HRP CONSTRUCTION - Brandeis Focusing on Solutions magazine

HRP CONSTRUCTION - Brandeis Focusing on Solutions magazine

HRP CONSTRUCTION - Brandeis Focusing on Solutions magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

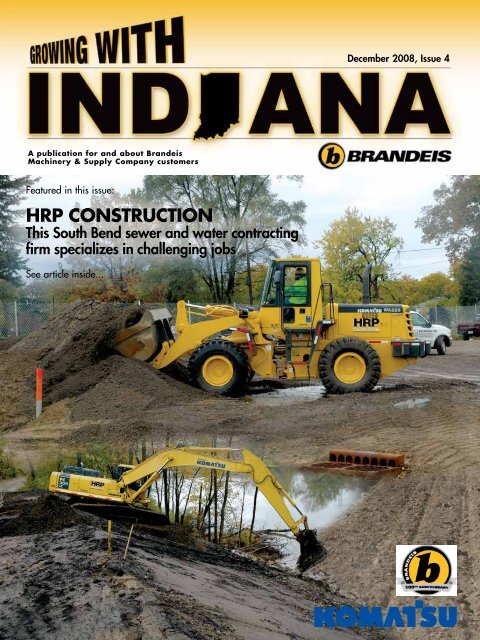

December 2008, Issue 4A publicati<strong>on</strong> for and about <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>Machinery & Supply Company customersFeatured in this issue:<str<strong>on</strong>g>HRP</str<strong>on</strong>g> <str<strong>on</strong>g>CONSTRUCTION</str<strong>on</strong>g>This South Bend sewer and water c<strong>on</strong>tractingfirm specializes in challenging jobsSee article inside...Pant<strong>on</strong>e 072 blue

A MESSAGE FROMTHE PRESIDENTGene Snowden, Jr.RELIABLEEQUIPMENTDear Equipment User:We all know c<strong>on</strong>structi<strong>on</strong> can be a cyclical entity, and througheach cycle we’ve always remained ready to help you in anyway we can. One way we can help is by working with you tounderstand the needs of your business and dem<strong>on</strong>strate how theoutstanding equipment lines we carry can benefit your bottomline. Another is backing up our equipment with resp<strong>on</strong>sive partsand service capabilities that are sec<strong>on</strong>d-to-n<strong>on</strong>e.Komatsu’s revoluti<strong>on</strong>ary dozers, which have drawn ravereviews from industry experts and users alike, are am<strong>on</strong>g ourfeature products in this issue of your <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> <strong>magazine</strong>. Find outhow the D155AX-6 with the Sigma blade is helping companiesmove more material faster. You’ll also see that the new D51recently w<strong>on</strong> a very prestigious industry award for its design,which increases operator visibility for more accurate and efficientwork in a large number of applicati<strong>on</strong>s.No matter what you use equipment for, we’re here to helpensure it maintains its productivity and reliability. We can dothat by working with you to schedule a preventive maintenanceinspecti<strong>on</strong> at your c<strong>on</strong>venience. During the process, we’ll checkyour equipment thoroughly and point out any issues that maycause a major problem down the road. That way, you avoid costlydowntime.To schedule an inspecti<strong>on</strong>, feel free to call us or stop by <strong>on</strong>e ofour locati<strong>on</strong>s. We’ll be happy to work with you any way we can.Sincerely,BRANDEIS MACHINERY & SUPPLY COMPANYGene Snowden, Jr.President and Chief Operating OfficerRESPONSIVESERVICE

THE PRODUCTS PLUSTHE PEOPLE TO SERVE YOU!IN THIS ISSUE<str<strong>on</strong>g>HRP</str<strong>on</strong>g> <str<strong>on</strong>g>CONSTRUCTION</str<strong>on</strong>g>Learn how a talented and committed work force has helped this SouthBend utility c<strong>on</strong>tractor succeed and grow.GUEST OPINIONAGC Chief Executive Officer Stephen E. Sandherr addresses c<strong>on</strong>structi<strong>on</strong>industry priorities as the organizati<strong>on</strong> outlines six specific issues forC<strong>on</strong>gress to act up<strong>on</strong>.INDUSTRY OUTLOOKRead what key industry leaders have to say about the state of thecountry’s infrastructure and what should be d<strong>on</strong>e to fund improvements.PRODUCT INNOVATIONSFind out why customers are praising Komatsu’s D155 dozer with therevoluti<strong>on</strong>ary Sigma blade.NEW EQUIPMENTSee how Komatsu’s new WA320PX-6 parallel tool carrier offers benefits tousers in a wide range of applicati<strong>on</strong>s.NEW UTILITY PRODUCTSIf you are looking for big-excavator features in a utility-size package, theKomatsu PC88MR-8 could be the answer.FORT WAYNE, IN7310 Venture LaneFort Wayne, IN 46818-1256(260) 489-4551FAX (260) 489-1620EVANSVILLE, IN2506 Highway 41 NorthEvansville, IN 47711-4048(812) 425-4491FAX (812) 425-1171LOUISVILLE, KY1801 Watters<strong>on</strong> TrailLouisville, KY 40299-2454(502) 491-4000FAX (502) 499-3195Published by C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc. for <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinerywww.brandeismachinery.comINDIANAPOLIS, IN8410 Zi<strong>on</strong>sville RoadIndianapolis, IN 46268-1524(317) 872-8410FAX (317) 872-8417STANVILLE, KY130 Mare Creek RoadStanville, KY 41659-7003(606) 478-9201FAX (606) 478-9208LEXINGTON, KY1389 Cahill DriveLexingt<strong>on</strong>, KY 40504-1167(859) 259-3456FAX (859) 254-0783SOUTH BEND, IN3160 Youngs CourtSouth Bend, IN 46614(574) 233-8770FAX (574) 233-8775PADUCAH, KY160 County Park Rd.Paducah, KY 42001(270) 444-8390FAX (270) 575-4907CORBIN, KY1484 American Greeting Card RoadCorbin, KY 40701-4813(606) 528-3700FAX (606) 528-9014J. A. (Jay) Paradis, III, ChairmanCharles Leis, Chief Executive OfficerGene Snowden Jr., President & Chief Operating OfficerT<strong>on</strong>y Estes, Senior Vice President/Sales & RentalsLarry Shuck, Senior Vice President/General Manager Crane & Material HandlingR<strong>on</strong> Weir, Used Equipment ManagerChuck Mueller, Vice President/Coal Services ManagerDavid Coultas, Vice President/Regi<strong>on</strong>al Sales ManagerKeith Harlan, Vice President/Product Support ServicesAnth<strong>on</strong>y Hillyard, Fleet Maintenance & Repair ManagerTodd Coffey, Corporate Service ManagerDan Brand<strong>on</strong>, Manager of Sales & Rental ServicesDave Bauer, Utility Equipment ManagerSean McGuire, Corporate Rental ManagerChris Hooker, Coal Sales ManagerSpencer DePoy, Regi<strong>on</strong>al Sales ManagerINDIANAPOLISJohn Newman,Branch ManagerJeff Woods,Product Support Sales Rep.Josh Farmer,Machine Sales Rep.Eric Baker,Machine Sales Rep.Chris Harman,Rental Rep.Pat Creel,Machine Sales Rep.Chet Blant<strong>on</strong>,Rental Rep.Mike Lovell,Product Support Sales Rep.EJ Fisher,Machine Sales Rep.FORT WAYNETim Kreider,Machine Sales Rep.Nathan Rhoades,Rental Rep.Tom Patrick,Product Support Sales Rep.Ralph Glick,Senior Branch Parts Rep.LOUISVILLESteve Seelbach,Branch ManagerWes Broyles,Service ManagerDoug Flynn,Machine Sales Rep.Lee Schilling,Machine Sales Rep.Gene Snowden III,Machine Sales Rep.Tommy Johns<strong>on</strong>,Product Support Sales Rep.John Harping,Product Support Sales Rep.Bob Bisig,Parts ManagerCraig Leis,Rental Rep.STANVILLEBarry Justice,Branch ManagerHarold Vititoe,Service ManagerRalph Scott,Machine Sales Rep.Randy Reynolds,Coal SalesmanJack Hunt,Product Support Sales Rep.Mike Roberts,Product Support Sales Rep.Ricky Johns<strong>on</strong>,Coal Product ServicesHarold Adams,Parts ManagerSOUTH BENDKevin Wolford,Operati<strong>on</strong>s ManagerTom Patrick,Product Support Sales Rep.Doug Fox,Machine Sales Rep.EVANSVILLEBob Morris,Branch ManagerRandy McCormick,Service ManagerKelly Cates,Coal SalesmanMatt Bueltel,Machine Sales Rep.Brand<strong>on</strong> Russell,Machine Sales Rep.Joe Barnard,Product Support Sales Rep.Chris Alcorn,Product Support Sales Rep.Jeff Vinnedge,Coal Product ServicesMike Reese, Parts ManagerRodney Spaw, Rental Rep.LEXINGTONTodd Daugherty,Branch ManagerBill Powell,Service ManagerKen Tate,Machine Sales Rep.John Morse,Product Support Sales Rep.Gayle Tipt<strong>on</strong>,Senior Branch Parts Rep.Lisle Dalt<strong>on</strong>,Rental Rep.PADUCAHDavid Smithmier,Operati<strong>on</strong>s ManagerCory Edwards,Machine Sales Rep.Chad Porter,Product Support Sales Rep.Justin Growel,Rental Rep.CORBINLarry Freeman,Branch ManagerRob Prewitt,Service ManagerJohn Estill,Machine Sales Rep.Robert Krutsinger,Machine Sales Rep.Larry J<strong>on</strong>es,Product Support Sales Rep.Mike Frederick,Coal Product ServicesDavid Helt<strong>on</strong>,Senior Branch Parts Rep.Printed in U.S.A © 2009 C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc.Pant<strong>on</strong>e 072 blue

