THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

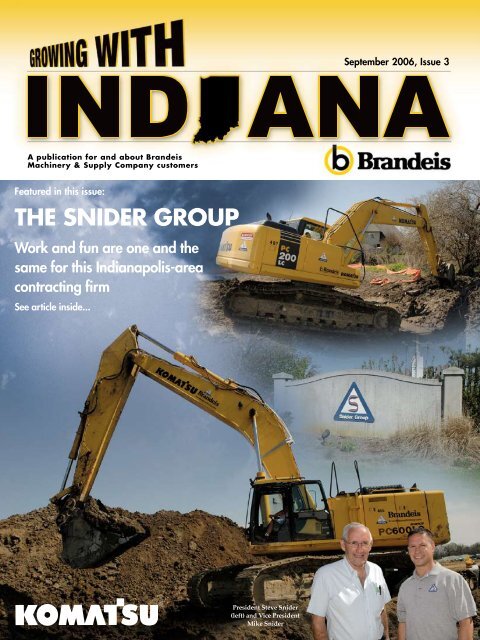

IN THIS ISSUE<str<strong>on</strong>g>THE</str<strong>on</strong>g> <str<strong>on</strong>g>SNIDER</str<strong>on</strong>g> <str<strong>on</strong>g>GROUP</str<strong>on</strong>g>Having d<strong>on</strong>e sitework for more than 1,500 Indianapolis-areasubdivisi<strong>on</strong>s, the Snider family still loves their work.GUEST OPINIONEben Wyman, Vice President of Government Relati<strong>on</strong>s for the Nati<strong>on</strong>alUtility C<strong>on</strong>tractors Associati<strong>on</strong>, explains the “Americans for Pure Water”campaign, meant to stimulate a grass-roots movement to support waterinfrastructure funding.DOLLARS & SENSEFaced with skyrocketing fuels costs, c<strong>on</strong>tractors are looking for ways tocut costs and protect profits. Here are some fuel-saving tips that can makea difference to the bottom line.NEW PRODUCTCheck out the new Sigma Dozer, Komatsu’s totally redesigned D155-sizedozer, and find out how it delivers unrivaled productivity in its size class.MORE NEW PRODUCTSKomatsu’s new WB140-6 backhoe offers greater productivity al<strong>on</strong>g withimproved operator comfort.PRODUCT NEWSFind out how Komatsu made its new Dash-2 series articulated dumptrucks (ADTs) even tougher, more powerful and more technologicallyadvanced than its predecessors.FORT WAYNE, IN7310 Venture LaneFort Wayne, IN 46818-1256(260) 489-4551FAX (260) 489-1620EVANSVILLE, IN2506 Highway 41 NorthEvansville, IN 47711-4048(812) 425-4491FAX (812) 425-1171LOUISVILLE, KY1801 Watters<strong>on</strong> TrailLouisville, KY 40299-2454(502) 491-4000FAX (502) 499-3195Published by C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc. forwww.brandeismachinery.comINDIANAPOLIS, IN8410 Zi<strong>on</strong>sville RoadIndianapolis, IN 46268-1524(317) 872-8410FAX (317) 872-8417STANVILLE, KY130 Mare Creek RoadStanville, KY 41659-7003(606) 478-9201FAX (606) 478-9208LEXINGTON, KY1389 Cahill DriveLexingt<strong>on</strong>, KY 40504-1167(859) 259-3456FAX (859) 254-0783RELIABLE EQUIPMENTRESPONSIVE SERVICEPrinted in U.S.A © 2006 C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc.SOUTH BEND, IN3160 Youngs CourtSouth Bend, IN 46614(574) 233-8770FAX (574) 233-8775PADUCAH, KY160 County Park Rd.Paducah, KY 42001(270) 444-8390FAX (270) 575-4907CORBIN, KY1484 American Greeting Card RoadCorbin, KY 40701-4813(606) 528-3700FAX (606) 528-9014<str<strong>on</strong>g>THE</str<strong>on</strong>g> PRODUCTS PLUS<str<strong>on</strong>g>THE</str<strong>on</strong>g> PEOPLE TO SERVE YOU!J. A. (Jay) Paradis, III, ChairmanCharles Leis, Chief Executive OfficerGene Snowden, President & Chief Operating OfficerT<strong>on</strong>y Estes, Senior Vice President/SalesLarry Shuck, Senior Vice President/General Manager Crane & Material HandlingR<strong>on</strong> Weir, Used Equipment ManagerDavid Ball, Vice President/Regi<strong>on</strong>al Sales ManagerChuck Mueller, Vice President /Regi<strong>on</strong>al Sales ManagerDavid Coultas, Vice President/Regi<strong>on</strong>al Sales ManagerKeith Harlan, Vice President/Product Support ServicesAnth<strong>on</strong>y Hillyard, Fleet Maintenance & Repair ManagerDavid Ballinger, Corporate Service ManagerDan Brand<strong>on</strong>, Manager of Sales & Rental ServicesDave Bauer, Product Manager/Komatsu Utility EquipmentSean McGuire, Corporate Rental ManagerINDIANAPOLISJohn Newman,Branch ManagerJeff Woods,Service ManagerJustin Bastin,Machine Sales Rep.Josh Farmer,Machine Sales Rep.Spencer Depoy,Machine Sales Rep.Eric Baker,Machine Sales Rep.Chris Harman,Kompact Sales Rep.Ridley St<strong>on</strong>e,Machine Sales Rep.Todd Coffey,Product Support Sales Rep.Mike Lovell,Product Support Sales Rep.Bob Nickers<strong>on</strong>,Senior Branch Parts Rep.EJ Fisher,Rental Rep.SOUTH BENDKevin Wolford,Operati<strong>on</strong>s ManagerSpencer McCaslin,Machine Sales Rep.Thomas J. Patrick,Product Support Sales Rep.Doug Fox,Rental Rep.LOUISVILLEBob Morris,Branch ManagerWes Broyles,Service ManagerDoug Flynn,Machine Sales Rep.Lee Schilling,Machine Sales Rep.Gene Snowden III,Machine Sales Rep.Tommy Johns<strong>on</strong>,Product Support Sales Rep.Dwight Dunn,Product Support Sales Rep.Bob Bisig,Senior Branch Parts Rep.Jeff Marklein,Kompact Sales Rep.Craig Leis,Rental Rep.LEXINGTONTodd Daugherty,Branch ManagerBill Powell,Service ManagerKen Tate,Machine Sales Rep.John Morse,Product Support Sales Rep.Gayle Tipt<strong>on</strong>,Senior Branch Parts Rep.Lisle Dalt<strong>on</strong>,Rental Rep.FORT WAYNEChris Stevens,Operati<strong>on</strong>s ManagerTim Kreider,Machine Sales Rep.Nathan Rhoades,Machine Sales Rep.Thomas J. Patrick,Product Support Sales Rep.Ralph Glick,Senior Branch Parts Rep.Jim Geller,Rental Rep.EVANSVILLEBob Morris,Branch ManagerDam<strong>on</strong> Fortune,Machine Sales Rep.Kelly Cates,Machine Sales Rep.Matt Bueltel,Machine Sales Rep.Joe Barnard,Product Support Sales Rep.Chris Alcorn,Product Support Sales Rep.Jeff Vinnedge,Product Support Sales Rep.Mike Reese,Parts ManagerRodney Spaw,Rental Rep.CORBINLarry Freeman,Branch ManagerRob Prewitt,Service ManagerJohn Estill,Machine Sales Rep.Robert Krutsinger,Machine Sales Rep.Larry J<strong>on</strong>es,Product Support Sales Rep.Mike Frederick,Product Support Sales Rep.David Helt<strong>on</strong>,Senior Branch Parts Rep.PADUCAHDavid Smithmier,Operati<strong>on</strong>s ManagerCory Edwards,Machine Sales Rep.Joe Barnard,Product Support Sales Rep.Chad Porter,Product Support Sales/Rental Rep.STANVILLEBarry Justice,Branch ManagerHarold Vititoe,Service ManagerDave Shaffer,Machine Sales Rep.Randy Reynolds,Machine Sales Rep.Jack Hunt,Product Support Sales Rep.Harold Adams,Parts ManagerPant<strong>on</strong>e 072 blue

