DLC 2100 & DLC 3200 Flying paster/splicer DLC ... - Megtec Systems

DLC 2100 & DLC 3200 Flying paster/splicer DLC ... - Megtec Systems

DLC 2100 & DLC 3200 Flying paster/splicer DLC ... - Megtec Systems

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

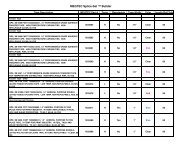

<strong>DLC</strong> <strong>2100</strong> & <strong>DLC</strong> <strong>3200</strong><strong>Flying</strong> <strong>paster</strong>/<strong>splicer</strong><strong>DLC</strong> <strong>2100</strong> & <strong>DLC</strong> <strong>3200</strong><strong>Flying</strong> <strong>paster</strong>/<strong>splicer</strong>AMERICASUnited StatesMEGTEC <strong>Systems</strong>, Inc.Telephone: +1-920-336-5715Toll-free: +1-800-558-2884Solvent Recovery DivisionMEGTEC <strong>Systems</strong>, Inc.Telephone: +1-772-567-1320BrazilMEGTEC <strong>Systems</strong>, Inc.Telephone: +55-19-3885-6116EUROPEFranceMEGTEC <strong>Systems</strong> SASTelephone: +33-1-69-89-47-93United KingdomMEGTEC <strong>Systems</strong>, Ltd.Telephone: +44-1628-59-1700MEGTEC Environmental Ltd.Telephone: +44-1257-42-7070GermanyMTS Environmental GmbHTelephone: +49-6181-94040SwedenMEGTEC <strong>Systems</strong> ABTelephone: +46-31-65-7800MEGTEC <strong>Systems</strong> Amal ABTelephone: +46-532-62900Standard Equipment & Features<strong>DLC</strong> <strong>2100</strong> <strong>DLC</strong> <strong>3200</strong>Std Auto Roll<strong>Flying</strong> <strong>paster</strong> with 2 arms Split arm Core acceleration and braking by 4 quadrant AC motors Control and regulation by PLC Splice pattern straight, V or W Black pasting tabs with photo cell detection Local push-button panel and WEBVIEWSimultaneous cut & paste under tension Motorised chuck insertion with torque assisted expansion Simple roll loading directly from fl oor into armsArm motorized positioningArm automatic positioning Automatic roll alignment before splicing Normal and Symmetric arrangement for centre loading MEGTEC webbing-up system or preparation for OEM’swebbing-up (drillings only)Manual cocking roller adjustment to assist running deformed rollsIndependent frames Fully assembled, pre-wired, pre-piped and tested for easy installationCabinets & doors painted in press colour MEGTEC motorized web-up deviceHigh Performance Paper Handling Systemfor Commercial, Directory and Newspaper printingASIA - PACIFICSingaporeSingapore Sales Branch -MEGTEC <strong>Systems</strong> SASTelephone: +65-6298-4666ChinaMEGTEC <strong>Systems</strong> (Shanghai) Ltd.Telephone: +86-21-6769-7878IndiaMEGTEC <strong>Systems</strong> India Pvt. Ltd.Telephone: +91-20-3026-9600JapanMEGTEC <strong>Systems</strong>, Inc.Telephone: +81-78-783-0161Versions at additional costSplit arms3 arms (with auto loading pre-positioning only) Load bearing frames (100 tonnes) Remote control panel for sidelay, web tension and brakes MEGTEC motorized web-up device option WEBCOM (WEBVIEW + interface for press communication) Integrated DSA Infeed Automatic roll alignment before splicing Automatic roll alignment before splicing and chuck web steeringROLLOAD Paper Handling System QUALIROLL Paper Management System AustraliaMEGTEC <strong>Systems</strong> Australia, Inc.Telephone: +61-3-9574-7450www.megtec.comAvril 2008 - 00Operating specifications<strong>DLC</strong> <strong>2100</strong> <strong>DLC</strong> <strong>3200</strong>Maximum roll weight <strong>2100</strong> daN (4600 lbs) <strong>3200</strong> daN (7000 lbs)Maximum running & splicing speed 17 m/s (3350 fpm) 17 m/s (3350 fpm)Minimum splicing speed 0,83 m/s (165 fpm) 0,83 m/s (165 fpm)Sidelay adjustment ± 20 mm (7/8 inch) ± 20 mm (7/8 inch)Maximum roll Ø 1300 mm (51 ") 1300 mm (51 ")Minimum roll Ø for splicing 500 mm (20 ") 500 mm (20 ")Minimum roll width for splice 250 mm (10 inches) 250 mm (10 inches)Roll core inner Ø 76 mm (3 ") 76 mm (3 ")Standard tension range 5-30 daN (11-66 lbs) 5-30 daN (11-66 lbs)Option web tension range : Integrated infeed 120 daN/m (260 lbs)180 daN/m (400 lbs)180 daN/m (400 lbs)210 daN/m (400 lbs)E-stop rate 100 m/mn/s 100 m/mn/SPaper weight range 37-150 gsm 37-150 gsmWeb width 1020-1370-1530-1700mm (40-54-60-67 ")1530-1700-2080 mm(60-67-82 ")This document is not contractual © MEGTEC <strong>Systems</strong>The <strong>DLC</strong> sets the industry performance standards. In 1991 it established the 15 m/s (3000 fpm)pasting specifi cation and in 2000 it extended this to 17 m/s (3350 fpm). In addition the maximumroll weight capacity has been increased to 2,1 tonnes (4720 lbs) for the <strong>DLC</strong> 100 and to 3,2 tonnes(7046 lbs) for the <strong>DLC</strong> <strong>3200</strong>.The bottom line is process knowledge

