ROGERS GROUP - Brandeis Focusing on Solutions magazine

ROGERS GROUP - Brandeis Focusing on Solutions magazine

ROGERS GROUP - Brandeis Focusing on Solutions magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A MESSAGE FROMTHE PRESIDENTDear Equipment User:Gene Snowden, Jr.We’re looking forward to the new year with optimism thatc<strong>on</strong>structi<strong>on</strong> will rebound. One reas<strong>on</strong> we’re hopeful is because ofthe recently approved ec<strong>on</strong>omic stimulus package, which includesan estimated $130 billi<strong>on</strong> in c<strong>on</strong>structi<strong>on</strong>-related spending.No matter the c<strong>on</strong>diti<strong>on</strong>s in the c<strong>on</strong>structi<strong>on</strong> industry, we shouldall look for ways to be more efficient in our equipment use. Thatmeans using quality machinery that helps you produce morein less time with decreased fuel c<strong>on</strong>sumpti<strong>on</strong> and emissi<strong>on</strong>s.Komatsu has a full line of c<strong>on</strong>structi<strong>on</strong>, utility, mining and forestryequipment that meets those standards.You can find out about some of those products in this issueof <str<strong>on</strong>g>Focusing</str<strong>on</strong>g> <strong>on</strong> Soluti<strong>on</strong>s. Am<strong>on</strong>g them are innovative machines,such as Komatsu’s largest utility excavator, the PC88MR-8; thePC200LC-8 excavator with thumb spec; and D31 and D37 dozers,which now feature the super-slant nose design. If it’s miningequipment you’re interested in, check out the MINExpo articleto see products that have made Komatsu the leader in miningmachinery.If you need more informati<strong>on</strong> <strong>on</strong> any of these products, or ifwe can help you with any of your service needs, d<strong>on</strong>’t hesitate toc<strong>on</strong>tact us. We’re here to help you in any way we can.Sincerely,BRANDEIS MACHINERY & SUPPLY COMPANYGene Snowden, Jr.President and Chief Operating Officer

IN THIS ISSUE<str<strong>on</strong>g>ROGERS</str<strong>on</strong>g> <str<strong>on</strong>g>GROUP</str<strong>on</strong>g>Learn how <strong>on</strong>e of the U.S.’s leading aggregate producers maintainsstr<strong>on</strong>g ties to its Indiana roots.GUEST OPINIONDavid Seiders, former NAHB Chief Ec<strong>on</strong>omist shares potential goodnews <strong>on</strong> the status of the housing market.INVESTING IN THE PRESENT AND THE FUTUREThe $787 billi<strong>on</strong> American Recovery and Reinvestment Act was signedinto law in mid-February. See how infrastructure spending is a crucialelement of this ec<strong>on</strong>omic stimulus plan.FIELD NOTESCheck out the photos from Komatsu’s recent Demo Days whereparticipants operated equipment and toured the ChattanoogaManufacturing Operati<strong>on</strong>.DESIGN INNOVATIONKomatsu is at the forefr<strong>on</strong>t of design innovati<strong>on</strong> with its award-winningsuper-slant design and other improvements to its D31 and D37 dozers.PRODUCT NEWSRead how the new PC200LC-8 Thumb Spec excavator offers greater liftcapacity and stability in a variety of applicati<strong>on</strong>s.UTILITY PRODUCTSIf you’re looking for an eight-t<strong>on</strong> excavator, check out the KomatsuPC88MR-8. It provides more value with m<strong>on</strong>ey-saving features.LOUISVILLE, KY1801 Watters<strong>on</strong> TrailLouisville, KY 40299-2454(502) 491-4000FAX (502) 499-3195STANVILLE, KY130 Mare Creek RoadStanville, KY 41659-7003(606) 478-9201FAX (606) 478-9208FORT WAYNE, IN7310 Venture LaneFort Wayne, IN 46818-1256(260) 489-4551FAX (260) 489-1620Published by C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc. for <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinerywww.brandeismachinery.comLEXINGTON, KY1389 Cahill DriveLexingt<strong>on</strong>, KY 40504-1167(859) 259-3456FAX (859) 254-0783PADUCAH, KY160 County Park Rd.Paducah, KY 42001(270) 444-8390FAX (270) 575-4907INDIANAPOLIS, IN8410 Zi<strong>on</strong>sville RoadIndianapolis, IN 46268-1524(317) 872-8410FAX (317) 872-8417CORBIN, KY1484 American Greeting Card RoadCorbin, KY 40701-4813(606) 528-3700FAX (606) 528-9014EVANSVILLE, IN2506 Highway 41 NorthEvansville, IN 47711-4048(812) 425-4491FAX (812) 425-1171SOUTH BEND, IN3160 Youngs CourtSouth Bend, IN 46614(574) 233-8770FAX (574) 233-8775THE PRODUCTS PLUSTHE PEOPLE TO SERVE YOU!J. A. (Jay) Paradis, III, ChairmanCharles Leis, Chief Executive OfficerGene Snowden Jr., President & Chief Operating OfficerT<strong>on</strong>y Estes, Senior Vice President/Sales & RentalsGary Hirsch, Vice President/General Manager Crane & Material HandlingR<strong>on</strong> Weir, Used Equipment ManagerChuck Mueller, Vice President/Coal Services ManagerDavid Coultas, Vice President/Regi<strong>on</strong>al Sales ManagerKeith Harlan, Vice President/Product Support ServicesAnth<strong>on</strong>y Hillyard, Fleet Maintenance & Repair ManagerTodd Coffey, Corporate Service ManagerDan Brand<strong>on</strong>, Manager of Sales & Rental ServicesDave Bauer, Utility Equipment ManagerSean McGuire, Corporate Rental ManagerChris Hooker, Coal Sales ManagerSpencer DePoy, Regi<strong>on</strong>al Sales ManagerLOUISVILLESteve Seelbach,Branch ManagerWes Broyles,Service ManagerDoug Flynn,Machine Sales Rep.Lee Schilling,Machine Sales Rep.Gene Snowden III,Machine Sales Rep.Tommy Johns<strong>on</strong>,Product Support Sales Rep.John Harping,Product Support Sales Rep.Bob Bisig,Parts ManagerCraig Leis,Rental Rep.STANVILLEBarry Justice,Branch ManagerHarold Vititoe,Service ManagerRalph Scott,Machine Sales Rep.Randy Reynolds,Coal SalesmanJack Hunt,Product Support Sales Rep.Mike Roberts,Product Support Sales Rep.Ricky Johns<strong>on</strong>,Coal Product ServicesHarold Adams, Parts ManagerINDIANAPOLISJohn Newman,Branch ManagerJeff Woods,Product Support Rep.Josh Farmer,Machine Sales Rep.Eric Baker,Machine Sales Rep.Chris Harman,Rental Rep.Pat Creel,Machine Sales Rep.Chet Blant<strong>on</strong>,Rental Rep.Mike Lovell,Product Support Sales Rep.EJ Fisher,Machine Sales Rep.FORT WAYNETim Kreider,Machine Sales Rep.Nathan Rhoades,Rental Rep.Tom Patrick,Product Support Sales Rep.Ralph Glick,Senior Branch Parts Rep.CORBINLarry Freeman,Branch ManagerRob Prewitt,Service ManagerJohn Estill,Machine Sales Rep.Robert Krutsinger,Machine Sales Rep.Larry J<strong>on</strong>es,Product Support Sales Rep.Mike Frederick,Coal Product ServicesDavid Helt<strong>on</strong>,Senior Branch Parts Rep.LEXINGTONTodd Daugherty,Branch ManagerBill Powell,Service ManagerKen Tate,Machine Sales Rep.John Morse,Product Support Sales Rep.Gayle Tipt<strong>on</strong>,Senior Branch Parts Rep.Lisle Dalt<strong>on</strong>,Rental Rep.PADUCAHDavid Smithmier,Operati<strong>on</strong>s ManagerCory Edwards,Machine Sales Rep.Chad Porter,Product Support Sales Rep.Justin Growel,Rental Rep.SOUTH BENDKevin Wolford,Operati<strong>on</strong>s ManagerTom Patrick,Product Support Sales Rep.Doug Fox,Machine Sales Rep.EVANSVILLEBob Morris,Branch ManagerRandy McCormick,Service ManagerKelly Cates,Coal SalesmanMatt Bueltel,Machine Sales Rep.Brand<strong>on</strong> Russell,Machine Sales Rep.Joe Barnard,Product Support Sales Rep.Chris Alcorn,Product Support Sales Rep.Jeff Vinnedge,Coal Product ServicesMike Reese, Parts ManagerRodney Spaw, Rental Rep.Printed in U.S.A © 2009 C<strong>on</strong>structi<strong>on</strong> Publicati<strong>on</strong>s, Inc.Pant<strong>on</strong>e 072 blue

