1413.06.08 Cam Followers.qxd - RBC Bearings

1413.06.08 Cam Followers.qxd - RBC Bearings

1413.06.08 Cam Followers.qxd - RBC Bearings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

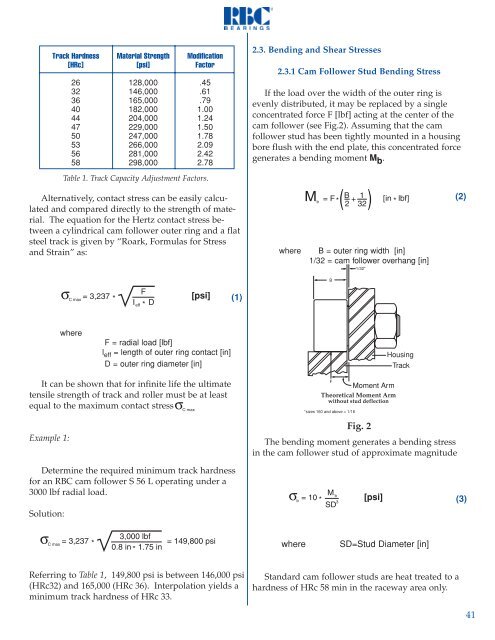

Track Hardness Material Strength Modification[HRc] [psi] Factor26 128,000 .4532 146,000 .6136 165,000 .7940 182,000 1.0044 204,000 1.2447 229,000 1.5050 247,000 1.7853 266,000 2.0956 281,000 2.4258 298,000 2.78Table 1. Track Capacity Adjustment Factors.2.3. Bending and Shear Stresses2.3.1 <strong>Cam</strong> Follower Stud Bending StressIf the load over the width of the outer ring isevenly distributed, it may be replaced by a singleconcentrated force F [lbf] acting at the center of thecam follower (see Fig.2). Assuming that the camfollower stud has been tightly mounted in a housingbore flush with the end plate, this concentrated forcegenerates a bending moment M b .Alternatively, contact stress can be easily calculatedand compared directly to the strength of material.The equation for the Hertz contact stress betweena cylindrical cam follower outer ring and a flatsteel track is given by “Roark, Formulas for Stressand Strain” as:whereMb= F* B 2 + 1 [in lbf]( 32) *B = outer ring width [in]1/32 = cam follower overhang [in]1/32*(2)Bσ = 3,237C max*IeffF* D[psi](1)whereF = radial load [lbf]l eff = length of outer ring contact [in]D = outer ring diameter [in]HousingTrackIt can be shown that for infinite life the ultimatetensile strength of track and roller must be at leastequal to the maximum contact stressExample 1:σ C maxFMoment ArmTheoretical Moment Armwithout stud deflection*sizes 160 and above = 1/16Fig. 2The bending moment generates a bending stressin the cam follower stud of approximate magnitudeDetermine the required minimum track hardnessfor an <strong>RBC</strong> cam follower S 56 L operating under a3000 lbf radial load.σb= 10 * M bSD 3[psi](3)Solution:σ = 3,237C max3,000 lbf* = 149,800 psi0.8 in * 1.75 inwhereSD=Stud Diameter [in]Referring to Table 1, 149,800 psi is between 146,000 psi(HRc32) and 165,000 (HRc 36). Interpolation yields aminimum track hardness of HRc 33.Standard cam follower studs are heat treated to ahardness of HRc 58 min in the raceway area only.41