Jacobs & Thompson - Partners in Project Green

Jacobs & Thompson - Partners in Project Green

Jacobs & Thompson - Partners in Project Green

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

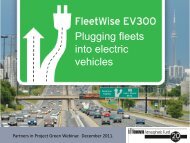

CASE STUDYLight<strong>in</strong>g RetrofitIn addition to these projects, <strong>Jacobs</strong> &<strong>Thompson</strong> also implemented a light<strong>in</strong>gretrofit at its Toronto facility. Inside andoutside the plant, the company replaced 416T-12 fixtures with 165 T-8 and light reflectivePL Type fixtures. Before the replacement, thecomb<strong>in</strong>ed wattage for the facility’s fixtureswas 62,885 watts and the cost of runn<strong>in</strong>gthe fixtures was $5,695 per month. After theretrofit, the comb<strong>in</strong>ed wattage was 25,578watts and the operat<strong>in</strong>g cost was $2,475. Theretrofit thus resulted <strong>in</strong> a sav<strong>in</strong>gs of 37,307New T-8 light<strong>in</strong>g saves <strong>Jacobs</strong> & <strong>Thompson</strong> $3,220 watts and $3,220 per month. In addition to theper month <strong>in</strong> energy costssubstantial f<strong>in</strong>ancial sav<strong>in</strong>gs achieved throughthe light<strong>in</strong>g retrofit, the company also benefitsfrom a higher lumen output and better colour rendition, and significantly <strong>in</strong>creased light<strong>in</strong>glevels. The $60,000 project cost, which has a payback period of about 1.5 years, was reduced by<strong>in</strong>centives from Natural Resources Canada and Toronto Hydro. Staff labour also helped reducecosts.<strong>Project</strong> ChallengesAccord<strong>in</strong>g to Peter Mauti, <strong>Jacobs</strong> & <strong>Thompson</strong>’s Ma<strong>in</strong>tenance Manager, the energy retrofitprocess went smoothly and no significant challenges arose. “The key,” he says, “is to do yourhomework, plan ahead, and keep track of the entire project from start to f<strong>in</strong>ish.”MOVING FORWARDAs an environmentally consciouscompany, <strong>Jacobs</strong> & <strong>Thompson</strong>is always work<strong>in</strong>g hard to bean environmentally susta<strong>in</strong>ablefabrication partner. Be<strong>in</strong>g aresponsible corporate citizenhas been a top priority for thecompany when design<strong>in</strong>g its wasterecycl<strong>in</strong>g programs and energyconservation plans. The companyis pleased that its efforts to datehave resulted <strong>in</strong> measurableenergy and natural gas sav<strong>in</strong>gs,thereby reduc<strong>in</strong>g the company’soverall contribution to greenhouse gasemissions and its carbon footpr<strong>in</strong>t.<strong>Jacobs</strong> & <strong>Thompson</strong>’s yearly CO2 emissions have decl<strong>in</strong>eds<strong>in</strong>ce 2006Between 2002 and 2011, the company achieved an overall reduction of 31 per cent <strong>in</strong> its hydroconsumption and a 47 per cent reduction <strong>in</strong> its natural gas consumption. Yearly CO2 emissionss<strong>in</strong>ce 2006 have also gone down by 46 per cent (see graph). By 2011, due to the light<strong>in</strong>g retrofitand heat reclamation projects, <strong>Jacobs</strong> & <strong>Thompson</strong> was consum<strong>in</strong>g less hydro and natural gas