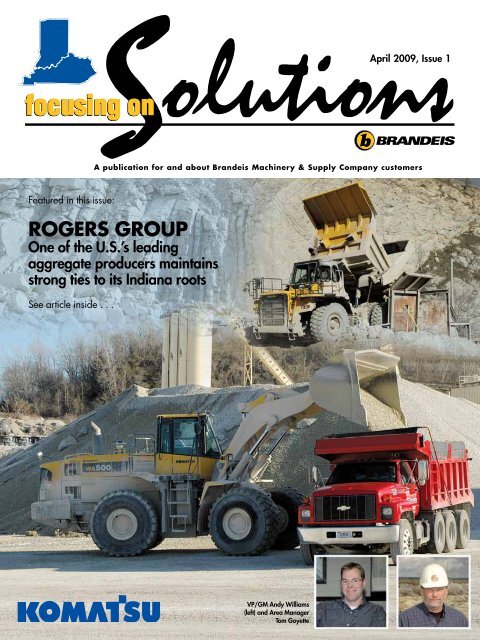

A SALUTE TO ACUSTOMER<str<strong>on</strong>g>ROGERS</str<strong>on</strong>g> <str<strong>on</strong>g>GROUP</str<strong>on</strong>g>One of the U.S.’s leading aggregate producersmaintains str<strong>on</strong>g ties to its Indiana rootsAndy Williams,VP/GMTom Goyette,Area ManagerMake no mistake, Rogers Group is <strong>on</strong>e ofthe big boys in U.S. aggregate circles. Thecompany, which last year celebrated its 100thyear in business, was founded in 1908 byRalph Rogers in Bloomingt<strong>on</strong>, Indiana. Today,in its fifth generati<strong>on</strong> of family ownership, ithas 81 locati<strong>on</strong>s (48 quarries) in six states andis No. 7 <strong>on</strong> the 2008 Pit & Quarry list of thenati<strong>on</strong>’s top 10 crushed-st<strong>on</strong>e producers.Despite its nati<strong>on</strong>al stature and str<strong>on</strong>gregi<strong>on</strong>al footprint, the local level is whereRogers Group has its greatest impact.“Being a valued participant in the communityis <strong>on</strong>e of the Rogers Group’s core values,” saidAndy Williams, VP and GM of Rogers Group’scentral Indiana operati<strong>on</strong>s. “We put a lot ofm<strong>on</strong>ey, time and effort back into the communitiesOne of the nati<strong>on</strong>’s largest crushed-st<strong>on</strong>e producers, Rogers Group was founded inBloomingt<strong>on</strong>, Indiana, in 1908.in which we’re located. For example, here inBloomingt<strong>on</strong>, we have many individuals whoserve in leadership roles <strong>on</strong> various boardsand volunteer causes. Giving back to the localarea is something we take a lot of pride in, andI think that type of company-encouraged civicinvolvement is something that separates us frommany of our competitors.”Going hand-in-hand with communityinvolvement is a company commitment to itsemployees. “I can tell you firsthand, as <strong>on</strong>ewho worked here, then left and came back,that Rogers Group does its best to live up toits stated goal to provide a rewarding life andcareer for its employees,” said Williams.“One way that’s dem<strong>on</strong>strated is throughwhat I believe is an unmatched commitmentto safety,” he added. “Every Rogers Groupmanager is required to do a m<strong>on</strong>thly safetyaudit of each locati<strong>on</strong>. We also have dailysafety meetings with employees. The goal is tocreate a culture of safety and an envir<strong>on</strong>mentwhere people truly care about, and look outfor, <strong>on</strong>e another. As a result, our incident rate isless than <strong>on</strong>e-fourth the industry average.”Committed employeesIn Indiana, Rogers Group has five quarries,four sand and gravel pits and a specialtyproducts business. The company employsmore than 250 people statewide.In additi<strong>on</strong> to Williams, key managementpers<strong>on</strong>nel in Indiana include Trent Carney,who runs the Bloomingt<strong>on</strong> complex, whichincludes an underground mine and a surfacemine, making it the largest quarry in theRogers Group; Tom Goyette, Area Managerfor Northern Indiana; and James Nichols whomanages Rogers Block.

“We believe our work force, across-the-board,is as good as there is in the industry,” saidWilliams. “We’re proud of everybody whoworks here — our managers, our office staffand our field pers<strong>on</strong>nel — because they all buyinto what we’re all about. To get the producti<strong>on</strong>and efficiency we achieve, al<strong>on</strong>g with thecommitment to safety and the community, takesa total team effort from everybody throughoutthe organizati<strong>on</strong>. We’ve been able to get thateffort pretty c<strong>on</strong>sistently because we attractgood people, and we do our best to keep them.”Quality rock productsIn additi<strong>on</strong> to the quality of its work force,another strength of the Rogers Group is thequality of its raw product.“Ralph Rogers did a great job back in theearly days of finding the highest qualityreserve in an area,” said Williams. “Forexample, around Bloomingt<strong>on</strong>, there are anumber of dimensi<strong>on</strong> st<strong>on</strong>e quarries. Theproduct is very attractive and good for exteriorlimest<strong>on</strong>e buildings, but it tends to be a softst<strong>on</strong>e that’s not suitable for c<strong>on</strong>structi<strong>on</strong> use.“At all of the Rogers Group quarries inIndiana, we’re able to produce DOT-approvedc<strong>on</strong>structi<strong>on</strong> products because of the quality ofthe rock,” he noted. “We also have a high-calciumst<strong>on</strong>e that can be used in anything from sandtraps to toothpaste to power plants.”In northern Indiana, the Rogers Group’sNewt<strong>on</strong> County St<strong>on</strong>e quarry is truly unique.“We’re a meteor impact site and I’m fairlycertain we’re the <strong>on</strong>ly such site in the U.S. that’sbeing mined,” said Tom Goyette, NorthernIndiana Area Manager. “The meteor hit hereduring the Jurassic period, perhaps 150 milli<strong>on</strong>to 200 milli<strong>on</strong> years ago. The impact causedlimest<strong>on</strong>e that was lying horiz<strong>on</strong>tally asmuch as 2,000 feet underground to be pushedvertically up to the surface — and that’s howwe have to mine it. It’s excellent quality rock butit’s challenging because there are faults all overthe property. As a result, we have to do a lot ofselective mining.”Productive equipment anddealer supportInterestingly, Rogers Group opened its doorsin Bloomingt<strong>on</strong> the same year that <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>Machinery & Supply opened in Louisville.Both companies have grown and prosperedduring the last century, and today, their serviceterritories are remarkably similar. Through theyears, Rogers Group has turned to <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>for much of its equipment needs, includingKomatsu wheel loaders and haul trucks.“We have two Komatsu WA700 wheelloaders, a WA600, numerous WA500s and anumber of 70-t<strong>on</strong> HD605 haul trucks here inthe central-Indiana regi<strong>on</strong>,” noted Williams.“We also have a Komatsu excavator and werent Komatsu dozers as needed.“Our experience with Komatsu machineshas been very good,” he added. “We especiallylike the new WA500-6s. They’re able to handleeight-and-<strong>on</strong>e-quarter-yard buckets so we cantwo-pass load a tri-axle and three-pass a quad inC<strong>on</strong>tinued . . .Rogers Group’s centralIndiana divisi<strong>on</strong> hasnumerous KomatsuWA500 wheel loaders.“Our experience withKomatsu machines hasbeen very good,” saidVP/General ManagerAndy Williams. “Weespecially like the newWA500-6s because we’reable to two-pass load atri-axle truck, and thefuel burn is less than 10gall<strong>on</strong>s per hour, whichis very good.”Trent Carney,Bloomingt<strong>on</strong> SiteManager

