Technical Data Sheet fischer fixit 2K Epoxy modelling putty 2K EK

Technical Data Sheet fischer fixit 2K Epoxy modelling putty 2K EK

Technical Data Sheet fischer fixit 2K Epoxy modelling putty 2K EK

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

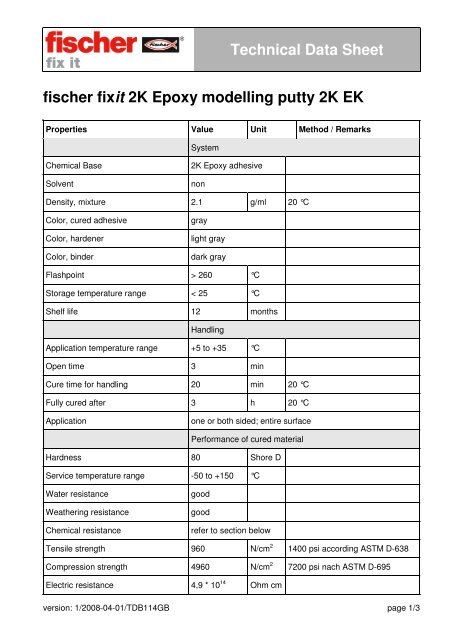

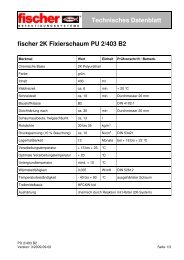

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong><strong>fischer</strong> <strong>fixit</strong> <strong>2K</strong> <strong>Epoxy</strong> <strong>modelling</strong> <strong>putty</strong> <strong>2K</strong> <strong>EK</strong>Properties Value Unit Method / RemarksSystemChemical BaseSolvent<strong>2K</strong> <strong>Epoxy</strong> adhesivenonDensity, mixture 2.1 g/ml 20 °CColor, cured adhesiveColor, hardenerColor, bindergraylight graydark grayFlashpoint > 260 °CStorage temperature range < 25 °CShelf life 12 monthsHandlingApplication temperature range +5 to +35 °COpen time 3 minCure time for handling 20 min 20 °CFully cured after 3 h 20 °CApplicationone or both sided; entire surfacePerformance of cured materialHardness 80 Shore DService temperature range -50 to +150 °CWater resistanceWeathering resistanceChemical resistancegoodgoodrefer to section belowTensile strength 960 N/cm 2 1400 psi according ASTM D-638Compression strength 4960 N/cm 2 7200 psi nach ASTM D-695Electric resistance 4,9 * 10 14 Ohm cmversion: 1/2008-04-01/TDB114GB page 1/3

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>ApplicationFills holes and grooves, repairs faulty bores and seals holes in tanks, drums, pipes, etc.. Suitable formetal, ceramic, stone, concrete, plastic and wood.Not suitable for PE, PP, Teflon®, acrylic glass and to repair pressurised pipelines.May be used under water and on damp application surfaces.Properties / Features- Bond, Repair, Fill, Seal- Model- May be drilled, ground and milled- Paint able- Withstands temperatures up to +150°CSurface cleaningThe parts to be joined together must be clean and free of oil and grease.Directions for useThe parts to be joined together must be clean and free of oil and grease.Lightly roughen the surfaces to improve adhesion.Cut off the required amount and knead it until a uniform colour is achieved and the material becomeswarm. Apply the <strong>putty</strong> to the parts and model; let rest for at least 20 minutes.When working under water, apply pressure to the material until it begins to harden.Do not use the <strong>putty</strong> in outside temperatures below +5°C.We recommend wearing protective gloves when working with the material.The product may be worked in as little as approx. 20 minutes (drilling, tapping and threading, filing,sandblasting, milling, sawing). Fully hardened after about 3 hours.CleanupBefore hardening – with cleaning solvent or acetone, after – mechanical cleaning.StorageStore at room temperature.Chemical resistanceThe <strong>putty</strong> is resistant to oils, fuel and many more.version: 1/2008-04-01/TDB114GB page 2/3

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>Classification and LabellingXi Irritant / N Dangerous for environmentIrritating to eyes and skin. May cause sensitization by skin contact. Toxic to aquatic organisms, maycause long-term adverse effects in the aquatic environment. Avoid contact with skin. In case ofcontact with eyes, rinse immediately with plenty of water and seek medical advice. Wear suitablegloves. This material and its container must be disposed of as hazardous waste (not hardenedmaterial)Only recycle when empty.For further safe handling information on this product, consult the Material Safety <strong>Data</strong> <strong>Sheet</strong> (MSDS).The information in this adhesives brochure and our application-technology consulting, verbally and inwriting, is given to the best of our knowledge, but is non-binding and is not a guarantee in the senseof § 443 BGB. We recommend that, before using our products, you check the suitability for theintended application. As the individual product can be used for a wide range of applications and theconditions on site that cannot be estimated, we also recommend testing the bonding before using theproduct.version: 1/2008-04-01/TDB114GB page 3/3