A SALUTE TO A CUSTOMERRELIABLE EQUIPMENTRESPONSIVE SERVICE<str<strong>on</strong>g>HRP</str<strong>on</strong>g> <str<strong>on</strong>g>CONSTRUCTION</str<strong>on</strong>g>People make the difference for this South Bendsewer and water c<strong>on</strong>tracting firm<str<strong>on</strong>g>HRP</str<strong>on</strong>g> C<strong>on</strong>structi<strong>on</strong> got its start in 1980 whenthe two principals of a mechanical c<strong>on</strong>tractingfirm in South Bend, Ind., formed it, primarily todo site utility work for their plumbing company.Since then, the company has expanded its list ofservices, but still specializes in water and sewerwork, specifically jobs that tend to be moredifficult rather than run-of-the-mill.“We’ve found we’re most competitive whena job has a large element of pipe work involvedwith it, and when it’s a little unusual, and/ormaybe a little tougher than the typical job,” said<str<strong>on</strong>g>HRP</str<strong>on</strong>g> President Paul Fall<strong>on</strong>. “We believe we’re atour best <strong>on</strong> the most challenging projects.”Fall<strong>on</strong> initially ran <str<strong>on</strong>g>HRP</str<strong>on</strong>g> for the twoplumbers before buying the business andbecoming sole owner in 2001. He says a skilledand dedicated work force is what enables thecompany to successfully complete difficultjobs <strong>on</strong>-time and <strong>on</strong>-budget.“I’d put our pers<strong>on</strong>nel up against anybodyin their ability to take <strong>on</strong> difficult projects andcomplete them in a safe, yet cost-effectiveBased in South Bend, <str<strong>on</strong>g>HRP</str<strong>on</strong>g> C<strong>on</strong>structi<strong>on</strong> specializes in water and sewer work throughoutnorth-central Indiana.manner,” said Fall<strong>on</strong>. “We have a goodcombinati<strong>on</strong> of experienced hands and youngtalent that complement each other. We’ve beenfortunate in finding good people and keepingthem. They’re h<strong>on</strong>est, hardworking men andwomen that I literally trust with my life andlivelihood. I’m very proud of what they’re ableto accomplish for us day-in and day-out.”The vast majority of <str<strong>on</strong>g>HRP</str<strong>on</strong>g>’s work is public,such as sewer or road rec<strong>on</strong>structi<strong>on</strong>s, muchof it for municipalities in north-centralIndiana. The company also does a lot of workfor highway departments and educati<strong>on</strong>alinstituti<strong>on</strong>s in the regi<strong>on</strong>.Talented work force<str<strong>on</strong>g>HRP</str<strong>on</strong>g> is well served by its eight fieldsupervisors, five estimators/project managers,and an efficient office support staff whichanswers to C<strong>on</strong>troller Bill Hoppe. Am<strong>on</strong>g thekey pers<strong>on</strong>nel are Senior Field Supervisor AndyRelias, Senior Estimator/Project Manager MattCain and Equipment Manager John Schafer.Fall<strong>on</strong> and Schafer also praised the company’sequipment operators and laborers.“Whatever good we’ve accomplished is allbecause of our people,” said Fall<strong>on</strong>. “While theyhave heard me say that before, they haven’theard it enough. We are lucky and blessed tohave them.”Fall<strong>on</strong> says even when work is slow, <str<strong>on</strong>g>HRP</str<strong>on</strong>g>is interested in talking to good, prospectiveemployees.“Some of our best hires were made when wedidn’t know what we were going to do withthem or how we were going to keep them busy.Fortunately, a number of our employees likedthe industry and us well enough to come <strong>on</strong>board and stick around. We try to promote from

<str<strong>on</strong>g>HRP</str<strong>on</strong>g> is <strong>on</strong>e of the c<strong>on</strong>tractors working at Eddy Street Comm<strong>on</strong>s, a mixed-use development that the City of South Bend and KiteDevelopment are building <strong>on</strong> land formerly owned by the University of Notre Dame. The development is adjacent to campus anddesigned to create more of a college-town atmosphere in South Bend. Here, <str<strong>on</strong>g>HRP</str<strong>on</strong>g> Operator Chris Molnar uses a Komatsu WA320 to movedirt at the job. “I prefer Komatsu wheel loaders,” said Molnar. “With the hydrostatic drive, you d<strong>on</strong>’t overheat the transmissi<strong>on</strong>, soyou d<strong>on</strong>’t have to stop all the time and let it cool down. For visibility, comfort and productivity, it’s hard to beat Komatsu wheel loaders.”within and give them a career path. Traineeshave become pipe layers and operators,apprentices have become skilled journeymen,laborers have become supervisors. These folkswho have grown with us are largely resp<strong>on</strong>siblefor what we’ve achieved and I’m very thankfulfor each and every <strong>on</strong>e of them.”Safety is a priorityIn doing the type of work that <str<strong>on</strong>g>HRP</str<strong>on</strong>g> takes <strong>on</strong>,in particular the deep sewer jobs, safety is amajor c<strong>on</strong>cern. It’s an issue that <str<strong>on</strong>g>HRP</str<strong>on</strong>g> decidedearly <strong>on</strong> would be a priority.“Even before OSHA started mandating a lot ofthings, we were c<strong>on</strong>ducting safety seminars forour crews,” said Fall<strong>on</strong>. “Back in the mid-1980sthere was a rash of deaths in trenching accidentsin Indianapolis. We were about to start thebiggest, deepest sewer job any of us had seenin a while, and we definitely didn’t want anyof our crew members to become a statistic, sowe decided right then and there that we’d getserious about safety, and it’s a commitment westill have today.“As an example, a few years ago, <strong>on</strong>e of ourcompetitors was complaining about having tobuy a sewer box for trench protecti<strong>on</strong>,” Fall<strong>on</strong>noted. “At the time, we probably had morethan 20 sewer boxes and today we probablyhave two dozen or more. The kind of work wedo can be dangerous, but we’re going to doeverything we can to avoid putting our peopleat risk. Owning trench boxes and using themregularly are part of the cost of doing businesssafely, and it’s a cost we happily pay to help usavoid a death or serious injury <strong>on</strong> the job.”Productive equipmentand dealer supportIn order to do its work productively andefficiently, as well as safely, <str<strong>on</strong>g>HRP</str<strong>on</strong>g> gives itsoperators a say in what equipment thecompany is going to use.“Before we buy, operators demo equipmentto give us input from the field,” said Schafer.“We value their opini<strong>on</strong>s. Ultimately, thedecisi<strong>on</strong> is made in the office based <strong>on</strong> value —trying to get the most bang for the buck — buttheir recommendati<strong>on</strong>s are definitely part ofwhat we take into account in determining theC<strong>on</strong>tinued . . .RELIABLEEQUIPMENTRESPONSIVESERVICE

Keeping customers happy is goal of <str<strong>on</strong>g>HRP</str<strong>on</strong>g>. . . c<strong>on</strong>tinuedJohn Schafer,EquipmentManagerbest value, because if the operator likes it, he’sprobably going to be more productive.”<str<strong>on</strong>g>HRP</str<strong>on</strong>g> has six Komatsu wheel loaders (threeWA320s and three WA200s) and two Komatsuhydraulic excavators (a PC300LC-7 and aPC300LC-6).“The PC300s are am<strong>on</strong>g our mainline pipemachines,” said Schafer. “We use them tolay pipe and pull trench boxes. They’re goodmachines, very well-built. We expect them tolast a l<strong>on</strong>g time.“The wheel loaders are great utility machinesfor us to move material around a jobsite,” headded. “We think ever since Komatsu came<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’ South Bend Branch Manager Kevin Wolford (left) and Sales Rep Doug Fox (right)work with <str<strong>on</strong>g>HRP</str<strong>on</strong>g> Equipment Manager John Schafer (center left) and President Paul Fall<strong>on</strong> toprovide equipment and support for <str<strong>on</strong>g>HRP</str<strong>on</strong>g>. “<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> is easy to work with and I trust them,”said Schafer. “They’re willing to go the extra mile for us and that means a lot.”This operator uses a Komatsu PC300LC-7 as <str<strong>on</strong>g>HRP</str<strong>on</strong>g> works to rebuild a part of Boland Avenuein South Bend that was washed out from almost a foot of rain that fell from the remnants ofHurricane Ike.out with the hydrostatic-drive loader, it’s beenthe way to go. They’re powerful, versatile,fuel-efficient and easy to maintain — and we’vefound that with Komatsu, we’re able to use asomewhat smaller loader than our competitors,but still do the same type of work. That helpskeep the purchase price down.”“It’s to Komatsu’s credit that nearly everyloader we’ve bought recently has beenKomatsu,” said Fall<strong>on</strong>. “We demo the othertop brands, but the operators tend to like theKomatsus the best.”Equally important to <str<strong>on</strong>g>HRP</str<strong>on</strong>g> is the support itgets from the <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery & SupplyCompany branch in South Bend.“<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> is easy to work with and I trustthem,” c<strong>on</strong>firmed Schafer. “If we’re in a bindand need a machine or a part, we know wecan count <strong>on</strong> our Sales Representative, DougFox, and Branch Operati<strong>on</strong>s Manager KevinWolford to do everything possible to get uswhat we need. I also appreciate that they’reeasy to get ahold of, even after hours. In short,Doug, Kevin and <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> are willing to go theextra mile for us — and that means a lot.”L<strong>on</strong>g-term optimismWhen Fall<strong>on</strong> started with <str<strong>on</strong>g>HRP</str<strong>on</strong>g>, he didn’thave any full-time help. He hired a coupleof temporary workers, as needed, to do jobs.Today, <str<strong>on</strong>g>HRP</str<strong>on</strong>g> employs 40 or more people duringthe busy summer seas<strong>on</strong>s.“Obviously, we’ve grown a lot, but it’s neverbeen a case of chasing growth for its own sake,”said Fall<strong>on</strong>. “Generally, we’ve added help aswe’ve needed to in order to handle the workload. The last few years, we’ve tried to runseven crews and keep them busy. We’d beengrowing pretty regularly, but recently, it’s beena little flat. Fortunately, we’ve landed a fairlygood-size street rec<strong>on</strong>structi<strong>on</strong> job in Elkhartthat should help keep us busy for a while.“Our goal as a company is to be here for thel<strong>on</strong>g term,” he added. “We intend to do that bykeeping our niche of not just doing the unusualand difficult jobs, but doing them right, with theowner’s goals in mind. As l<strong>on</strong>g as we c<strong>on</strong>tinue totake good care of our customers, I’m optimisticabout our l<strong>on</strong>g-term future.” ■

