Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

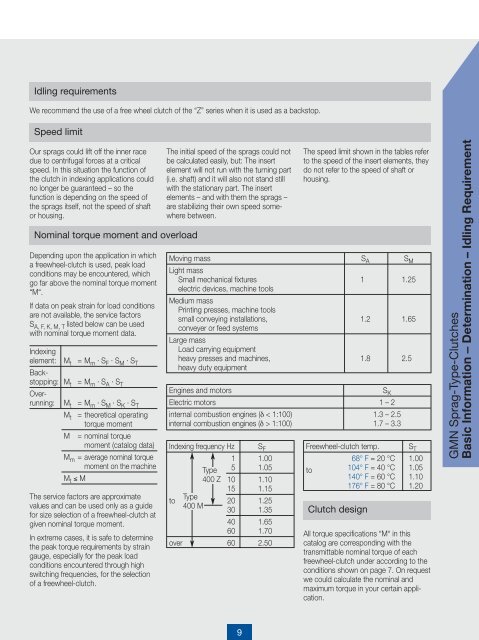

Idling requirementsWe recommend the use of a free wheel clutch of the “Z” series when it is used as a backstop.Speed limitOur sprags could lift off the inner racedue to centrifugal forces at a criticalspeed. In this situation the function ofthe clutch in indexing applications couldno longer be guaranteed – so thefunction is depending on the speed ofthe sprags itself, not the speed of shaftor housing.Nominal torque moment and overloadDepending upon the application in whicha freewheel-clutch is used, peak loadconditions may be encountered, whichgo far above the nominal torque moment“M“.If data on peak strain for load conditionsare not available, the service factorsS A, F, K, M, T listed below can be usedwith nominal torque moment data.Indexingelement: M t =M m · S F · S M · S TBackstopping:M t =M m · S A · S TOverrunning:M t =M m · S M · S K · S TM t =theoretical operatingtorque momentM = nominal torquemoment (catalog data)M m = average nominal torquemoment on the machineM t ≤ MThe service factors are approximatevalues and can be used only as a guidefor size selection of a freewheel-clutch atgiven nominal torque moment.In extreme cases, it is safe to determinethe peak torque requirements by straingauge, especially for the peak loadconditions encountered through highswitching frequencies, for the selectionof a freewheel-clutch.The initial speed of the sprags could notbe calculated easily, but: The insertelement will not run with the turning part(i.e. shaft) and it will also not stand stillwith the stationary part. The insertelements – and with them the sprags –are stabilizing their own speed somewherebetween.The speed limit shown in the tables referto the speed of the insert elements, theydo not refer to the speed of shaft orhousing.Moving mass S A S MLight massSmall mechanical fixtures 1,2 1.25electric devices, machine toolsMedium massPrinting presses, machine toolssmall conveying installations, 1.2 1.65conveyer or feed systemsLarge massLoad carrying equipmentheavy presses and machines, 1.8 2.50heavy duty equipmentEngines and motorsS KElectric motors 1 – 2internal combustion engines (δ < 1:100) 1.3 – 2.5internal combustion engines (δ > 1:100) 1.7 – 3.3Indexing frequency Hz<strong>Type</strong>400 ZS F1 1.005 1.0510 1.1015 1.15to<strong>Type</strong>20 1.25400 M30 1.3540 1.6560 1.70over 60 2.50<strong>Freewheel</strong>-clutch temp. S T68° F = 20 °C 1.00to 104° F = 40 °C 1.05140° F = 60 °C 1.10176° F = 80 °C 1.20Clutch designAll torque specifications “M“ in thiscatalog are corresponding with thetransmittable nominal torque of eachfreewheel-clutch under according to theconditions shown on page 7. On requestwe could calculate the nominal andmaximum torque in your certain application.GMN <strong>Sprag</strong>-<strong>Type</strong>-<strong>Clutches</strong>Basic Information – Determination – Idling Requirement9