ROTTNE H-14 - dominga.lt

ROTTNE H-14 - dominga.lt

ROTTNE H-14 - dominga.lt

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ROTTNE</strong> H-<strong>14</strong>THE RIGHT CHOICEH-<strong>14</strong>

ECO-FRIENDLY ENGINERottne H-<strong>14</strong> has a powerful 6-cylinder Tier 3 eco-friendlyengine that comfortably fulfils applicable emissionrequirements for current diesel engines.The engine is named Power Tech Plus, and it has,among other things, modern 4-valve technology, avariable turbocharger and a common rail injectionsystem, which provides excellent responsivenesswhen rapid power output is needed.This technology and electronic means of controlenables the power curve and torque to be adapted tothe optimum rpm range for harvesters.The harvester can therefore be operated at a slightlylower working engine speed, resu<strong>lt</strong>ing in a lower noiselevel, less vibrations and, most importantly, lower fuelconsumption.LARGE AND COMFORTABLE CABThe spacious and comfortable cab with its large windows affords the operator an excellent view of theentire working area. The cab is able to swivel 45º, has a levelling function 15º/15º and automaticallyfollows the loader from side to side, but can also be controlledmanually by joystick. The ergonomically-designed operatorstation has well-thought-out instrument panels to the side andin front of the operator’s seat, which has air suspension and isequipped with Airvent.Great overview and vision.The infinitely adjustable armrests feature integrated leverpanels with function keys used regularly during felling andprocessing. The computer screens for the D5 machine controlsystem and the D4 measuring system, which are both colourwith a touch screen function, are positioned low down in frontof the operator so as not to interrupt the field of view.An efficient air conditioning system with ACC ensures that theoperator always has fresh air and a comfortable cab temperature.The cab has a lot of features as standard and there areplenty of boxes and storage compartments for equipment thatneeds to be carried as part of the operator’s day-to-day work.

EASY-TO-DRIVE HARVESTERRottne H-<strong>14</strong> has a 6-wheel, robust chassis with single rear axle andfront portal bogie that ensures excellent ground clearance. With a largesteering angle and the articulated joint in the centre, the harvesteroffers exact tracking, thus minimising the risk of driving damage alongstrip roads in dense thinning areas.The design of the cab combined with its levelling and swivelling capabilitiesgives the operator a fantastic overview around the machine,and if the harvester is equipped with a reversing camera this improvesthe view to the rear. The transmission is rapid and precise with goodtractive force, but also allows gentle precision operation when required.Operation is simple and once driving direction has been selected theaccelerator pedal is used as the drive pedal. When the pedal is presseddown, brakes and articulated frame locks are released automaticallyand the machine starts to move. The speed increases as the pedal isdepressed further and the machine stops when the pedal is released,at which point brakes and articulated frame locks are activated. Steeringis controlled via a joystick on the lever panel in the armrest.EGS 590HARVESTING HEADRottne H-<strong>14</strong> has a head designated EGS 590 as standard, with amaximum cutting diameter of 65 cm. The head has three feed rollers,two of which are located in supporting wheel arms that pushthe stem in towards the frame where the third roller is mounted.Using this principle the stem is held in a steady grip and supportedby the rollers instead of the limbing knives. This allows the knifepressure to be lowered, which reduces friction against the stem andensures better utilisation of the feed force.The upper and lower limbing knives and wheel arms are jointlycontrolled initially, but can also be operated individually. Diametermeasurement is performed via sensors in the lower knives andlength measurement by a separate free-running measuring wheel.Rottne H-<strong>14</strong> can also be equipped with the smaller SP451 LF and EGS402 heads, which are both adapted for the harvester.<strong>ROTTNE</strong> H-<strong>14</strong>WELL DESIGNEDAn intermediate-class harvester frequently switches betweenthinning and final felling and should therefore be designedso that it is suitable for both types of felling. Rottne H-<strong>14</strong> hasthe qualities required to thin from the strip road with a loaderreach of 11-12 metres and a smaller head or to perform finalfelling with a larger head and shorter loader reach.H-<strong>14</strong> has a stable chassis, yet is still flexible and easy todrive. The portal bogie provides extra ground clearance andimproves the harvester’s properties in difficu<strong>lt</strong> terrain. Thepower train has tried and trusted components also found inforwarder models F12 and F<strong>14</strong>.The powerful and fast loader provides good reach and theswivel cab that follows the loader ensures excellent visibilitywhen manoeuvring the head. There are several sizes of headavailable for modifying the harvester for different tasks.

