ROTTNE H-20 - dominga.lt

ROTTNE H-20 - dominga.lt

ROTTNE H-20 - dominga.lt

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ECO-FRIENDLEY ENGINERottne H-<strong>20</strong> has a powerful 6-cylinder Tier 3 ecofriendlyengine that comfortably fulfils applicableemission requirements for current diesel engines.The engine is named Power Tech Plus, and it has,among other things, modern 4-valve technology, avariable turbocharger and a common rail injectionsystem, which provides excellent responsivenesswhen rapid power output is needed. This technologyand electronic means of control enables the powercurve and torque to be adapted to the optimum rpmrange for harvesters. The harvester can therefore beoperated at a slightly lower working engine speed,resu<strong>lt</strong>ing in a lower noise level, less vibrations and,most importantly, lower fuel consumption.Bui<strong>lt</strong> for tough final fellingLARGE AND COMFORTABLE CABThe spacious and comfortable cab with its large windows affords the operator an excellent view of the entireworking area. The cab is able to swivel 45º, has a levelling function 15º/15º and automatically follows the loaderfrom side to side, but can also be controlled manually by joystick.The ergonomically-designed operator station haswell-thought-out instrument panels to the side and infront of the operator’s seat, which has air suspensionand is equipped with Airvent. The infinitely adjustablearmrests feature integrated lever panels with functionkeys used regularly during felling and processing.Large windows with ti<strong>lt</strong>ing and swivelling cab provides good visibility of the work area.The computer screens for the D5 machine controlsystem and the D4 measuring system, which are bothcolour with a touch screen function, are positioned lowdown in front of the operator so as not to interrupt thefield of view. An efficient air conditioning system withACC ensures that the operator always has fresh air anda comfortable cab temperature. The cab has a lot offeatures as standard and there are plenty of boxes andstorage compartments for equipment that needs to becarried as part of the operator’s day-to-day work.

TRIED AND TRUSTED HARVESTERRottne H-<strong>20</strong>, which has been on the market for several years, has proven itself to be a highly efficient harvester in large sized forest.Operational reliability, high productivity and low operating costs are characteristic of this large harvester, which has become verypopular. The 6-wheel robust chassis with front bogie and singlerear axle has large, wide wheels, a very low centre of gravity and thus excellentstability even when working on downhill slopes. The strong articulated joint with integratedarticulated frame lock has large steering angles, making the harvester flexibledespite its size. The design of the cab combined with its levelling andswivelling capabilities gives the operator a fantastic overview aroundthe machine, and if the harvester is equipped with a reversing camerathis improves the view to the rear.The transmission is rapid and precise with good tractive force, but also allowsgentle precision operation when required.Operation is simple and once drivingdirection has been selected the accelerator pedal is used as the drive pedal.When the pedal is pressed down, brakes and articulated frame locks areEGS 700released automatically and the machine starts to move. The speed increasesas the pedal is depressed further and the machine stops when the pedal is released,at which point brakes and articulated frame locks are activated. Steering is controlled via a joystick on the lever panel in the armrest.HARVESTING HEADStandard models of Rottne H-<strong>20</strong> have a head designated EGS 700 and acutting diameter of 75 cm. The head has five feed rollers, two of which arelocated in supporting wheel arms that push the stem in towards the framewhere the other three rollers are mounted. Using this principle the stemis held in a steady grip and supported by the rollers instead of the limbingknives. This allows the knife pressure to be lowered, which reduces frictionagainst the stem and ensures better utilisation of the feed force.The upper and lower limbing knives and wheel arms are jointly controlledinitially, but can also be operated individually. Diameter measurement isperformed via sensors in the lower knives and length measurement by aseparate free-running measuring wheel. Rottne H-<strong>20</strong> can also be equippedwith the slightly smaller EGS 590 head, which is bui<strong>lt</strong> along the same linesbut has three feed rollers and a cutting diameter of 65 cm.<strong>ROTTNE</strong> H-<strong>20</strong>WELL DESIGNEDA stable harvester with significant power resources and an appropriately-dimensionedhead is required to handle heavy final felling.The objective when developing Rottne H-<strong>20</strong> was to design a harvesterwith the properties required of an efficient large harvesteroperating in heavy forest. The chassis as well as the loader and headare designed to cope with this demanding work month after monthwhile yielding the same good level of profitability.The vital components in Rottne H-<strong>20</strong> have been selected with greatcare right from the start, and this is the reason why this harvesterhas an excellent track record when it comes toreliability and low operating costs.The H-<strong>20</strong> concept is also characterised by its swivelling andlevelling cab offering fantastic visibility and superb operator comfortas well as great ease of access for servicing and maintenance.