Rogers Group begins sec<strong>on</strong>d century. . . c<strong>on</strong>tinuedVP/GM Andy Williams (left)appreciates the support RogersGroup gets from <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>Machinery & Supply andSales Rep Josh Farmer. “Joshand <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> take care of usbetter than the competiti<strong>on</strong>does,” said Williams. “Ifthere’s a problem, we knowthey’re going to stand behindthe product and stand behindus — and we appreciate that.”At Newt<strong>on</strong> County St<strong>on</strong>e in northern Indiana, the Rogers Group mines this uniquevertical limest<strong>on</strong>e formati<strong>on</strong>, which was caused milli<strong>on</strong>s of years ago by a meteor impact.“I’m fairly certain we’re the <strong>on</strong>ly meteor-impact quarry in the country,” said NorthernIndiana Area Manager Tom Goyette.At Newt<strong>on</strong> County St<strong>on</strong>e, Rogers Group uses a 61-t<strong>on</strong> Komatsu HD465 haul truck tocarry and dump rock into the crusher.8the quarry. Also, the fuel burn is less than 10gall<strong>on</strong>s per hour, which is very good.”In northern Indiana, Rogers Group has anew Komatsu WA500 wheel loader and a61-t<strong>on</strong> Komatsu HD465 haul truck at Newt<strong>on</strong>County St<strong>on</strong>e, and two older model WA500s atInterstate Sand & Gravel.“We got the new WA500 last spring andit worked great for us all year,” reportedGoyette. “Same with the HD465. Both unitshave provided excellent productivity andthe operators appreciate that they’re verycomfortable. We’ve had the other wheel loadersat Interstate much l<strong>on</strong>ger and they’re still veryproductive, reliable machines.”Both Goyette and Williams say they alsoappreciate the service they get from <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>and Sales Representative Josh Farmer. “Bottomline, Josh and <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> take care of us betterthan the competiti<strong>on</strong> does,” acknowledgedWilliams. “If we’re down, they get here quicklyand get us back up and running quickly. Equallyimportant, if we have a failure, we know they’regoing to stand behind the product and standbehind us — and we appreciate that.”Still growingLike most parts of the country, commercial andresidential c<strong>on</strong>structi<strong>on</strong> has slowed in Indiana,but the state’s “Major Moves” highway programhas made up for much, if not all of that.“DOT spending has been very str<strong>on</strong>gthroughout Indiana and the energy sector hasalso been good for us,” Williams pointed out.“As a result, our quarry producti<strong>on</strong> was uplast year. Through 2015, the state is committedto spending more than $1 billi<strong>on</strong> <strong>on</strong> roads.And like everybody else, we’re hoping thenew presidential and c<strong>on</strong>gressi<strong>on</strong>al emphasis<strong>on</strong> infrastructure spending will also spurc<strong>on</strong>structi<strong>on</strong> activity.“Regardless, at Rogers Group, it’s obviouswe’re in this for the l<strong>on</strong>g haul. As l<strong>on</strong>g as wec<strong>on</strong>tinue to uphold the values Ralph Rogersinstilled — to always do the right thingsbased <strong>on</strong> unwavering integrity, a standard ofexcellence in every undertaking, and placing thehighest value <strong>on</strong> people — then we expect tohave a good start <strong>on</strong> our sec<strong>on</strong>d 100 years.” ■

Indianapolis, IN • (317) 872-8410South Bend IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551

G O R M A N - R U P P P R I M I N G - A S S I S T P U M P SSizes up to 30".Heads to 470'.Flows to 40,000 GPM.There’s no comparis<strong>on</strong>. Gorman-Ruppdelivers the biggest, broadest pumpline in the business. On c<strong>on</strong>structi<strong>on</strong>and sewage bypass jobs with trickyintermittent flow, a Gorman-Rupppump easily handles solids upto 6" in diameter. Get your hands<strong>on</strong> a Gorman-Rupp, the world’sundisputed standard in prime-assistperformance.Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456 Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700 Paducah, KY • (270) 444-8390Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551 South Bend, IN • (574) 233-8770A-404 © Copyright, The Gorman-Rupp Company, 2002 Gorman-Rupp Pumps – Mansfield Divisi<strong>on</strong> is an ISO 9001 Registered Company

GUEST OPINIONPOTENTIAL GOOD NEWSFormer NAHB Chief Ec<strong>on</strong>omist says there may be lightat the end of the housing tunnel so<strong>on</strong>C<strong>on</strong>gress should c<strong>on</strong>sider providingfurther “sorely needed” ec<strong>on</strong>omic stimulusto encourage home ownership and limitforeclosure in order to pull the U.S. ec<strong>on</strong>omyout of recessi<strong>on</strong>, according to David Seiders,who recently stepped down as ChiefEc<strong>on</strong>omist for the Nati<strong>on</strong>al Associati<strong>on</strong> ofHome Builders (NAHB). He spoke at theNAHB’s C<strong>on</strong>structi<strong>on</strong> Forecast C<strong>on</strong>ference.The steep decline in sales of newsingle-family homes should be coming to anend in 2009, Seiders said, setting the stagefor “tepid” improvement in new residentialc<strong>on</strong>structi<strong>on</strong> later this year. However, hewarned, that outcome has grown increasinglyuncertain in light of the turmoil that hasgripped world financial markets.“Things are a lot worse than any of us hadanticipated six m<strong>on</strong>ths ago,” Seiders said, andthe nati<strong>on</strong>al housing market — which is theroot cause of the collapse in c<strong>on</strong>fidence am<strong>on</strong>glenders — has c<strong>on</strong>tinued to spiral downward.“Risks are piling up <strong>on</strong> the down side. Theseare tough times, no questi<strong>on</strong>,” he said.While remaining reas<strong>on</strong>ably optimisticthat a housing recovery is beginning totake shape, “The uncertainties out there areunprecedented,” Seiders observed, “and thereis a growing risk that today’s major housingc<strong>on</strong>tracti<strong>on</strong> could get even worse.”On the brighter side, Seiders said thathousing in the first half of 2009 should behelped by the $7,500 tax credit available tofirst-time home buyers; legislative effortsto address foreclosures; the c<strong>on</strong>tinuati<strong>on</strong> ofaffordable mortgage rates; and the availabilityof fixed-rate mortgage financing throughFannie Mae, Freddie Mac, the Federal HousingAdministrati<strong>on</strong> and the Department ofVeterans Affairs.Restoring affordabilityCiting an increase in pent-up demand forhousing, he added that declines in home pricesand increases in pers<strong>on</strong>al income have helpedto restore housing affordability to the morenormal levels that existed prior to the peak ofthe housing boom.However, even as the demand for housingbegins to grow, housing producti<strong>on</strong> will bec<strong>on</strong>strained by tighter credit for the loansbuilders and developers need to break ground<strong>on</strong> new residential projects, he said. ■David Seiders,former NAHBChief Ec<strong>on</strong>omistFormer NAHB Chief Ec<strong>on</strong>omist David Seiders said the steep decline in sales of newhomes should be coming to an end in 2009, setting the stage for “tepid” improvement innew residential c<strong>on</strong>structi<strong>on</strong> later this year.