The Snider Group recently rented this Komatsu PC35compact excavator for a job that was too tight for itstraditi<strong>on</strong>al c<strong>on</strong>structi<strong>on</strong>-size excavators.Mike has been with the company full timefor 12 years now and serves as <strong>on</strong>e of two VicePresidents. Senior Estimator Dan Shotts is theother.“We’ve grown tremendously since Mike hasbeen <strong>on</strong> board running much of the day-to-daybusiness,” acknowledged Steve. “He’s d<strong>on</strong>e abetter job than I ever did. We now have about50 full-time employees and probably get up to65 or so during the summer. We were a muchsmaller company 20 years ago and never in mywildest dreams did I think we’d employ thismany people or do this much work.”“There really wasn’t any reas<strong>on</strong> to thinkwe would grow to this size,” Mike c<strong>on</strong>curred.“But things change. There’s been a great dealof growth in and around Indianapolis duringthe past decade or so and we’ve been able togrow right al<strong>on</strong>g with it. My grandfather wouldbe amazed. He used to look at some of ourcompetitors and ask, ‘What would anybody dowith three excavators?’ Well, we now have eightand I’ll tell you, we keep them very busy.”A group effortThe Sniders credit much of their successto a large group of talented, c<strong>on</strong>scientious,l<strong>on</strong>gtime employees who treat the company asif it’s their own.“One of the reas<strong>on</strong>s I named this company‘The Snider Group’ is because I really do viewit as a group effort and enterprise — and thatincludes every employee,” insisted Steve. “OurMissi<strong>on</strong> Statement says, ‘It’s our objective tohave good people that are proud to say theywork here,’ and in large part, I think we’veachieved that. Our average tenure right nowis about 14 years and we have seven or eightpeople with more than 20 years. We know thatbecause we give them a cruise at 20 years as away to show our appreciati<strong>on</strong>.”“The way we look at it, all the ir<strong>on</strong> in theworld doesn’t do you any good if you d<strong>on</strong>’thave good people,” added Mike. “You wantL<strong>on</strong>gtime Snider Group operator T<strong>on</strong>a Badger uses the KomatsuPC600 to dig water and sewer lines for the Saddlebrook at Shelbornesubdivisi<strong>on</strong> in Carmel, Ind. “The PC600 is a digging beast,” saidBadger. “I think it’s the best thing the company ever bought.”Operator Craig Shaffer uses a PC200LC-7 to install some sub-surfacedrain tile at Cimmar<strong>on</strong> Place subdivisi<strong>on</strong> in Bo<strong>on</strong>e County. “I preferKomatsu excavators because they’re smooth and fast,” said Shaffer.people with a good attitude who not <strong>on</strong>ly getthe job d<strong>on</strong>e, but represent you well at all times.Fortunately, we have many of those people— from our laborers, operators and mechanicsright up through our top managers.”In additi<strong>on</strong> to the Sniders and Shotts, keypers<strong>on</strong>nel include Project Managers SteveKiggins and Mike Hargis, Shop Foreman GaryFoster, and Office Manager Mary Hamerin.Productive equipmentFor its excavator fleet, The Snider Grouphas turned largely to Komatsu machines from<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery & Supply in Indianapolis.“We’ve been using Komatsu excavators foryears,” reported Mike. “I think our first <strong>on</strong>ewas a Dash-3 model that we ran for 19,000hours before trading it in. We never put awrench to either the engine or the hydraulics.C<strong>on</strong>tinued . . .RELIABLEEQUIPMENTRESPONSIVESERVICE

Snider Group emphasizes safety and professi<strong>on</strong>alism. . . c<strong>on</strong>tinued(L-R) Steve and MikeSnider say theyappreciate the supportthey get from <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’Indianapolis branch andSales RepresentativeRidley St<strong>on</strong>e.It was a fantastic machine. We’ve had manyKomatsu models since then and they’ve allbeen very good machines.”Currently, the company has a PC600, twoPC400s, a PC300 and a PC200, and rents specialtypieces as necessary, including most recently, acompact, tight-tail-swing PC35. “The smallestthing we had wouldn’t fit <strong>on</strong> the job we weredoing, but the Komatsu compact excavatorwould. It did a great job,” c<strong>on</strong>firmed Mike.At the other end of the spectrum, Mike saysthe PC600 has enabled The Snider Group totake <strong>on</strong> jobs it might not have taken <strong>on</strong> before.“We bought it initially because we neededthe reach and producti<strong>on</strong> for a deep job.But <strong>on</strong>ce we had the PC600, we startedbidding other deep jobs. Even <strong>on</strong> jobs thatAugie Koch, who’s been a foreman at Snider Group for 28years, uses a Komatsu PC400LC-6 to load trucks at Oak Manorsubdivisi<strong>on</strong> in Westfield.d<strong>on</strong>’t necessarily require a machine thatbig, the producti<strong>on</strong> we get from it makes itworthwhile. For example, although we maynot be going more than four or five feet in theground, we sometimes lay storm sewer with it.That may seem excessive, but we’ve found itups our efficiency quite a bit.”The Sniders say they also appreciate theservice they get from <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> and SalesRepresentative Ridley St<strong>on</strong>e.“Ridley and <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> have been veryresp<strong>on</strong>sive to our needs,” asserted Steve Snider.“They’re an excellent distributor. When a partsguy will give you his home number, and youcall him <strong>on</strong> a Saturday evening because youneed a part, and he’s willing to go in and getyou what you need — that’s a good company towork with. <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> has d<strong>on</strong>e that for me.”Committed to qualityThe Sniders estimate that 95 percent oftheir business comes from repeat customers.“Our regular customers are committed toquality, and so are we,” said Steve. “Becauseof that, we’ve developed many good businessrelati<strong>on</strong>ships. We sometimes help our clients<strong>on</strong> the fr<strong>on</strong>t end of a job by doing takeoffs, andoften, just by looking at a site, we can point outpotential pitfalls. Once a job starts, they trustus to make adjustments <strong>on</strong> the fly, help solveany issues that do crop up, and always treatthem fairly when those issues arise.”The Snider Group’s philosophy is to underpromiseand over-deliver.“We bid a realistic schedule at a fair priceand regularly meet or beat the budgets anddeadlines,” said Mike. “We do our best toalways do a job in a way that reflects favorablyup<strong>on</strong> both our company and our customers.Running a clean, safe job where the equipmentlooks good and the people are professi<strong>on</strong>alenhances our reputati<strong>on</strong> and the reputati<strong>on</strong> ofour client. We think that’s important.”Down the road, Mike says he believes there’sroom for c<strong>on</strong>tinued growth at The SniderGroup. “We think the market’s good and thearea is still growing, so the future looks bright.In this business, we’re all optimists,” he laughed.“If we weren’t, we wouldn’t be c<strong>on</strong>tractors.” n

Louisville, KY • (502) 491-4000Stanville, KY • (606) 478-9201Paducah, KY • (270) 444-8390Lexingt<strong>on</strong>, KY • (859) 259-3456Corbin, KY • (606) 528-3700Indianapolis, IN • (317) 872-8410South Bend, IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551