GUEST OPINION<str<strong>on</strong>g>CONSTRUCTION</str<strong>on</strong>g> INDUSTRY PRIORITIESAssociated General C<strong>on</strong>tractors calls <strong>on</strong> C<strong>on</strong>gressto act <strong>on</strong> six specific issuesStephen E. Sandherr,AGC Chief ExecutiveOfficerThe Associated General C<strong>on</strong>tractors ofAmerica (AGC) recently called <strong>on</strong> membersof the U.S. House and Senate to focus <strong>on</strong> sixpriority areas — those that will most impactthe ability of AGC members to hire, managetheir businesses and pay taxes into the future.“The c<strong>on</strong>structi<strong>on</strong> industry is suffering adrop in employment, especially in highwayand transportati<strong>on</strong> c<strong>on</strong>structi<strong>on</strong>, which hasseen employment drop more than 5 percent inthe past year,” said Stephen E. Sandherr, ChiefExecutive Officer of AGC. “We have also seensignificant volatility in diesel/energy pricesover the last five years.”AGC urged C<strong>on</strong>gress to focus <strong>on</strong> thefollowing top six priorities:AGC is urging C<strong>on</strong>gress to focus <strong>on</strong> six priorities, including fixing a shortfall in theHighway Trust Fund and shoring up domestic energy security as volatility is seen in suchareas as diesel fuel prices.1. Fixing the shortfall in the Highway TrustFund. The administrati<strong>on</strong> has admittedthat the situati<strong>on</strong> is dire and that earlierthan expected, the balance in the HighwayAccount of the Highway Trust Fund isinsufficient to pay its bills <strong>on</strong> time and in full.C<strong>on</strong>gress must fix this shortfall immediatelyso that states and private industry are notleft holding the bag.2. Extending authorizati<strong>on</strong> for the AirportImprovement Program (AIP) in the 111thC<strong>on</strong>gress. C<strong>on</strong>gress needs to give the FAAprograms the authorizati<strong>on</strong> they need tomodernize and improve safety at America’sc<strong>on</strong>gested airports and air space.3. Finalizing appropriati<strong>on</strong>s for FY 2009 andproviding ec<strong>on</strong>omic stimulus that creates jobs.Making decisi<strong>on</strong>s <strong>on</strong> the full FY 2009 programwill help c<strong>on</strong>tractors and the federalgovernment work together to ensure that about$100 billi<strong>on</strong> in federal funds is spent wisely.4. Improving domestic energy security. C<strong>on</strong>gressmust act now to lay a solid energy foundati<strong>on</strong>for the safety and security of the country.5. Extending tax provisi<strong>on</strong>s. Each year,C<strong>on</strong>gress grapples with the decisi<strong>on</strong>s <strong>on</strong>extending tax provisi<strong>on</strong>s, including haltingthe effects of the alternative minimum tax.6. Reauthorizing E-Verify. The simple,straightforward reauthorizati<strong>on</strong> ofE-Verify gives employers across the countrythe c<strong>on</strong>fidence they need to deal with themounting pressures of hiring a competent,legal work force.“In the legislative days that remain, weurge C<strong>on</strong>gress to address these c<strong>on</strong>structi<strong>on</strong>industry priorities,” said Sandherr. ■

years. That estimate includes $134.4 billi<strong>on</strong> forwastewater and collecti<strong>on</strong> systems, $54.8 billi<strong>on</strong>for combined sewer overflow correcti<strong>on</strong>s and$9 billi<strong>on</strong> for stormwater management.“We have an aging infrastructure,” saidSusie Bruninga, Director of Legislative andPublic Affairs with the Nati<strong>on</strong>al Associati<strong>on</strong>of Clean Water Agencies. “Many pipes are100 or more years old. We have a growingpopulati<strong>on</strong>; we have more regulatoryrequirements; we have new challengesc<strong>on</strong>fr<strong>on</strong>ting us, including climate changes; andat the same time, we’re seeing federal fundingfor clean water decreasing.”C<strong>on</strong>cerns about complacencyWhile the scope and extent of infrastructuredeficiencies may vary from regi<strong>on</strong> to regi<strong>on</strong>,most of the nati<strong>on</strong> has seen some impact.Janet Kavinoky, Director of Transportati<strong>on</strong>Infrastructure at the U.S. Chamber ofCommerce, suggests decades of familiarity havehelped lead to our current level of complacency.“People today take our infrastructure forgranted because so much of it was a gift to usfrom our parents and our grandparents,” shesaid. “They started with nothing and knewthey had to have it. Now that we’ve got it, thechallenge is thinking about maintaining whatwe have and then modernizing and expandingits capacity. But because we already have theinfrastructure, it’s too easy to take for granted.”M<strong>on</strong>gan said competing interests for dollarsare the main culprit, but he also attributes aserious lack of forethought at every level ofgovernment. “I think it’s a lack of visi<strong>on</strong> <strong>on</strong>the part of our leadership at the local, stateand federal level,” he said. “There are clearlyexcepti<strong>on</strong>s to that statement, but overall there’sa lack of leadership and understanding —and I’m not talking about simply spendingtax dollars. I’m talking about user fees andother sources of revenue that will make aninvestment in America’s future.”Wake-up callsRecent disasters like Midwest flooding in2008 and the Minneapolis bridge collapsein 2007 have raised public awareness ofinfrastructure needs for brief periods of time,but Kavinoky said the focus created by thoseevents has not been sustained.“I certainly think there’s greater interest, inparticular in bridges and roads, and we seethat reflected in nati<strong>on</strong>al news stories,” shesaid. “But in other respects, such catastrophicevents are a wake-up call for about three weeksand then people start saying that’s not going tohappen in my community or that the answeris to just reprogram the m<strong>on</strong>ey we have — thatwe actually d<strong>on</strong>’t need more m<strong>on</strong>ey. Eventhough organizati<strong>on</strong>s like the U.S. Chamberhave tried to educate people about the needfor more investment and for prioritizati<strong>on</strong>, thatmessage didn’t get through or it didn’t stick.”Most agree, however, that the issue ofinfrastructure needs has shown more stayingpower during the 2008 presidential campaignthan in campaigns of the past. Still, M<strong>on</strong>gansaid it isn’t nearly enough. C<strong>on</strong>tinued . . .Pipe work is a c<strong>on</strong>stantneed as our nati<strong>on</strong>’sinfrastructure c<strong>on</strong>tinuesto age. “Many pipes are100 or more years old,”said Susie Bruninga,Director of Legislativeand Public Affairs withthe Nati<strong>on</strong>al Associati<strong>on</strong>of Clean Water Agencies.

Groups and individuals work to increase awareness. . . c<strong>on</strong>tinued“I think there needs to be a greater debateand a greater realizati<strong>on</strong> that this simplyisn’t spending tax dollars,” he said. “Thisis an investment in America’s future. We’rehammering away, trying to get people tounderstand that and recognize the importanceof an investment in America’s infrastructure.”The impact of acti<strong>on</strong>Such an investment, M<strong>on</strong>gan c<strong>on</strong>tends, canhave a l<strong>on</strong>glasting impact. “A billi<strong>on</strong> dollarsspent <strong>on</strong> highway c<strong>on</strong>structi<strong>on</strong> typicallysupports more than 30,000 jobs,” M<strong>on</strong>gan said.“It’s not insignificant.”“There are studies in different communitiesthat show investment in public transportati<strong>on</strong>returns $6 for every $1 that’s put intoinfrastructure in transit systems,” Kavinokyadded. “We know that transportati<strong>on</strong>investment, in particular, really paysdividends, and not just immediately, but in thel<strong>on</strong>g run.”The cost of inacti<strong>on</strong> can be equally asdramatic. “That’s the ‘patch-and-pray’mentality,” M<strong>on</strong>gan described. “We’llpatch things as they break and we’ll keepthings running together as best we can. Butinfrastructure will c<strong>on</strong>tinue to deteriorate andwe will be simply putting off a bill that weought to be paying today.”The Nati<strong>on</strong>al Surface Transportati<strong>on</strong> Policy and Revenue Study Commissi<strong>on</strong> recentlyfound that the U.S. needs to invest $225 billi<strong>on</strong> a year at all levels of government simplyto maintain current levels of surface transportati<strong>on</strong>. Investment today stands at less than40 percent of that figure.“It’s like taking care of your house,”Kavinoky explained. “If you d<strong>on</strong>’t take careof your roof, if you just keep putting bucketsunder the leaks, eventually it’s going to costyou a lot more than what it would have costto make repairs and replace things when youfirst needed to.”“It’s easier to maintain than it is to rebuild,”agreed Brian Deery, Senior Director/Highwayand Transportati<strong>on</strong> Divisi<strong>on</strong> with theAssociated General C<strong>on</strong>tractors of America.“If we have to go out and rebuild many ofour pavements, we’re talking about hugeinvestments and huge time delays for peopleas we do that kind of work. So it’s better to doit now than to wait.”Signs of progressThere are signs that these pleas for acti<strong>on</strong> arebeing heard. C<strong>on</strong>gress has discussed creating aNati<strong>on</strong>al Infrastructure Bank that would issueb<strong>on</strong>ds to raise funds for select infrastructureprojects that meet certain criteria.Additi<strong>on</strong>ally, California Governor ArnoldSchwarzenegger, Pennsylvania GovernorEdward Rendell and New York City MayorMichael Bloomberg recently announced aninitiative to expand the Building America’sFuture Infrastructure Coaliti<strong>on</strong> to includestate legislative leaders. That coaliti<strong>on</strong> isattempting to build support in pushing thefederal government to play a larger role in thefunding of America’s infrastructure.“I think there is an increased c<strong>on</strong>cern andawareness,” M<strong>on</strong>gan said. “Is it at the levelthat we would like to see it? No. But there areclearly indicati<strong>on</strong>s that it is a step in the rightdirecti<strong>on</strong>, including the coaliti<strong>on</strong>s that we seebeing developed all across the country.”M<strong>on</strong>gan added individuals can have animpact in these funding decisi<strong>on</strong>s, either byworking through various associati<strong>on</strong>s orc<strong>on</strong>tacting their legislators.“There may not be a crisis right now interms of things literally falling down beneathour feet,” Kavinoky said. “But if we actuallymake the investments we need, we cancertainly avert a crisis 10 or 20 years fromnow.” n

