may like to ensure that quarrying of mineral grade be discontinued<strong>and</strong> reserve <strong>for</strong> downstream projects, which could have greater socio-economic benefits. Further,the Government should discontinue leasing out quarries <strong>for</strong> specific projects/institutions at placeswhere there are already quarry operators.7. Conclusion13

8. Observation of the Individual <strong>Mines</strong>Captive <strong>Mines</strong>A captive mines are those mines dedicated <strong>for</strong> the mineral processing industries. As per the <strong>Mines</strong><strong>and</strong> Mineral Management Regulation 2002, each industry shall have one mine <strong>for</strong> a particularindustry.8.1 Titi Limestone MineTiti Limestone mine started its operation in 1992 <strong>and</strong> it is a captive mine <strong>for</strong> Lhaki Cement Plant.The mine is located at Titi which is about 15 km from Gomtu <strong>and</strong> falls in the survey of IndianTopo-sheet no. 78F/1. The deposit is across India-Bhutan border <strong>and</strong> in between Pugli <strong>and</strong> Titiriver. The mine shares a common border with Pugli Limestone mine.General DetailsAddressContact PersonType of mineral minedStripping Ratio 1:4Operation <strong>and</strong> AnnualProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodObservationTiti Limestone <strong>Mines</strong>C/o Lhaki CementGomtu, SamtseTel No. 05-371042/371181Mr. Manoj KumurGeneral Manager (<strong>Mines</strong>)Limestone.The mine is operated throughout the year, six months <strong>for</strong> minedevelopment <strong>and</strong> six months <strong>for</strong> production. The annualproduction is 65, 000 MT (metric ton). The production capacityis likely to increase to 2, 25, 000 MT per annum.Total mineable reserve is estimated at 1.33 million MT <strong>and</strong>Residual Reserve at 0.6 million MTThe lease area is 33.46 hectares <strong>and</strong> the lease period is <strong>for</strong> tenyears (22/08/06-21/08/2015)1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater <strong>and</strong> SanitationFacilitiesThe mine is operated from top-down where the operatingbench pit slope varies in-between 55 to 70 0 .Bench heights are maintained between 3 to 6 meters.Bench widths are maintained between 2.8 to 5 meters.The management has provided the workers with protectivegears which are limited to helmets <strong>and</strong> breathing masks.Drinking water <strong>and</strong> first-aid-kit is available at the siteoffice.A pit latrine is available at the mining site.14

First-Aid-Kit3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/reject,Overburden/inter-burden<strong>and</strong> Other materialsMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental BondThe management has not provided disposal facilitates <strong>for</strong>sanitary waste.The management has provided separate area <strong>for</strong> storingthe top soil which is estimated to be 10, 000 MT.The overburden inclusive of undersize/rejects <strong>and</strong> othermaterials are disposed at the pre-determined site.Waste material is displaced downhill by the bulldozer atthe pre-determined site. A check dam is constructed at thebase, made of rein<strong>for</strong>ced concrete cement <strong>and</strong>embankment. There is a need to extend the check dam.The Pit slope ranges from 60 to 70 0 <strong>and</strong> bench height morethan 20 meters from the base.The management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.The mine has been in operation <strong>for</strong> about 16 years.Af<strong>for</strong>estation has been carried out at the periphery of themain mining area within the leased area.Approach road to the mine starts from Gomtu town.Road between Pugli Limestone mine <strong>and</strong> Titi mine needsto be repaired <strong>and</strong> maintained, in particular the drainage.The restoration of the mine is primarily focused on theconstruction of check dams <strong>and</strong> af<strong>for</strong>estation only.Environmental bond deposited Nu. 24, 00, 000.007. Others A total of 23 people are employed.Water is sprinkled at-least once a day on the access roadto the mining area. There is a natural pond developedwhich could substitute the shortage of water in thevicinity.As per the mine plan, there are four dump-yardsidentified. Check dams are constructed with RCC.Check dams constructed at the base of the dump-yard hasarrested some waste materials <strong>and</strong> has prevented it fromfalling into Titi Khola.The surface water from the mining area is not channeled.Drinking water is not available at the mining site.There is no electricity at the base office.1.1 RecommendationBased on the estimated reserve <strong>and</strong> annual requirement <strong>for</strong> the exp<strong>and</strong>ed Cement Plant, themine may last <strong>for</strong> 1 to 2 years only. In this respect, management has to start preparing MineRestoration Plan.The height of the waste disposed is high. In order to decrease the height, development ofproper benches is necessary.The drainage system of the access road <strong>and</strong> the mine channeling need to be improved.15