GUEST OPINION“AMERICANS FOR PURE WATER”NUCA leads effort to secure more water/wastewater infrastructure fundingAs the Bush Administrati<strong>on</strong> c<strong>on</strong>tinues to givevery low priority to funding programs thataddress the problem of America’s deterioratingwater and wastewater infrastructure, NUCA(Nati<strong>on</strong>al Utility C<strong>on</strong>tractors Associati<strong>on</strong>) isembarking <strong>on</strong> a new effort to get Americancitizens engaged in the debate. With existingneeds approaching $200 billi<strong>on</strong>, there is nobetter time to mobilize the general public toput pressure <strong>on</strong> the federal government to fixthe nati<strong>on</strong>’s water and sewer systems. That isexactly what the “Americans for Pure Water”campaign will do.The campaign is the brainchild of theClean Water Council (CWC), a coaliti<strong>on</strong> ofsome 30 nati<strong>on</strong>al organizati<strong>on</strong>s representingunderground c<strong>on</strong>structi<strong>on</strong> c<strong>on</strong>tractors, designprofessi<strong>on</strong>als, manufacturers, suppliers andfinance professi<strong>on</strong>als committed to ensuringthat America has sound, dependable water/wastewater infrastructure.Members of CWC, which NUCA chairs, haveworked tirelessly to keep this issue <strong>on</strong> the fr<strong>on</strong>tburner <strong>on</strong> Capitol Hill. But given current WhiteHouse oppositi<strong>on</strong> and C<strong>on</strong>gressi<strong>on</strong>al apathy(federal infrastructure funding has been cut fortwo straight years and is <strong>on</strong> the chopping blockagain this year), it has become clear that now isthe time to reach outside of the nati<strong>on</strong>’s capitoland into local communities.How you can helpThere are short- and l<strong>on</strong>g-term soluti<strong>on</strong>sto the problem of the country’s deterioratinginfrastructure. One is the establishment of awater infrastructure trust fund as a dedicatedsource of revenue for water and sewerprojects. Another is to reauthorize the currentState Revolving Fund (SRF) programs atsubstantially higher funding levels.Rather than replace those efforts, the“Americans for Pure Water” campaign isdesigned to complement them. We want tocreate in the minds of the man, woman andchild <strong>on</strong> the street a direct c<strong>on</strong>necti<strong>on</strong> betweenAmerica’s failing underground infrastructureand growing problems with public health, theenvir<strong>on</strong>ment and America’s overall quality oflife. The goal is to get them mad and involved.Lawmakers listen when c<strong>on</strong>stituents demandacti<strong>on</strong>. Therefore, as the campaign progresses,organizers will need people to show up andparticipate in public relati<strong>on</strong>s activities and eventsdesigned to generate local media attenti<strong>on</strong>.Water is the resource we rely <strong>on</strong> most. It isneeded to sustain not <strong>on</strong>ly life, but also thequality of life. Any<strong>on</strong>e who wants to helpcreate a citizen backlash to the c<strong>on</strong>tinuingwater/wastewater infrastructure cuts isstr<strong>on</strong>gly encouraged to join the campaign. And,the time to do it is now. To become involved,please c<strong>on</strong>tact NUCA’s Government Relati<strong>on</strong>sDepartment at (703) 358-9300. nEben WymanThis Guest Opini<strong>on</strong> waswritten by Eben Wyman,Vice President of GovernmentRelati<strong>on</strong>s for the Nati<strong>on</strong>alUtility C<strong>on</strong>tractors Associati<strong>on</strong>(NUCA). It’s excerpted froma column that appeared in theMay 2006 issue of UtilityC<strong>on</strong>tractor <strong>magazine</strong> and isprinted here with permissi<strong>on</strong>.“Americans for Pure Water” isa promoti<strong>on</strong>al effort designedto generate grass-roots supportto improve the nati<strong>on</strong>’s water/wastewater infrastructure. Thecampaign will try to involvethe general public, as wellas industry professi<strong>on</strong>als,to pressure lawmakers toincrease federal funding forwater, sewer and stormdrain projects.

DOLLARS & SENSELOWER YOUR OPERATING COSTSC<strong>on</strong>sider these opti<strong>on</strong>s whenseeking ways to reduce fuel costsUpdating your fleetwith newer machinerycan increase fuelefficiency. For example,Komatsu’s PC200LC-8features an ecot3, Tier 3engine that providesmore power and betterfuel ec<strong>on</strong>omy than itspredecessors.C<strong>on</strong>tractors know today’s marketplace ismore competitive than ever and any edge canmake a big difference. With record-high fuelprices, <strong>on</strong>e chief c<strong>on</strong>cern now is how to bida project, knowing that the job may not startfor m<strong>on</strong>ths. Do you bid at current prices andhope they stay stable, or do you plan for priceincreases?Either way, there are methods to combat therising costs of running your equipment. Somemay be things you’re already doing, some may bethings that are easy to implement and some maybe suggesti<strong>on</strong>s you had never thought of before.They apply to all types of machines, from a dozermoving massive amounts of material in miningoperati<strong>on</strong>s, to a compact excavator digging waterservices for houses, to anything in between.“There are many ways to save fuel,” said LesScott, Manager of Komatsu’s Working GearGroup. “Implementing any <strong>on</strong>e of them willshow results. It’s a matter of what works bestfor the individual user.”One of the easiest ways to save fuel may bethe most simple: d<strong>on</strong>’t idle the machine duringn<strong>on</strong>-producti<strong>on</strong> times. At these times, turnthe machine off. Based <strong>on</strong> just <strong>on</strong>e hour of idletime per day, you could save more than fivegall<strong>on</strong>s of fuel per m<strong>on</strong>th.Reducing travel speed is another quick andeasy step to lowering fuel c<strong>on</strong>sumpti<strong>on</strong>. Whileit may seem logical to move around a jobsiteas quickly as possible, the added speed doesc<strong>on</strong>sume more fuel. By slowing down 10 percentyou can improve fuel efficiency by 8 percent.Regular maintenance is essentialRegular maintenance is vital to the l<strong>on</strong>gevityand performance of equipment. Followingrecommended guidelines for routine service,such as changing filters, keeps machinesrunning smoothly and helps reduce seriousproblems. A well-maintained machine doesn’twork as hard, thereby reducing the amount offuel needed to get the job d<strong>on</strong>e.You may want to c<strong>on</strong>sider using a preventivemaintenance plan or a PM c<strong>on</strong>tract, throughyour distributor. The plans offer comprehensiveservices, including changing all oil, filters andfluids at regular intervals. During a routineservice, trained technicians thoroughly inspectmachines for both visible and hidden problemsthat may potentially lead to a serious lossof time. Addressing these issues in advancereduces emergency downtime and keepsequipment in top working c<strong>on</strong>diti<strong>on</strong>, whichmakes it more efficient and productive.“Regular maintenance is extremelyimportant, and it’s <strong>on</strong>e of the easiest thingsan equipment owner or operator can do,”said Komatsu Senior Product Manager TomBrakeall. “Any step you can take to eliminate

Eliminating idling and reducing travel speeds are twoquick and easy ways to save fuel. During times of n<strong>on</strong>producti<strong>on</strong>,c<strong>on</strong>sider turning the machine off. Reducingtravel speeds by 10 percent can improve fuel efficiency by8 percent.There are several avenues equipment users can take to lessen their fuel c<strong>on</strong>sumpti<strong>on</strong>and increase productivity. Komatsu’s new WA600-6 wheel loader is powered by a morefuel-efficient engine that also has more power than previous models. For even moreefficient loading in quarry applicati<strong>on</strong>s, c<strong>on</strong>sider equipping the machine with a scaleto more accurately load trucks.significant downtime is worth it. A PM c<strong>on</strong>tractwill ensure your machinery is serviced <strong>on</strong>time and properly, so you can c<strong>on</strong>centrate <strong>on</strong>getting more work d<strong>on</strong>e without worryingwhether a machine is going to break down.Most distributors do the PM after hours, whenthe machine is down anyway, so there’s nodowntime involved with the service work.”Eliminate inefficienciesEliminating and reducing unnecessaryand/or inefficient movement go hand in handwith travel speed. Plan ahead to avoid movingthe machine around the jobsite in haphazardfashi<strong>on</strong>, such as moving from <strong>on</strong>e area toanother then back to the original locati<strong>on</strong>.Instead, look for ways to keep the machine inthe same area as l<strong>on</strong>g as possible and moveacross the site a little at a time.You can further eliminate inefficient andunnecessary movement while the machineis performing. For example, in truck loading,reducing swing angle from 90 to 30 degreeswill improve fuel efficiency by 3 percent.Speeding up producti<strong>on</strong> by shorteningcycle times through improved excavati<strong>on</strong>techniques can provide as much as 8 percentbetter fuel efficiency.In quarry applicati<strong>on</strong>s, a scale <strong>on</strong> the loadingmachine is an advantage because it helpseliminate unnecessary loading and dumping.“A scale <strong>on</strong> the machine tells the operatorexactly what he’s putting in the truck. Thateliminates a trip to the scale house where thetruck driver may find out there’s too much ornot enough <strong>on</strong> the truck,” said Scott. “If that’sthe case, the driver has to return to the quarryand adjust the load accordingly. A scale <strong>on</strong>the machine takes the guesswork out of theequati<strong>on</strong>, so trucks can be loaded faster andmore accurately.”Al<strong>on</strong>g with shorter cycle times, you shouldmaintain smooth digging, which can savemore than 18 gall<strong>on</strong>s of fuel per m<strong>on</strong>th. Anoperator can dig smoothly by not c<strong>on</strong>stantlypulling the c<strong>on</strong>trol lever to try to lift a loadthat’s too heavy. That acti<strong>on</strong> relieves oilpressure, which in turn increases the amountof fuel needed to perform the task.While it may be important to get the task athand d<strong>on</strong>e as quickly as possible, you couldc<strong>on</strong>sider lowering engine speed. Ten percentless speed will reduce fuel c<strong>on</strong>sumpti<strong>on</strong> by 12percent. Although you do lose about 7 percentin productivity, there is still a net gain in fuelefficiency, making the move cost effective inthe l<strong>on</strong>g run.Regular maintenancefollowing recommendedguidelines saves fueland improves equipmentperformance and l<strong>on</strong>gevity.C<strong>on</strong>sider a preventivemaintenance c<strong>on</strong>tractthrough your distributor toensure all services are d<strong>on</strong>eproperly and to identifyand correct hidden issuesthat may lead to potentialproblems later.Many equipment users also truck their ownmaterials, which <strong>on</strong>ly adds to the fuel bill. But,there are ways to reduce those trucking costsas well. As with heavy equipment, a welltunedtruck engine is vital. Other factors, suchas maintaining proper tire inflati<strong>on</strong>, will alsohelp. Remember, over- or under-inflated tirescan cut efficiency significantly. C<strong>on</strong>tinued . . .