USETHEBESTto be your best.Genesis attachments include:• XP Mobile Shears• New! Rebar Shears• Hydraulic C<strong>on</strong>crete Processors• New! Mechanical Pulverizers• New! Quick Coupler System• DemoPro C<strong>on</strong>crete & Steel Processors• and many more . . .<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery and Genesis.Two of the best, ready to help you do yours.Call today.As a designer and manufacturer of high-qualityattachments, we at Genesis are committed toproviding soluti<strong>on</strong>s to professi<strong>on</strong>als in thec<strong>on</strong>structi<strong>on</strong>, demoliti<strong>on</strong>, recycling and utilityindustries. Because <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery haschampi<strong>on</strong>ed that same commitment for decades,we are especially proud to be a member of<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’ family of suppliers.Now, equipment users in Kentucky and Indiana canbenefit from both <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’ expertise and Genesisattachments, which are designed to provide thehighest levels of performance, productivity andbottom-line profits.1000 Genesis DriveSuperior, WI 54880Ph<strong>on</strong>e: (715) 395-5252Fax: (715) 395-5255www.genesisattachments.comE-mail: info@genesisattachments.com

Louisville, KY • (502) 491-4000Stanville, KY • (606) 478-9201Paducah, KY • (270) 444-8390Lexingt<strong>on</strong>, KY • (859) 259-3456Corbin, KY • (606) 528-3700Indianapolis, IN • (317) 872-8410South Bend, IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551

PRODUCT INNOVATIONSRELIABLE EQUIPMENTRESPONSIVE SERVICEIMPROVING EFFICIENCYCustomers throughout U.S. praise Komatsu’s D155dozer with revoluti<strong>on</strong>ary “Sigma blade”As so<strong>on</strong> as Lou Anders, Vice Presidentof Nighthawk Oilfield Services, demo’d aKomatsu D155AX-6 dozer with the Sigmablade, he was c<strong>on</strong>vinced it was the machine heneeded. The Little Rock, Ark.-based companybuilds oil field locati<strong>on</strong>s throughout Arkansas,Texas, Louisiana, Oklahoma and New Mexicoand needs to cut and level massive amounts ofdirt quickly and efficiently.“I’ve always been a loyal user of a competitivebrand, so when my Komatsu sales representativeapproached me about trying the D155, I told himhe’d have to c<strong>on</strong>vince me it would do everythingthe other brand would do, and then some,”he recalled. “It didn’t take l<strong>on</strong>g to figure out itwould be <strong>on</strong>e of our key machines. The Sigmadesign <strong>on</strong> the blade helps us push dirt farther.The old-style blade — what I call a straightblade — loses too much dirt as you’re pushing.This dozer allows us to roll into a cut, load upand just keep pushing and cutting at the sametime without losing power or stalling. Comparedto the competitive brand in its size class, we’removing between 20 percent and 25 percent morematerial. It’s a significant difference.”That’s been a comm<strong>on</strong> finding for usersof the D155AX-6 since Komatsu introducedit in 2006. Komatsu designed the 44-t<strong>on</strong>,354-horsepower dozer to push more materialthan ever before. With its patented dozer blade— shaped like the Greek letter Sigma (∑) —the results are impressive. It carries 15 percentmore material than the previous Komatsumodel and 20 percent more than the leadingcompetitor. The 12.3-cubic-yard Sigma bladehas dual pitch and tilt, and a hydraulic c<strong>on</strong>trolsystem that is easier <strong>on</strong> the operator. Komatsuintroduced a Sigma blade to its new D275dozers in April.Rave reviewsBecause of its ease of operati<strong>on</strong> and morematerial push, Cherokee Builders GeneralSuperintendent Bobby Burns said the needfor additi<strong>on</strong>al dozers <strong>on</strong> a jobsite is decreased.Based in Tulsa, Okla., Cherokee Builders doesgeneral dirt work, utility installati<strong>on</strong> andc<strong>on</strong>crete work for residential, commercial andhighway c<strong>on</strong>structi<strong>on</strong>.“The material doesn’t roll out, like it does withother blade styles; instead, it rolls in,” Burnsexplained. “That equates to more material beingpushed at any <strong>on</strong>e time, and allows us to movemore material over a l<strong>on</strong>ger distance. Instead ofhaving two or three smaller dozers <strong>on</strong> a job, we’reable to do the same work with the D155. It’s alsofuel-efficient, so our cost per yard is very good.” C<strong>on</strong>tinued . . .Komatsu’s patented Sigma dozer blade is designed to promote rolling of material andto keep it from spilling around the sides. It allows the D155AX-6 to push and carry 15percent more material than the previous Komatsu model and 20 percent more than theleading competitor.

Sigma dozer boosts productivity, lowers costs. . . c<strong>on</strong>tinuedOrlando Ruiz, Owner of Orlando Excavati<strong>on</strong>sin Chaplin, C<strong>on</strong>n., said his cost per yard isgreatly improved since he bought a D155 abouta year ago. The excavati<strong>on</strong> c<strong>on</strong>tractor uses thedozer for all types of projects.“It’s really sped up producti<strong>on</strong> because theSigma blade will push so much more material,”Ruiz said. “Specificati<strong>on</strong>s say the bladecapacity is a little more than 12 yards, but sincethe material rolls to the middle, we’ve foundthat it will push more than 20 yards in the rightc<strong>on</strong>diti<strong>on</strong>s. If the c<strong>on</strong>diti<strong>on</strong>s are less-than-ideal,it w<strong>on</strong>’t push that much, but it will go bey<strong>on</strong>dthe 12 yards and significantly outperformsany competitive dozer we’ve used. It has goodbalance, and the fuel ec<strong>on</strong>omy is great.”Gary Schmidt, North Central Iowa Regi<strong>on</strong>alSolid Waste Authority Director, was <strong>on</strong>e of thefirst to use the D155AX-6 with the Sigma blade.Schmidt has used it in cell c<strong>on</strong>structi<strong>on</strong> at theFort Dodge landfill since NCIRSA purchased adozer right when they came <strong>on</strong> the market.“It didn’t take l<strong>on</strong>g to notice that we wereburning far less fuel than we were with ourold dozer,” Schmidt said, who noted thatthe machine now has more than 2,000 hours<strong>on</strong> it. “That’s still the case. Most of the timeit’s around 10 gall<strong>on</strong>s an hour, which isvery good. Couple that with the amount ofmaterial we can move, and our cost to movedirt is lower than before. Compared to atraditi<strong>on</strong>al U-shape blade, the Sigma bladeholds the material much better. It doesn’t leavewindrows like traditi<strong>on</strong>al dozing does. It’s agreat machine.”Anders feels the same way. In fact, becausehis D155AX-6 with the Sigma blade has beenso efficient, he said it’s likely he’ll add more tohis fleet.“We have several yards across the mid-Southand we have several dozers at those locati<strong>on</strong>s.Quite a number of them are competitivebrands, but based <strong>on</strong> the performance of ourKomatsu D155, that’s going to change.” nSuper-slant design earns IDEA awardKomatsu’s D51 dozerreceived a Silver Awardfrom IDEA for itssuper-slant nose designthat offers operators betterblade and area visibility inall grading applicati<strong>on</strong>s.The design is also part ofKomatsu’s new D31, D37and D39 dozers.Komatsu’s innovative D51EX-22/D51PX-22model dozers received a Silver Award fromthe Internati<strong>on</strong>al Design Excellence Awards(IDEA) competiti<strong>on</strong> for the unique design thatprovides outstanding operator visibility ofthe top blade edge and the area in fr<strong>on</strong>t of theblade at all times.That’s accomplished with the uniquesuper-slant nose design. “It allows the operatorto see objects that are very close to the blade,dramatically increasing safety and efficiency<strong>on</strong> the jobsite. This new design assures animprovement in fundamental dozer workparameters,” according to the IDEA awardcitati<strong>on</strong>. The IDEA program is an internati<strong>on</strong>alcompetiti<strong>on</strong> h<strong>on</strong>oring design excellence. The sidesand back of the D51 cab are also slanted to givethe operator better views all around the machine.“Last year, the D51 was named am<strong>on</strong>g theTop 100 c<strong>on</strong>structi<strong>on</strong> equipment machinesby C<strong>on</strong>structi<strong>on</strong> Equipment <strong>magazine</strong>, so theaccolades keep coming,” said Bruce Boebel,Product Marketing Manager, Crawler Dozers.“What we find most gratifying about the IDEAaward is that it reflects the feedback we get fromour customers about the D51: that they’re moreproductive because of better visibility, as well asother productive features of the machine.”