Pugli Limestone Mine1. Mining Operation DesignPit slope Angle.Bench Height <strong>and</strong>Width.The mine was operated top-down where the operatingbench pit slope varies in-between 50 to 75 0 .Bench heights were maintained at minimum of 7 meters tomaximum of 20 meters on an average.Bench widths were maintained between 6 to 22 meters.The Pugli Limestone mine is a captive mine <strong>for</strong> Penden Cement Authority Limited (PCAL) whichstarted its operation from 1977. The mine is located at Pugli, about 9 km from Gomtu <strong>and</strong> falls onIndian surveyed topo-sheet No. 78F/1 facing SSE of Titikhola.PCAL Plant which was initially designed <strong>for</strong> 300 TPD latter upgraded to 400 tpd (tons per day) to1, 200 tpd clinker at present.General DetailsAddressContact PersonType of minerals minesStripping Ratio 1:4Operation <strong>and</strong> AnnualProductionGeological/Residual ReserveLease Area <strong>and</strong> PeriodPugli Limestone <strong>Mines</strong>C/o Penden Cement Authority LimitedGomtu, SamtseTel No.05-371010/15Mr. Tshering , Mining SupervisorMr. Tshetup Wangdi, SurveyorMr. Tshering Samdrup, Environmental Focal PersonLimestoneOperated though out the Year (26 days a months) <strong>and</strong> annualproduction is 2, 90, 000 MT. However, it targets <strong>for</strong> 2009 is 2,20, 000 MTGeological reserve is estimated at 6.98 million MT <strong>and</strong>Mineable Reserve at 5.13 million MT133.182 hectares (01/11/04-31/12/2022 :18 Yrs)Observation17

2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater <strong>and</strong> SanitationFacilitiesFirst-Aid-Kit3. Waste <strong>and</strong> OverburdenManagementSanitary Waste.Topsoil.Undersize/rejectsOverburden/interburden&<strong>and</strong> OthermaterialsMechanism of Dumping<strong>and</strong> Arresting.Pit slope Angle, BenchHeight <strong>and</strong> Length ofWidth.4. Environmental AspectsAir Environment.Water Environment.Noise Environment.Biological Environment.5. Approach/AccessRoad Conditions.Water Drainage System.6. Environment <strong>and</strong>Progressive RestorationRestoration.Environmental Bond.The management has provided the workers withprotective gears limited to helmets <strong>and</strong> breathing masks.A tank capacity of 1, 500 litres was made available at thesite.First-aid-kit was available at the site office.The management has not provided disposal facilitates <strong>for</strong>sanitary waste.The management has not provided separate area <strong>for</strong>storing the top soil. The overburden inclusive ofundersize/rejects <strong>and</strong> other materials were disposed at thepre-determined site.Waste materials were managed in two ways (loaded on atruck <strong>and</strong> displaced downhill, <strong>and</strong> displaced directlydownhill from the mining area). The mechanism <strong>for</strong>arresting the overburden <strong>and</strong> undersize/rejects were donethrough construction of check-dams made out ofRein<strong>for</strong>ced concrete cement <strong>and</strong> Gabion walls.The Pit slope was in-between 60 to 70 0 <strong>and</strong> bench heightwas more than 45 meters.The management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site, even though it hascontributed to the siltation of Titi Khola <strong>and</strong> Pugli Khola.The mine had been in operation <strong>for</strong> about 28 years; novegetative cover was found at the mining site. Even at thesite where natural regeneration was taking place wasdisturbed by the mineral excavation.Approach road to the mine starts from Gomtu town. Thesame road is used by other companies, namely JigmeMining Corporation Ltd. <strong>and</strong> Bhutan Stone <strong>and</strong> MineralCompany till they enter into their own mine areas.The restoration of the mine was primarily focused on theconstruction of check dam. As of now, no restoration orplanning has been undertaken <strong>for</strong> total environmentalrestoration.Environmental bond deposit Nu. 27, 48, 000.007. Others A total of 293 people were employed by themanagement. In addition to above contract was awardedto an Indian which consist of additional 158 numbers ofworkers.Every morning, water is sprayed with the help of tankerof 1, 200 litres capacity pulled by a tractor.There were five dump-yards as per the mine plan.Presently dump-yard two, three <strong>and</strong> four were in use. The18

