Environmental report 2006 (.pdf) - Kemira

Environmental report 2006 (.pdf) - Kemira

Environmental report 2006 (.pdf) - Kemira

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

e n v i r o n m e n ta l r e p o rt 2 0 0 6

ContentsA smaller ecological footprint 2From good to great in safety 3The environment– responsibility andan opportunityThe environment plays an important role in<strong>Kemira</strong>’s business. We aim not only to bear<strong>Environmental</strong> work at the sites 5• <strong>Kemira</strong> Water 5• <strong>Kemira</strong> Pulp&Paper 5• <strong>Kemira</strong> Specialty 5• <strong>Kemira</strong> Coatings 6<strong>Environmental</strong> statistics 7<strong>Environmental</strong> and safety managementsystems at production sites in <strong>2006</strong> 9<strong>Environmental</strong> data for the <strong>Kemira</strong> group 10Assurance statement 11our environmental responsibility but also todevelop and provide environmental solutionsand pro-environmental products andservices for our customers.In <strong>2006</strong>, we continued to reduce ourenvironmental releases and improved oursafety performance. The environmentalcosts were on the rise, mainly due to investmentsin new waste minimization technology.Preparations to implement the REACHregulation in Europe continued intensivelywithin product safety. Strong growth tookplace in <strong>Kemira</strong>’s environmental business,now representing around 36% of company’srevenue.1

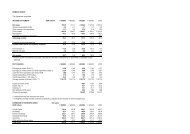

A smaller ecologicalfootprint<strong>Kemira</strong> undertakes to prevent and minimize the harmful effectson the environment, people and property caused by itsoperations, and to make effective use of natural resources.We have been successful in these long-term efforts, as evidencedby major reductions in emissions, effluents and wastevolumes (see the graphs and tables attached to this <strong>report</strong>).Structural changes in our business have also contributed tosmaller environmental effects reflected, for example, in thevery low amounts of greenhouse gas emissions generatedby our current operations. As a result of lower emissions anddischarges, we have shifted our environmental focus towardsclosed manufacturing processes, more efficient recycling andwaste treatment.The environmental ‘footprint’ of <strong>Kemira</strong> has diminishedby c. 80% in under ten years, calculated as an environmentalindex. The reduction from the previous year was 20% whilethe net sales of the Group were up by 26%.In <strong>2006</strong>, environmental operating costs totaled EUR 35.4million (33.3 million), up by 6.3% on the year before, andenvironmental capital spending EUR 12.2 million (7.4 million),up by 65% on a year earlier. Capital expenditure of EUR 25.9million on the management and productization of the Poriplant’s by-products will be our largest single environmentalinvestment. Due for completion by the end of 2007, thisproject will end the series of environmental investments ofover EUR 100 million made in the plant.All of <strong>Kemira</strong>’s production sites have been subject to soiland ground water assessments, now covering 96 sites ona global basis, including those received through the latestcompany acquisitions. We have made a provision of EUR 16.8million for future soil remediation measures.2

<strong>Environmental</strong>responsibilityFrom good to great in safetyAs a result of active safety management efforts, the frequency of occupationalaccidents fell to 6.0 (8.4) accidents per million working hours. Although wehave made good progress in occupational safety, there is still much room forimprovement. The ultimate target is clear – zero incidents.As part of the <strong>Kemira</strong> – from Good to Great program, thefinancial year saw the launch of the Safety – from Good toGreat scheme aimed at enhancing the safety culture andoccupational safety. We have also a tighter internal auditscheme running at the same time. The Tiel site in the Netherlandswas named our ‘best improver’ in <strong>2006</strong> – starting froma relatively high level of incidents the plant has been ableto go down to zero within two years. Following the Groupcertification of our activities in Finland in <strong>2006</strong>, the OHSAS18000 safety management system will also become part ofour EHSQ systems in all the business areas.We are committed toPreventing and minimizing anyharmful effects of our operationsContinuously improving ourenvironmental performancePromoting sustainable developmentby making efficient use of energy andnatural resourcesThere were no lethal accidents, or accidents resulting inenvironmental damage. However, a storage fire at a paintmanufacturing plant in Russia and an explosion at one plantunit in Joutseno, Finland, caused substantial property damage.Product safety – responding to REACHThe REACH regulation of the European Union was finalized atthe end of December <strong>2006</strong> and <strong>Kemira</strong> is committed to complyingwith the regulation. Under the guidance of <strong>Kemira</strong>’sReach Competence Center in Finland, <strong>Kemira</strong> has madean inventory of its substances and is preparing for futureregistration. Following recent acquisitions, <strong>Kemira</strong> manufacturesor imports approximately 200 substances which mustbe registered in accordance with REACH within the next11 years. About ten of these substances will be subject toauthorization.The direct cost of REACH compliance on <strong>Kemira</strong> will be inthe order of €30 million during the next ten years. However,this is a very rough estimate since the actual substance levelcosts depend on many factors, and any business acquisitionsor divestments may change the total figure considerably.Although we do not expect material business impacts, amajor workload lies ahead of us, especially within the next3-5 years.<strong>Kemira</strong> began preparatory work on REACH several yearsago, and established a Reach Competence Center (REACH CC)in Finland in <strong>2006</strong> to co-ordinate its efforts. Data collectionwith other EU manufacturers and importers, in the so-calledSIEFs (Substance Information Exchange Forum), will hopefullyrun smoothly and keep to the tight schedules set out by theregulation.3

