Z-1500 Zero Speed Splicers - Megtec

Z-1500 Zero Speed Splicers - Megtec

Z-1500 Zero Speed Splicers - Megtec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Z-<strong>1500</strong><strong>Zero</strong> <strong>Speed</strong> <strong>Splicers</strong>Z-<strong>1500</strong> Z-<strong>1500</strong> with center loadingEasy roll handling with roll cart to integrate withfully motorized hoist combined with shaft armPerformance Benefits• Virtual elimination of splicercausedweb breaks• Rapid and stable web tensioncontrol (core braking)• Reduced paper waste and highpress availability• Simultaneous loading of differentroll widths• No minimum roll size for loadingand splicing• Simple splice preparation• Overlapped splice with securedtail for sensitive productions• Deformed rolls can be splicedwith higher reliability• Simple operation and lowmaintenance• Simple hoist loading• Nested festoon with low friction,low inertia dancer rollers• Air expanding roll shaft• Dual disc pnuematic brakes• Reliable rolling nip splice headSimple & Reliable SolutionsFunctional performance is assured byusing the simplest and most reliablesolutions. Roll support uses air shaftsto allow different roll widths to be loadedsimultaneously to speed-up make ready.The Z-<strong>1500</strong> is a true flat floor installationwith an integrated electric hoist whichcan also provide roll weighing.The vertical nested festoon design isthe industry performance reference.It is a model of simplicity with very fewparts and easy to access. The splicehead, braking and acceleration systemcombine the same attributes to providereliable performance, fewer componentsand reduces maintenance costs. Ease ofuse and ergonomic efficiency are integralfeatures to help attain high productivityand safety.The performance and reliability ofMEGTEC zero speed splicers are basedon technology developed during 35years of experience from over 15,000installations. The Z-<strong>1500</strong> models combineproven productivity, rugged constructionwith extremely good value for a lifetimeof reliability.Configuration ChoiceThe Z-<strong>1500</strong> is available in several configurationsto ideally suit varying needs:• Vertical Roll-over-Roll model providesa compact solution for single webs.• Center loading Roll-over-Roll providesthe most efficient and compact zerospeed configuration available for 2-webapplications.• The innovative horizontal Roll-beside-Roll model provides easy loading forsingle web presses but retains thepositive attributes of a vertical festoon.Exemplary Splicing<strong>Zero</strong> speed splicing provides 99% orhigher splice reliability.The rolling nip splice head combinesease of use with high reliability on alltypes and weights of paper. The vacuumsplice preparation bar eliminates therisk of cutting into the nip roller and thepneumatic nip lock allows the operator toposition the splice more precisely to allowreduced tail length.There is a choice of either standardoverlapped splice with short tail, or anoverlap with a secured tail for sensitivesheeter and folder production. Nominimum roll diameter for loading andsplicing provides complete flexibility torun part rolls without special handling orre-winding.The Ultimate FestoonMEGTEC’s vertical nested festoondesign is the most reliable and efficientavailable.The air loaded operation is simpler, withless maintenance and easier operationthan those with motors, clutch drives orcounter weights. It is equipped for easyweb-upand in the event of a web breakthere is good access to remove paper fromthe festoon. Web tension is particularly