dump-yard four is the continuation of two <strong>and</strong> three.Even though dump-yard one <strong>and</strong> five were not in used,waste is still disposed down the hill in number one.If there is a flash flood, dump-yard two <strong>and</strong> three, mayaffect PCAL camp.Dump-yard number five was not in use. If used, it couldaffect the access road to Chunaikhoal Dolomite mine.Waste material from dump-yard one has caused majorsiltation problem.There was no proper channeling of mine water.1.2 RecommendationThe maintenance of pit slope <strong>and</strong> bench height <strong>for</strong> both mining area <strong>and</strong> waste dump-yardneed to be improved.The management has to start planning <strong>and</strong> developing environmental restoration plan, sincethe mine may last <strong>for</strong> another 3 to 5 years. With good environmental practice <strong>and</strong>restoration program, it will have a positive impact of the Company <strong>for</strong> future miningactivities.Benches were not need to be <strong>for</strong>med in the waste disposal site to decrease the height <strong>and</strong>width of the area.The management needs to store the overburden at top of the mine rather than disposingdown hill as there is adequate space. The management must construct series of check damsin the overburden dump-yards 2, 3, <strong>and</strong> 4 <strong>and</strong> retaining wall where PCAL camp is located.In-order to minimize generation of undersize material, the management should carry out astudy to find an alternative use.Since water is quite scarce, the management has to make wise use of the available water.The management should not use dump yard number one.19

Chuniakhola Dolomite MineThe Chuniakhola Dolomite was earlier operated by the Chundu Dolomite <strong>Mines</strong>. The mine waslater auctioned <strong>and</strong> Jigme Mining Corporation Pvt. Ltd won the bid <strong>and</strong> was leased to thecompany. The company started the operation after signing the lease agreement in the year 2004.The mine is located at Pugli, about 10 km from Gomtu <strong>and</strong> falls on survey of Indian topo-sheetNo. 78F/1.General DetailsAddressContact PersonType of minerals minedStripping RatioOperation <strong>and</strong> AnnualProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodChunaikhola Dolomite MineC/o Jigme Mining CorporationGomtu, SamtseTel No. 5-240158/240164Mr. Manoj KumurGeneral Manager (<strong>Mines</strong>)DolomiteGeneration of waste is negligible.Operated though out the year <strong>and</strong> annual production is 6, 00, 000MTTotal mineable reserve is 22.47 Million MT.70.47 hectares (04/07/2004/-14/05/2010, 15 Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater <strong>and</strong> SanitationFacilitiesFirst Aid Kit3. Waste <strong>and</strong> OverburdenManagementSanitary WasteUndersize/reject,The mine was operated top-down approach where theoperating benches pit slope varies in-between 50 to 60 0 .Bench heights were maintained at minimum of 5 to 10meters.Bench widths were maintained between 6 to 15 meters.The management has provided the workers withprotective gears limited to helmets <strong>and</strong> breaking masks.Drinking water <strong>and</strong> first-aid-kit were made available atthe site office.A pit type toilet was made available at the mining siteThe management has not provided disposal facilitates <strong>for</strong>sanitary waste.The undersize materials generated were all consumed.Overburden generation was negligible because of which20

Overburden/inter-burden& Other materialsTopsoilMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentL<strong>and</strong> Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental Bondcheck dam was not constructed.The management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.There is no vegetative cover at the mining site.Approach road to the mine starts from Gomtu town. Thesame road is commonly used by other companies namelyPCAL <strong>and</strong> Bhutan Stone <strong>and</strong> Mineral Company untilthey enter into their own mining areas.The mine is still active. However, the management hasplanted some seedling <strong>and</strong> grasses where earliermanagement had disposed some overburden.Environmental bond deposit is still not updated7. Others A total of 31 people are employed by the management.A 5,000 litre tank was used to suppress dust generated onthe approach road to the mining area. The sprinkler waspulled by a Tipper.The mining operation was of box type.Even though the waste generation was nil, there are stillsome stretches where greenish talc, phylite <strong>and</strong> quartziteare found.The management has already started touching the terracewhich was left untouched in the past.Drinking water was not available at the mining area.1.3 RecommendationSince the waste generation is negligible, whatever little amount is generated themanagement could keep it within the mining area.Even though, the mining is within the lease area, it is advisable to prevent some areas frommining. This is in particular to area where regeneration has already taken place (Mountainterrace).The management should maintain the af<strong>for</strong>estation carried out.Since water is quite scarce, the management has to make prudent use of it.21