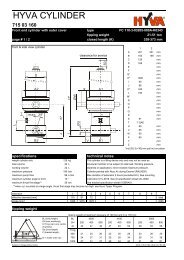

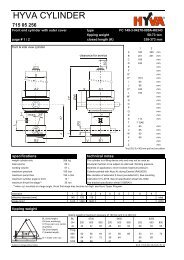

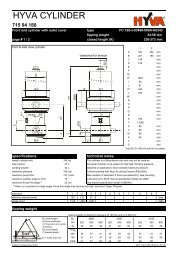

SERVICE ACCESSSpecifications and equipment are subject to a<strong>lt</strong>eration.Images do not always show the machine in its standard design.Serviceability is an importantfactor in development work on allRottne machines. Downtime can proveexpensive for machine owners andgood service access can significantlyreduce the time needed for servicing,repairs and cleaning.Rottne H-<strong>14</strong> is an extremely servicefriendlyharvester. The entire rearsection, housing the engine andtransmission, can be quickly openedup for inspection and servicing.The hinged belly plates underneathfacilitate servicing work, but alsomake the entire rear section veryeasy to keep clean.A vacuum pump for the hydraulicsystem reduces oil spillage whenreplacing hoses, for example, anda pump for hydraulic oil simplifythe oil filling.The main electrical distributionbox with fuses and relays,and the computers, are wellpositioned for easy accesswhen the right-hand cab dooris opened. Troubleshootingon the electrical system canlargely be carried out via themachine control system’soperating screen.TECHNICAL SPECIFICATIONENGINEJOHN DEERE 6068 HF 485, Tier 3Cylinder volume ....................6.8 litres (415 in³)Torque at 1,400 rpm .............1,025 Nm (756 lbf ft)Output at 1,800 rpm .............168 kW (225 hp)Tank capacity...........................460 litres (122 US gal)TRANSMISSIONHydraulic/mechanical with load regulation.Tractive force .................................168 kN (37 800 lbf)BRAKES2-circuit hydraulic wet disc brakes, automaticwork brake. Spring-assisted parking andemergency brake.HYDRAULIC SYSTEMFully independent systems for transmission and working hydraulics.Pump capacity ..............323 litres/1,700 rpm (85 gal)Working pressure...........3.0 – 25.0 MPa (440-3625 psi)ELECTRICAL SYSTEM24-vo<strong>lt</strong> with CAN bus technologyMachine control system Rottne D5Bucking system Rottne D4Work lighting………….………….20 lampsCABTi<strong>lt</strong>ing and swivellingSwivelling angle................................45°Ti<strong>lt</strong>, forwards, backwards, side.....15°, <strong>14</strong>°, 11°Noise level..........................................65 dBALOADERRK <strong>14</strong>0Parallel knuckle boom loader, ti<strong>lt</strong>ing loader baseand 2 m or 3.2 m extension.Ti<strong>lt</strong> angle, loader base....forwards 20°/backwards <strong>14</strong>°Lift torque............................................202 kNm (<strong>14</strong>9 000 lbf ft)Torque / Angle of rotation...............36 kNm/260° (26 550 lbf ft)Reach.....................................................10.3m or 12.0m (33 ft or 39 ft)HARVESTING HEAD EGS 590Feed mechanism 3 feed rollersMax. cutting diameter........600 mm (24 in)Limbing diameter................50-600 mm (2-24 in)Feed force/speed................25 kN / 4.0 m / sec (5620 lbf/13 ft/s)Weight....................................1,100 kg (2425 lb)WEIGHT AND DIMENSIONSService weight......................19 500 – 21 000 kg (42 990-46 300 lb)Width (with 700 wheels)...2,890 mm (1<strong>14</strong> in)EQUIPMENTSprinkler. Engine/cab heater with heating coil for hydraulic tank.Sunvisors. Green oil. Xenon work lighting.Reversing camera. Colour marking. GPS. Geoinfo,Air compressor, Stump treatment.