INVESTING IN THE PRESENT AND THE FUTURESTIMULUS PASSEDInfrastructure spending is a crucial elementof the recovery planThe American Recovery and ReinvestmentAct, more comm<strong>on</strong>ly known as the ec<strong>on</strong>omicstimulus package, was passed and signedinto law in mid-February. The total cost of thepackage is estimated at $787 billi<strong>on</strong>.“The goal at the heart of this plan is to createjobs,” said President Barack Obama. “Not justany jobs, but jobs doing the work Americaneeds d<strong>on</strong>e: repairing our infrastructure,modernizing our schools and hospitals,and promoting the clean, alternative energyInfrastructure spending for items such as new utilities is a centerpiece of the newec<strong>on</strong>omic stimulus package.sources that will help us finally declareindependence from foreign oil.”Of course, the $64,000 questi<strong>on</strong> about thisthree-quarters-of-a-trilli<strong>on</strong>-dollar plan is, willit succeed in its job-creati<strong>on</strong> goal?Where the m<strong>on</strong>ey will go?The stimulus package is a combinati<strong>on</strong>of direct spending, tax breaks andappropriati<strong>on</strong>s. Direct spending,which includes items such as higherunemployment benefits and food stamps,accounts for $267 billi<strong>on</strong> or about 34 percentof the total. Tax breaks for individualsand businesses total $212 billi<strong>on</strong>, about 27percent of the total. The largest piece of thepie is appropriati<strong>on</strong>s spending, which comesin at more than $308 billi<strong>on</strong> or 39 percent ofthe total.It’s the appropriati<strong>on</strong>s spending thatincludes the infrastructure investmentsthat are crucial to the c<strong>on</strong>structi<strong>on</strong> industry.Total infrastructure spending will be about$135 billi<strong>on</strong>. If you’re w<strong>on</strong>dering whatmight be in it for you, take a look at how theAssociated General C<strong>on</strong>tractors of America(AGC) breaks down the act’s infrastructureand public building investment provisi<strong>on</strong>s(see chart <strong>on</strong> next page).According to the C<strong>on</strong>gressi<strong>on</strong>al BudgetOffice (CBO), <strong>on</strong>ly about $35 billi<strong>on</strong> worthof stimulus appropriati<strong>on</strong>s will be spent bySept. 30, which is the end of FY 2009. TheCBO estimates nearly $111 billi<strong>on</strong> will bespent in FY 2010.The Obama administrati<strong>on</strong> estimates thestimulus package will create or save at least 3milli<strong>on</strong> jobs. n

DESIGN INNOVATIONNEW DOZERSAward-winning super-slant design am<strong>on</strong>gimprovements in D31, D37 modelsBruce Boebel,Komatsu DozerProduct ManagerKomatsu’s award-winning,super-slant nose design, isnow available in its newD31 and D37 models. Alsoavailable in D39 and D51models, it allows operatorsa better view of the bladefor increased efficiency.The revoluti<strong>on</strong>ary design that madeKomatsu’s first super-slant dozer, the D51EX-22,an award winner is now available in the newD31 and D37 models. They are ideal for ownersand operators looking for better visibility andperformance in smaller-dozer applicati<strong>on</strong>s.Both new models, available instandard-track EX and wide-track PX versi<strong>on</strong>s,feature Komatsu’s super-slant nose coupledwith a new cab-forward design that puts theoperator closer to the blade, while improvingmachine balance, ride and stability.“Slanting the nose and moving operatorsforward allows them a better view all around,and especially gives them a great view of thematerial they’re pushing,” said Bruce Boebel,Komatsu Dozer Product Manager. “Cabs arelarger than their predecessors, with more glassto enhance visibility, making the operator moreefficient. Owners could put a new operator inthese machines and be c<strong>on</strong>fident they’ll learnBrief Specs <strong>on</strong> Komatsu D31 and D37 DozersModel Output Operating weight Blade capacityD31EX-22 78 hp 18,056 lbs. 2.11 cu. yd.D31PX-22 78 hp 18,827 lbs. 2.11 cu. yd.D37EX-22 89 hp 18,298 lbs. 2.32 cu. yd.D37PX-22 89 hp 19,070 lbs. 2.55 cu. yd.how to run a dozer faster so they’re productivemore quickly.“We didn’t stop with improving the cab,”he added. “The dozers are more durable withthick plate steel and rigid frames, and tracks arewelded <strong>on</strong>to the frame, unlike most competitors,which have bolt-<strong>on</strong> track frames. Both have morehorsepower than their predecessors, increasingpushing capabilities for better producti<strong>on</strong>and cost per yard. Couple that with new Tier3 engines that reduce fuel c<strong>on</strong>sumpti<strong>on</strong>, andmaintenance time, and they’re am<strong>on</strong>g the mostefficient dozers <strong>on</strong> the market.”Those attributes are helped by largepower-angle-tilt blades that hold morematerial, especially useful in mass dozing.Each hydrostatic dozer has a steering systemthat provides smooth movement duringdozing, even in gradual turns. That also allowsthe operator to approach objects accurately incorner and sidewall operati<strong>on</strong>s.By simply pushing a butt<strong>on</strong>, operators canselect between variable and quick-shift speedc<strong>on</strong>trol for maximum efficiency during fine orrough grading with optimal travel speeds tomatch job c<strong>on</strong>diti<strong>on</strong>s and operator preferences.With variable speed, travel speed is adjustedthrough a range of 20 incremental speeds,while quick-shift allows operators to selectthree predetermined speed settings to matchjob c<strong>on</strong>diti<strong>on</strong>s.“All models come standard with KOMTRAXto help track utilizati<strong>on</strong> and maintenance,”noted Boebel. “The D31 is great in residentialapplicati<strong>on</strong>s and tight places for generalfinish work, and the D37 is a step up for thosewanting a little bigger machine, but can’tjustify going to a larger D39. They’re both greatinvestments that will pay big dividends.” n