Uttarey Limestone MineThe Uttarey Limestone Mine started its operation from 2002 as a second captive mine <strong>for</strong> PCALplant at Gomtu. This was done to meet the raw material grade, by blending with limestone fromPugli mine. The mine is about 10 km from Gomtu town.The Uttarey mine is divided into three different blocks, Quarry 1, 2 <strong>and</strong> 3.General DetailsAddressUttarey Limestone MineC/o Penden Cement Authority LimitedGomtu, SamtseTel No.05-371010/15Contact PersonMr. Pema TenzinGeneral Manager (<strong>Mines</strong>)Type of minerals mines LimestoneStripping Ratio 1: 5Operation <strong>and</strong> Annual Operated though out the year <strong>and</strong> annual production increasedProductionfrom 15, 656.75 to 1, 29, 448.00 MT as of 2008Geological/Residual Reserve Geological reserve is estimated at 5.4 million MT<strong>and</strong> projected year to lastLease Area <strong>and</strong> Period 75.009 hectares (01/04/1999-31/03/2009, 10 Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater <strong>and</strong> SanitationFacilitiesFirst Aid Kit3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/Rejects/,Overburden/InterburdenThe mine was operated top-down approach where theoperating benches pit slope varies in-between 50 to 75 0 .Bench heights were maintained between 4 to 20 meters.Bench widths were kept between 8 – 30 meters.The management has provided the workers withprotective gears limited to helmets <strong>and</strong> breathing masks.Drinking water <strong>and</strong> first-aid-kit were made available atthe site office.A pit type toilet was made available at the mining site.The management has not provided disposal facilitates <strong>for</strong>sanitary waste.The management has not provided any separate area <strong>for</strong>storing the top soil.The overburden <strong>and</strong> inter-burden including theundersize/rejects <strong>and</strong> other materials were disposed at thepre-determined site.22

Mechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental BondThe mechanisms applied were of two ways: disposingdownhill with the help of a bulldozer <strong>and</strong>, loaded, hauledby tippers <strong>and</strong> dumped at the pre-determined site.There was no benching <strong>and</strong> pit slope was more than 45 owhere waste materials were disposed.The management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.The mine has been in operation <strong>for</strong> about 8 years <strong>and</strong> therewas no vegetative cover at the mining site. Themanagement has however carried out some af<strong>for</strong>estationprogram at the waste dump-yard <strong>and</strong> mine out areas.Approach road to the mine starts from Gomtu town.The restoration of the mine was primary focused on theconstruction of check dams <strong>and</strong> af<strong>for</strong>estation.Environmental bond deposit is still not updated.7. Others A total of 669 people were employed by themanagement.A tanker was provided to sprinkle water to suppress dustalong the approach road to the mine.The channeling of water at the mine site was notdeveloped.Some of the check dam need immediate repairs <strong>and</strong> newcheck dam will be required to be constructed.1.4 RecommendationThe management has to maintain the af<strong>for</strong>estation carried out.The management has to start planning <strong>and</strong> developing environmental restoration programsince the residual reserve may last <strong>for</strong> 3 to 5 years. With good environmental practice <strong>and</strong>restoration program, it will have a positive impact of the Company <strong>for</strong> future miningactivities.The management has to construct new check dams <strong>and</strong> repairs the damaged one. Some ofthe waste dump-yards need to be discontinued.Since water was quite scarce, the management has to make effective utilization of water.23

Kalapani Calc Tufa MineThe Kalapnai Calc Tufa mine is an old mine located at Kalapni about 100 meter aerial distancefrom India. The mine was in operation since 1979. The fist lease was executed in April 24, 1998<strong>for</strong> 10 years period. Of the total area of 58.34 hectares only 24.88 is active <strong>and</strong> deposit is workedout <strong>for</strong> 5 years of operation. The approach road to the mine passes through India at some stretches.General DetailsAddressContact PersonType of minerals minedStripping RatioOperation <strong>and</strong> AnnualProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodKalapani Calc Tufa MineC/o Penden Cement Authority LimitedGomtu, SamtseTel No. 05-371010/15Mr. Tshering , Mining SupervisorMr. Tshetup Wangdi, SurveyorMr. Tshering Samdrup, Environmental Focal Person)Sweetener – Calc TufaNo overburden8 months in a year <strong>and</strong> 30,894 MT spread over 5 years.Of the Geological reserve 5, 28, 891 MT the Residual Reserve isabout 30, 894 MT which is expected to be exhausted by 200958.34 hectares (23/01/09-22/01/2014- 5 Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater <strong>and</strong> SanitationFacilitiesFirst Aid Kit3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/Rejects/Overburden/Inter-The mine was operated from top-down approach wherethe operating benches pit slope varies in-between 45 to50 oBench heights <strong>and</strong> width are maintained as per the PitPlan.The management has provided the workers withprotective gears limited to helmets <strong>and</strong> breathing masks.Drinking water, first-aid-kit <strong>and</strong> bathroom facilities werenot available. There is a stream flowing right next to themine.The management has not provided disposal facilitates <strong>for</strong>sanitary waste.The deposits were mostly outcrop <strong>and</strong> there was hardlyany top soil <strong>and</strong> waste materials. All the waste materialswere left where mining was done.24

