WACC-01 Flow Controls & Accessories - Watts Fluid Air

WACC-01 Flow Controls & Accessories - Watts Fluid Air

WACC-01 Flow Controls & Accessories - Watts Fluid Air

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

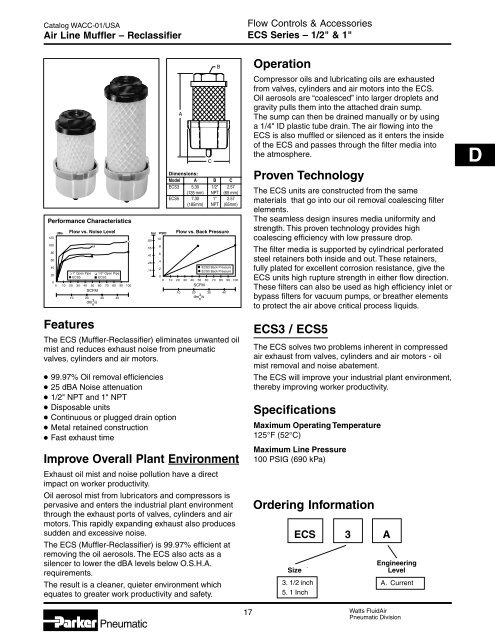

Catalog <strong>WACC</strong>-<strong>01</strong>/USA<strong>Air</strong> Line Muffler – Reclassifier<strong>Flow</strong> <strong>Controls</strong> & <strong>Accessories</strong>ECS Series – 1/2" & 1"Performance Characteristics12<strong>01</strong>008060dBa<strong>Flow</strong> vs. Noise Level■4020❍ 1" Open Pipe ❏ 1/2" Open Pipe● ECS5 ■ ECS300 10 20 30 40 50 60 70 80 90 100SCFMFeatures❏10 20 30 40dm 3 /sn❍●Pneumatic.69.55.41.28.14bar10PSID86ADimensions:Model A B CECS3 5.30 1/2" 2.57(135 mm) NPT (65 mm)ECS5 7.30 1" 2.57(185mm) NPT (65mm)<strong>Flow</strong> vs. Back Pressure■4■2ECS3 Back Pressure● ECS5 Back Pressure00 10 20 30 40 50 60 70 80 90 100SCFMCB10 20 30 40dm 3 /snThe ECS (Muffler-Reclassifier) eliminates unwanted oilmist and reduces exhaust noise from pneumaticvalves, cylinders and air motors.• 99.97% Oil removal efficiencies• 25 dBA Noise attenuation• 1/2" NPT and 1" NPT• Disposable units• Continuous or plugged drain option• Metal retained construction• Fast exhaust timeImprove Overall Plant EnvironmentExhaust oil mist and noise pollution have a directimpact on worker productivity.Oil aerosol mist from lubricators and compressors ispervasive and enters the industrial plant environmentthrough the exhaust ports of valves, cylinders and airmotors. This rapidly expanding exhaust also producessudden and excessive noise.The ECS (Muffler-Reclassifier) is 99.97% efficient atremoving the oil aerosols. The ECS also acts as asilencer to lower the dBA levels below O.S.H.A.requirements.The result is a cleaner, quieter environment whichequates to greater work productivity and safety.●OperationCompressor oils and lubricating oils are exhaustedfrom valves, cylinders and air motors into the ECS.Oil aerosols are “coalesced” into larger droplets andgravity pulls them into the attached drain sump.The sump can then be drained manually or by usinga 1/4" ID plastic tube drain. The air flowing into theECS is also muffled or silenced as it enters the insideof the ECS and passes through the filter media intothe atmosphere.Proven TechnologyThe ECS units are constructed from the samematerials that go into our oil removal coalescing filterelements.The seamless design insures media uniformity andstrength. This proven technology provides highcoalescing efficiency with low pressure drop.The filter media is supported by cylindrical perforatedsteel retainers both inside and out. These retainers,fully plated for excellent corrosion resistance, give theECS units high rupture strength in either flow direction.These filters can also be used as high efficiency inlet orbypass filters for vacuum pumps, or breather elementsto protect the air above critical process liquids.ECS3 / ECS5The ECS solves two problems inherent in compressedair exhaust from valves, cylinders and air motors - oilmist removal and noise abatement.The ECS will improve your industrial plant environment,thereby improving worker productivity.SpecificationsMaximum Operating Temperature125°F (52°C)Maximum Line Pressure100 PSIG (690 kPa)Ordering InformationECS 3 ASize3. 1/2 inch5. 1 InchEngineeringLevelA. Current17 <strong>Watts</strong> <strong>Fluid</strong><strong>Air</strong>Pneumatic DivisionCD