Liitetiedosto (pdf) - Virtasenkauppa.fi

Liitetiedosto (pdf) - Virtasenkauppa.fi

Liitetiedosto (pdf) - Virtasenkauppa.fi

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

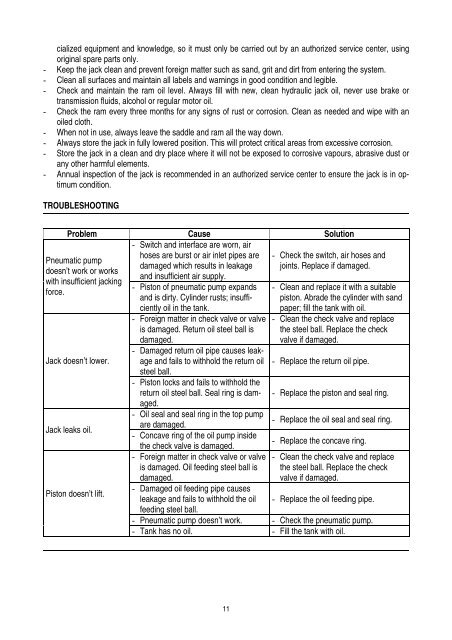

cialized equipment and knowledge, so it must only be carried out by an authorized service center, usingoriginal spare parts only.- Keep the jack clean and prevent foreign matter such as sand, grit and dirt from entering the system.- Clean all surfaces and maintain all labels and warnings in good condition and legible.- Check and maintain the ram oil level. Always <strong>fi</strong>ll with new, clean hydraulic jack oil, never use brake ortransmission fluids, alcohol or regular motor oil.- Check the ram every three months for any signs of rust or corrosion. Clean as needed and wipe with anoiled cloth.- When not in use, always leave the saddle and ram all the way down.- Always store the jack in fully lowered position. This will protect critical areas from excessive corrosion.- Store the jack in a clean and dry place where it will not be exposed to corrosive vapours, abrasive dust orany other harmful elements.- Annual inspection of the jack is recommended in an authorized service center to ensure the jack is in optimumcondition.TROUBLESHOOTINGProblem Cause Solution- Switch and interface are worn, airhoses are burst or air inlet pipes aredamaged which results in leakageand insuf<strong>fi</strong>cient air supply.Pneumatic pumpdoesn’t work or workswith insuf<strong>fi</strong>cient jackingforce.Jack doesn’t lower.Jack leaks oil.Piston doesn’t lift.- Piston of pneumatic pump expandsand is dirty. Cylinder rusts; insuf<strong>fi</strong>cientlyoil in the tank.- Foreign matter in check valve or valveis damaged. Return oil steel ball isdamaged.- Damaged return oil pipe causes leakageand fails to withhold the return oilsteel ball.- Piston locks and fails to withhold thereturn oil steel ball. Seal ring is damaged.- Oil seal and seal ring in the top pumpare damaged.- Concave ring of the oil pump insidethe check valve is damaged.- Foreign matter in check valve or valveis damaged. Oil feeding steel ball isdamaged.- Damaged oil feeding pipe causesleakage and fails to withhold the oilfeeding steel ball.- Check the switch, air hoses andjoints. Replace if damaged.- Clean and replace it with a suitablepiston. Abrade the cylinder with sandpaper; <strong>fi</strong>ll the tank with oil.- Clean the check valve and replacethe steel ball. Replace the checkvalve if damaged.- Replace the return oil pipe.- Replace the piston and seal ring.- Replace the oil seal and seal ring.- Replace the concave ring.- Clean the check valve and replacethe steel ball. Replace the checkvalve if damaged.- Replace the oil feeding pipe.- Pneumatic pump doesn’t work. - Check the pneumatic pump.- Tank has no oil. - Fill the tank with oil.11