DOZERS100%(productivity runs in this family)c<strong>on</strong>trolYou’re committed to getting things d<strong>on</strong>e <strong>on</strong> time and <strong>on</strong> budget, and you need dependable,hard-working machines to meet your deadlines day after day. The Komatsu D31, D37and D39 dozers all feature the reliability and versatility that have made Komatsu thechoice of owners and operators for years:• KomStat II Hydrostatic Transmissi<strong>on</strong> (HST) for superb accuracy and smooth c<strong>on</strong>trol• Excellent blade visibility that minimizes operator guesswork and reduces cycle times• All the daily maintenance items centralized in <strong>on</strong>e locati<strong>on</strong> for c<strong>on</strong>venient accessWhether you’re looking for a 75, 85 or 95 horsepower machine, you can be c<strong>on</strong>fidentyou’ll get a full day’s work—and then some—from dozers that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA06

NEW EQUIPMENTRELIABLE EQUIPMENTRESPONSIVE SERVICENEW PZ TOOL CARRIERWA320PZ-6 offers benefits to help usersin a wide range of applicati<strong>on</strong>sWhether you’re in c<strong>on</strong>structi<strong>on</strong>, utility, wasteor agriculture, the WA320PZ-6 offers benefitsthat can make your applicati<strong>on</strong> more productive,including a new parallel Z-Bar linkage thatoffers parallel movements in both fork andbucket applicati<strong>on</strong>s. The recently introducedWA320PZ-6 replaces the WA320PT parallel toolcarrier in Komatsu’s wheel loader lineup.“The parallel Z-Bar linkage has twoadvantages,” said Mike Gidaspow, ProductManager Wheel Loaders, who notes theversatility of the WA320PZ-6 makes it excellentin fork and logging applicati<strong>on</strong>s. “Buckets andforks stay more level than with regular wheelloaders, so the operator doesn’t have to adjustthe load to keep it from tipping forward. Also,users will be able to clearly see the load, andeven the end of the tine in fork applicati<strong>on</strong>s,because of the better visibility the WA320PZ-6offers throughout a cycle.”The parallel Z-Bar linkage also offers largetilt force at all heights, large dump angle atmaximum boom height and a two-modebucket leveler. L<strong>on</strong>g lift arms give highdumping clearances and maximum dumpingreach so the operator can level loads <strong>on</strong> thebody of a dump truck.Like other PZ models (WA200PZ-6and WA250PZ-6), the WA320PZ-6 hasan electr<strong>on</strong>ically c<strong>on</strong>trolled hydrostatictransmissi<strong>on</strong> that provides quick travelresp<strong>on</strong>se and aggressive drive into the pile. Aninching pedal gives the operator simultaneousc<strong>on</strong>trol of travel and hydraulic speeds. Thenew variable tracti<strong>on</strong> c<strong>on</strong>trol system with itsunique S-Mode allows the operator to adjust thetractive effort to the job c<strong>on</strong>diti<strong>on</strong>s and reducetire slippage, even in slippery road c<strong>on</strong>diti<strong>on</strong>sduring such applicati<strong>on</strong>s as snow removal.Valuable additi<strong>on</strong>The WA320PZ-6 got a boost in horsepowercompared to the previous PT model, and ispowered by Komatsu’s high-torque, ecot3,Tier 3 engine with high performance, lessfuel c<strong>on</strong>sumpti<strong>on</strong> and lower emissi<strong>on</strong>s asmain features. Keeping track of the machine’sperformance is easier with Komatsu’s KOMTRAXm<strong>on</strong>itoring system, which comes standard andsends informati<strong>on</strong> such as hours, locati<strong>on</strong> andmaintenance alerts wirelessly to a secure Web site.“Al<strong>on</strong>g with other great benefits, such asimproved operator comfort with a roomiercab and easier maintenance and serviceability,KOMTRAX is a fantastic tool for keeping trackof the machine’s productivity and maintenanceschedule,” said Gidaspow. nMike Gidaspow,Product ManagerWheel LoadersBrief Specs <strong>on</strong> Komatsu WA320PZ-6 Parallel Tool CarrierModel Net hp Operating weight Bucket capacity Breakout forceWA320PZ-6 167 hp 32,480-33,900 lbs. 3.25-3.5 cu. yd. 31,810 lbs.The WA320PZ-6 has a new parallel Z-Bar linkage for parallel movements in both fork andbucket applicati<strong>on</strong>s. In additi<strong>on</strong>, the Z-Bar linkage provides excellent digging ability andbetter visibility throughout the cycle.

NEW UTILITY PRODUCTSRELIABLE EQUIPMENTRESPONSIVE SERVICEPC88MR-8 HYDRAULIC EXCAVATORSThese machines deliver big-excavator featuresin a utility-size packageKomatsu’s new PC88MR-8 sets the standardfor large utility-size excavators in the eight-t<strong>on</strong>class. It features a new look that includes aredesigned counterweight and new paintscheme like Komatsu’s c<strong>on</strong>structi<strong>on</strong>-sizemachines. But, that’s just the beginning. Thesefull-featured machines are designed to providethe ultimate in compact excavator comfort,value, productivity, service and maintenanceaccess, and peace of mind.Well-placed handholds and a wide-opening,upper-rail sliding door allow the operator toeasily enter and exit the machine. Operatorswill find that the cab <strong>on</strong> the PC88MR-8 is anextremely spacious platform from which towork. After all, it is the same cab found <strong>on</strong> thelarger PC138USLC-8 and includes standardair c<strong>on</strong>diti<strong>on</strong>er, seven-inch color m<strong>on</strong>itorpanel, AM/FM radio, power outlets and cupholder. The fully adjustable, cloth, high-backsuspensi<strong>on</strong> seat with arm rests is designedto lessen fatigue, and the pilot proporti<strong>on</strong>aljoystick c<strong>on</strong>trols enable the operator to workcomfortably for l<strong>on</strong>g periods of time.The short tail swing of these machinesallows the operator to c<strong>on</strong>centrate <strong>on</strong> thework in fr<strong>on</strong>t of him, instead of worryingabout rear-swing impacts. The result is a morerelaxed and more productive operator, evenwhen working in a c<strong>on</strong>fined area.Komatsu c<strong>on</strong>tinues to focus <strong>on</strong> providinghigh-strength work equipment. ThePC88MR-8 features a new, single boom-swingpin that places extra strength in a high-stresscomp<strong>on</strong>ent, and has an extended lubricati<strong>on</strong>interval of up to 500 hours.Another high-strength element is the X-trackframe. This is the same type of track framefeatured <strong>on</strong> larger Komatsu excavators. TheX-frame design is very rigid and transfers shockevenly throughout the frame. The sloped designof the track frame deters the buildup of dirt anddebris, helping to minimize the time required toclean the machine for transport.Komatsu’s proven Road-Liner tracksystem provides a reliable and l<strong>on</strong>ger-lastingalternative to rubber track. It is mounteddirectly to the rail like a steel grouser, butunlike steel, it is surface-friendly. C<strong>on</strong>tinued . . .Komatsu’s new PC88MR-8 replaces the PC78 model and features a new look that includesa redesigned counterweight and new paint scheme like Komatsu’s larger machines. Thesefull-featured machines are designed to provide the ultimate in compact excavator comfort,value, productivity, service and maintenance access, and peace of mind.ValueThe new PC88MR-8 is equipped with theKOMTRAX machine-m<strong>on</strong>itoring system asstandard equipment — nothing to install andno m<strong>on</strong>thly fees for at least five years. WithKOMTRAX, the owner can access: hour-meterreading, fuel level, travel notificati<strong>on</strong>, machinelocati<strong>on</strong>, cauti<strong>on</strong>s, maintenance replacementnotificati<strong>on</strong>s, and high water-temperature mark.