urden <strong>and</strong> OthermaterialsMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental BondThe management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.The mine has been in operation since 1979 <strong>and</strong> there wasno vegetative cover at the active mining site. Those mineswhere materials were exhausted or mine-out areas,vegetation were thick <strong>and</strong> consisted of mostly shrubs. Itwas difficult to say, whether the area was natural or wasplanted.Approach road was already inexistence to the mine withno side drain <strong>and</strong> cross drain to channel the surface water.There was no restoration being undertaken, except thatmining benches <strong>and</strong> width were maintained within 5meters <strong>and</strong> pit slope 45 to 50 0 .Environmental bond deposit is still not updated.7. Others The mine will be exhausted within 2009.There was a huge outcrop worshiped by the local peopleacross the boundary.A total of 20 people were employed by the management.Mine water was not channeled.1.5 RecommendationBased on the remaining deposit the mine may last till 2009. There<strong>for</strong>e, the management hasdeveloped Mine Restoration Plan. The restoration activities should include those mine-outareas if it was not restored earlier.The management has to ensure that the outcrop of calc tufa worshiped by the local peopleacross the border to be kept as it.If the mining activities are carried out as it was observed, the need <strong>for</strong> construction ofcheck dam is not necessary.25

Tintalley Quartzite MineTintalley quartzite mine is a captive mine leased in 1993 to Bhutan Ferro Alloys Limited, whosePlant is located at Pasakha, under Chukha Dzongkhag. The mine is located about 1 km north ofTintalley village which falls under survey toposheet no 78 A/16 on the left bank of Jiti Khola <strong>and</strong>Kali Khola Confluence under Samtse Dzongkahg. The approach road measuring about 5 kmtakes–off from Samtse –Sibsoo highway towards Jiti village <strong>and</strong> to the mining area. The miningoperation started in 1994 with an annual production of 13, 516 MT of quartzite. However, theproduction was subsequently decreased in the late nineties <strong>and</strong> early twenties. In 2008, theproduction was limited to 8, 000 MT. The mine is seasonal in operation.Starting from 1994 onward till 2008, the management has excavated about 1, 81, 746.9 MT ofquartzite <strong>and</strong> is used as the main raw material <strong>for</strong> production Ferro Silicon.General DetailsAddressContact PersonType of minerals minedStripping Ratio (Ore to Waste) 1:0.73 (1:0.4)Number of working days <strong>and</strong>Annual ProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodTintalley Quartzite MineC/o Bhutan Ferro Alloys Ltd.Phuentsholing, ChukhaTel No. 05-252246/252420/252109Mr. S. K. Giri, General Manager (<strong>Mines</strong>)Mr. B.P. Sharma, Manager (DTL)Quartzite200 days year (November-April). Production target is fixed onaverage 20, 000 MT per annum. As of now the production hasranged between 5, 437.9 to 24, 108.6 MTTotal mineable reserve is estimated at 0.89 million MT. Basedon residual reserve, the mine might last <strong>for</strong> 36 years startingfrom 2009.4.56 hectares (01/01/05-31/12/2009; 5Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> Protective GearsWater <strong>and</strong> sanitationfacilitiesFirst-Aid- KitThe mine was operated top-down where the operatingbenches pit slope varies in-between 55 to 75 0 .Bench heights were maintained at minimum of 2.5meters to maximum of 25 meters on an average.Bench widths were kept at 5 to 14 meters.The management has provided the workers withprotective gears limited to helmets <strong>and</strong> breathingmasks.Drinking water, first-aid-kit <strong>and</strong> bathroom wereavailable at the site office.26

