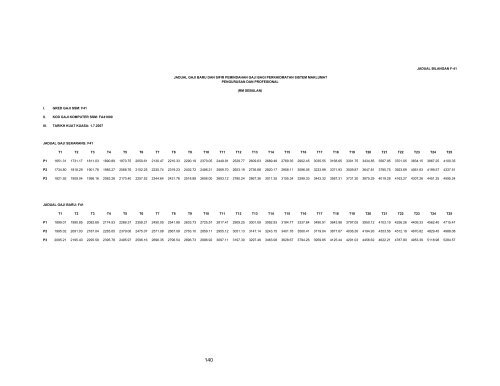

I. GRED GAJI SSM: F41 II. KOD GAJI KOMPUTER SSM: FA41000 III ...

I. GRED GAJI SSM: F41 II. KOD GAJI KOMPUTER SSM: FA41000 III ...

I. GRED GAJI SSM: F41 II. KOD GAJI KOMPUTER SSM: FA41000 III ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

It can be estimated from the failures (Table 2) that most of the 17 forms of failure werecaused by linear wear (friction, adhesion, corrosion) or volumetric wear (e.g. cracks). In theSulzer RD engine crankshaft-piston assembly and timing gear system they made up: in 1972 -60%, in 1973 – 66%, in 1974 – 71% of all failures. Additionally, from the share in the CZUoverall failure structure: 1972 – 0.42; 1973 – 0.42; 1974 – 0.54 the increasing number offailures with increasing engine age can be seen. Therefore, Table 3 presents failures occurredin 1974.Cracks, fractures and breaks, which may lead even to engine stoppage, took the secondplace in the registered failure forms. Table 3 shows that these type of failures occur mostoften in the piston-rings subsystem (21%) and the piston rod-crosshead subsystem (51%).Such subsystem failures require comprehensive analysis of the failure event causes as well aslaboratory examinations in order to verify the operational experience conclusions.3. Model of the piston-rings and piston rod-crosshead subsystem failuresAnalysis of the Sulzer RD engine crankshaft-piston assembly and timing gear systemfailures indicates that subsystems requiring the most thorough examination are piston withrings and piston rod with crosshead – parts of the crankshaft-piston assembly. The twosubsystems are considered operational when respective characteristics of the subsystemcomponent elements are contained within limits defined by their work character. When one ofthe work characteristics [2,3,4,5,9] (e.g. working medium parameters) exceeds the admissiblelimits and for instance the crosshead bearing begins to work defectively, then it is treated asinefficiency.The work characteristic of any main element of the crankshaft-piston assembly (Fig.1) getsmonotonically worse under the impairing relaxation stimuli. It may be assumed that thesubsystem inefficiency occurs when one of its elements exceeds the admissible limits given inthe specification. The element trouble-free operation time “T” is counted until the momentwhen the work characteristic exceeds the assumed limit value. Fig.1 presents also a situationwhen single stimuli of a determined value occur at randomly selected moments. After “r”such occurrences the element as a whole appears nonoperational (inefficient). Action of asingle stimulus appears as stepwise decrease of the element efficiency by a certain value “y”[2,3].(t)yrLimit levelTFig. 1. Action of impairing relaxation stimuli: (t) – operating characteristic of a crankshaft-piston element; t –time; T – trouble-free operation time, element durability; r – number of stimuli necessary to cause elementineffeiciency; y – stepwise wearThe failure model may be considered useful when it describes a stable (or normal) periodof the impairing stimulus action. Then the probability of an increase of the number of failurest

JADUAL BILANGAN F-54JADUAL <strong>GAJI</strong> BARU DAN SIFIR PEMINDAHAN <strong>GAJI</strong> BAGI PERKHIDMATAN SISTEM MAKLUMATPENGURUSAN DAN PROFESIONAL(RM SEBULAN)I. <strong>GRED</strong> <strong>GAJI</strong> <strong>SSM</strong>: F54<strong>II</strong>.<strong>KOD</strong> <strong>GAJI</strong> <strong>KOMPUTER</strong> <strong>SSM</strong>: FA54000<strong>II</strong>I. TARIKH KUAT KUASA: 1.7.2007JADUAL <strong>GAJI</strong> SEKARANG: F54T1 T2 T3 T4 T5 T6 T7 T8P1 4566.20 4746.49 4946.14 5145.79 5345.44 5545.09 5744.74 5944.39P2 4970.34 5186.93 5403.52 5620.11 5836.70 6053.29 6269.88 6486.47JADUAL <strong>GAJI</strong> BARU: F54T1 T2 T3 T4 T5 T6 T7 T8P1 5251.13 5458.46 5688.06 5917.66 6147.26 6376.86 6606.46 6836.06P2 5715.89 5964.97 6214.05 6463.13 6712.21 6961.29 7210.37 7459.45144