THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

THE SNIDER GROUP - Brandeis Focusing on Solutions magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

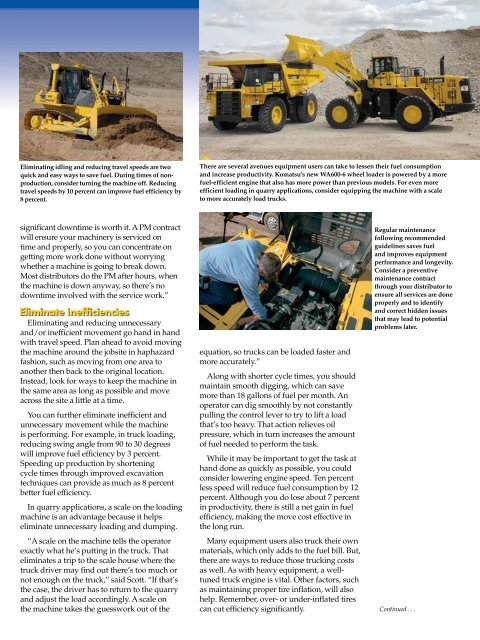

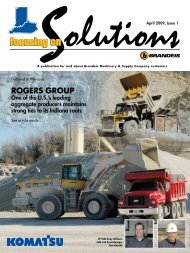

Eliminating idling and reducing travel speeds are twoquick and easy ways to save fuel. During times of n<strong>on</strong>producti<strong>on</strong>,c<strong>on</strong>sider turning the machine off. Reducingtravel speeds by 10 percent can improve fuel efficiency by8 percent.There are several avenues equipment users can take to lessen their fuel c<strong>on</strong>sumpti<strong>on</strong>and increase productivity. Komatsu’s new WA600-6 wheel loader is powered by a morefuel-efficient engine that also has more power than previous models. For even moreefficient loading in quarry applicati<strong>on</strong>s, c<strong>on</strong>sider equipping the machine with a scaleto more accurately load trucks.significant downtime is worth it. A PM c<strong>on</strong>tractwill ensure your machinery is serviced <strong>on</strong>time and properly, so you can c<strong>on</strong>centrate <strong>on</strong>getting more work d<strong>on</strong>e without worryingwhether a machine is going to break down.Most distributors do the PM after hours, whenthe machine is down anyway, so there’s nodowntime involved with the service work.”Eliminate inefficienciesEliminating and reducing unnecessaryand/or inefficient movement go hand in handwith travel speed. Plan ahead to avoid movingthe machine around the jobsite in haphazardfashi<strong>on</strong>, such as moving from <strong>on</strong>e area toanother then back to the original locati<strong>on</strong>.Instead, look for ways to keep the machine inthe same area as l<strong>on</strong>g as possible and moveacross the site a little at a time.You can further eliminate inefficient andunnecessary movement while the machineis performing. For example, in truck loading,reducing swing angle from 90 to 30 degreeswill improve fuel efficiency by 3 percent.Speeding up producti<strong>on</strong> by shorteningcycle times through improved excavati<strong>on</strong>techniques can provide as much as 8 percentbetter fuel efficiency.In quarry applicati<strong>on</strong>s, a scale <strong>on</strong> the loadingmachine is an advantage because it helpseliminate unnecessary loading and dumping.“A scale <strong>on</strong> the machine tells the operatorexactly what he’s putting in the truck. Thateliminates a trip to the scale house where thetruck driver may find out there’s too much ornot enough <strong>on</strong> the truck,” said Scott. “If that’sthe case, the driver has to return to the quarryand adjust the load accordingly. A scale <strong>on</strong>the machine takes the guesswork out of theequati<strong>on</strong>, so trucks can be loaded faster andmore accurately.”Al<strong>on</strong>g with shorter cycle times, you shouldmaintain smooth digging, which can savemore than 18 gall<strong>on</strong>s of fuel per m<strong>on</strong>th. Anoperator can dig smoothly by not c<strong>on</strong>stantlypulling the c<strong>on</strong>trol lever to try to lift a loadthat’s too heavy. That acti<strong>on</strong> relieves oilpressure, which in turn increases the amountof fuel needed to perform the task.While it may be important to get the task athand d<strong>on</strong>e as quickly as possible, you couldc<strong>on</strong>sider lowering engine speed. Ten percentless speed will reduce fuel c<strong>on</strong>sumpti<strong>on</strong> by 12percent. Although you do lose about 7 percentin productivity, there is still a net gain in fuelefficiency, making the move cost effective inthe l<strong>on</strong>g run.Regular maintenancefollowing recommendedguidelines saves fueland improves equipmentperformance and l<strong>on</strong>gevity.C<strong>on</strong>sider a preventivemaintenance c<strong>on</strong>tractthrough your distributor toensure all services are d<strong>on</strong>eproperly and to identifyand correct hidden issuesthat may lead to potentialproblems later.Many equipment users also truck their ownmaterials, which <strong>on</strong>ly adds to the fuel bill. But,there are ways to reduce those trucking costsas well. As with heavy equipment, a welltunedtruck engine is vital. Other factors, suchas maintaining proper tire inflati<strong>on</strong>, will alsohelp. Remember, over- or under-inflated tirescan cut efficiency significantly. C<strong>on</strong>tinued . . .