Features add value to new utility excavator. . . c<strong>on</strong>tinuedThe new PC88MR-8has a 65-horsepower,turbocharged andaftercooled Komatsuengine that provides 17percent more horsepowerthan the PC78MR-6, 10percent greater arm-crowdforce and travel speed,and more pushing powerwith a 3.5 percent increasein drawbar pull than themachine it replaces.To further enhance the value of thePC88MR-8, Komatsu has made single/bidirecti<strong>on</strong>al-flow auxiliary hydraulicsstandard equipment. This allows the operatorto use a variety of attachments, such ashydraulic hammers, hydraulic thumbs, tilting/grading/ditching buckets, grapples etc.ProductivityAutomatic load-sensing, two-speed travelenhances the productivity of the PC88MR-8by automatically shifting from high speed tolow speed when under load, and then fromlow speed to high speed when the load <strong>on</strong> themachine is reduced.Standard pilot proporti<strong>on</strong>al joysticks withproporti<strong>on</strong>al thumb c<strong>on</strong>trol for auxiliaryhydraulics allow the operator to usehydraulic attachments efficiently and easily.Furthermore, five working modes allow theoperator to choose the mode that best matchesthe job he is trying to perform.Other enhancements that will improveproductivity include a 65-horsepower,turbocharged and aftercooled Komatsu enginethat provides 17 percent more horsepowerthan the PC78MR-6, 10 percent greaterarm-crowd force and travel speed, and morepushing power with a 3.5 percent increase indrawbar pull than the machine it replaces.The PC88MR-8 is equipped with severalfuel-management features. The “eco gauge”provides the operator with a visual indicator<strong>on</strong> the m<strong>on</strong>itor panel that enables the operatorto maximize fuel efficiency by working in the“green” range as much as possible.Auto idle helps to c<strong>on</strong>serve fuel by reducingthrottle to low idle after the joysticks and travellevers are left in the neutral positi<strong>on</strong> for foursec<strong>on</strong>ds. Once a machine functi<strong>on</strong> is activated,the machine returns to the preset throttle positi<strong>on</strong>.If the machine is left to idle for more thanfive minutes, an excessive idle warningprovides the operator with both a visual alert<strong>on</strong> the m<strong>on</strong>itor panel and an audible warning.The operator can then determine whether toshut the machine down to c<strong>on</strong>serve fuel.ServiceabilityWide-opening covers and panels provideoutstanding access to daily checkpoints, and thefuel tank and hydraulic tank are side-by-sidefor easy inspecti<strong>on</strong> and access.The radiator andoil cooler are side-by-side, making both easyto inspect and clean, ensuring clean, fresh airreaches each comp<strong>on</strong>ent.Maintenance and lubricati<strong>on</strong> intervals forengine oil and filter, fuel filter, and lubricati<strong>on</strong> ofarm, boom, and boom swing are now 500 hours,making it easy to schedule machine maintenance.Finally, Komatsu provides a standardthree-year, 3,000-hour warranty <strong>on</strong> thePC88MR-8, dem<strong>on</strong>strating Komatsu’scommitment to total customer satisfacti<strong>on</strong> andpeace of mind.“The PC88MR-8 is loaded with featuresthat will enhance operator comfort, value,productivity, and peace of mind. By providinga larger operator stati<strong>on</strong> with many standardfeatures (air c<strong>on</strong>diti<strong>on</strong>er, seven-inch colorm<strong>on</strong>itor panel, 12-volt and 24-volt outlets, andPPC joysticks with thumb-c<strong>on</strong>trolled auxiliaryhydraulic functi<strong>on</strong>), standard auxiliaryhydraulics, and a larger, more powerfulKomatsu engine, Komatsu engineers took thebest and made it better,” said David Caldwell,Product Manager. n

Indianapolis, IN • (317) 872-8410South Bend IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551www.TramacUS.com

KOMATSU & YOURELIABLE EQUIPMENTRESPONSIVE SERVICESTICKING TO THE FUNDAMENTALSListening to the customer is vitalsays VP/GM of C<strong>on</strong>structi<strong>on</strong> Divisi<strong>on</strong>This is <strong>on</strong>e of a series of articlesbased <strong>on</strong> interviews with keypeople at Komatsu discussingthe company’s commitment to itscustomers in the c<strong>on</strong>structi<strong>on</strong> andmining industries — and theirvisi<strong>on</strong>s for the future.Ed PowersVice President and General Manager,C<strong>on</strong>structi<strong>on</strong> Equipment Divisi<strong>on</strong>Ed Powers has been with Komatsu 20 years. He began his careerin April 1988 with the Finance Divisi<strong>on</strong>. He has worked in variouscapacities within the company, most recently as Vice President andGeneral Manager, C<strong>on</strong>structi<strong>on</strong> Equipment Divisi<strong>on</strong>.“During my career, I’ve worn many hats with Komatsu. The thingsI have found that are universal in determining success throughout allfacets of this business are <strong>on</strong>going communicati<strong>on</strong> and the philosophythat the customer always comes first. We can manufacture the mosttechnologically innovative machines in the world, but if they arenot what the customer needs, they are useless. Today, the customerdetermines value, not the manufacturer. As a manufacturer, it isimportant to listen and establish <strong>on</strong>going communicati<strong>on</strong>, not <strong>on</strong>lywith the customer (end user), but also with our distributors. Thisprovides us a better understanding of how Komatsu can build andservice equipment to fit our customers’ needs. In the end, it is all aboutthe relati<strong>on</strong>ship and providing the appropriate soluti<strong>on</strong>.”Ed oversees all activities associated with planning, operati<strong>on</strong>s,selling and servicing Komatsu’s c<strong>on</strong>structi<strong>on</strong>-size equipment line.The c<strong>on</strong>structi<strong>on</strong> line c<strong>on</strong>sists of D31 to D275 dozers; PC128 toPC1250 excavators; WA150 to WA700 wheel loaders; GD555 to GD675motor graders; articulated trucks and rigid-frame trucks less than715 horsepower. “I’m very excited about my new resp<strong>on</strong>sibilities,which now allow me to work closely with our manufacturing plants.My 20-year career with Komatsu has given me the opportunity tocross-functi<strong>on</strong>ally develop the necessary relati<strong>on</strong>ships, so I was able tohit the ground running in my new positi<strong>on</strong>.“Today, it’s just as important knowing your customer, as it isknowing your product.”QUESTION: You have been with Komatsu invarious capacities throughout your career as ithas grown into <strong>on</strong>e of the top two equipmentmanufacturers in the world. How has Komatsubeen able to achieve such a positi<strong>on</strong>?ANSWER: Primarily by adhering to thefundamentals. First and foremost, how well welisten will ultimately determine how successfulwe will be. Today, in many instances, customersknow as much about our product as we do.They have all the readily available resources attheir fingertips. We must not be threatened bythis, but embrace it, listen and be prepared tosupport their unique value propositi<strong>on</strong>. Withthe ever-escalating cost of materials and fuel,many customers are now applying dollars andcents to “value,” and the cost of owning andoperating is <strong>on</strong>e of today’s key differentiators.The questi<strong>on</strong> is no l<strong>on</strong>ger, “What can you do forme <strong>on</strong> the fr<strong>on</strong>t end?” but rather, what can weoffer during their entire owning and operatingexperience, including a return <strong>on</strong> the back end?Believe me, Komatsu is ahead of the game.Through our life-cycle analysis with our miningand c<strong>on</strong>structi<strong>on</strong> equipment, we have provenour return-<strong>on</strong>-asset (ROA) is <strong>on</strong>e of the industry’smost profitable.I have often been asked, “Why doesn’t Komatsuadvertise more?” in publicati<strong>on</strong>s, etc. My reply isthat Komatsu has <strong>on</strong>e of the largest advertisingdepartments in the industry; it comes in theform of engineers. In the past, I may have saidKomatsu isn’t a marketing company, it’s anengineering company. But we understand theimportance of establishing a universal brandidentity, and globally, we’re making progress.As our technological world c<strong>on</strong>tinues to evolveat a tremendous rate, so does the rate of change.There is no other manufacturer in the industrythat embraces and keeps up with today’s rate

of change better than Komatsu. We and ourdistributors take extreme pride with the level ofKomatsu’s global sophisticati<strong>on</strong> and engineeringcapabilities. Komatsu is the leader in research anddevelopment. Much of Komatsu’s technologicalengineering focuses <strong>on</strong> preventive maintenanceand innovati<strong>on</strong>.For example, within the past three years, we haveeither updated or introduced new model changesfor more than 90 percent of our North Americaproduct offering. And, of course, all as a resultof listening and delivering a better value to ourcustomers.As for being an industry innovator in terms oftechnology and design, we c<strong>on</strong>tinue to raisethe bar, with the launch of our latest line of HSTdozers, such as our D51 model with the uniquesuper-slant-nose design, which provides betteroperator visibility and safety and recently w<strong>on</strong>the silver award in the IDEA (Internati<strong>on</strong>alDesign Excellence Awards) competiti<strong>on</strong>. TheIDEA program is the premier internati<strong>on</strong>alcompetiti<strong>on</strong> h<strong>on</strong>oring design excellence inproducts and is sp<strong>on</strong>sored by BusinessWeek<strong>magazine</strong>. In additi<strong>on</strong>, C<strong>on</strong>structi<strong>on</strong> Equipment<strong>magazine</strong> named the D51 <strong>on</strong>e of the “Top 100Products of 2007.”Another example of our innovati<strong>on</strong> can be foundwith our telemetric (GPS) devices, such as ourKOMTRAX remote machine-m<strong>on</strong>itoring system.QUESTION: How is this technology beneficial?And what distinguishes Komatsu from theothers?ANSWER: KOMTRAX is a very powerful toolthat has evolved bey<strong>on</strong>d a device that simplytracks a machine’s locati<strong>on</strong> and hours. It providesreal-time data that can help our customersand distributors better manage their overallbusinesses. From an operati<strong>on</strong>al standpoint,KOMTRAX provides priceless informati<strong>on</strong>,such as idle time, fuel efficiency/c<strong>on</strong>sumpti<strong>on</strong>,operati<strong>on</strong>al performance, load factors andmaintenance reminders. It empowers our dealersto provide proactive support. The KOMTRAXWeb applicati<strong>on</strong> is tied into our Service Supporttools, so when a machine generates a faultcode, instantaneously the local distributor andcustomer are notified. With the click of a butt<strong>on</strong>,our distributor can find the soluti<strong>on</strong>, requiredparts, tools and time it should take to replace orrepair the affected comp<strong>on</strong>ent, preventing anycatastrophic problems. No matter the department— service, sales, parts or finance — telemetricstransforms the business.Globally and domestically, Komatsu leads theway in telemetrics technology and functi<strong>on</strong>ality.More than 16,000 machines in North America andmore than 120,000 units globally are presentlyequipped with KOMTRAX. No other heavyequipment manufacturer comes close, and we arejust scratching the surface. Would you expect lessfrom an engineering company?QUESTION: In what other ways is Komatsuadding value, especially under today’schallenging ec<strong>on</strong>omic times?ANSWER: One way is by providing ourdistributors a more ec<strong>on</strong>omically efficient supplychain, without sacrificing quality. Typically, in thepast, depending <strong>on</strong> the machine spec, it couldtake between 60 and 90 days from the time amachine is ordered until it is delivered to thecustomer. Today, we have reduced (improved)delivery lead times for a significant porti<strong>on</strong> of ourproducts to a four-week or same-m<strong>on</strong>th delivery,minimizing our distributors’ inventory-relatedexpenses. We want our distributors to rely<strong>on</strong> Komatsu for their delivery needs so theycan focus <strong>on</strong> what they do best — selling andsupporting the product.QUESTION: What else is <strong>on</strong> the horiz<strong>on</strong>?ANSWER: It is obvious Komatsu isinnovati<strong>on</strong>-driven. We are always looking forways to stay ahead of the curve. As we speak, weare fully engaged in Tier 4 engineering. As withTier 3, this emissi<strong>on</strong> regulati<strong>on</strong> requirement alsoprovides opportunity. Komatsu looks forwardnot <strong>on</strong>ly to meeting the emissi<strong>on</strong> standards, butelevating our existing innovati<strong>on</strong> to suit ourever-evolving customer needs. It’s clear wherewe are now and the directi<strong>on</strong> Komatsu is going. nMany new features ofKomatsu equipment arethe direct result of not<strong>on</strong>ly new governmentalstandards but alsoof listening to whatcustomers need forbetter producti<strong>on</strong>.