In addition, preparations were begun for closing on-site pilingareas after 2007, and for moving all landfill activities to Kipsikorpiafterwards. The frequency of lost time accidents wassignificantly lower than in the previous year, and there wereno major accidents.In Oulu, Finland, the outsourcing of energy productionlowered many of the <strong>report</strong>ed environmental figures. The sitealso made improvements in the process safety of gasification,and cut the VOC emissions of hydrogen peroxide plants.The expansion of formic acid production will also enhance theenergy efficiency of the plant. In the Netherlands, the Tiel sitehad zero incidents (see above) and investigated noise reductionand spill control options.In Helsingborg, Sweden, the construction of a new sulphuricacid and liquid sulphur tank farm as well as a new coolingwater system were completed on the site. These projectswere related to the major sulphuric acid tank accident in2005. The off-site <strong>Kemira</strong> landfill at Rökille was outsourced toa regional recycling company, Nordvästra Skånes RenhållningsAB (NSR). NSR will begin preparations for closing the landfillin compliance with EU landfill regulations.<strong>Kemira</strong> CoatingsThe relocation of production and the construction of a stateof-the-artnew paint plant at Nykvarn, Sweden, will furtherreduce environmental risks and releases. A substantial part ofthe acquired production of Kraski Teks on two sites in Russiais solvent-free. The fire that took place in the paint storageof the St. Petersburg site had no environmental impacts, andis under close investigation. The site also improved its washwater treatment. The Debica plant in Poland obtained ISOEHSQ certification in late <strong>2006</strong>, and continued its soil remediationproject. Handling of wood-protection products containingchrome was halted at Pigrol, Germany. The Vantaa site inFinland launched a challenging safety program for reducingoccupational incidents further.6

<strong>Environmental</strong> statistics<strong>Kemira</strong>’s 13th environmental <strong>report</strong> deals with the Groupcompanies in line with financial <strong>report</strong>ing. The <strong>report</strong> hasbeen prepared, where applicable, in accordance with:• The Finnish Accountancy Standards Board’s recommendationon the recognition, measurement and disclosure ofenvironmental issues in the annual accounts and annual<strong>report</strong>s of companies• CEFIC (European Chemical Industry Council): Health, Safetyand Environment Reporting Guidelines, November 1998.Data in this <strong>report</strong> contains information from 84 productionplants worldwide. Six sites were <strong>report</strong>ing for the first time,while seven were either closed or sold. The Group’s productionvolumes and energy use increased slightly from theprevious year.The total environmental index of the Group shows areduction of 20% from the previous year, while revenues increasedby 26%. Long-term development has also been verygood. The changes in <strong>2006</strong> were mainly related to acquisitionsand divestments, but also to the sum of many minor ormedium-scale performance improvements on the sites.The <strong>report</strong>ed carbon dioxide emissions decreased furtherby three quarters due to the divestment of two power plantsin Finland. The remaining emission level is less than one tenthof the levels observed in early 2000. In this case, the changereflects the fact that the business portfolio of the Group hasbeen moved into sectors which do not generate direct CO2emissions.Releases of inorganic gases like sulphur dioxide andnitrogen oxide, as well as dust, decreased substantially forthe reasons explained above. However, the emission ofvolatile organic compounds (VOC) was up by c. 32% due toacquisitions. All <strong>report</strong>ed waste water components showed adownward or flat trend.The generation of non-hazardous waste decreased byclose to 20% from the previous year, mainly as a result of increasedrecycling activities. Hazardous waste generation wasup 23% due to acquisitions in the <strong>Kemira</strong> Coatings businessarea and occasional off-spec items.<strong>Environmental</strong> liabilities and risksThe bulk of <strong>Kemira</strong>’s business is in the chemical industry,whose products and operations are governed by numerousinternational agreements and national legislation all over theworld. The Group treats its environmental liabilities and risksin accordance with IFRS and observes established internalprinciples and procedures.In the context of all of its major mergers and acquisitionsin <strong>2006</strong>, <strong>Kemira</strong> carried out due diligence analyses relatedto the contamination of soil and groundwater caused byprevious operations. Acquisitions and divestments didnot alter the Group’s environmental liabilities significantly.No significant environmental liabilities were connected to thepurchase of the Lanxess Group’s paper chemicals business,announced at the end of 2005, and that of the Kraski Tekspaint business in Russia. <strong>Kemira</strong> conducted detailed assessmentsat the five sites of the water chemicals businessacquired from Cytec Inc., and the seller is responsible forany environmental liabilities which have been found in theseassessments and can be verified.Provisions for environmental remediation totaled EUR 16.8million in <strong>2006</strong>, the largest pertaining to the future rehabilitationof the piling areas connected to the Pori site, the isolationof the sold waste disposal area at the Kokkola site andthe reconditioning of the sediment of a lake adjacent to theVaasa plant.Emissions allowancesUnder the EU Emission Trading System, the Group holds assignedemissions allowances at one site in Sweden. In netvolumes, these allowances at Group level showed a surplusof 5592 carbon dioxide tons in <strong>2006</strong>.7