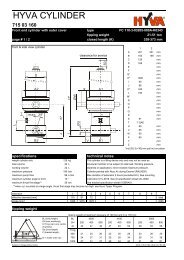

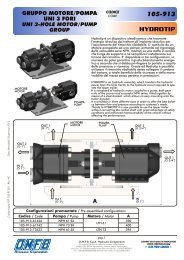

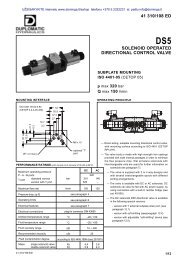

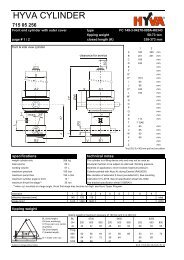

SERVICE ACCESSServiceability is an important factor in development work on all Rottne machines. Downtime can prove expensive formachine owners and good service access can significantly reduce the time needed for servicing, repairs and cleaning.Rottne H-<strong>20</strong> is a very service-friendly harvester. The entire rear section, housing the engine and transmission, can bequickly opened up for inspection and servicing.The hinged belly plates on the underside facilitate servicing work, but also make the entire rear section very easy to keepclean. A vacuum pump for the hydraulic system reduces oil spillage when replacing hoses, for example, and a pump forhydraulic oil simplify the oil filling. The distribution box with fuses and relays, and the computers, are well positioned foreasy access when the right-hand cab door is opened. Troubleshooting on the electrical system can largely be carried outvia the machine control system’s operating screen.TECHNICAL SPECIFICATIONENGINEJOHN DEERE 6090 HF 485, Tier 3Cylinder volume....................9.0 litres (549 in³)Torque at 1,500 rpm............1,095 Nm (808 lbf ft)Output at 1,800 rpm............187 kW (250 hp)Tank capacity........................490 litres (130 US gal)TRANSMISSIONHydraulic/mechanical with load regulationTractive force.........................180 kN (40 465 lbf)BRAKES2-circuit hydraulic wet disc brakes, automatic work brakeSpring-assisted parking and emergency brake.HYDRAULIC SYSTEMFully independent systems for transmission and workinghydraulics.Pump capacity…………………357 litres/1,700 rpm (94 gal)Working pressure..................3.0-25.0 MPa (440-3625 psi)ELECTRICAL SYSTEM24-vo<strong>lt</strong> with CAN bus technologyMachine control system...................Rottne D5Bucking system..................................Rottne D4Work lighting.......................................<strong>20</strong> pcsCABTi<strong>lt</strong>ing and swivellingSwivels.............................................................+/- 45°Ti<strong>lt</strong>ing, forwards, backwards, side……….15°, 14°, +/- 11°Noise level.......................................................65 dBALOADERRK <strong>20</strong>0Parallel knuckle boom loader, ti<strong>lt</strong>ing loader baseand 1.4 m extension.Ti<strong>lt</strong> angle, loader base............+/- 15°Lifting torque............................254 kNm (187 300 lbf ft)Torque / Angle of rotation....40 kNm / 240° (29 500 lbf ft)Reach...........................................10 m (33 ft)HEADEGS 700Feed mechanism.............5 feed rollersMax. cutting diameter....750 mm (30 in)Limbing diameter............50-700 mm (2-28 in)Feed force / speed..........27 kN / 4.0 m/sec (6050 lbf/12 ft/s)WEIGHT AND DIMENSIONSWeight.…………. 23,000 kg (50 700 lb)Width...……………3,000 mm (118 in)EQUIPMENTSprinkler. Engine and cab heater with heating coil forhydraulic tank. Sunvisors. Green oil. Xenon work lighting.Reversing camera. Colour marking. GPS, Geoinfo,Air compressor.Specifications and equipment are subject to a<strong>lt</strong>eration.Images do not always show the machine in its standard design.

<strong>ROTTNE</strong> H-<strong>20</strong> our strong final felling harvester with low operating costs.

<strong>ROTTNE</strong> H-<strong>20</strong>AWINNINGCONCEPTRottne H-<strong>20</strong> is a very competitive harvester,bui<strong>lt</strong> for demanding final felling andheavy forests, with a top-class operatorenvironment.The extremely powerful loader, RK <strong>20</strong>0,has a ti<strong>lt</strong>ing loader base and a reach of10 metres.It is located directly above the bogie togive the harvester optimum stability, whichis necessary to enable the large EGS 700head to be used at full reach.No matter what the rpm range, the largecylinder volume of this powerful dieselengine always ensures high torque, whichmeans the engine can handle jobs at arelatively low working engine speed.The hydrostatic transmission works smoothlyand dynamically with the Rottne D5machine control system.The hydraulic system, which is loadsensing, has a large pump capacity andreturn fi<strong>lt</strong>ers submerged in the tank,which reduce the risk of air mixing in theoil when using biodegradable oil.<strong>ROTTNE</strong> H-<strong>20</strong>

Rottne Industri ABwww.rottne.com