<strong>ROTTNE</strong> H-<strong>14</strong> - For thinning and final felling

<strong>ROTTNE</strong> H-<strong>14</strong>THE ALLROUND HARVESTERRequirement specifications for the developmentwork on Rottne H-<strong>14</strong> emphasisedthat the harvester should be suitable forboth thinning and final felling and be ableto work with different sizes of head.The hydraulic system, which is loadsensing, has a large pump capacityand return fi<strong>lt</strong>ers submerged in the tank,which reduce the risk of air mixing inthe oil when using biodegradable oil.The a<strong>lt</strong>ernative heads for H-<strong>14</strong> haveidentical connections for both hydraulicsand measuring systems, making it quickand easy to switch heads.Rottne H-<strong>14</strong> therefore has a robust chassiswith a low centre of gravity. To ensuregood stability when felling on downhillslopes, the wheel base is adapted so thatthe rear provides a good counterweight.The loader, RK <strong>14</strong>0, is located directlyabove the portal bogie and features a ti<strong>lt</strong>function with ample forward/backwarddeflection.The reach for a standard machine is 10metres, but a different extension boom isavailable as an option, enabling reachesof 10 to 12 metres depending on the sizeof head being used.<strong>ROTTNE</strong> H-<strong>14</strong>

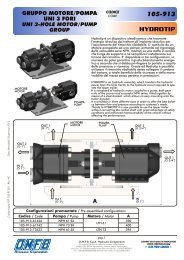

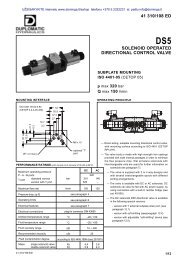

710/45x26,5<strong>ROTTNE</strong> D5 MACHINE CONTROL SYSTEMThe Rottne D5 machine control system, which is based on CAN bus technology, controls and monitors the engine,transmission and loader. D5 comprises a main computer, a 7” colour touch screen and a number of control unitsplaced out on the machine close to the functions to be controlled. The main computer communicates by means of aCAN bus cable linked to all the control units. The operator can adjust settings for the loader, transmission and engine,monitor pressure, temperatures and fluid levels and perform troubleshooting using the display (touch screen) onan adjustable arm slightly forward of the operator’s position. Alarms are indicated by visual and audible signals andare displayed in clear text on the display.<strong>ROTTNE</strong> D4 BUCKING SYSTEMRottne D4 is a well-tested and reliable bucking system consisting of various computer-based units, which areinterconnected via a CAN bus. The cab features a large, clear touch screen and a keyboard in front of the operator,as well as a printer integrated into the ceiling panel. The screen displays length and diameter as well asother information on the tree currently being processed in the head. The touch screen also enables settings tobe made and modified easily as well as generation of production reports, etc.Otherwise, data entry and price list changes are made using the keyboard. Communication is via USBmemory, e-mail or printer. Bucking is optimised with value or distribution bucking, but, as an a<strong>lt</strong>ernative,there is also a simpler program for priority bucking. Control and calculation computers as well as IO boxesand sensors are located on the head, and signal transfer to the cab is via CAN bus. The controlling of thehead and the processing are performed using keypads on the loader levers, located in lever panels onthe seat’s armrests. The operator can check and adjust settings for pressure, times and other functionson the head from the touch screen in the cab. A GPS receiver and map software as well as systems foroperations follow-up are available for D4.<strong>ROTTNE</strong> RK <strong>14</strong>0<strong>ROTTNE</strong>710/55x34710/45x26,521"525118"3000<strong>14</strong>4"min 3650157"4000307"7800472"12000<strong>14</strong>2"360059"1500 85"85"215021500165"4200InchmmRitn. nr. 32246

Rottne Industri ABwww.rottne.com