AR70A Flying Paster/Splicer

AR70A Flying Paster/Splicer

AR70A Flying Paster/Splicer

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>AR70A</strong><strong>Flying</strong> <strong>Paster</strong>/<strong>Splicer</strong>Proven Performance & High Productivity for NewspaperSemi-Commercial & Commercial PrintingThe <strong>AR70A</strong> continues the success story of the AMAL AR60 and AR70 proven in hundreds of installations.Consequently, the advantages of these models have been combined into the new model <strong>AR70A</strong>.Manufactured with the latest production methods, the <strong>AR70A</strong> delivers highest perfomance at an attractiveprice.The bottom line is process knowledge

Splicing : The new roll runs at synchronousspeed. When the pre-set splicing diameteris reached, a splice roller presses the webstogether. The cutting knife severs the old webLoading of rolls of different web width duringrun is possibleOperator displayPLC ControlThe pasting cycle and running operationsare automatically managed by a PLC. Likeall MEGTEC Webline products, the pastercan be integrated with the press controlsystem. The integration of the paster intothe web-up system is available for manypress types.Operator InterfaceThe operator panel features a touchscreen control for paster setting with adisplay screen for status, fault history,service diagnosis and help screens. Keyfunctional hard buttons are available inthe machine side frame.Stable TensionStable web tension with minimum variationis assured from the pneumaticdancer roller assembly with potentiometermeasurement. Tension is managed by acontroller which regulates the core brakesto keep the dancer constantly in balance.Core braking provides fast and stabletension control with minimum variation toimprove productivity by reducing paperwaste. The pneumatic brakes on each armensure optimum operation and requirelow maintenance. Tension performance isfurther improved by the short web leadsof the <strong>AR70A</strong>.Easy Roll LoadingThe loading of the pasters by lightweightshafts is very easy. When changing toanother production run, a roll of adifferent width can be loaded whilerunning the press. Roll loading is directlyfrom the floor into the arms, no hoist isrequired. The low minimum roll diameterfor splicing of 275 inches (700 mm) allowssignificant flexibility for running part rollswithout re-winding or special handling.Normal and symmetric configurations areavailable for dual web center loading.Illustration HereThe optional ROLLOAD® handlingsystem enables i.e. roll preparation at acentral unwrapping station. Roll data canbe registered and processed. The benefitsof operation include reduced paper waste,higher efficiency and enhanced safety.Reel ShaftsFor over 40 years MEGTEC has usedpneumatic reel shafts for variousapplications. Continuous developmentand experience result in the design andthe quality. The reel shafts of the <strong>AR70A</strong>have been optimized specially for lowweight and long life. An aluminium type37.4 lbs (17 kg) and optional combinedcarbon-fiber/aluminium type 28.6 lbs (13kg) are available.Optional InfeedTension control begins at the paster.MEGTEC pasters and infeeds canbe controlled in tandem for optimumperformance. This allows the paster tooperate at a low tension to limit tensionvariations to the infeed (which alsoreduces brake maintenance). Infeedsprovide more stable web tensions thantraditional designs. Their extremely stabletension is made possible by the use ofhigh dynamic servo regulation with lowinertia mechanical elements, a load celland nipping roller.Shaftless infeeds provide fast andaccurate tension control. Two versions areavailable:• Integrated version can reduce overallpress length by up to 6.5 ft (2m)• Independent units with optional webguides

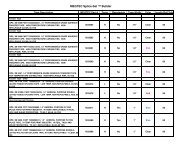

<strong>AR70A</strong><strong>Flying</strong> <strong>Paster</strong>/<strong>Splicer</strong>AMERICASUnited StatesMEGTEC Systems, Inc.Telephone: +1-920-336-5715Toll-free: +1-800-558-2884Solvent Recovery DivisionMEGTEC Systems, Inc.Telephone: +1-772-567-1320BrazilMEGTEC Systems, Inc.Telephone: +55-19-3885-6116EUROPEFranceMEGTEC Systems SASTelephone: +33-1-69-89-4793United KingdomMEGTEC Systems, Ltd.Telephone: +44-1628-59-1700MEGTEC Environmental Ltd.Telephone: +44-1257-42-7070GermanySequa GmbH & Co.MEGTEC Systems KGTelephone: +49-6181-94040SwedenMEGTEC Systems ABTelephone: +46-31-65-7800MEGTEC Systems Amal ABTelephone: +46-532-62900ASIA-PACIFICSingaporeSingapore Sales Branch -MEGTEC Systems SASTelephone: +65-6298-4666ChinaMEGTEC Systems (Shanghai) Ltd.Telephone: +86-21-6769-7878IndiaMEGTEC Systems India Pvt. LtdTelephone: +91-20-3231-2877 (78)JapanMEGTEC Systems, Inc.Telephone: +81-78-783-0161AustraliaMEGTEC Systems Australia, Inc.Telephone: +61-3-9574-7450www.megtec.comJanuary 2008Standard <strong>AR70A</strong> Model Features••••••••••••••2 arm flying pasterRoll-loading by shaftsBrake controller with pneumatic dancer armPneumatic brakes on each arm with web tension control from roll coreCore acceleration of the new roll<strong>Splicer</strong> carriage with pneumatic activated knife and rollerSimultaneous cut & paste under tensionRoll loading directly from floor into armsLoading and unloading on same sideDrillings for MEGTEC standard web-up systemControl and regulation by PLCRemote control of sidelay, web tension and brakesIndependent frames (non-load bearing)Fully assembled, pre-wired, pre-piped and tested for easy installationVersions at Additional Cost•••••••••Normal and symmetric configurations for center loadingIntegrated infeedIndependent DSA 130 or 180 infeed with web guidesMEGTEC motorized web-up deviceLightweight roll shaft in aluminum/carbon-fiber 28.6 lbs (13 kg)ROLLOAD® manual roll handling systemCommunication with press90° installationDouble unwindOperating SpecificationsSpeed m/s 6.7 8.3 10.0 10.0 12.2 12.2fpm 1320 1630 1970 1970 2400 2400Roll weight kg 850 1000 1000 1350 1000 1350lbs 1870 2200 2200 3000 2200 3000Maximum running & splicing speed 6.7-12.2 m/s 1320-2400 fpmMaximum web width 1020 mm 40 inchesMaximum roll diameter 1270 mm 50 inchesRoll core inner diameter 76 mm 3 inchesMaximum roll weight 850-1350 daN 1850-2900 lbsStandard tension range-1000Kg 80-350 daN 18-80 lbsSidelay adjustment