Effortless shaft arm handling option liftsbutt rolls and shafts up to 200 lbs (90 daN)to eliminate physical effort and risk of shaftdamageRoll shaft cart is a simple and inexpensivesolution for shaft and butt roll handlingstable due to the minimal friction andinertia of the festoon rollers, which aremaintained at a low position duringnormal running to decrease paper lengthand tension oscillations in the festoonwrinkles. Festoon rollers are available ineither uniform or tapered profiles to selfcenterthe web.Easy Roll LoadingThe splicer holds two full size rolls on airshafts which reduce make-ready time byallowing different roll widths to be loadedsimultaneously (shafts are equipped withindicators to easily position rolls laterally).The air shafts are automatically coupledand centered with the motorized sidelay(a range of shaft handling options areavailable to provide ergonomic operationand eliminate shaft damage).An integrated electric hoist directly loadsrolls to both positions and its safetyfeatures include positive locking and hoisthook deflectors (to lock out hoist accesswhen the shaft is coupled). Removing aheavy unfinished roll is easily performedby the hoist.Tension & ControlStable web tension with minimum variationis assured from the vertical nested festoonwith dancer air regulation, dancer downrunning and core brakes controlled by aProgrammable Logic Controller (PLC), anoperator interface panel. Pneumatic dualdisc high torque brakes ensure optimumoperation and low maintenance; they areventilated and mounted on the splicerin-line with each roll shaft for maximumefficiency. Acceleration is assured byhighly reliable pull rollers. The PLCcontrols the splice cycle operation andcontinuously monitors the roll to maintainoptimum web tension and brake setting.Illustration HereHigh ReliabilityThe extremely solid manufacture andsimple mechanical layout featuresa minimum number of motors and long lifeparts. Most components are grouped onthe operator side for easy access.The design minimizes both maintenanceand adjustments to almost eliminatedown-time.Ergonomic EfficiencyThe Z-<strong>1500</strong> provides plenty of room for theoperator to work comfortably and thereforeefficiently and safely. Roll loading, splicepreparation and maintenance are alloperator friendly. The electric hoist andtraverse provide easy loading and anoptional shaft handler eliminates allphysical effort. Motorized sidelay, shaftcoupling and uncoupling eliminate othermanual tasks.Flexibility• Rolls can be unwound in bothdirections• Different roll widths can be loadedsimultaneously• No minimum roll size for loading andsplicing• Choice of overlapped splice with tail, oroverlapped splice with secured tail• Splices papers from bible stock toheavy weight coated• Deformed rolls can be spliced withhigher reliability• Flat floor installation without pit<strong>Splicers</strong> can be installed inline or at rightangles. Rolls can be loaded from one sideso the splicer can be installed againsta wall. The Z-<strong>1500</strong> model providesergonomic roll loading for single websand compact center loading for 2-webapplications.

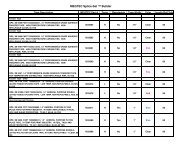

Z-<strong>1500</strong><strong>Zero</strong> <strong>Speed</strong> <strong>Splicers</strong>AMERICASUnited StatesMEGTEC Systems, Inc.Telephone: +1-920-336-5715Toll-free: +1-800-558-2884Solvent Recovery DivisionMEGTEC Systems, Inc.Telephone: +1-772-567-1320BrazilMEGTEC Systems, Inc.Telephone: +55-19-3885-6116EUROPEFranceMEGTEC Systems SASTelephone: +33-1-69-89-4793United KingdomMEGTEC Systems, Ltd.Telephone: +44-1628-59-1700MEGTEC Environmental Ltd.Telephone: +44-1257-42-7070GermanySequa GmbH & Co.MEGTEC Systems KGTelephone: +49-6181-94040SwedenMEGTEC Systems ABTelephone: +46-31-65-7800MEGTEC Systems Amal ABTelephone: +46-532-62900ASIA-PACIFICSingaporeSingapore Sales Branch -MEGTEC Systems SASTelephone: +65-6298-4666ChinaMEGTEC Systems (Shanghai) Ltd.Telephone: +86-21-6769-7878Standard Z-<strong>1500</strong> Features• Z-<strong>1500</strong>: Roll-over-Roll configuration with air shaft roll support available models• Z-<strong>1500</strong>: Horizontal Roll-Behind-Roll configuration with airshaft roll support available models• Vertical nested festoon with low friction, low inertia bearings and rollers• Tapered festoon roller profiles• Rolling nip splice head with manual nip lock• Vacuum blower• Seimens S7 PLC Controlled• Dual disc ventilated high torque pneumatic brakes• Pull roll web acceleration• Motorized coupling/uncoupling and centering of shaft to sidelay• Motorized sidelay ± 1” (25 mm)• Direct roll loading upper and lower• Hoist: Motorized lift and traverse, equipped with hook deflectors• Right or left hand arrangement• Center loading tandem web model includes web over for 2-web applications• Fully assembled, pre-piped, pre-wired and tested• Signal for splice warning and occurredVersions at Additional Cost• Chain web-up assist• Web-up platform• 90° turn bars• Hoist load sensors• Dual unwind• Roll shaft handling cart• Roll shaft handling arm• Manual ROLLOAD• Paper Management• Heavy duty cutting package with pneumatic nip lock• CE norms includes safety guards• Automatic hoistIndiaMEGTEC Systems India Pvt. LtdTelephone: +91-20-662033-70 (71, 72)JapanMEGTEC Systems, Inc.Telephone: +81-78-783-0161AustraliaMEGTEC Systems Australia, Inc.Telephone: +61-3-9574-7450www.megtec.comAugust 2007This document is not contractual. © MEGTEC®