3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/Rejects/OthermaterialsOverburden/Inter-burdenMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length of WidthThe management has not provided disposal facilitates<strong>for</strong> sanitary waste.The management has not provided any separate area<strong>for</strong> storing the top soil.The overburden including undersize/rejects <strong>and</strong> othermaterials were disposed at the pre-determined site.There was hardly any waste generation. The littlewaste generated mostly consisted of undersizematerials.Waste material was displaced downhill at the predeterminesite. A check dam was under construction,which is expected to be completed be<strong>for</strong>e the onset ofmonsoon.The Pit slope was in between 65 to 75 0 <strong>and</strong> benchheight about 15 meters from the base.4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong> ProgressiveRestorationRestorationEnvironmental BondThe management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.The mine has been in operation <strong>for</strong> about 15 years <strong>and</strong>there was no vegetative cover at the mining site.The management has not carried out any af<strong>for</strong>estationprogram.Approach road to the mine starts from Jiti villagewhich is about 5 km. The access road was pitchedwithout side <strong>and</strong> cross drain to channel the surfacewater.The restoration of the mine was primary focused on theconstruction of check dam.Environmental bond deposit Nu.12,24,212.7. Others The undersize material generation constituted about 30to 40% of the total production. The undersize materialsgenerated were sold to exporters who supply them toBangladesh <strong>and</strong> India. However the market has beenerratic in nature. As of 2008, only 20, 500.86 MT hasbeen exported.Top of the mine was a plateau type <strong>and</strong> it belongs to aprivate individual. In-order to mine further, themanagement has to procure the l<strong>and</strong> to mine moresystematically.On an average 25 workers were employed <strong>and</strong> duringthe season the number increases to 60.Drinking water was available at the base camp <strong>and</strong> alsothere is a Kalikhola River at the base of the mine.There was no channel to drain the mine water.27

There was no electricity at the base office.1.6 RecommendationThe Pit slope of the mining area <strong>and</strong> waste disposal site were in-between 55 to 75 0 . Themanagement has to operate the mine <strong>and</strong> dispose the waste in such a way, that it is easier toattend the final pit slope of 45 0 .The management has to strictly follow FMFS <strong>and</strong> EMP <strong>and</strong> maintain uni<strong>for</strong>m bench height<strong>and</strong> width as mentioned in the report, based on which environmental clearance was issued.The height of the waste disposal site was high <strong>and</strong> there were no proper benches. Themanagement has to decrease the height <strong>and</strong> <strong>for</strong>m proper benches.In-order to carry out further mining, the private l<strong>and</strong> which lies on the top of the mine hasto be procured.Starting from 1994 to 2008, the management has excavated about 1, 81, 746.9 MT withundersize material of 72, 698.76 MT. The management could sell only 28% of theundersize materials <strong>and</strong> the rest was disposed as waste materials. Instead of disposing aswaste, the management has to find an alternative use of the undersize materials.In-order to reduce generation of undersize materials, the management should carry out astudy to find an alternative use.28

Hourikhola Limestone MineHourikhola Limestone mine falls on toposheet no. 78 F/5 which lie just across the border withIndia. The mine started its operation since 1987 <strong>and</strong> the area allocated was 23.59 hectares. Laterpart of the year some of the mining areas were closed due to erection of 400 kV line which passedright across the mining area. The new area of 9.55 hectares was then leased <strong>and</strong> started itsoperation in 2003.The mining operation is divided the following phases:Phase 1- 1986-87;Phase 6 &10-1988-1992;Phase 40 & 33, 1992-203, closed due to tower erection;Phase 13, 19 &28, 1994-2004, closed due to tower erection; <strong>and</strong>Phase 2 & 7 measuring 9.65 hectares are under operation.Contact DetailsAddressContact PersonType of minerals minedStripping Ratio 1:2.85 (1:4)Operation <strong>and</strong> AnnualProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodHourikhola Limestone MineC/o Bhutan Carbide & Chemicals LimitedPhuentsholing, ChukhaTel No. 05-252246/252420Mr. Golong TsheringGeneral Manager (<strong>Mines</strong>)LimestoneOperated though out the year <strong>and</strong> annual production is 20, 000MT.Production target is 15, 000 MT per annum <strong>and</strong> the highestproduction was 24, 000 MT.Total mineable reserve is estimated at 1, 22, 430 MT9.65 hectares (01/04/05-31/03/2010; 5Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetyThe mine was operated top-down approach where theoperating benches pit slope varies in-between 80 to 85 0 .Bench heights were maintained between 15 to 50 meters.A slide had occurred on top of the mine which hasresulted in extension of bench height above 50 meters.Bench widths were maintained between 4.2 to 21 meters.The management has provided the workers with protectivegears such as helmets <strong>and</strong> dust masks only.29