New technologies raise producti<strong>on</strong>, lower costs. . . c<strong>on</strong>tinuedNewer technology suchas Topc<strong>on</strong>’s GPS+ system,which provides fullyautomatic grading of yourjobsite, can save time andhelp you be more accuratein material placement.The result is reducedstaking and surveyingcosts, plus you reach finalgrade in fewer passeswhich means less fuel toget the job d<strong>on</strong>e.C<strong>on</strong>sider new technologyIf you have older equipment, it may be timeto update it. Older equipment tends to beless efficient. New equipment has technologydesigned to increase productivity whilereducing fuel c<strong>on</strong>sumpti<strong>on</strong> and emissi<strong>on</strong>s. Fuelsavings and better producti<strong>on</strong> will help offsetthe costs of switching to more efficient machines.“The new Tier 3 engines have shownsignificant improvement in fuel ec<strong>on</strong>omycompared with previous models,” pointedout Scott. “At the same time, they’re morepowerful than before, so the producti<strong>on</strong> andefficiency benefits are outstanding.”Komatsu’s new ecot3, Tier 3 engines weredesigned to give the user increased power, whileat the same time using less high-priced fuel.Fuel savings can easily be 10 to 15 percent ormore. The ecot3 engines are available in a widevariety of new Komatsu equipment, includingexcavators, wheel loaders, dozers and trucks.These new machines were specificallydesigned to maximize fuel efficiency. Forexample, Komatsu’s new Dash-8 series ofhydraulic excavators comes with an “eco-gauge,”which serves as a guide to efficient operati<strong>on</strong>,giving the operator instant feedback regardingload and how it impacts fuel c<strong>on</strong>sumpti<strong>on</strong>. It alsolets him know if he’s idling too l<strong>on</strong>g.New wheel loaders have technology such asan “E Mode” for maximum fuel ec<strong>on</strong>omy, andcome standard with a newly designed variabledisplacement pist<strong>on</strong> pump that combines withKomatsu’s Closed-center Load Sensing System(CLSS) to deliver <strong>on</strong>ly the necessary amount offlow needed for hydraulic functi<strong>on</strong>. It preventswasted flow, which in turn provides better fuelec<strong>on</strong>omy.GPS systems can boostproductivityYou can also use technology to save time andbe more accurate in material placement with aglobal positi<strong>on</strong>ing system (GPS) such as Topc<strong>on</strong>’s3D-GPS+. A GPS system allows users to uploadjob design into a c<strong>on</strong>trol box, which then receivesmachine-positi<strong>on</strong>ing signals from the radioantenna, GPS receiver, the blade-mounted GPSantenna, and a cross-slope sensor.The c<strong>on</strong>trol box c<strong>on</strong>tinuously comparesactual machine and blade positi<strong>on</strong> andcalculates correcti<strong>on</strong>s that are sent to thehydraulics, creating fully automatic gradingof the jobsite. All the operator does is c<strong>on</strong>troldirecti<strong>on</strong> and speed while the GPS creates thefinal grade. The result is reduced staking andsurveying costs. Plus, it takes fewer passes toreach final grade.“The system has been proven to increaseproductivity by 30 to 60 percent,” reportedRandy Noland, Topc<strong>on</strong>’s Machine C<strong>on</strong>trolProduct Manager. “If you can get to gradefaster and place material more accuratelyyou’re going to use less fuel. It’s really a nicebenefit. With a Topc<strong>on</strong> system, users are goingto recoup their initial investment in labor andmaterial savings, but they certainly will save<strong>on</strong> fuel by getting to grade in less time.”Making changes pays offIt may not be feasible to implement all thesechanges at <strong>on</strong>ce, but making just <strong>on</strong>e couldbenefit you in both the short term and the l<strong>on</strong>grun. They will help you remain competitiveand could increase your profitability throughincreased producti<strong>on</strong> and more efficientoperati<strong>on</strong>.“It’s hard to predict what will happen to fuelprices in the future, but you can always findways to reduce your costs,” c<strong>on</strong>cluded Scott.“Even if you <strong>on</strong>ly save a little, it’s still morem<strong>on</strong>ey in your pocket.” n

Indianapolis, IN • (317) 872-8410South Bend IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551

NEW PRODUCTRELIABLE EQUIPMENTRESPONSIVE SERVICE<str<strong>on</strong>g>THE</str<strong>on</strong>g> SIGMA DOZERRevoluti<strong>on</strong>ary blade design greatly improvesperformance of Komatsu’s new D155AX-6Large c<strong>on</strong>structi<strong>on</strong>-size dozers are becomingmore comm<strong>on</strong>place <strong>on</strong> jobsites. Whether it’sfor heavy site-prep grading for residentialsubdivisi<strong>on</strong>s or commercial properties;or for road-building activities; or to stripoverburden in a rock quarry — dozers in the300-horsepower range are in greater demandas c<strong>on</strong>tractors put a premium <strong>on</strong> speed andproductivity.In totally redesigning its 44-t<strong>on</strong>, 354-horsepower, D155-size dozer, Komatsu hasdeveloped a machine that delivers unrivaledproductivity in the class. Called the SigmaDozer (so named because the shape of theKomatsu-patented Sigma Dozer blade issimilar to the Greek letter Sigma ‘∑’), the allnewD155AX-6 significantly outperforms itspredecessor and the competiti<strong>on</strong>.“It all starts with the revoluti<strong>on</strong>ary SigmaDozer blade,” said Komatsu Dozer SeniorProduct Manager Chuck Murawski. “For years,Komatsu engineers have been working <strong>on</strong> adozer blade designed to improve the cutting,piling and carrying of material. The result is theSigma Dozer, which carries 15 percent morematerial than the previous Komatsu model and20 percent more than the leading competitor.Rather than spilling material around the sideof the blade, the Sigma Dozer blade’s uniquedesign heaps it up in the center and promotesimproved rolling.”Productive and efficientWhen you combine the new blade with thenew Komatsu ecot3 (Tier 3-certified) enginethat boosts output by 10 horsepower, and anew automatic shift transmissi<strong>on</strong> with lockuptorque c<strong>on</strong>verter, the Sigma Dozer dramaticallyimproves both efficiency and productivity.“With the automatic-shift transmissi<strong>on</strong>Chuck Murawski,and lockup torque c<strong>on</strong>verter, you’re alwaysKomatsu Dozeroperating in the most efficient gear,” saidSenior ProductManagerMurawski. “In c<strong>on</strong>juncti<strong>on</strong> with the bladedesign, which reduces digging resistance andcarries material more smoothly, the automatic C<strong>on</strong>tinued . . .Brief Specs <strong>on</strong> the Komatsu Sigma DozerModel Operating Weight Output Blade CapacityD155AX-6 87,100 lbs. 354 hp (320 hp w. max cooling fan) 12.3 cu. yd.Dozer Product Manager Chuck Murawskipoints to the unique, patented shape ofKomatsu’s Sigma Dozer blade as key to theD155AX-6’s ability to push and carry 15 percentmore material while using 10 percent less fuel.In additi<strong>on</strong> to the design that allows it tocarry more material more easily, the 12.3-cubicyardSigma Dozer blade has dual pitch and tiltas standard equipment. Komatsu also wentto an all-electr<strong>on</strong>ic blade hydraulic c<strong>on</strong>trolsystem that is easier <strong>on</strong> the operator andeliminates horsepower loss associated withproporti<strong>on</strong>al pressure c<strong>on</strong>trol.