403020100<strong>Environmental</strong>operating costEUR million97 02 03 04 05 0650EUR million20151050<strong>Environmental</strong>capital spending97 02 03 04 05 0620151050Lost time incidents (LTI)per millionworking hours97 02 03 04 05 06Growth of environmentalbusinessLost time incidents,Tiel site, the NetherlandsHeavy metaldischargesEUR million1,00080060040020097 02 03 04 05 06per millionworking hours432101 02 03 04 05 06tonnes504030201098 02 03 04 05 0600LTA EmployeesLTA Contractors0Hg, Cd, Pb, Cr, As, Cu, Ni, ZnGreenhouse gas emissionsDust emissions at <strong>Kemira</strong>Pigments, Pori, FinlandHazardous wastetreatment1,000 tonnes CO 2 eq.7,0006,0005,0004,0003,0002,0001,000097 02 03 04 05 06CO 2N 2 O as CO 2 eq.tonnes10080604020093 97 03 04 05 0620%31%0.4%1%On-site incinerationOff-site incinerationOff-site landfillingRecyclingOther treatmentOn-site landfilling24%22%1%24%22%31%20%0.4%VOC emissionsper paint literNon-hazardouswaste generation<strong>Environmental</strong> indexand net sales indexg/l1,501 02 03 04 05 061,000 tonnes2,40097 02 03 04 05 0612097 02 03 04 05 061202,0001001001,01,60080801,<strong>2006</strong>0600,5800404040020200,000<strong>Environmental</strong> indexNet sales index08

<strong>Environmental</strong> and safety management systemsat production sites in <strong>2006</strong>Site Environment SafetyKrems, Austria ISO 14001 1)Sao Paolo/Sao Bernardo do Campo, Brazil ISO 14001Telêmaco Borba, Brazil ISO 14001Kolin and Zelivka, Czech Republic ISO 14001Prerov, Czech Republic ISO 14001 OHSAS 18001 2)Esbjerg, Denmark ISO 14001 OHSAS 18001Tallinn Vivacolor, Estonia ISO 14001Harjavalta, Finland ISO 14001 OHSAS 18001Joutseno, Finland ISO 14001 OHSAS 18001Kokkola, Finland ISO 14001 OHSAS 18001Kuusankoski, Finland ISO 14001 OHSAS 18001Oulu, Finland ISO 14001 OHSAS 18001Pori, Finland ISO 14001 OHSAS 18001Siilinjärvi, Finland ISO 14001 OHSAS 18001Vaasa, Finland ISO 14001 OHSAS 18001Vantaa, Finland ISO 14001, EMAS 3)Äetsä, Finland ISO 14001 OHSAS 18001Lauterbourg, France ISO 14001Leverkusen, Germany ISO 14001Rheinberg, Germany ISO 14001Ube city, Japan ISO 14001Ulsan, Korea ISO 14001Rozenburg, The Netherlands ISO 14001Tiel, The Netherlands ISO 14001 OHSAS 18001Fredrikstad, Norway ISO 14001Debica, Poland ISO 14001 OHSAS 18001Police, Poland ISO 14001Swiecie, Poland ISO 14001 OHSAS 18001Wroclav, Poland ISO 14001Estarreja , Portugal ISO 14001Bistrita, Romania ISO 14001Fundulea, Romania ISO 14001Flix, SpainISO 14001, EMASSantander, SpainISO 14001, EMASSevilla, SpainISO 14001, EMASTarragona, SpainISO 14001, EMASHelsingborg, Sweden ISO 14001Kvarntorp, Sweden ISO 14001Stockholm, Sweden ISO 14001Goole, United Kingdom ISO 140011)International Organization for Standardization, <strong>Environmental</strong> management system standard.2)Occupational Health and Safety, management system standard.3)European Union, Eco-Management and Audit Scheme.9