INDUSTRY NEWSEXTENDING BENEFITSAED-NUCA report shows positive effects of ESA,urges an extensi<strong>on</strong> through 2009An AED-NUCA studyshows the depreciati<strong>on</strong>b<strong>on</strong>us and additi<strong>on</strong>alexpensing underthe Ec<strong>on</strong>omicStimulus Act arehaving a positiveeffect as companiessee significant taxadvantages to buyingadditi<strong>on</strong>al equipment.Results of the depreciati<strong>on</strong> b<strong>on</strong>us and Sec. 179expensing levels have been positive, according toa study by the Associated Equipment Distributors(AED) and Nati<strong>on</strong>al Utility C<strong>on</strong>tractorsAssociati<strong>on</strong> (NUCA). Now the AED is pushingfor an extensi<strong>on</strong> of the benefits through 2009.Organizati<strong>on</strong>s such as AED and NUCA are urging lawmakers and the President toextend the equipment-buying benefits of the Ec<strong>on</strong>omic Stimulus Act through 2009,and encouraging investment in such areas as water infrastructure.Part of the Ec<strong>on</strong>omic Stimulus Act passedearlier this year, depreciati<strong>on</strong> b<strong>on</strong>us andadditi<strong>on</strong>al expensing allow companies buyingnew and used equipment to see significant taxadvantages. The catch is that the equipmenthas to have been purchased this year and putinto service before January 1, 2009. One-thirdof resp<strong>on</strong>dents to the AED-NUCA study saidthey purchased equipment to take advantageof the depreciati<strong>on</strong> b<strong>on</strong>us and/or the increasedSec. 179 expensing levels. A quarter said theyplan to purchase additi<strong>on</strong>al equipment beforethe end of the year, but many resp<strong>on</strong>dents saidthey were reluctant to buy machinery due tothe slow housing market and other ec<strong>on</strong>omicfactors.More than three-quarters of resp<strong>on</strong>dents saidthat if the ESA’s capital investment incentiveswere extended, they would be more likely topurchase additi<strong>on</strong>al equipment next year, with77 percent saying the same about the increasedexpensing levels. “Extending the depreciati<strong>on</strong>b<strong>on</strong>us and increased Sec. 179 expensinglevels through the end of 2009 would provideadditi<strong>on</strong>al ec<strong>on</strong>omic stimulus next year,”according to the report.Urging more investmentThe joint organizati<strong>on</strong>s sent a letter to PresidentBush, House Speaker Nancy Pelosi and theHouse and Senate majority and minority leaders,showing the positive impact the depreciati<strong>on</strong>b<strong>on</strong>us and increased expensing have had forc<strong>on</strong>tractors and urging them to extend thebenefits.The organizati<strong>on</strong>s are also urging additi<strong>on</strong>alinvestment in several key areas, such as waterinfrastructure, that will have an impact <strong>on</strong> theec<strong>on</strong>omy. n

MACHINE MANAGEMENTRELIABLE EQUIPMENTRESPONSIVE SERVICEINCREASE PROFITS WITH KOMTRAXHow Komatsu’s fleet-m<strong>on</strong>itoring systemcan save m<strong>on</strong>ey and make m<strong>on</strong>eyIIf you’re a Komatsu equipment user, you’reprobably already somewhat familiar withKOMTRAX, Komatsu’s industry-leading,satellite-based, fleet-m<strong>on</strong>itoring system— which (in stark c<strong>on</strong>trast to othermanufacturers’ comparable systems) comesstandard and with free communicati<strong>on</strong> <strong>on</strong>almost all new Komatsu machines.For example, you may already be using itto track service-meter readings and schedulemaintenance services; to find where aparticular machine is located; and perhapseven to m<strong>on</strong>itor load frequency and machineoperating informati<strong>on</strong>. There’s also a goodchance you’ve been c<strong>on</strong>tacted by yourKomatsu distributor about a machine cauti<strong>on</strong>,possibly even before your operator noticedanything was wr<strong>on</strong>g.All of those are important, worthwhilefeatures that make your Komatsu machinemore valuable. But the real key to a successfulfleet-m<strong>on</strong>itoring system is whether it makesthe owner more profitable. Here’s a primeexample of how KOMTRAX can do just thatby helping reduce machine idle time.Fuel savings and increasedresale valueAccording to Komatsu, throughout the lifeof a machine, idle time typically accountsfor nearly 20 percent of that machine’s totalfuel burn. As an owner, if you can eliminateeven 50 percent of n<strong>on</strong>-productive idle time,your fuel costs can be cut by 10 percent. Intoday’s world of high diesel fuel prices, that’sa significant savings in and of itself, but thebenefits of reducing idle time d<strong>on</strong>’t stop there.Less idling also means higher machine trade-invalue.Let’s say you have two PC200 excavatorsthat actually work 600 hours per year doingidentical work, but <strong>on</strong>e idles 40 percent of thetime whereas the other idles just 20 percentof the time. After five years, the machinethat idles 40 percent of the time will register5,000 hours <strong>on</strong> the service meter, while themachine that idles 20 percent of the time willregister fewer than 4,000 hours. Not <strong>on</strong>ly isthe machine with fewer hours worth more,it will also have had two fewer maintenanceintervals, which means increased availabilityand lower operating expense.By measuring and giving you an accuratepicture of machine idle time versus worktime, KOMTRAX can help you alter operatortendencies to achieve substantial fuel savings,improved owning and operating costs andgreater residual machine value.KOMTRAX can be installed <strong>on</strong> almost anypiece of equipment. It’s available as a retrofitboth for older Komatsu machines and forn<strong>on</strong>-Komatsu equipment. nKOMTRAX canactually makeequipment ownersmore profitable byidentifying wastefulidle time, trackingusage patternsand m<strong>on</strong>itoringmaintenance needs.

EQUIPMENT DESIGNRELIABLE EQUIPMENTRESPONSIVE SERVICETHE ‘PLUS’ ADVANTAGETests show Komatsu’s revoluti<strong>on</strong>ary newundercarriage design significantly reduces costsKomatsu’s new PLUS (Parallel LinkUndercarriage System) has proven it’s possibleto extend the life of a dozer undercarriagethrough a revoluti<strong>on</strong>ary design that limits wearand the need for pin and bushing turns. WithPLUS, that means less costly undercarriagerepairs and replacements, which have proven tobe as much as 50 percent of per-hour operatingcosts throughout the life of a dozer.Extensive testing shows Komatsu’s PLUSundercarriage — available <strong>on</strong> D65EX/PX/WX,D61EX/PX and D51EX/PX models — as muchas doubled the life of a crawler track compared toc<strong>on</strong>venti<strong>on</strong>al types used in both sand and clay.The PLUS Undercarriage features a rotarybushing design that eliminates the need forbushing turns, which eliminates the costsassociated with the turn. Two additi<strong>on</strong>alinternal spacers help maintain bushingalignment, extending durability and overallbushing and seal life.“Unlike a c<strong>on</strong>venti<strong>on</strong>al undercarriage, PLUSuses a parallel bushing that freely rotates,so it doesn’t slide up against the sprocket,”explained Les Scott, Crawler Dozer ProductManager. “That reduces wear and tear andextends the life of the bushing, resultingin l<strong>on</strong>ger undercarriage life and in loweroperating costs throughout the life of themachine.”Links have 45 percent more wear material,increased depth hardness that extendswear life, and a strutted design for addedstrength. All link assembly comp<strong>on</strong>ents canbe field replaced <strong>on</strong>e at a time, as opposedto replacing an entire undercarriage system.Additi<strong>on</strong>ally, sprockets are segmented forsimple replacement and designed to minimizematerial packing.Changing c<strong>on</strong>venti<strong>on</strong>al thinkingAnother key enhancement of the PLUSsystem is track roller-flange height that’sincreased 33 percent over c<strong>on</strong>venti<strong>on</strong>al tracks,with the flange profile matched to the new linkshape. It has alternating single/double flangerollers for improved alignment.“Komatsu tested PLUS under severalc<strong>on</strong>diti<strong>on</strong>s and in each it showed significantreducti<strong>on</strong> in repair and maintenance costs,including 40 percent in an extremely abrasiveapplicati<strong>on</strong>,” said Scott. “In general soilc<strong>on</strong>diti<strong>on</strong>s with a general applicati<strong>on</strong>, thecost reducti<strong>on</strong> was 32 percent, and in rock,10 percent. So PLUS can benefit just aboutevery<strong>on</strong>e who uses a mid-size dozer.” nThe PLUSundercarriagesystem is availablefor several mid-sizedozer models.Komatsu’s PLUSundercarriage system asmuch as doubles the life ofa crawler track comparedto c<strong>on</strong>venti<strong>on</strong>al types usedin both sand and clay.