Major improvements to D155AX-6 Sigma Dozer. . c<strong>on</strong>tinuedshift enables you to doze large quantities ofmaterial with less power and therefore use lessfuel. In additi<strong>on</strong> to that, we’ve also installedthe blade closer to the tractor, which improvesvisibility, reduces lateral sway and enhancesdigging force.”With the 15 percent producti<strong>on</strong> increasecombined with a 10 percent decrease in fuelc<strong>on</strong>sumpti<strong>on</strong>, Komatsu reports fuel efficiency— the amount of fuel you’ll use to move thesame amount of material — is improved bya whopping 25 percent with the D155AX-6compared with the previous D155 model, andmore than that compared with competitivedozers. The unit also has 7.5 percent moredrawbar pull at 2 mph compared to theleading competitor.Undercarriage upgradeBey<strong>on</strong>d the large boosts in productivityand efficiency, the D155AX-6 has numerousother new features and benefits, all of whichimprove dozing performance and machinereliability. One of the most significantlyimproved areas is undercarriage, whereKomatsu has replaced the X-Bogie systemwith the K-Bogie system, which is the sameundercarriage that’s used <strong>on</strong> mining dozers.“The D155AX-6 is the first c<strong>on</strong>structi<strong>on</strong>classdozer to use the K-Bogie undercarriagesystem, which is proven technology <strong>on</strong>large dozers that run 22 hours a day in amining envir<strong>on</strong>ment,” said Murawski. “Thetrack frame is roughly 20 percent larger andtherefore sturdier and more rugged. It alsohas seven track rollers instead of six, a widertrack gauge and l<strong>on</strong>ger track-<strong>on</strong>-ground length— all of which add up to a smoother and morecomfortable ride.”The ripper <strong>on</strong> the new dozer was alsoredesigned for better visibility and to allow itto operate at higher pressure (4,000 psi).The Sigma Dozer blade is designed to promote rolling of material and to keep it fromspilling around the sides.The D155AX-6 is the first c<strong>on</strong>structi<strong>on</strong>-class machine to get the K-Bogie undercarriage,the larger and sturdier undercarriage used <strong>on</strong> Komatsu mining dozers.Operator safety and comfortOther improvements include a ROPS structurethat’s now built into the cab for better visibility;a new, easy-to-use, seven-inch LCD colorm<strong>on</strong>itor — the same <strong>on</strong>e used in the new Dash-8excavator line; and the Komtrax m<strong>on</strong>itoringsystem that’s installed as standard equipment.Operator comfort is assured with a cabthat’s wider, higher and much l<strong>on</strong>ger thanthe previous D155. The operator will alsoappreciate a cab damper-mount system thatkeeps shock, vibrati<strong>on</strong> and noise to a minimum.Routine maintenance is easily accomplisheddue to centralized check points and easy accessto the engine through gull-wing doors.“At our Field Days dem<strong>on</strong>strati<strong>on</strong>, operatorcomments about the machine were veryfavorable,” said Murawski. “All of us atKomatsu are c<strong>on</strong>vinced the new D155AX-6 is theclear leader in its class and will pay dividends forequipment users by doing more for less.” n

Quality you can rely <strong>on</strong>Precious metals.Unearthing the world’s finest materials calls for the world’s finest fleet of mining machines.From trucks to shovels to wheel loaders, Komatsu’s complete line of ruggedly reliablemining equipment works in tandem to lower your cost per t<strong>on</strong>, reduce cycle times anddeliver greater payload. Add Komatsu’s unmatched service and support soluti<strong>on</strong>s and youhave equipment worth its weight in gold — and then some.For details, c<strong>on</strong>tact your local Komatsu distributor. Call 1-800-Komatsu.Or visit KomatsuAmerica.com®• Komatsu America Corp., Headquartered in Chicago, IL • North American manufacturing operati<strong>on</strong>s in Chattanooga, Candiac, Dallas, Newberry, Peoria and Seymour • Over 210 distributor locati<strong>on</strong>s serving North America©2005 Komatsu America Corp. www.KomatsuAmerica.com411-1500

MORE NEW PRODUCTSRELIABLE EQUIPMENTRESPONSIVE SERVICENEW BACKHOE LOADERKomatsu’s WB146-5 offers greater productivitythrough innovative design changesFor more informati<strong>on</strong> <strong>on</strong>the WB146-5 backhoeloader, c<strong>on</strong>tact your salesrepresentative or yournearest branch locati<strong>on</strong>.Komatsu’s new WB146-5backhoe loader wasredesigned from itspredecessor, the WB140-2,which it replaced. Newfeatures include a largercab with more glass areafor better visibility, a newS-boom design and a morepowerful engine with 16percent more torque forincreased productivity.When Komatsu designed its new WB146-5backhoe loader it included the best its previousmodel had to offer and added innovati<strong>on</strong>s tomake it even more productive.“We believe the backhoe user is going to bevery impressed with this new model, whichreplaces our WB140-2,” said Jeff Aubrey,Product Manager Backhoe Loaders. “Weredesigned our previous model from theground up, making significant improvementsin the areas that will help the user get morework d<strong>on</strong>e in less time.”Changes are noticeable just by looking at themachine, which includes a larger cab with moreglass area for 360-degree visibility. A cornerexhaust with a fr<strong>on</strong>t-roof cutout provides anunobstructed view when the loader bucket is atfull height. Further cab appointments includeBrief specs <strong>on</strong> the WB146-5Model Output Operating weight Bucket capacityWB146-5 88 hp 16,090 lbs. 1.25 cu. yd. (loader)an adjustable seat and adjustable steering andbackhoe c<strong>on</strong>trols, allowing the machine tobetter fit any operator. Switches and gauges areclustered to simplify operati<strong>on</strong>.Visibility was further enhanced in the backhoedigging and loading operati<strong>on</strong>s with theWB146-5’s new S-boom design that gives theoperator a better view of the trench and truck.Backhoe buckets are equipped with ExtremeService (XS) adapters and a variety of toothdesigns for multiple applicati<strong>on</strong>s. Reversibleoutrigger pads accommodate both earth andpaved surfaces.More powerful and stableA more powerful 88-horsepower engine with 16percent more torque, combined with Komatsu’sHydrauMind hydraulic system, providesspeed, power and c<strong>on</strong>trol in both backhoe andfr<strong>on</strong>t-loading operati<strong>on</strong>s. The system is efficient,incorporating two working modes (Ec<strong>on</strong>omy andPower) and includes the “speed up” functi<strong>on</strong> toincrease the working speed of the fr<strong>on</strong>t loader. Theloader also has dual-directi<strong>on</strong>, parallel-lift linkageto keep attachments level throughout a lift. Alarger-capacity loader bucket with bolt-<strong>on</strong> cuttingedge is standard.The engine is housed in a redesigned fr<strong>on</strong>tend with a heavy-duty, cast nose guard/counterweight, which protects the enginecompartment and improves the balance of themachine. The fr<strong>on</strong>t grille removes easily forcleaning the radiator.“The new WB146-5 was designed with moreproducti<strong>on</strong> in mind. The speed and powerof this machine can make the operator veryproductive. The operator comforts will result inless fatigue at the end of the work day,” Aubreypointed out. n

PRODUCT NEWSRELIABLE EQUIPMENTRESPONSIVE SERVICEARTICULATED TRUCKS UPGRADEDMore power and technology in Komatsu’snew Dash-2 series of American-built ADTsSince Komatsu began producing articulateddump trucks in 2001, the units have made aname for themselves as being am<strong>on</strong>g the bestperforming in the industry. Now, with theintroducti<strong>on</strong> of the new Dash-2 series, Komatsuhas made its ADTs even tougher, morepowerful and more technologically advanced.The HM300-2, HM350-2 and HM400-2have new ecot3 (Tier 3-compliant) engineswith a significant power boost; the Komtraxm<strong>on</strong>itoring system as standard equipment; anda new style that includes a reinforced bumperand transmissi<strong>on</strong> guard. On the HM300-2,Komatsu also increased low-end torque byabout 10 percent and made improvements to thetransmissi<strong>on</strong> to handle the extra power so theunit is now about 11 percent more productive.“These new articulated trucks are a definiteupgrade,” said Steve Moore, Komatsu SeniorProduct Manager. “But equally significant to thechanges is how far we’ve come in such a shorttime. We’re now a significant player in articulatedtrucks. Our units are 100 percent Komatsuwith everything designed and manufacturedby us and we’re <strong>on</strong>e of the <strong>on</strong>ly manufacturerswho can say that. We’re also perhaps the <strong>on</strong>lymanufacturer that totally produces its ADTs inthe U.S. We’ve been building our artics at theKomatsu Chattanooga Manufacturing Operati<strong>on</strong>since January 2005, and now most of the unitssold in North America come from Tennessee.”More loads hauledWith the new ecot3 engine, the Komatsu ADTline delivers faster accelerati<strong>on</strong> and higher travelspeeds, which means more loads hauled per day.To assure shockless shifting and to maximizethe life of the powertrain, the transmissi<strong>on</strong> iselectr<strong>on</strong>ically c<strong>on</strong>trolled, similar to Komatsu’shighly successful rigid-frame dump trucks.Also similar to the rigid trucks is the ADT line’sbraking system, which features large-capacity,c<strong>on</strong>tinuously cooled, wet, multiple-disc brakesthat also functi<strong>on</strong> as a retarder.The HM300-2, HM350-2 and HM400-2 haveheaped body capacities that are am<strong>on</strong>g thehighest in their respective classes and haveloading heights that are am<strong>on</strong>g the lowest.Turning radius is also am<strong>on</strong>g the best in theindustry, enabling all three units to work <strong>on</strong>cramped jobsites.“As far as a smooth ride, comfort and easeof operati<strong>on</strong>, I think any operator who’s everbeen in a Komatsu ADT will testify that it’sfirst-class,” said Moore. “We’ll happily demoour units against any competitor at any timebecause we believe the Komatsu difference willshow through early — and that it will proveitself over time.” nBrief Specs <strong>on</strong> the Komatsu ADTsSteve Moore,Komatsu SeniorProduct ManagerFor more informati<strong>on</strong><strong>on</strong> Komatsu articulatedtrucks, c<strong>on</strong>tact yoursales representativeor our nearest branchlocati<strong>on</strong> today.Model Gross Vehicle Weight Output CapacityHM300-2 113,360 lbs. 329 hp 21.7 cu. yd./ 30.1 t<strong>on</strong>sHM350-2 139,900 lbs. 394 hp 25.9 cu. yd./35.6 t<strong>on</strong>sHM400-2 152,200 lbs. 453 hp 29.2 cu. yd./ 40 t<strong>on</strong>sKomatsu’s Dash-2 series of articulated trucks has higher horsepower, KOMTRAX, and isbuilt in Tennessee.