<strong>Environmental</strong> data for the <strong>Kemira</strong> groupReleases into water, tonnes2002 2003 2004 2005 <strong>2006</strong>Chemical Oxygen Demand (COD) 1) 159 173 309 79 29Nitrogen (N) 753 686 542 96 87Phosphorus (P) 16 19 15 7 4Suspended solids, 1,000 tonnes 0.9 1.1 1.3 0.9 0.9Metals (Hg+Cd+Pb+Cr+As+Cu+Ni+Zn) 2.8 3.6 4.0 2.0 2.3Releases into air, tonnesParticulates 850 801 257 128 40Sulphur dioxide (SO 2) 2) 4,580 4,436 4,330 3,036 1,813Nitrogen oxides (NO 2) 3) 3,950 4,038 2,864 1,152 298Carbon dioxide (CO 2), 1,000 tonnes 2,369 2,364 1,828 805 224Volatile organic compounds (VOC) 4) 199 186 136 130 171Volatile inorganic compounds (VIC) 5) 2,581 2,627 1,310 24 23Waste 6) , tonnesHazardous wastes, total 5,858 8,473 10,310 5,290 6,497– Off-site landfill 1,038 1,356 3,621 1,316 2,161– Off-site incineration 3,752 5,390 4,892 1,933 2,332– On-site landfill 29 64 94 35 35– Other treatment 1,040 1,663 1,704 2,006 1,969Non-hazardous wastes, 1,000 tonnes 2,289 2,299 1,903 654 526Natural resourcesFuel consumption, ktoe 7) 523 533 427 292 148Fuel consumption as raw material, ktoe 740 757 560 81 93Purchased electricity, TJ 4,654 4,633 4,137 9,594 10,420Purchased heat, TJ 794 982 907 1,177 6,754Cooling water volume, million m 3 , approx. 336 349 239 202 213Waste water volume, million m 3 , approx. 15 15 13 5.4 5.7SafetyNumber of accidents 8) per million working hours 9.7 7.3 6.7 8.4 6.0Reference data, EUR millionGroup net sales 2,612 2,738 2,533 1,994 2,523<strong>Environmental</strong> capital expenditure 12.3 9.5 10.3 7.4 12.2<strong>Environmental</strong> operating costs 47.3 46.7 40.4 33.3 35.4Total environmental costs, % of net sales 2.3 2.1 2.0 2.0 1.91)Estimate. In this case, partly caused by inorganic discharges.2)All sulphur compounds calculated as SO 2.3)Nitric oxide and nitrogen dioxide calculated as NO 2.4)VOC is a sum of volatile organic compounds.5)Sum of ammonia, hydrogen chloride and six other simple inorganic compounds.6)Reported figures do not include on-site incineration, waste which is further processed into products at the sites,or sold as a co-product to external recycling. Figures are on wet basis.7)1,000 tonnes of oil equivalent.8)Accidents causing an employee absence at least one day (LTA1).10

Assurance statementAt the request of <strong>Kemira</strong> Oyj, we have reviewed the information, systems and methodologiesbehind the data and statements presented in the <strong>Environmental</strong> review of the Annual Report andin the separate <strong>Environmental</strong> Report <strong>2006</strong> of <strong>Kemira</strong> Oyj. The <strong>report</strong> is the responsibility of andhas been approved by the Board of Directors of <strong>Kemira</strong> Oyj. The inherent limitations of completenessand reliability of the data are set out in the <strong>report</strong>. <strong>Kemira</strong> Oyj complies in its environmental<strong>report</strong>ing, where appropriate, with the Finnish Accountancy Standards Board’s recommendation onthe recognition, measurement and disclosure of environmental issues in the annual accounts andannual <strong>report</strong>s of companies (24.10.<strong>2006</strong>) and the CEFIC Health, Safety and <strong>Environmental</strong> ReportingGuidelines).The assurance work was undertaken in accordance with the International Standard on AssuranceEngagements (ISAE) 3000 principles. We planned and carried out our work to provide moderateassurance on the reliability of presented data that was subject to assurance. Our review has consistedof the following procedures:• enquiries of management responsible for compiling the <strong>report</strong>;• an examination of relevant supporting information for data and statements presented;• a review in more detail of the systems for collection and processing environmental data atoperating level at one site in Germany and at one in Spain, selected by us.Based on our activities undertaken, nothing has come to our attention that causes us to believethat the presented data and statements in the <strong>Environmental</strong> review of the Annual Report and inthe <strong>Environmental</strong> Report <strong>2006</strong> of <strong>Kemira</strong> Oyj would not appropriately describe the condition anddevelopment of the issues presented in the <strong>Environmental</strong> Report of <strong>Kemira</strong> Oyj.Helsinki, 6 February 2007KPMG OY ABPekka PajamoAuthorized Public AccountantOlli MiettinenAdvisor, Sustainability Services11