Safety <strong>and</strong> ProtectiveGearsDrinking Water,Sanitation <strong>and</strong> First-Aid-Kit facilities3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/Rejects,Overburden/Interburden&other materialsMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental BondDrinking water, first-aid-kit <strong>and</strong> bathroom were availableat the site office.The management has not provided disposal facilitates <strong>for</strong>sanitary waste.The management has not provided any separate area <strong>for</strong>storing the top soil.The overburden <strong>and</strong> inter-burden includingundersize/rejects <strong>and</strong> other materials were disposed at thepre-determined site.The mechanism applied <strong>for</strong> disposing the waste was bydisposing downhill at the pre-determined site. A series ofcheck dam were constructed, which were washed awaycompletely during 2007 monsoon.The Pit slope, bench height <strong>and</strong> width were maintainedwith a help of series of check dams constructed at thedump-yard.The management has not carried out monitoring of air,water <strong>and</strong> noise at the mining site.The mine has been in operation <strong>for</strong> about 5 years <strong>and</strong> therewas no vegetative cover at the mining site. Themanagement has carried out some af<strong>for</strong>estation program atthe old mining site.Approach road to the mine starts from Totapora, India.The drain needs to be improved.The restoration of the mine was primary focused on theconstruction of check dams <strong>and</strong> some af<strong>for</strong>estationprogram at the old mining area.Environmental bond deposit Nu. 10,10979.007. Others The mine was located just below a private l<strong>and</strong>. Therewere two houses, about 100 meters aerial distance fromthe mine. One house was lying right above the miningarea.A total of 55 people were employed.Drinking water was not available at the site.Channel to drain mine water is claimed to have washedaway.The entire check dam constructed needs immediate repair<strong>and</strong> new check dam has to be constructed simultaneously.There was no electricity at the base office.30

1.7 RecommendationThe management has to prevent mining at the top of the mine where slide has occurred <strong>and</strong>the corresponding side towards power transmission line.The management has take precaution to ensure that the mining does not affect the privatel<strong>and</strong> <strong>and</strong> house above. Also, the management should ensure that waste disposed is arrestedto the extent possible to prevent widening of base/mouth of the gorge.The management has to start planning <strong>and</strong> developing environmental restoration plan sincethe residual reserve may last <strong>for</strong> another 2 years. With good environmental practice <strong>and</strong>restoration program, it will have a positive impact of the Company <strong>for</strong> future miningactivities.The management has to construct a new check dam <strong>and</strong> repair the damaged one. Themanagement should explore the idea of constructing the check dam with combination ofgabion walls <strong>and</strong> RCC.The undersize/reject material generation is comparatively high (40%). In-order to reducegeneration of undersize materials, the management has to carry out a study to find analternate use.31

Tinpawa Qaurtzite MineTinpawa quartzite mine is a captive mine leased in 2007 to Druk Wang Alloys Limited (DWAL),whose Plant is located at Singyegoan Industrial Estate, under Chukha Dzongkhag. The mine islocated on the left bank of Diana Khola Tinpawa Quarzite which is an extension of DhapparQuartzite b<strong>and</strong> <strong>and</strong> <strong>for</strong>ms part of Toposheet No. 78F/1 from the nearest Samtse-Sibsoo highwayunder Samtse Dzongkhag. The approach road to the mine takes–off from Samtse–Sibsoo highwayunder the Diana Bridge <strong>and</strong> is about 6 km to the mining area. Tinpawa stream flows through themine site which joins Daina Khola.The mine was not in operation but development works had started. Quartzite will be used as themain raw material <strong>for</strong> the production Ferro Silicon.Contact DetailsAddressContact PersonTinpawa Quartzite MineC/o Druk Wang Alloys Ltd.Phuentsholing, ChukhaTel No. 05-254184/254192Type of minerals mines QuartziteStripping Ratio (Ore to Waste) 1:0.42Number of working days <strong>and</strong>Annual ProductionThroughout year (300 days) <strong>and</strong> the estimated annual averageproduction is 20, 000 MT.Geological/Residual Reserve Total mineable reserve is estimated at 0.89 million MT.Lease Area <strong>and</strong> Period14.65 hectares (04/06/07-03/06/2017; 10Yrs)ObservationThe mine was not in operation <strong>and</strong> it seems that the development work was stopped <strong>for</strong> than amonth. However, the observations were noted even though it was not in operation.1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetyDevelopment work was carried out from top–downapproach where pit slope varies in-between 55 to 80 0 .Bench heights were maintained at minimum of 5 metersto maximum of 10 meters.Bench widths were about 5 meters.Mine was not in full operation.3. Waste <strong>and</strong> OverburdenManagementSanitary WasteTopsoilUndersize/Rejects/,Waste materials were disposed downhill which has agentle gradient identified as waste dump-yard in the Pitplan.The management has not provided any separate area <strong>for</strong>storing the top soil.32