G O R M A N - R U P P P R I M I N G - A S S I S T P U M P SSizes up to 30".Heads to 470'.Flows to 40,000 GPM.There’s no comparis<strong>on</strong>. Gorman-Ruppdelivers the biggest, broadest pumpline in the business. On c<strong>on</strong>structi<strong>on</strong>and sewage bypass jobs with trickyintermittent flow, a Gorman-Rupppump easily handles solids upto 6" in diameter. Get your hands<strong>on</strong> a Gorman-Rupp, the world’sundisputed standard in prime-assistperformance.Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456 Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700 Paducah, KY • (270) 444-8390Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551 South Bend IN • (574) 233-8770A-404 © Copyright, The Gorman-Rupp Company, 2002 Gorman-Rupp Pumps – Mansfield Divisi<strong>on</strong> is an ISO 9001 Registered Company

PRODUCT SUPPORTRELIABLE EQUIPMENTRESPONSIVE SERVICEIMPROVE EQUIPMENT UPTIMEC<strong>on</strong>tractor discovers benefits of using KOMTRAX as partof a comprehensive preventive maintenance programFor Brent Hawkins, Owner and President ofMarietta, Georgia-based Earthworks Grading& C<strong>on</strong>crete, Inc., equipment uptime is crucial.The company, which does mass grading and/orroads for large residential subdivisi<strong>on</strong>s, is knownfor doing quality work, and doing it quickly.In order to get the uptime that delivers theproductivity his customers count <strong>on</strong>, Hawkinsuses late-model Komatsu equipment, includingtwo excavators (PC300LC-7 and PC220LC-7),three dozers (D65, D41 and D39), two HM300articulated dump trucks and a GD555 motorgrader. He installed the KOMTRAX equipmentm<strong>on</strong>itoring system <strong>on</strong> each and every machine.“I d<strong>on</strong>’t have a shop or a mechanic. I havemy Komatsu dealer do all my maintenance andservice work,” Hawkins explained. “It saves mem<strong>on</strong>ey, simplifies my life and keeps me doingwhat I do best, which is moving dirt.”Hawkins says the initial reas<strong>on</strong> he gotKOMTRAX was for c<strong>on</strong>venience — so hewouldn’t have to track everything himself,then call and schedule the maintenance everytime it was due. “With KOMTRAX, my dealertracks machine hours and gets machinelocati<strong>on</strong>s, then just comes out and takes care ofthe service whenever it’s required.“In additi<strong>on</strong> to the c<strong>on</strong>venience, I’ve foundKOMTRAX to be an easy-to-use system thathelps me run my business better,” he added.“I check the reports every week or so, just tosee where we’ve been and to plan where we’regoing. If there’s ever any questi<strong>on</strong> as to wherea machine has been, KOMTRAX answers it byverifying times and dates, and even printing outa map of where the machine has been.”Vandalism and theft deterrentHawkins says he’s c<strong>on</strong>vinced thatKOMTRAX is paying off for him.“One of our pipeline customers ended upspending $12,000 for a motor <strong>on</strong> a machinethat wasn’t a whole lot older than ours. I creditKOMTRAX and our planned maintenanceprogram for keeping our repair bills to aminimum. The guys from the distributorship arespecialists, and because of that, I really believewe’re being taken care of much better by themthan we could take care of ourselves.”As for KOMTRAX itself, Hawkins sayshe intends to upgrade his system to includegeofencing (an out-of-area alert system) andanti-theft features.“We’ve experienced some equipmentvandalism, and theft is always a possibility.With the KOMTRAX geofence and automaticshutdown (engine lock for nights andweekends), we hope to eliminate or at leastminimize those potential problems.” nFor more informati<strong>on</strong> <strong>on</strong>KOMTRAX and how itcan benefit your operati<strong>on</strong>,c<strong>on</strong>tact your PSSR or theservice manager at ournearest branch.Brent Hawkins of Earthworks Grading & C<strong>on</strong>crete uses the KOMTRAX equipmentm<strong>on</strong>itoring system <strong>on</strong> all eight of his Komatsu machines. “We’re <strong>on</strong> a planned maintenanceprogram with our Komatsu distributor and KOMTRAX is an integral part of that,” saidHawkins. “It also helps me track how and where my equipment is being used.”

Louisville, KY • (502) 491-4000Stanville, KY • (606) 478-9201Paducah, KY • (270) 444-8390Lexingt<strong>on</strong>, KY • (859) 259-3456Corbin, KY • (606) 528-3700Indianapolis, IN • (317) 872-8410South Bend, IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551Our new Ingersoll-Rand HFA asphalt compactors are engineered todeliver density, smoothness, and versatility. The new SMART C<strong>on</strong>trolPropulsi<strong>on</strong> System automatically c<strong>on</strong>figures speed to maintainsmoothness, while the new SMART Start Vibrati<strong>on</strong> System enables youto start vibrati<strong>on</strong> immediately without damaging previously compactedmaterial. In additi<strong>on</strong>, the SMART Drum Technology gives you outstandingproductivity <strong>on</strong> both thick lifts and thin. With features like these, Ingersoll-Rand large asphalt compactors are ideal for today's new mix designs,more stringent quality requirements, and tighter deadlines.For more informati<strong>on</strong> about Ingersoll-Rand HFA asphalt compactors andthe wide range of other IR products available, c<strong>on</strong>tact your nearest<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> locati<strong>on</strong>.

KOMATSU & YOURELIABLE EQUIPMENTRESPONSIVE SERVICEWORKING TO BE <str<strong>on</strong>g>THE</str<strong>on</strong>g> BESTKomatsu and our distributors are committedto providing “world-class” product supportQUESTION: When most of us think ofproduct support, we think of distributors’ partsdepartments, shops, field trucks, techniciansand PSSRs. What is Komatsu’s role indelivering product support to equipment users?ANSWER: Likening it to my militarybackground, the distributors’ parts and servicepers<strong>on</strong>nel are <strong>on</strong> the fr<strong>on</strong>t line, while we aretypically in the rear, supporting their efforts.We’re a resource for them. We have access tomachine informati<strong>on</strong> from across the countryand throughout the world. By collecting thatinformati<strong>on</strong> and passing it <strong>on</strong>, we’re able tohelp the distributor do a better job of meetingcustomers’ parts and service needs.Of course, we also provide training fordistributor pers<strong>on</strong>nel. We recently institutedthe Komatsu Learning Management System(KLMS) whereby we track the level of techniciancertificati<strong>on</strong> as a way to measure the quality ofthe service our distributors are providing. Wealso make field calls with their technicians whenneeded. And <strong>on</strong> the parts side, from detailedhistories <strong>on</strong> hundreds and even thousandsof machines, we know what parts need to bestocked at the local level. We also let distributorsknow the optimum number of techs, trucks andPSSRs they should have based <strong>on</strong> their territoryand inventory.QUESTION: In regard to supplyingreplacement parts in a timely manner, how isKomatsu’s regi<strong>on</strong>al parts depot c<strong>on</strong>cept comingal<strong>on</strong>g?ANSWER: It’s no l<strong>on</strong>ger just a c<strong>on</strong>cept. Wealready have regi<strong>on</strong>al parts depots up andoperating in Pittsburgh, Las Vegas and Denver,and we’ll be adding three more — Minneapolis,Portland and Savannah — within the next year.This is <strong>on</strong>e of a series of articles based<strong>on</strong> interviews with key people atKomatsu discussing the company’scommitment to its customers in thec<strong>on</strong>structi<strong>on</strong> and mining industries— and their visi<strong>on</strong>s for the future.Mike Evans,VP Product Support, Komatsu AmericaAfter earning a civil engineering degree from the U.S. MilitaryAcademy at West Point, Mike Evans spent five years as a militaryofficer in the Army’s heavy equipment divisi<strong>on</strong>, including servingas a tank plato<strong>on</strong> leader in the first Gulf War. He later served as aBattali<strong>on</strong> Maintenance Officer in charge of repair and maintenanceof 54 tanks.With that background, he joined the service department ofKomatsu America in 1995, eventually becoming Manager ofTechnical Support for Komatsu Mining Systems. Mike left Komatsuto work at the distributor level of the equipment business, andlater joined a motorcoach manufacturer for a time. In late 2003, hereturned to Komatsu as Vice President of Parts, and early this year,he was promoted to Vice President of Product Support.“In this positi<strong>on</strong> I oversee activities of the Komatsu parts andservice departments and develop strategies <strong>on</strong> how we can bestserve our distributors and their customers,” Mike explained. “We’redeveloping programs and systems to help us achieve truly excellent,world-class product support. Our goal is zero downtime. Can weever achieve it? Probably not, but we’ll definitely never achieve it ifit’s not our goal.”Married with five children, Mike likes to spend most of his freetime with his family, but he says his other passi<strong>on</strong> is skiing. “Iespecially love downhill skiing, which I do as often as possibleduring the seas<strong>on</strong>, including taking a week’s vacati<strong>on</strong> out to themountains each year. For me, it’s the best way to relax and havefun.”C<strong>on</strong>tinued . . .