G O R M A N - R U P P P R I M I N G - A S S I S T P U M P SSizes up to 30".Heads to 470'.Flows to 40,000 GPM.Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456 Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700 Paducah, KY • (270) 444-8390Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551 South Bend, IN • (574) 233-8770A-404 © Copyright, The Gorman-Rupp Company, 2002 Gorman-Rupp Pumps – Mansfield Divisi<strong>on</strong> is an ISO 9001 Registered Company

NEWS & NOTESRELIABLE EQUIPMENTRESPONSIVE SERVICEGary Hirsch to head Crane & Material Handling Divisi<strong>on</strong>Bramco Inc. has hired Gary Hirsch to fillthe positi<strong>on</strong> of General Manager of Crane& Material Handling when Larry Shuck,Senior Vice President/GM Crane & MaterialHandling, retires. After serving Bramco and<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> for 35 and <strong>on</strong>e-half years, Shuckplans to retire in January 2009.Hirsch comes to Bramco with c<strong>on</strong>structi<strong>on</strong>industry experience gained from workingwith Terex Roadbuilding and IngersollRand. He is a graduate of Drexel Universityin Philadelphia, where he earned a B.S. incommerce and engineering sciences with amanagement major. Hirsch has been activein AED (Associated Equipment Distributors)and SAMA (Strategic Account ManagementAssociati<strong>on</strong>).In his new positi<strong>on</strong>, Hirsch will work withcustomers and staff to further advance the craneand material-handling business for <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>and sister company Power Equipment.Hirsch and his wife, Gina, who are originallyfrom Pennsylvania, have lived in Franceand England, in additi<strong>on</strong> to Virginia, Texasand most recently, Oklahoma City. They arenow living in Louisville. Their s<strong>on</strong>, Steven, iscurrently attending the University of Texasat Austin and daughter Lauren is at theUniversity of North Texas in Dent<strong>on</strong>. ■Gary HirschWorld of Asphalt, ARTBA and AGG1 come to OrlandoThe 2009 World of Asphalt Show &C<strong>on</strong>ference is scheduled for March 9-12 inOrlando, Fla., and will be held in c<strong>on</strong>juncti<strong>on</strong>with two other shows, including The AmericanRoad and Transportati<strong>on</strong> Builders Associati<strong>on</strong>Transportati<strong>on</strong> Development Foundati<strong>on</strong>’s(ARTBA-TDF) “Nati<strong>on</strong>al Traffic Managementand Work Z<strong>on</strong>e Safety C<strong>on</strong>ference.”The World of Asphalt is the asphaltindustry’s leading expositi<strong>on</strong> and educati<strong>on</strong>alresource with educati<strong>on</strong>al programs andexhibits that showcase the latest technologiesin asphalt products and services. The Nati<strong>on</strong>alTraffic Management and Work Z<strong>on</strong>e SafetyC<strong>on</strong>ference will also include educati<strong>on</strong>alopportunities.Also co-located is AGG1: Aggregates Forumand Expo 2009, which features exhibits andeducati<strong>on</strong> focused <strong>on</strong> the latest technologies inaggregate-related equipment.To find out more about these upcomingevents, you can visit their Web sites — www.worldofasphalt.com and www.agg1.org. ■AGC urges repeal of 3-percent withholdingThe Associated General C<strong>on</strong>tractors (AGC)is urging c<strong>on</strong>tractors and organizati<strong>on</strong>s toc<strong>on</strong>tact their senators and representatives in aneffort to repeal a law that requires federal, stateand local governments to withhold 3 percentfrom all payments for goods and servicesunder governmental c<strong>on</strong>tracts. The law takeseffect in 2011, and the withholding applies tothe total c<strong>on</strong>tract, not to the revenue generatedfrom the project.AGC points out that most c<strong>on</strong>structi<strong>on</strong>c<strong>on</strong>tracts average less than 3 percent profit,and the law will tighten cashflow that willrestrict b<strong>on</strong>ding capacity. The law places anundue burden <strong>on</strong> S corporati<strong>on</strong>s and jointventures, says the AGC.On its Web site, AGC has a letter that canbe filled out and sent to representatives andsenators. ■

C.P.I.P.O. Box 1689C.R., IA 52406-1689Change Service RequestedPresortedStandardUS Postage PaidC.P.I.USED EQUIPMENT SPECIALS2005 KomatsuPC300LC7L, U20981-1,2,277 hrs.$184,6672006 Komatsu HM400,BT8812, 3,505 hrs.$280,000ARTICULATED HAUL TRUCKS2005 Komatsu HM400, BT8813, 5,834 hrs........................$210,0002005 Komatsu HM400, BT8814, 5,820 hrs........................$210,0002006 Komatsu HM400-1, BT8812, 3,505 hrs....................$280,000ASPHALT PAVER1996 LeeBoy L8500T, BT8811.............................................$15,000BACKHOE LOADERS2001 Komatsu WB140-2, 4X 4x4, BC7708, 3,368 hrs.........$30,0002005 Komatsu WB140-2N, PT20635-1, 1,875 hrs..............$32,667COMPACTION1989 Cat CS433B, BT8806...................................................$25,0001993? IR ST105, PT24748, 5,074 hrs......................................$8,000CRAWLER DOZERS1999 Komatsu D39E-1, BT8503, 4,142 hrs.........................$39,0002004 Cat D5G XL, BT8815, 3,464 hrs...................................$65,0001993 Cat D6H, BT8805..........................................................$61,000DOZERS2006 Komatsu D39EX-21A, U21322-1, 1,641 hrs...............$65,3331999 Komatsu D39P-1, PT16603-1, 2,778 hrs....................$28,0002000 Komatsu D41E-6, U17487-1, 6,998 hrs......................$26,5332006 Komatsu D41E-6, U24586, 786 hrs..........................$105,333EXCAVATORS1980 Cat 225, BT8602, 955 hrs.............................................$22,0002004 Cat 330CL, BT8820, 5,323 hrs...................................$156,0001996 Case 9030B, U24592, 6,818 hrs..................................$40,0002005 Case CX50B, PT24676, 1,660 hrs...............................$26,6672003 Komatsu PC120-6E0, U23797, 1,881 hrs..................$72,0002005 Komatsu PC160LC-7, U24366, 840 hrs...................$114,2672000 Komatsu PC200LC-6LE, U22137-1, 4,532 hrs..........$61,3332003 Komatsu PC200LC-7, U19635-1, 4,097 hrs...............$86,6672000 Komatsu PC200LC-6, U17638-1, 10,210 hrs.............$50,6671994 Komatsu PC250LC-6, U24000, 7,643 hrs..................$36,000Most machinesare availablefor rentalpurchaseopti<strong>on</strong>. Allmachinessubject toprior sale. Yearlisted is year ofmanufacture.2005 Komatsu PC300LC-7L, U20983-1, 2,669 hrs.$175,9162005 Komatsu PC300LC-7L, U20530-2, 3,300 hrs...........$182,6672005 Komatsu PC300LC-7L, U20983-1, 2,669 hrs...........$175,9162005 Komatsu PC300LC-7L, U20981-1, 2,277.................$184,6672006 Komatsu PC400LC7-E0, PT22435, 2,380 hrs..........$311,3332006 Komatsu PC35MR-2, U21737-1, 300 hrs...................$37,3332007 Komatsu PC35MR-2, U22911-1, 392 hrs...................$30,0002005 Komatsu PC78MR-6, U20387-2, 759 hrs...................$68,2802006 Komatsu PC78MR-6, PT21984-1, 1,036 hrs..............$56,000FORESTRY2006 Prentice 210E, U21583-1, 1,200 hrs...........................$94,6671995 Prentice 410D, PT24691.............................................$10,6671997 Prentice 410E, U24649, 6,410 hrs..............................$22,0001998 Timberjack 460C, U24575, 5,090 hrs.........................$33,3331996 Cat 525, U24432...........................................................$25,3332003 Deere 535, PT24745, 6,089 hrs...................................$46,6672001 Hydro Ax 570, PT24749, 7,351 hrs..............................$33,3332006 Valmet 603, U22776-1, 390 hrs.................................$124,6671987 Deere 648D, U24518......................................................$9,3332003 Hydro Ax 670, U24352, 2,759 hrs....................................P.O.R2003 Franklin Q80, U24360, 6,057 hrs.................................$40,0001993 Bell Super T, U24591...................................................$17,3331998 Timbco T425C, U24579, 14,573 hrs............................$52,000MILLING MACHINE2000 Roadtec RX60C, PT24687, 4,300 hrs........................$120,000SKID STEERS1981 Bobcat 743, U24589, 3,566 hrs.....................................$4,6672006 Bobcat T190, BC0000, 460 hrs...................................$39,000SWEEPER1997 Broce RC300, U014559-1............................................$14,667OFF-ROAD TRUCKS1996 Haulpak 330M, BP1712, 19,699 hrs................................P.O.R2000 Komatsu HD605-5, BP7405, 13,602 hrs.........................P.O.RWHEEL LOADER2002 Cat IT28G, BT8816, 6,949 hrs......................................$61,000For additi<strong>on</strong>al informati<strong>on</strong>, please call (502) 493-43802006 Komatsu D41E-6,U24586, 786 hrs.$105,333Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551South Bend IN • (574) 233-8770 Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700 Paducah, KY • (270) 444-8390