Overburden/Interburden& OthermaterialsMechanism of Dumping<strong>and</strong> ArrestingPit slope Angle, BenchHeight <strong>and</strong> Length ofWidth4. Environmental AspectsAir EnvironmentWater EnvironmentNoise EnvironmentBiological Environment5. Approach/AccessRoad ConditionsWater Drainage System6. Environment <strong>and</strong>Progressive RestorationRestorationEnvironmental BondNo check dam was constructed.Mine was not in full operation.Approach road to the mine takes-off from Samtse-Sibsoohighway from the Diana Bridge <strong>and</strong> is about 6 km to themine area. The approach road was seasonal in nature.Mine was not in full operation.Environment Bond deposited Nu. 4,09,000.007. Others There was huge outcrop at the top of the mine about 700meters in height <strong>and</strong> facing opposite side on same hilllock, there was a settlement.Boundary pillar might have pass through the private l<strong>and</strong>on the opposite site.On the right h<strong>and</strong> side of the mine, a l<strong>and</strong>slide hasoccurred, which has more or less stabilized. The sameslide has continued to the base of the mine.There was no electricity.1.8 RecommendationOn the same hillock facing opposite site, there is settlement. Also the boundary pillarpasses through their l<strong>and</strong>. In-order to ensure that mining operation does not affect thesettlement, continuous monitoring is necessary.Pit slope mining area <strong>and</strong> waste disposal site is in-between 55 to 80 0 . The management hasto operate the mine <strong>and</strong> dispose the waste in such a way, that it is easier to attend the finalpit slope of 45 0 .As per the environmental clearance, the check dam has to constructed, prior to theoperation of the mine. So-far there is no sign of check dam being constructed as mentionedin the pit plan. The management has to construct the check-dam first.The management should ensure that top soil is preserved <strong>for</strong> future restoration works.By looking at the nature of the deposit, generation of undersize materials may be quitesubstantial. The management may have to blasting charge to minimize generation ofundersize materials.33

Pakchina Quartzite MinePakchina quartzite mine is a captive mine leased in 2004 to Bhutan Ferro Alloys Limited, whosePlant is located at Pasakha, under Chukha Dzongkhag. The mine is located at Pakchina underChukha Dzongkhag <strong>and</strong> the area falls under survey of India Toposheet No. 78F/5 <strong>and</strong> F/9. Theapproach road to the mine is from Pasakha-Manitar-Gedu highway at 22 km point <strong>and</strong> takesadditional 6 km to reach the mining area. The initial mining area was 47.15 hectares which waslater reduced to 30.04 hectares prior to the operation.The mining operation started from 2006 with annual production of 15, 000 MT of quartzite. Theproduction was enhanced during the later years to 39, 000 MT. The mine is operated throughoutyear <strong>and</strong> the quartzite is used as the main raw material <strong>for</strong> the production Ferro Silicon.Contact DetailsAddressContact PersonType of minerals minedStripping Ratio (Ore to Waste) 1:0.35 (1:0.12)Number of working days <strong>and</strong>Annual ProductionGeological/Residual Reserve<strong>and</strong> projected year to lastLease Area <strong>and</strong> PeriodPakchina Quartzite MineC/o Bhutan Ferro Alloys Ltd.Phuentsholing, ChukhaTel No. 05-252246/252420/252109Mr. S. K. Giri, General Manager (<strong>Mines</strong>)Mr. Sangay Tshering, ManagerQuartziteThrough out the year. The target fixed by the management on anannual average is 60, 000 MT. As of now the production hasrange between 15, 000 to 39, 000 MT <strong>and</strong> the target <strong>for</strong> 2009 is45, 000 MT.Total mineable reserve is estimated at 3.15 million MT. Basedon the residual reserve, the mine may last <strong>for</strong> 51 years from2009.30.04 hectares (20/08/04-19/08/2024; 20Yrs)Observation1. Mining Operation DesignPit slope AngleBench Height <strong>and</strong> Width2. Occupational Health <strong>and</strong>SafetySafety <strong>and</strong> ProtectiveGearsWater, sanitation <strong>and</strong>First –Aid-Kit facilities3. Waste <strong>and</strong> OverburdenManagementSanitary WasteThe mine was operated top-down approach where theoperating benches pit slope varies in between 45 to 55 0 .Bench heights were maintained at 5 meters <strong>and</strong> Benchwidth between 5 to 39 meters.The management has provided the workers with protectivegears which were limited to helmets.First-aid-kit was available at the site office. However,drinking water <strong>and</strong> bathroom facilities were not available.The management has not provided disposal facilitates <strong>for</strong>sanitary waste.The management has not provided any separate area <strong>for</strong>34