<strong>DLC</strong> <strong>2100</strong> & <strong>DLC</strong> <strong>3200</strong><strong>Flying</strong> <strong>paster</strong>/<strong>splicer</strong>Acceleration torque4Rewinding1Unwinding32Braking torque<strong>DLC</strong> <strong>2100</strong> Splicer <strong>DLC</strong> <strong>3200</strong> Splicer Split arms are standard equipment to speedup make ready by simultaneously loadingdifferent roll widths on the <strong>DLC</strong> <strong>2100</strong>.Combined core drive and braking used orboth unwinding and rewinding.The touch screen control provides theoperator with easy control and rapid accessto information.Operator displayPerformance benefits••••••••••••Reduced paper waste and highpress availabilityExtremely rapid web tensioncontrol reduces wasteVirtual elimination of <strong>paster</strong>caused web breaksVery low web up tension avoidsweb breaksBetter handling of damaged andout of round rollsFlexibility to splice small rolldiametersSimple splice preparationShort web leadsFast make readyLow maintenanceAutomation levels up to “100% nooperator presence” roll changingSplit arm optionCommercial and directory<strong>DLC</strong> <strong>2100</strong>’s specifi cations meet theneeds for high performance tensioncontrol, reliability and ease of use. Splitarms are standard to reduce makeready times; simple splice preparationand numerous automated features furtherreduce make ready time.The <strong>DLC</strong> <strong>3200</strong> has been specifi cally developedfor complete performance compatibilitywith high volume, ultra widecommercial printing for web widths of1530-2080 mm.NewspapersThe <strong>DLC</strong> <strong>2100</strong>/<strong>3200</strong> is the high performance<strong>paster</strong> for double-width newspapers.Full colour printing quality withreduced waste can be aided by theintegration of a compact infeed andchuck web steering option. The <strong>paster</strong>is available with 2 or 3 arms, split arms,independent or load bearing frames,Normal and Symmetric arrangement forcentre loading.Complete design reviewThe design and manufacturing reviewshave taken advantage of fi eld operatingexperience and the availability of newtechnologies to ensure excellence inevery detail. Some of the improvementsinclude:••••••Long life and more effi cient chucksFaster accelerationMore accurate tension controlLow web-up tension 3 daN ± 1 daN(6.74 ± 2.25")High vibration resistanceReduced maintenanceAn extremely high level of automationis now included as standard equipmentconsistent with ultra high productivityprinting plants.Optimum tension controlThe new AC motors with vectorial fl owcontrol are a highly responsive driveand braking system which provides tensioncontrol up to 10 times faster thanconventional systems. This provides amore constant web tension irrespectiveof variations of press speed. Butt rewindingis another function.Stable web tension is assured from thepneumatic dancer roller assembly withpotentiometer measurement. Tensionis managed by the PLC which controlsthe four quadrant motors to constantlymaintain the dancer in balance. Tensionperformance is further improved by theshort web leads of the <strong>DLC</strong>.Core braking replaces conventionalpneumatic disc brakes. Additional benefits are reduced maintenance and noiselevel. Separate electric brakes preventroll rotation during splice preparationand if required supply additional torqueduring an emergency stop.Roll acceleration from the core improvescontrol and eliminates contact with thepaper surface. It gives better handlingof damaged