1413.06.08 Cam Followers.qxd - RBC Bearings

1413.06.08 Cam Followers.qxd - RBC Bearings

1413.06.08 Cam Followers.qxd - RBC Bearings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

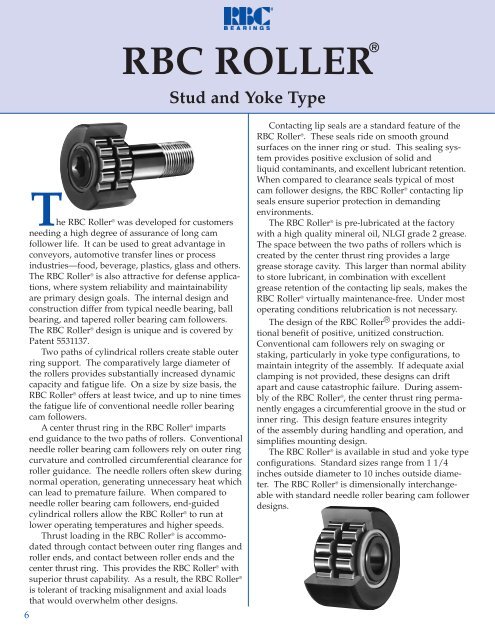

<strong>RBC</strong> ROLLER®Stud and Yoke Type6The <strong>RBC</strong> Roller ® was developed for customersneeding a high degree of assurance of long camfollower life. It can be used to great advantage inconveyors, automotive transfer lines or processindustries—food, beverage, plastics, glass and others.The <strong>RBC</strong> Roller ® is also attractive for defense applications,where system reliability and maintainabilityare primary design goals. The internal design andconstruction differ from typical needle bearing, ballbearing, and tapered roller bearing cam followers.The <strong>RBC</strong> Roller ® design is unique and is covered byPatent 5531137.Two paths of cylindrical rollers create stable outerring support. The comparatively large diameter ofthe rollers provides substantially increased dynamiccapacity and fatigue life. On a size by size basis, the<strong>RBC</strong> Roller ® offers at least twice, and up to nine timesthe fatigue life of conventional needle roller bearingcam followers.A center thrust ring in the <strong>RBC</strong> Roller ® impartsend guidance to the two paths of rollers. Conventionalneedle roller bearing cam followers rely on outer ringcurvature and controlled circumferential clearance forroller guidance. The needle rollers often skew duringnormal operation, generating unnecessary heat whichcan lead to premature failure. When compared toneedle roller bearing cam followers, end-guidedcylindrical rollers allow the <strong>RBC</strong> Roller ® to run atlower operating temperatures and higher speeds.Thrust loading in the <strong>RBC</strong> Roller ® is accommodatedthrough contact between outer ring flanges androller ends, and contact between roller ends and thecenter thrust ring. This provides the <strong>RBC</strong> Roller ® withsuperior thrust capability. As a result, the <strong>RBC</strong> Roller ®is tolerant of tracking misalignment and axial loadsthat would overwhelm other designs.Contacting lip seals are a standard feature of the<strong>RBC</strong> Roller ® . These seals ride on smooth groundsurfaces on the inner ring or stud. This sealing systemprovides positive exclusion of solid andliquid contaminants, and excellent lubricant retention.When compared to clearance seals typical of mostcam follower designs, the <strong>RBC</strong> Roller ® contacting lipseals ensure superior protection in demandingenvironments.The <strong>RBC</strong> Roller ® is pre-lubricated at the factorywith a high quality mineral oil, NLGI grade 2 grease.The space between the two paths of rollers which iscreated by the center thrust ring provides a largegrease storage cavity. This larger than normal abilityto store lubricant, in combination with excellentgrease retention of the contacting lip seals, makes the<strong>RBC</strong> Roller ® virtually maintenance-free. Under mostoperating conditions relubrication is not necessary.The design of the <strong>RBC</strong> Roller ® provides the additionalbenefit of positive, unitized construction.Conventional cam followers rely on swaging orstaking, particularly in yoke type configurations, tomaintain integrity of the assembly. If adequate axialclamping is not provided, these designs can driftapart and cause catastrophic failure. During assemblyof the <strong>RBC</strong> Roller ® , the center thrust ring permanentlyengages a circumferential groove in the stud orinner ring. This design feature ensures integrityof the assembly during handling and operation, andsimplifies mounting design.The <strong>RBC</strong> Roller ® is available in stud and yoke typeconfigurations. Standard sizes range from 1 1/4inches outside diameter to 10 inches outside diameter.The <strong>RBC</strong> Roller ® is dimensionally interchangeablewith standard needle roller bearing cam followerdesigns.