PRODUCT NEWSADDED VALUEPC200LC-8 Thumb Spec excavator offersgreater lift capacity and stabilityWhen Komatsu designed its PC200LC-8Thumb Spec excavator, it kept all the sameinnovative attributes of its PC200LC-8 counterpartand beefed up the counterweight to 11,113pounds. The result was a 20-percent increasein lifting capacity compared to the standardPC200LC-8 and increased stability when workingwith heavy loads at maximum reach.“This is really a great machine for any<strong>on</strong>ewho’s working in c<strong>on</strong>diti<strong>on</strong>s that warrant thatextra lift and stability needed in applicati<strong>on</strong>ssuch as digging trenches or setting pipe andstructures,” said Armando Najera, ProductManager Excavators. “The thumb and bucket,as well as attachment piping, can be factoryinstalled. The PC200LC-8 Thumb Spec also hasa heavy-duty arm for improved durability andincreased support for thumb installati<strong>on</strong>.”Also available for customers who requirefactory piping is an HD Spec (Heavy Duty) thatincludes an HD boom, HD revolving frameunder covers and HD decals. The HD Spec is asetup that is suited for demoliti<strong>on</strong>-type work.Other major producti<strong>on</strong> numbers remain thesame for both the Thumb Spec and the HD Spec,with bucket capacity between 0.66 and 1.57 cubicyards and 148 net horsepower.“Keeping those numbers c<strong>on</strong>sistent meansthe Thumb Spec machine will c<strong>on</strong>tinue tobe productive and fuel efficient, even whilehandling heavier work loads,” said Najera.“The PC200LC-8 Thumb Spec has increased inpopularity because of that. C<strong>on</strong>tractors are seeingthe benefit and asking for this machine.”Efficient featuresPart of its popularity comes from the standardfeatures, similar to its counterpart, that makeit am<strong>on</strong>g the most productive in its size class,including low fuel c<strong>on</strong>sumpti<strong>on</strong> and emissi<strong>on</strong>sfrom a Komatsu turbocharged, aftercooled Tier 3engine. Operators can maximize fuel efficiencyby using the Ec<strong>on</strong>omy mode (<strong>on</strong>e of fiveavailable modes), and using the Eco-gauge forenergy-saving operati<strong>on</strong>s. An extended idlingcauti<strong>on</strong> helps operators remember to shut themachine down for fuel c<strong>on</strong>servati<strong>on</strong>.Operators can set the modes using aneasy-to-view, seven-inch LCD color m<strong>on</strong>itorin the large, comfortable cab that has dampermounting for low noise and vibrati<strong>on</strong>. Extendedreplacement intervals for engine oil and filter andhydraulic filters means less downtime. Like allnew Komatsu excavators, the PC200LC-8 ThumbSpec comes with Komatsu’s KOMTRAX remotemachine-m<strong>on</strong>itoring system.“Like the standard PC200LC-8, this is truly agreat machine that can benefit almost any<strong>on</strong>edoing mass excavati<strong>on</strong>, site preparati<strong>on</strong> or utilityinstallati<strong>on</strong>. The Thumb Spec is not just forcustomers with machines that will use a thumb,”said Najera. “If they need a little extra kick oradditi<strong>on</strong>al stability, they should c<strong>on</strong>sider thismachine. They’ll definitely see the difference.” nArmando Najera,Product ManagerExcavatorsKomatsu’s PC200LC-8Thumb Spec excavator hasthe innovative features of itsstandard counterpart, plusa reinforced mainframe andadditi<strong>on</strong>al counterweightfor increased liftingcapacity and stability whenworking with heavy loads atmaximum reach.Brief Specs <strong>on</strong> Komatsu PC200LC-8 Thumb Spec ExcavatorModel Operating weight Net hp Bucket capacityPC200LC Thumb Spec 51,199-53,115 lbs. 148 hp 0.66-1.57 cu. yd.

100%(the LOGICAL CHOICEfor your next excavator)LCKomatsu excavators have set the standards for productivity, operator comfort and reliability over theyears. And, with the introducti<strong>on</strong> of our mid-sized –8 series, the standards have been raised yet again.• Tier-3 engines deliver reduced emissi<strong>on</strong>s without sacrificing power or productivity.• Electr<strong>on</strong>ics, engine and hydraulics are optimized for maximum efficiency andminimum fuel c<strong>on</strong>sumpti<strong>on</strong> (10% reducti<strong>on</strong> compared to –7 models).• Multi-functi<strong>on</strong> LCD m<strong>on</strong>itor provides critical operating informati<strong>on</strong> at a glance(and it can do this in 10 languages).From enhanced safety features to extended maintenance intervals, the PC200LC-8, PC220LC-8and PC270LC-8 show what happens when the best engineers put the latest technology to work.The results are always…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA03

UTILITY PRODUCTSEXPERIENCE PAYS OFFKomatsu designs the ultimateeight-t<strong>on</strong> size class excavatorKomatsu recently introduced its newPC88MR-8 excavator to the North Americanmarket to much critical acclaim. There are anumber of competitive units in its eight-t<strong>on</strong>size class, but the comparis<strong>on</strong> ends there asside-by-side tests show that the PC88MR-8offers more value from the start and cansave more m<strong>on</strong>ey throughout the life of themachine.Before the test was c<strong>on</strong>ducted, Komatsulooked at 13 obvious areas of comparis<strong>on</strong>,such as the manufacturer’s own hydraulicsand engine, short tail swing, fuel managementfeatures and number of working modes. Ineach case, the PC88MR-8 was equal to orbetter than the competitive model. Majorareas where Komatsu stood out were workingmodes — the PC88MR-8 has five to maximizeproducti<strong>on</strong> and fuel ec<strong>on</strong>omy — and fuelmanagement features, such as auto-idle, ecogauge, Ec<strong>on</strong>omy mode and excess idle alarm.The competiti<strong>on</strong> had <strong>on</strong>ly <strong>on</strong>e mode, auto-idle.After comparing the models, they wereput to the test under c<strong>on</strong>trolled c<strong>on</strong>diti<strong>on</strong>sat Komatsu’s Training and Dem<strong>on</strong>strati<strong>on</strong>Center in Cartersville, Ga. Komatsu was theclear winner in several categories, including 15percent faster cycle time in Producti<strong>on</strong> modeand nearly the same cycle time in Ec<strong>on</strong>omymode. The PC88MR-8 moved 6 percent morespoil per hour in the Working mode.While the Komatsu PC88MR-8 moved morematerial, it used less fuel — 8 percent lessin Power mode and a whopping 45 percentless in Ec<strong>on</strong>omy mode. In the same mode,Komatsu was 22 percent more efficient interms of cubic yards per gall<strong>on</strong>.C<strong>on</strong>tinued . . .In a side-by-side comparis<strong>on</strong>, Komatsu’s PC88MR-8 showed faster cycle times, moving 6percent more spoil per hour in the Working Mode. In additi<strong>on</strong>, it used less fuel, making itmore efficient and productive than the competiti<strong>on</strong>.