and out of round rolls andsimplifi es splice preparation.Easy roll loadingThe <strong>DLC</strong> <strong>paster</strong>s work with many differentconfi gurations of rolload systems,from manual to fully automatic.Fully automatic chucks improve operatingeffi ciency and safety. Loading iscontrolled by a push button for chuckengagement with automatic tighteningat the end of insertion. The chucks arepositively locked into the core and do nothave to be re-tightened during running— even after an emergency stop. As anadded safety feature, the lock will not releaseeven if electricity and compressedair supply is interrupted.The optional ROLLOAD® automatedhandling system allows up to “100% nooperator presence” roll changing. Thebenefi ts of operation include reducedpaper waste, higher effi ciency and enhancedsafety.PastingThe gapless splice pattern is simple toprepare. It can be either straight, V orW. The detection system uses a photocell with black biodegradable tabs. Pasteand cut are made simultaneously undertension with a constant short tail lengthto minimise potential folder jams.Control systemThe pasting cycle, tension and runningoperations are automatically managedby a PLC. Operating status and faultfi nding diagnosis are displayed on thesupervision screen. Like all MEGTECWebline products the <strong>paster</strong> can be integratedwith the press control system.A paper management data system isalso available.Roll alignmentAccurate pre splice alignment of the incomingroll to the running web is essentialto eliminate overlapped edges whichcan be a major cause of web breaks.On the <strong>DLC</strong> <strong>2100</strong>, motorised individualroll alignment is standard equipment,a completely automatic version is alsoavailable.On the <strong>DLC</strong> <strong>3200</strong>, automatic individualroll alignment is standard equipment.Infeed versionsTension control begins at the <strong>paster</strong>.MEGTEC’s <strong>paster</strong>s and DSA infeedscan be controlled in tandem for optimumperformance. This allows the <strong>paster</strong> tooperate at a low tension to limit tensionvariations to be processed by the infeed.The DSA’s extremely stable tension of± 0,5 daN (1,1 lbs) is made possible bythe use of high dynamic servo regulationwith low inertia mechanical elements,twin dancer rollers and a nipping roller.Integrated or independent DSA shaftlessinfeeds provide fast and accuratetension control from 5 daN (11 lbs) upto 210 daN (460 lbs) with optional webguides.Web guidesHigh precision web guides, integratedin the web lead in a compact way areavailable (optionally integrated in independentinfeeds) and can be connectedwith the <strong>paster</strong>’s sidelay to provide webpre-alignment. This also eliminates anycounter correction between sidelay andthe web guide.Split Arm DesignErgonomic correctness and user friendlinesshave been two of the most importantconsiderations in the design of the<strong>2100</strong>. The machine roll width is adjustedto the printing width of the press and variationsof up to 2000 mm are possible.Two motorized roll holders are placed oneach side of the roll arm. These can bemoved sideways by linear control independentlyof the other roll position. Thispermits the loading of two rolls of differentwidths in the machine. In turn, thisfacilitates very simple and rapid splicingto other roll widths without fi rst having totake out both rolls and then re-adjustingthe position of the roll arm.This split arm version is also availableas an option on the <strong>DLC</strong> <strong>3200</strong>.