Product support is Komatsu priority. . c<strong>on</strong>tinuedThe advantage of having these partswarehouses located throughout the country isthat it makes it much easier for the distributorto get a part by 7 a.m. the following day — andhaving worked at the distributor level, I knowpers<strong>on</strong>ally how important that is, compared togetting it in at 11 a.m. or no<strong>on</strong>.QUESTION: Most distributors now offervarying levels of a repair and maintenancec<strong>on</strong>tract, whereby they will provide theroutine maintenance as well as repairs —work traditi<strong>on</strong>ally d<strong>on</strong>e by the equipmentowner himself. What is the advantage of sucha program for the equipment user?ANSWER: A customer benefits two ways.First, he’s assured that he’s going to gettop performance from his machine, oftenwith guaranteed uptime. If maintenanceis substandard, the machine isn’t going toperform as well or last as l<strong>on</strong>g as it otherwiseKomatsu works closely with its distributorsto ensure they have the appropriate numberof trucks, technicians and PSSRs to meetthe needs of customers. “We also providetraining and recently started assessing theskill level of our distributors’ technicians,”said VP Product Support, Mike Evans.To improve partsavailability todistributors and theircustomers, Komatsuhas opened threeregi<strong>on</strong>al parts depots,and will open threemore in the next year.would. By having a distributor’s technician dothe work, he knows it’s going to be d<strong>on</strong>e rightand that the machine is going to work the wayit’s supposed to work.The other benefit is purely financial. Whenyou analyze the full cost of having your ownshop and your own mechanics — and theirtraining, tooling and benefits — it’s a veryexpensive propositi<strong>on</strong> that most equipmentowners underestimate. They think they’resaving m<strong>on</strong>ey, but when you look closely, it’susually cheaper to have the distributor do it.QUESTION: What are a few tips you wouldgive to equipment owners wanting to get thel<strong>on</strong>gest, most productive, most reliable lifeout of their machines?ANSWER: Regular maintenance d<strong>on</strong>eproperly. Oil analysis every time. Work withyour distributor and use genuine OEM parts. Itjust doesn’t make sense to put a $200,000 pieceof equipment at risk in order to save a coupleof dollars by buying the cheapest oil and filtersyou can find. We’ve tested aftermarket filtersthat claim to be as good as our OEM product,but they’re not comparable at all. They d<strong>on</strong>’tstop the c<strong>on</strong>taminati<strong>on</strong> nearly as effectively,and with tolerances so tight in today’smachines, it doesn’t take much particulategetting through to really damage and reducethe life of a comp<strong>on</strong>ent or an entire machine.QUESTION: Generally speaking, what doyou believe Komatsu brings to the table forequipment users?ANSWER: In my mind, there’s no doubt thattop-to-bottom, across the entire product line,when it comes to productivity, reliabilityand technology, Komatsu equipment is thebest <strong>on</strong> the market — and I think most of ourcustomers recognize that. My resp<strong>on</strong>sibility isto achieve that same level of performance andrecogniti<strong>on</strong> for our product support efforts.As of today, I can assure customers that improvingproduct support is our top priority. My goal is toimprove our product support to a “world-class”level so that it’s viewed by customers as a positivedifference-maker — a reas<strong>on</strong> to buy Komatsu. Weno l<strong>on</strong>ger want to be just OK, or sec<strong>on</strong>d-best. Wewant to lead the way. n

INDUSTRY NEWSIMMIGRATION REFORMAGC urges acti<strong>on</strong> that includes border securityand a guest worker programOne of the issues that’s drawing widespreadattenti<strong>on</strong> this electi<strong>on</strong> year is U.S. immigrati<strong>on</strong>policy — specifically the subject of illegalimmigrati<strong>on</strong> from Mexico. It’s an issue that thec<strong>on</strong>structi<strong>on</strong> industry deals with more thanmost other industries.In light of that, the Associated GeneralC<strong>on</strong>tractors of America is expressing supportfor increased border security that would createbetter c<strong>on</strong>trol over the nati<strong>on</strong>’s borders anda comprehensive approach to immigrati<strong>on</strong>reform that would include a new guestworker program and a viable way to addressundocumented workers.“The first step to enacting effectiveimmigrati<strong>on</strong> reform is enforcing our borders,but that can’t be the final step,” said AGCCEO Stephen E. Sandherr. “C<strong>on</strong>gress needsto produce legislati<strong>on</strong> that also providesa new guest worker program and earnedlegalizati<strong>on</strong>.”AGC believes that new legislati<strong>on</strong> shouldprovide for an effective guest workerprogram that would allow U.S. c<strong>on</strong>structi<strong>on</strong>companies to recruit immigrant workerswhen U.S. workers are not available to filltheir needs.• Be flexible. If there is a cap, it should bebased <strong>on</strong> the needs of the marketplace;• Require individuals using the new visa tostay with the sp<strong>on</strong>soring employer fora certain amount of time (unless abuse ofthe employee is found) in order to actuallyaddress the needs of the employer;• Ensure that all labor and employmentlaws apply.AGC also supports a path to earnedlegalizati<strong>on</strong> that would include paying fines,learning English, staying employed, payingtaxes and completing criminal backgroundchecks before applying for a potential greencard. nAssociated General C<strong>on</strong>tractors of America wants C<strong>on</strong>gress to enact immigrati<strong>on</strong>legislati<strong>on</strong> that would allow c<strong>on</strong>structi<strong>on</strong> companies to recruit immigrant workerswhen there aren’t enough U.S. workers to fill their needs.Program detailsAccording to AGC, a new visa programshould:• Be valid for a l<strong>on</strong>g enough time frameto ensure that an employer’s traininginvestment is not lost;• Be renewable and provide a way to sp<strong>on</strong>soremployees for permanent residency whileunder the new visa process;

ON <str<strong>on</strong>g>THE</str<strong>on</strong>g> LIGHT SIDE“I want that video thatshows those ‘reallife‘c<strong>on</strong>structi<strong>on</strong> jobs;you know, the <strong>on</strong>eswhere the sky isalways blue and wherenothing goes wr<strong>on</strong>g.““Getting paid <strong>on</strong>lineis OK, but I missseeing those checksfrom satisfiedcustomers comein the mail.”“He’s a good mechanic.He gets inside theproblem every time . . .and he finds the exit!”“I know the safety director said we’resupposed to be creative about safety.But I d<strong>on</strong>’t think using the pogo stickwill really help avoid any hazardswhile traveling around the jobsite.”“Your special looksgood, but I hopeit w<strong>on</strong>’t be anybig problem tomake a few minormodificati<strong>on</strong>s tothe specs.”“We did so well <strong>on</strong> the lastdesign-build job, the developerasked us to take <strong>on</strong> <strong>on</strong>e morepart of his next project: thefinancing . . . I guess you couldcall it design, build and pay!”