PC88MR-8 offers higher productivity, lower cost. . . c<strong>on</strong>tinuedAdding to the PC88MR-8’s productivitynumbers is a quiet cab that’s more comfortablefor the operator. During the comparis<strong>on</strong>,operators noted they could better hear thestandard radio in the Komatsu, making for amore pleasant operating envir<strong>on</strong>ment.Komatsu PC88MR-8 Field Test ResultsP ModeE ModeCycle timein sec<strong>on</strong>dsPC88MR-8Competitor12.31 14.1714.2714.17Komatsu had a 15% faster cycle time in Producti<strong>on</strong> Mode and nearly thesame cycle time in Ec<strong>on</strong>omy Mode.P ModeKomatsu moved 6.2% more spoil.P ModeE ModeGall<strong>on</strong>s per hourGall<strong>on</strong>s per hourPC88MR-8Komatsu used 8.1% less fuel in P Mode and 45.1% less in E Mode.P ModeE ModeTruck LoadingFuel C<strong>on</strong>sumpti<strong>on</strong>Fuel EfficiencyCycle timein sec<strong>on</strong>dsLoading AmountPC88MR-8Competitor2.74 2.962.04CompetitorCubic yards per hour 114.6 107.4Cubic yards per gall<strong>on</strong>Cubic yards per gall<strong>on</strong>Komatsu was more efficient by as much as 22.6%.PC88MR-82.96Competitor41.9 36.346.9has <strong>on</strong>ly<strong>on</strong>e modeKOMTRAX saves m<strong>on</strong>eyIn today’s competitive envir<strong>on</strong>ment, theavailability of accurate operating informati<strong>on</strong> canimprove the bottom line. Helping provide thataccurate informati<strong>on</strong> is Komatsu’s KOMTRAXsystem, standard <strong>on</strong> every new machine withfive years of free communicati<strong>on</strong>s. To put such asystem <strong>on</strong> a machine using existing aftermarketofferings would cost well in excess of $2,000.Komatsu sampled the KOMTRAXinformati<strong>on</strong> <strong>on</strong> several of its first PC88 modelssold, and found the following informati<strong>on</strong>:• Six of eight machines analyzed idled 50percent of the time. That excessive idlingwastes fuel, increases engine wear andadds unnecessary hours to the enginehour meter, which may affect machineresale value at trade-in time. The excesshours require more frequent maintenanceresulting in higher costs. By knowingand managing engine idling time, ownerscan reduce maintenance costs and increaseuseful life and resale value.• Those operators who idled the machineless, also used the Ec<strong>on</strong>omy modetwo-thirds of the time. Using the E modeand idling less saved nearly 60 percent infuel c<strong>on</strong>sumpti<strong>on</strong>. Assuming a fuel priceof $3 per gall<strong>on</strong>, that equates to more than$3,300 savings over the course of 1,000hours of operati<strong>on</strong>.Higher resale value,peace of mindThe c<strong>on</strong>clusi<strong>on</strong> from Komatsu’s testing andm<strong>on</strong>itoring is that the PC88MR-8 is truly theultimate eight-t<strong>on</strong> excavator. It gives ownersmore up-fr<strong>on</strong>t at time of purchase and it keeps<strong>on</strong> giving with exclusive fuel-managementfeatures, five working modes to match machineperformance to demand and the exclusiveKOMTRAX machine-m<strong>on</strong>itoring system thatcan enhance efficient, m<strong>on</strong>ey-saving operati<strong>on</strong>.Komatsu believes that the KOMTRAX historyrecord will pay dividends at trade-in time withhigher resale values.For additi<strong>on</strong>al peace of mind, the PC88MR-8comes with a standard three-year/3,000-hourwarranty. n

100%precisi<strong>on</strong>Komatsu compact excavators are right at home working in tight spaces. With advanced Proporti<strong>on</strong>alPressure C<strong>on</strong>trol (PPC) joysticks, these machines give you precise handling without sacrificingspeed, reach or capacity. Plus, they have all the features that make Komatsu excavators the choiceof owners and operators across the country.• Low-effort Proporti<strong>on</strong>al Pressure C<strong>on</strong>trol (PPC) joysticks• Spacious, erg<strong>on</strong>omically designed operator platform• Industry-leading 360-degree visibility• Tilt-forward operator cab structure for ease of service access• Switchable excavator c<strong>on</strong>trol pattern without tools (ISO/SAE)When there’s no room for error, the choice is 100% clear. Put our compact excavators to worktoday and enjoy the c<strong>on</strong>fidence that comes from machines that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA10

Louisville, KY • (502) 491-4000Stanville, KY • (606) 478-9201Paducah, KY • (270) 444-8390Lexingt<strong>on</strong>, KY • (859) 259-3456Corbin, KY • (606) 528-3700Indianapolis, IN • (317) 872-8410South Bend, IN • (574) 233-8770Evansville, IN • (812) 425-4491Fort Wayne, IN • (260) 489-4551

Innovati<strong>on</strong> helps Komatsu remain a leader in mining machinery. . . c<strong>on</strong>tinuedTom Stedman,Product MarketingManager forMechanical MiningEquipmentA Komatsu 860E-1KThas 2,700 horsepower formoving mass amountsof material faster.engine that works to help the 246,000-pound-plusmachine push nearly 60 cubic yards of materialwith its Super Dozer blade.“The D475ASD-5 Tier 2 is great for l<strong>on</strong>g,c<strong>on</strong>sistent pushes where operators can utilize allits horsepower,” pointed out Rich Smith, ProductManager for Mechanical Drive Equipment. “Ituses a lockup torque c<strong>on</strong>verter that gets theengine’s power to the tracks and down to theground where it bel<strong>on</strong>gs. With the Super Dozerblade, it’s about 15 percent more effective than astandard blade.“That becomes even greater in uphillpushes,” he added. “For instance, <strong>on</strong> a12-percent or 15-percent grade, users may see20 percent to 25 percent greater productivityadvantages over a standard full-U blade.In additi<strong>on</strong>, it offers greater travel speedwhile the engine kicks down in rpms, so ituses 3 percent to 5 percent less fuel than thecompetiti<strong>on</strong>. With today’s fuel prices, thatadds up significantly in a fleet of machines.”WA 1200-3 leads the packRounding out Komatsu’s equipment offeringsat MINExpo was its largest wheel loader,the WA1200-3. This machine has a 1,560-nethorsepowerengine and a 26.2-cubic-yardbucket capacity in its standard c<strong>on</strong>figurati<strong>on</strong>. Anopti<strong>on</strong>al high-lift model provides an additi<strong>on</strong>altwo and a half feet of reach.The standard WA1200-3 is not <strong>on</strong>lyKomatsu’s largest loader, but <strong>on</strong>e of theworld’s largest at more than 452,000 poundswith a dumping clearance higher than 20 feet.It has more than 286,000 pounds of breakoutforce and 253,000 pounds of tracti<strong>on</strong> force.Steering is c<strong>on</strong>trolled by the Advanced JoystickSteering System (AJSS) with light, short strokesfor perfect steering accuracy, and stopping issafe with closed, wet-disc brakes.The D475ASD-5 Tier 2 dozer pushes nearly 60 cubic yards of material with itsSuper Dozer blade.Komatsu’s newest mining truck, the 960E-1, is also its largest with a payload of 360 t<strong>on</strong>s.“Of the world’s largest loaders, it gives thebest advantage in tractive effort and diggingpower,” said Tom Stedman, Product MarketingManager for Mechanical Mining Equipment.“Komatsu loaders are well-known throughoutthe range of sizes for their powerful digging,breakout force, stability and outstandingtipping load weight and ratio, and we believethe WA1200-3 is unmatched in all these areas.“The WA1200-3 has a wide range ofapplicati<strong>on</strong>s,” he added. “They are in use in alltypes of mines around the globe because theymatch up very well with our electric miningtrucks. In additi<strong>on</strong>, because of their stability,they make great load-and-carry machines forapplicati<strong>on</strong>s such as charging a hopper.” n

100%compatible(it’s the perfect working relati<strong>on</strong>ship)“Synergy” isn’t a word often associated with c<strong>on</strong>structi<strong>on</strong> equipment, but it’s the perfectword to describe the Komatsu PC600LC-8 and HM300-2 working together… especiallywhen the terrain is less than perfect. Both of these hard-working machines deliver:• Rugged, dependable, go-anywhere productivity• Tier-3 certified engines to meet emissi<strong>on</strong>s standards• Advanced hydraulics for faster cycle timesIf you want maximum efficiency—no matter how rough the terrain might be—put thispair to work. At the end of the day, you’ll see the results from machines that are…100% Komatsu. 866.513.5778 www.komatsuamerica.comKA02

