Design Example 5 Welded joint - Steel-stainless.org

Design Example 5 Welded joint - Steel-stainless.org

Design Example 5 Welded joint - Steel-stainless.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

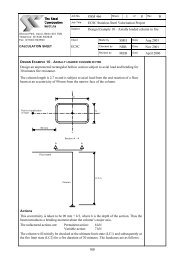

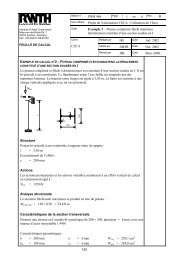

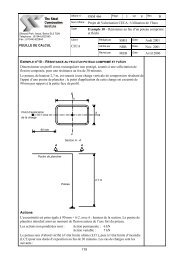

Job No. Sheet 4 of 8 Rev B102, Route de LimoursF-78471 St Rémy Lès Chevreuse CedexFranceTel : +33 (0)1 30 85 25 00Fax : +33 (0)1 30 52 75 38CALCULATION SHEETJob TitleSubjectClientECSCECSC Stainless <strong>Steel</strong> Valorisation Project<strong>Design</strong> <strong>Example</strong> 5 <strong>Welded</strong> <strong>joint</strong>Made by IR Date Aug 2002Checked by FH/NB Date Oct 2002Revised by MEB Date April 2006For the present case of a plane fillet weld <strong>joint</strong> with right angle (equal leg) welds this lattercheck is not critical. However it may be so for partial penetration welds in bevelled <strong>joint</strong>s.Instead of having to calculate the stresses (σ ⊥ , τ ⊥ and τ ⎥⎥ ) in the weld throat the followingdesign check expression may be used for y-z plane <strong>joint</strong>s with right angle (equal leg)welds:2F2w, x+ 2F+ 2Fw,yFw,z2w, y+ 2F2w, z+ F2w, y⎛ fSinθCosθ≤ ⎜au⎝ βwγ2Cos θ +M22F w, z2⎞⎟⎠2Sin θ − 2FNote : The subscripts have been shortened: F w,x for F wx,Ed etc.w,xFw,ySinθ+ 2Fw,xFw,zCosθIn the above expression the angle θ is that between the y axis and the axis of the weld asshown in the following figure.attachedelementSection 1-1F w,xsupportattachedelement11F w,zzF w,yθyattachedelementFillet weld axis2θF w,zz2F w,yyF w,xattachedelementsupportSection 2-2The force components at the critical point of the weld are determined in theAppendix to this design example.1. <strong>Design</strong> using the simplified design shear strength approachThe design shear strength for the simplified design approach is:f u530f vw,d = =≈ 245N/mm 2 EN 1993-1-8,γ 3 1.0 × 1,25×3Eq. 4.4β wM2The value of the resultant induced force per unit length in a weld throat of 1mm is :2 2 2 2 2 2wx, Ed wy, Ed wz, Ed=F w,Ed = F + F + F = 243 + 747 + 966 1245 N/mmThe required throat size is therefore:Fw,Ed1245a ≥ = ≈ 5, 0 mmf 245vw,d138