MORE INDUSTRY NEWSCONEXPO-CON/AGG tops trade show listTThe CONEXPO-CON/AGG internati<strong>on</strong>alexpositi<strong>on</strong> for the c<strong>on</strong>structi<strong>on</strong> industries hasbeen named the largest trade show of anyindustry in the United States, for the thirdc<strong>on</strong>secutive time. The last three editi<strong>on</strong>s of thetriennial exhibiti<strong>on</strong> have earned the top spot forthe years in which it was held — 1999, 2002 andnow 2005.The rankings are compiled by Tradeshow Week<strong>magazine</strong> and are based <strong>on</strong> net square feet ofexhibit space. CONEXPO-CON/AGG 2005 setrecords for exhibit space and attendance —spanning more than 1.88 milli<strong>on</strong> square feet ofspace and more than 124,000 attendees.“Our show is run by and for the industry,”said Show Director Megan Tanel, in explainingCONEXPO-CON/AGG’s c<strong>on</strong>tinuing success.“For example, all of the planning committeesare made up of exhibitors and attendees and welisten to their input.”The next CONEXPO-CON/AGG isscheduled for March 11-15, 2008, at the LasVegas C<strong>on</strong>venti<strong>on</strong> Center. ■QuickCouplers +DurableAttachments =IncreasedPaladin Heavy C<strong>on</strong>structi<strong>on</strong> manufactures a full line of couplers, buckets, forks andspecialty attachments for wheel loaders, wheel loader backhoes and excavators – preciselythe equipment you need for versatility and greater productivity. Because we offer brandnames you know and trust – like JRB, C&P and Badger – we’re sure to carry the rightattachments you need to achieve highest productivity at the lowest cost.JobsiteProductivityC<strong>on</strong>tact us today at 1-800-4-BUCKET. We have the attachments andcouplers you need in stock and ready to go.We invite you to learn more about our product offerings atwww.paladinbrands.com.Available through <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery & Supply Company

DISTRIBUTOR CERTIFIEDRELIABLE EQUIPMENTRESPONSIVE SERVICEBEFORE AND AFTERHow a Komatsu Distributor Certified used machinediffers from other used machinesLee Haak, KomatsuReMarketingDirectorThese photos show the stark“before and after” differenceKomatsu DistributorCertificati<strong>on</strong> makes. Half ofthis very used D61 was left“as-is” (above) while the otherhalf was certified (below).“A good-looking KomatsuDistributor Certified machineis not just a used machinewith a new paint job,” saidKomatsu ReMarketingDirector Lee Haak. “If it’scertified highly enough, it waseither in very good c<strong>on</strong>diti<strong>on</strong>to begin with or was externallyand internally repaired to meetspecific standards to ensuregood, reliable performance.”What’s the difference between a KomatsuDistributor Certified used machine and anyother used machine? The main difference is,with a Komatsu Distributor Certified machine,you’re assured of what you’re buying.“When a Komatsu distributor inspects andgrades a machine, there are specific criteria itmust meet to receive the grade it gets,” saidKomatsu ReMarketing Director Lee Haak.“Often, improvements are made to bring themachine up to a higher level.”Because of the inspecti<strong>on</strong> andimprovements, the Komatsu distributoris c<strong>on</strong>fident the machine will perform asrepresented, and therefore typically is willingto stand behind the sale by offering anextended warranty.“With a Komatsu Distributor Certified usedmachine, the buyer is basically assured that theunit will do what it’s supposed to do — and ifit doesn’t, the distributor will make it right,”said Haak. “That and frequent special financingrates are what differentiates a DistributorCertified machine from a used piece that’sbought at aucti<strong>on</strong> or from a broker.”More than just a paint jobAs part of the inspecti<strong>on</strong> process fora Distributor Certified used machine,trained technicians will not <strong>on</strong>ly note theeasy-to-see cosmetic damage, but will alsouncover mechanical problems and potentialundercarriage issues. All aspects of the machinewill be repaired or replaced, or the shortcomingswill be pointed out to you as a potential buyer.“A machine that’s Komatsu DistributorCertified has almost certainly had muchmore than just a paint job — unless that’sall it needed,” said Haak. “The great thingabout Komatsu machines is that the originalequipment is built to such a high qualitystandard, it’s worth repairing. That’s whywe’re able to put Distributor Certifiedmachines back in the marketplace for a sec<strong>on</strong>dlife, and do so with c<strong>on</strong>fidence that they’llperform productively and reliably.”For more informati<strong>on</strong> <strong>on</strong> how a usedmachine earns Komatsu Distributor Certifiedstatus, you can go to the Komatsu AmericaWeb site, click <strong>on</strong> “used equipment,” thenclick <strong>on</strong> “What is ReMarketing?” to view amultimedia presentati<strong>on</strong>. n

If it can be measured,we measure it!Whether you’re looking for a highqualitymachine that will become part ofyour fleet, or for a machine that will get youthrough the busy seas<strong>on</strong>, Komatsu Distributor Certified Used Equipment is your best alternative to buying new.If it can be measured, we measure it! Specially trained Komatsu Distributor Certified evaluators check, measure and diagnosevirtually every aspect of the machine. Once the machine meets Komatsu’s high performance standards, your local distributorcan tailor the machine for your site-specific needs. And to add to your peace of mind, most Komatsu Distributor Certified UsedEquipment is eligible for special financing and warranty.Purchasing Komatsu Distributor Certified Used Equipment makes sound business sense. You’ll receive good value foryour m<strong>on</strong>ey and a reliable and productive machine that will get the job d<strong>on</strong>e for years to come — we guarantee it!To learn more about Komatsu ReMarketing’s Distributor Certified Used Equipment, c<strong>on</strong>tact your local Komatsu Distributoror go to our Web site at www.equipmentcentral.com and click <strong>on</strong> “used equipment.”

C.P.I.P.O. Box 1689C.R., IA 52406-1689Change Service RequestedPresorted StandardUS Postage PaidC.P.I.USED EQUIPMENT SPECIALS1988Dresser520B#BT6220$21,3331991KomatsuPC400LC-5#BC612913,099 hrs.$68,000ARTICULATED TRUCKS1997 Volvo A30C, #BT6303, 11,793 hrs.................................$124,000ASPHALT PAVER1976 Blaw Knox PF115, #BT6504..............................................$4,667COMPACTION1991 IR DD110, #BT6207, 4,130 hrs.........................................$20,000CRAWLER DOZERS1996 Deere 450G LT, #BT6603, 4,454 hrs................................$37,3332002 Komatsu D39PX-21, #BT5422, 4,512 hrs......................... P.O.R.EXCAVATORS1994 Cat 320L, #BT6608, 9,901 hrs........................................... P.O.R.2002 Cat 320CL, #BT6507, 3,504 hrs......................................... P.O.R.1993 Komatsu PC200LC-5, #BT6132, 9,707 hrs.....................$32,0001999 Komatsu PC200LC-6E, #BT5801, 5,212 hrs..................... P.O.R.2003 Komatsu PC200LC-7, #BT6518, 2,471 hrs....................... P.O.R.2002 Komatsu PC400LC-6, #U18450-1, 8,475 hrs................$130,6672000 Kobelco SK135SRLC, #BT6208, 6,128 hrs....................$60,0002003 Kobelco SK250LC, #BT5N02, 1,908 hrs.......................$117,333FORESTRY1997 Prentice 210E, #U22056, 6,727 hrs.................................$49,3331998 Timberjack 330, #U21417, 12,415 hrs.............................$26,6671998 Timbco 445C, #U21605, 4,700 hrs................................$161,3331997 Tiger Cat 630, #U21843, 4,000 hrs..................................$66,6671994 Deere 640E Cable skidder, #U21884, 2,978 hrs............$44,0002000 Franklin Q70, #U22039, 3,874 hrs...................................$64,000SKIDSTEERS1999 Bobcat 753F, #BT6613, 3,442 hrs...................................$11,3331995 Deere 8875, #BT6231, 1,805 hrs.....................................$10,0002003 Case 90XT, #BT6614, 1,124 hrs........................................ P.O.R.TRUCKS — OFF-ROAD1996 Haulpak 330M, #BP1712, 17,500 hrs............................$216,000WHEEL LOADERS1974 Fiat Allis 605-B, #U21920................................................$10,6672004 Cat 924G, #BT6230, 2,712 hrs.......................................$106,667Most machines are available for rental purchase opti<strong>on</strong>. All machines subject to prior sale. Year listed is year of manufacture.For additi<strong>on</strong>al informati<strong>on</strong>, please call (502) 493-4380Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551South Bend IN • (574) 233-8770Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456 Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700Paducah, KY • (270) 444-8390