KOMATSU & YOUKOMATSU’S “GREEN” COMMITMENTVP says the company’s efforts impact boththe envir<strong>on</strong>ment and customers’ bottom lineErik Wilde,Vice President,Product MarketingThis is <strong>on</strong>e of a series of articlesbased <strong>on</strong> interviews with keypeople at Komatsu discussingthe company’s commitment to itscustomers in the c<strong>on</strong>structi<strong>on</strong> andmining industries — and theirvisi<strong>on</strong>s for the future.Erik Wilde has been with Komatsu more than a decade, the lastfive as Director and now Vice President of Product Marketing.“One of my primary missi<strong>on</strong>s is to help our product managersand distributors get the message out about how our products canmake our customers more efficient and productive at the sametime,” said Wilde. “Komatsu has d<strong>on</strong>e that in several ways that not<strong>on</strong>ly improve machine and operator performance, but reduce fuelc<strong>on</strong>sumpti<strong>on</strong> and harmful emissi<strong>on</strong>s. We believe we’re the mostenvir<strong>on</strong>mentally friendly equipment company in the market.”Wilde has seen several of the changes that have led to betterowning and operating costs since he joined Komatsu in 1997 as aWarranty Coordinator and Assistant Service Engineer for miningdozers. He was with the Mining Divisi<strong>on</strong> nearly four years beforemoving into the C<strong>on</strong>structi<strong>on</strong> Divisi<strong>on</strong> as Product Manager ofhydraulic excavators. He completed an MBA in Marketing in 2003,which led to his positi<strong>on</strong> as Director of Product Marketing later thatyear.A San Francisco Bay-area native, Wilde has adapted well to theMidwest as he’s based at Komatsu’s Corporate Headquarters inRolling Meadows, Ill. He and his wife have three children under age10 who keep them busy with various activities.QUESTION: Komatsu has introduced a largenumber of new machines in the past fewyears. What’s changed and why?ANSWER: In the past three years, Komatsuhas redesigned or replaced nearly 95percent of its vast equipment offerings,some as a result of increased governmentalstandards, but just as importantly, becausewe’ve listened to our customers’ desiresfor improved technology, better partsavailability and other improvements thatbenefit their businesses’ bottom lines. Fromthe governmental standpoint, nearly everymachine in Komatsu’s lineup has a Tier 3 orEPA-compliant engine. With the Tier 3 engines,we not <strong>on</strong>ly meet governmental standardsfor reduced emissi<strong>on</strong>s, but we often exceedthem. At the same time, we reduced fuelc<strong>on</strong>sumpti<strong>on</strong> and increased service intervals,both of which add up to more efficiency andcost savings. We simplified the machines forbetter operator efficiency and added itemssuch as lock-up torque c<strong>on</strong>verters for betterproductivity. We’re very proud of thoseachievements because they fit right in withour goal of being an envir<strong>on</strong>mentally friendlycompany with sustainable and “green”soluti<strong>on</strong>s as part of our corporate commitment.QUESTION: What else has Komatsu d<strong>on</strong>e togo “green?”ANSWER: Well in some sense, we believewe’ve always been the greenest equipmentcompany in the marketplace, stretching backdecades. All our equipment is designed andbuilt to last. That means fewer machinesbeing put out to pasture, so to speak. Anexample where we’ve extended life is inour new PLUS undercarriage <strong>on</strong> the D51,D61 and D65 machines, which doubles the

undercarriage life. But we all know that atsome point, every machine outlives its usefullife and will be taken out of service. Komatsudesigns machines that are virtually 100-percentrecyclable, from the steel to the plastic to theglass. We use recycled materials in their initialproducti<strong>on</strong>. That way, there’s less waste andmore reusable material that can go into makingfuture products.Komatsu c<strong>on</strong>tinues to implement greenpractices in its manufacturing operati<strong>on</strong>s.It’s adopted an Earth Envir<strong>on</strong>mental Charterthat lays out our principles and activities for agreen and sustainable company. All our plantsare near-zero-waste facilities, so that everymaterial that comes in is used or reused insome way. Waste oil is recaptured and used forheating. We’ve adopted new painting practicesthat cut waste and envir<strong>on</strong>mental impact,while making our paint jobs better. In additi<strong>on</strong>,we’ve strategically located our parts depotsto be closer to our customers so less fuel isused to get parts to them quickly, and we’veteamed with suppliers and carriers who areclose to our manufacturing operati<strong>on</strong>s, so thereare shorter shipping distances and less fuelburned in getting materials in and productsout of our manufacturing facilities.QUESTION: What are some ways Komatsuis working with equipment users <strong>on</strong> greenpractices?ANSWER: Komatsu prides itself <strong>on</strong> beingahead of the technological curve. With ourKOMTRAX m<strong>on</strong>itoring system, which isfree for five years and standard <strong>on</strong> most newmachines, users can see how a machine isperforming in various modes that Komatsuoffers. It’s widely believed that being inPower mode offers the best producti<strong>on</strong>. That’sunderstandable, but our data show that in70-plus percent of applicati<strong>on</strong>s, they get thesame productivity in the Ec<strong>on</strong>omy mode ata lower cost. The benefits are less fuel used,less engine wear and more profit. Komatsuis also introducing a “Green Guide,” whichoffers ways for equipment users to promoteand implement green practices into theircompanies and run their machinery moreefficiently. We’re encouraging users to checkit out <strong>on</strong>line so they’re not using paper. IfUtility machines, such as the CK30 compact track loader, were required to meet Tier 4emissi<strong>on</strong> standards in 2008. Tier 4 is <strong>on</strong> the horiz<strong>on</strong> for 175 horsepower and up machinesin 2011 and 75 to 175 horsepower must be Tier 4 in 2012.When Komatsu designed its Tier 3 engine machines, it not <strong>on</strong>ly lowered emissi<strong>on</strong>s, in manycases it increased horsepower and reduced fuel c<strong>on</strong>sumpti<strong>on</strong>, making them am<strong>on</strong>g the mostproductive and efficient machines in utility, c<strong>on</strong>structi<strong>on</strong> and mining applicati<strong>on</strong>s.they want a paper copy, it will be printed <strong>on</strong>recycled paper using soy ink, which is muchmore envir<strong>on</strong>mentally friendly.QUESTION: What else is <strong>on</strong> the horiz<strong>on</strong> forKomatsu?ANSWER: Our utility products already haveinterim Tier 4 engines and we’re working tomeet Tier 4 standards <strong>on</strong> time, or ahead oftime, like we did with Tier 3 <strong>on</strong> the balanceof the product line. Engines 175 horsepowerand up are required to be Tier 4 compliant by2011, 75 through 175 horsepower in 2012. Tier 4standards reduce emissi<strong>on</strong>s even more, whichfurther reduces envir<strong>on</strong>mental impact. As withour other products, we’re working to furtherimprove performance and efficiency <strong>on</strong> ourTier 4 machines, delivering more value for ourcustomers. n

USETHEBESTto be your best.Genesis attachments include:• XP Mobile Shears• New! Rebar Shears• Hydraulic C<strong>on</strong>crete Processors• New! Mechanical Pulverizers• New! Quick Coupler System• DemoPro C<strong>on</strong>crete & Steel Processors• and many more . . .<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery and Genesis.Two of the best, ready to help you do yours.Call today.As a designer and manufacturer of high-qualityattachments, we at Genesis are committed toproviding soluti<strong>on</strong>s to professi<strong>on</strong>als in thec<strong>on</strong>structi<strong>on</strong>, demoliti<strong>on</strong>, recycling and utilityindustries. Because <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery haschampi<strong>on</strong>ed that same commitment for decades,we are especially proud to be a member of<str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’ family of suppliers.Now, equipment users in Kentucky and Indiana canbenefit from both <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g>’ expertise and Genesisattachments, which are designed to provide thehighest levels of performance, productivity andbottom-line profits.1000 Genesis DriveSuperior, WI 54880Ph<strong>on</strong>e: (715) 395-5252Fax: (715) 395-5255www.genesisattachments.comE-mail: info@genesisattachments.com

SIDE TRACKSOn the light side“The good news is that we got the job . . . the bad news isthat they want us to loan them the m<strong>on</strong>ey to pay for it.”“In local news, police seized 40 t<strong>on</strong>s of smuggled asphaltworth an estimated street value of $1.5 milli<strong>on</strong> . . .”Did you know...• Recycling <strong>on</strong>e aluminum can saves enough energyto run a televisi<strong>on</strong> for three hours.• 80% of the earth’s surface is water.• A ‘jiffy’ is an actual unit of time for 1/100thof a sec<strong>on</strong>d.• Ten inches of snow equals <strong>on</strong>e inch of rain inwater c<strong>on</strong>tent.• The WD in WD-40 stands for Water Displacement.It was invented <strong>on</strong> the 40th try for a formulathat worked.“Just between you and me, we were counting <strong>on</strong> a big stockmarket rally, so Wall Street could bail out the government.”Brain TeasersUnscramble the letters to reveal some comm<strong>on</strong>c<strong>on</strong>structi<strong>on</strong>-related words. Answers are <strong>on</strong> theright side of this page.1. M A M R H E __ __ __ __ __ __2. Z R O D E __ __ __ __ __3. M T C C O P A __ __ __ __ __ __ __4. I R P P A R __ __ __ __ __ __5. C R T E N H __ __ __ __ __ __6. R P O A T E R O __ __ __ __ __ __ __ __Brain Teaser answers: 1. hammer 2. dozer 3. compact 4. riprap 5. trench 6. operator

Available through <str<strong>on</strong>g>Brandeis</str<strong>on</strong>g> Machinery & Supply Company

C.P.I.P.O. Box 1689C.R., IA 52406-1689Change Service RequestedPresortedStandardUS Postage PaidC.P.I.USED EQUIPMENT SPECIALS2005 Komatsu HM400,BT8813, 5,834 hrs.$210,0002002 Komatsu D41P-6,PT1843702, 2,467 hrs.$47,900Most machinesare availablefor rentalpurchaseopti<strong>on</strong>. Allmachinessubject toprior sale. Yearlisted is year ofmanufacture.2003 Komatsu PC200LC-7,U19635-1, 4,097 hrs.$69,9002005 Komatsu WA320-5,PT20985-1, 3,946 hrs.$91,600ARTICULATED HAUL TRUCKS2005 Komatsu HM400, BT8813, 5,834 hours....................$210,0002005 Komatsu HM400, BT8814, 5,820 hours....................$210,0002006 Komatsu HM400-1, BT8812, 3,505 hours................$280,000BACKHOE LOADERS2001 Komatsu WB140-2, PTC5017-1, 2,796 hours............$22,667COMPACTION1988 Ingersoll Rand DA50, PT24838....................................$4,6671994 Ingersoll Rand DD110, PT24831, 224 hours.............$13,3332002 Ingersoll Rand DD110, PT23248-1, 2,620 hours.......$39,9002002 Hamm HD12, U24515, 1,462 hours............................$10,9001993 Ingersoll Rand ST105, PT24748, 5,074 hours ............$8,900DOZERS2003 Case 1850K, PT24830, 3,143 hours............................$65,3332004 Komatsu D39PX-21, PT19523-1, 3,200 hours...........$46,6672006 Komatsu D37EX-21A, BT8012, 511 hours.................$75,0002006 Komatsu D41E-6, U24586, 786 hours........................$75,0002002 Komatsu D41P-6, PT18437-2, 2,467 hours................$47,9001998 Cat D5M, PT24843, 6,368 hours..................................$33,333EXCAVATORS1980 Cat 225, BT8602, 955 hours.........................................$22,0001996 Case 9030B, U24592, 6,818 hours..............................$35,9001982 Mitsubishi MS280, PT24833, 2,396 hours.................$10,6672005 Komatsu PC160LC-7, U24366, 840 hours...............$114,2672003 Komatsu PC200LC-7, U19635-1, 4,097 hours...........$69,9002005 Komatsu PC300LC-7L, U20530-2, 3,306 hours......$142,9002005 Komatsu PC300LC-7L, U20981-1, 2,277 hours......$142,9002002 Komatsu PC30MR-1, PT18591-1, 2,082 hours..........$17,3332006 Komatsu PC35MR-2, U21737-1, 300 hours...............$37,3332006 Komatsu PC400LC-7E0, PT22435, 2,380 hours.....$225,0001991 Komatsu PC60-6Z, PT24811, 3,609 hours.................$15,9002005 Komatsu PC78MR-6, U20387-2, 759 hours...............$68,2802002 Kobelco SK35SR-2E, U24645, 2,408 hours...............$16,900FORESTRY1995 Prentice 410D, PT24691.............................................$10,6672003 Deere 535, PT24745, 6,089 hours...............................$49,9001996 Franklin 560 PTM, PT23840-2, 5,011 hours...............$26,9002001 Hydro Ax 570, PT24749, 7,351 hours..........................$33,3332006 Valmet 603, U22776-1, 390 hours.............................$109,0002005 Deere 748GIII, PT24812, 4,631 hours.........................$81,6002008 Komatsu Forest 890.3, 23983, 1,881 hours............$375,0002003 Franklin Q80, U24360, 6,057 hours.............................$39,9001993 Bell Super T, U24591...................................................$22,9001998 Timbco T425C, U24579, 14,573 hours.......................$74,667MILLING MACHINE2000 Roadtec RX60C, PT24687, 4,300 hours...................$110,000PAVER1999 Blaw Knox PF-150, PT23237, 4 hours......................$111,600TRACK LOADER1994 Cat 939, PT24810, 416 hours.......................................$29,900OFF-ROAD TRUCKS1996 Haulpak 330M, BP1712, 19,699 hours...........................P.O.R.2000 Komatsu HD605-5, BP7405, 13,602 hours...................P.O.R.WHEEL LOADERS2001 Case 621CXT, 913 hours.............................................$33,3332006 Komatsu WA250-5, PP22379-1, 900 hours................$92,0002005 Komatsu WA320-5, PT20985-1, 3,945 hours.............$91,600For additi<strong>on</strong>al informati<strong>on</strong>, please call (502) 493-4380Evansville, IN • (812) 425-4491 Indianapolis, IN • (317) 872-8410 Fort Wayne, IN • (260) 489-4551South Bend IN • (574) 233-8770 Louisville, KY • (502) 491-4000 Lexingt<strong>on</strong>, KY • (859) 259-3456Stanville KY • (606) 478-9201 Corbin, KY • (606) 528-3700 Paducah, KY • (270) 444-8390