Air Induction Systems

Air Induction Systems

Air Induction Systems

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

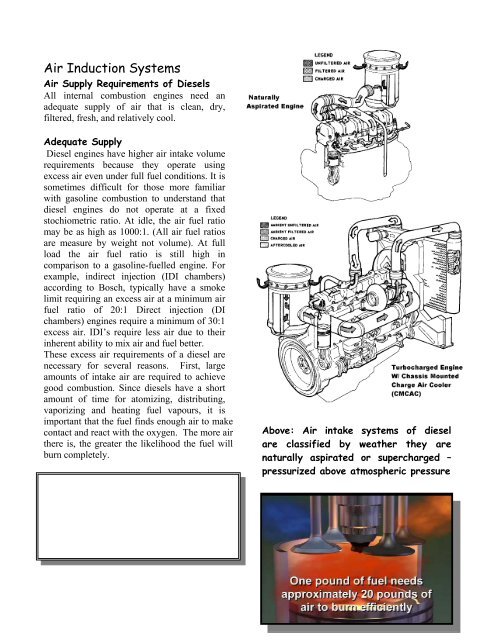

<strong>Air</strong> <strong>Induction</strong> <strong>Systems</strong><strong>Air</strong> Supply Requirements of DieselsAll internal combustion engines need anadequate supply of air that is clean, dry,filtered, fresh, and relatively cool.Adequate SupplyDiesel engines have higher air intake volumerequirements because they operate usingexcess air even under full fuel conditions. It issometimes difficult for those more familiarwith gasoline combustion to understand thatdiesel engines do not operate at a fixedstochiometric ratio. At idle, the air fuel ratiomay be as high as 1000:1. (All air fuel ratiosare measure by weight not volume). At fullload the air fuel ratio is still high incomparison to a gasoline-fuelled engine. Forexample, indirect injection (IDI chambers)according to Bosch, typically have a smokelimit requiring an excess air at a minimum airfuel ratio of 20:1 Direct injection (DIchambers) engines require a minimum of 30:1excess air. IDI’s require less air due to theirinherent ability to mix air and fuel better.These excess air requirements of a diesel arenecessary for several reasons. First, largeamounts of intake air are required to achievegood combustion. Since diesels have a shortamount of time for atomizing, distributing,vaporizing and heating fuel vapours, it isimportant that the fuel finds enough air to makecontact and react with the oxygen. The more airthere is, the greater the likelihood the fuel willburn completely.Stochiometric Ratio: The minimum quantityof air required to burn all fuel completely in acombustion chamber.• Measured as weight – not volume.Stochiometric for• Gasoline 14.73:1• Diesel fuel 15.1Above: <strong>Air</strong> intake systems of dieselare classified by weather they arenaturally aspirated or supercharged –pressurized above atmospheric pressure

eathing becomes more difficult or onebecomes short of breath faster when physicallyactive on those days. This is because there isless oxygen content in the air. Enginesexperience similar problems when hightemperatures are combined with high humidity.The result is often lower power output andhigher levels of exhaust smoke. (Emissiontesting is restricted on those days!)Below: Note the differences in Oxygencontent under different temperatureand atmospheric conditionsAbove: <strong>Air</strong> Inlet temperature EffectsOn Pre-Ignition TemperaturesWater Content of <strong>Air</strong>It is important for the technician diagnosingperformance complaints to note water vapour orhumidity in the air displaces oxygen. A roomwith a relative humidity of 50% at 20C willhave more oxygen content than a room at thesame temperature with will have with 80%relative humidity.(The chemical law that explains this observationis Avrogadro’s Theorem.) Higher humidityresults in lower oxygen content. Warmertemperatures also are capable of dissolvingmore water than cooler air temperatures. Youmay notice on warm humid days that your

<strong>Air</strong> intakes design is important to minimizenoise, and the quantity of dirt and water enteringthe air filter. They are used to also optimizetheairflow into the engine<strong>Air</strong> intakes ideally should have minimal bendingand smooth interior surfaces for maximumairflow.Resonator boxes or chambers may be located onthe intake system in passenger applications toinject pressure waves which cancel intake noisefrom created from the large amount of valveoverlap that is characteristic of a diesel engine.Above: A gasoline engine with water injectionthrough the intake manifold – these systemscan enhance performance by allowing for highercompression ratios or advanced timing. Indiesels, higher fuel rates can be used with thewater as a combustion chamber coolant. Thistechnology also reduces N0x emissionsSee also: http://www.frii.com/~maphill/wi.htmlIntakesFactors Affecting <strong>Air</strong> IntakeEfficiency:• Smoothness of air intake passages.• Degree and number of bends in air passages.• Size, design (Crossflow Vs Uniflow) of portsand passages.• Valve timing, lift and duration of valveopening.Because diesel engines often have largeamounts of valve overlap, some exhaust gasesmay leak by the intake valve during overlap.Soot loading of an intake manifold is normal ina diesel. Intake noise is louder in a diesel for thesame reason. The intake valve can become veryhot to the point of being damaged. Valveadjustment is important!Lack of sufficient airflow to an enginecan result in these conditions:- Low turbocharger or blower boost pressure- Higher exhaust temperatures- Incomplete combustion- Lower fuel economy- Lack of power- Smoke at the exhaust stack- Increased exhaust emissions- Shorter valve and piston life- Increased lube oil useMany current engines, which are electronicallycontrolled, are equipped with a variety of airinlet system sensors. These three sensors canhelp identify a problem in the intake system andcause the engine ECM to adapt protection orperformance strategies. For example, intake air

temperature is monitored on many engines toprevent damage from high intake temperatures.Typically, the engine power will be de-rated iftemperatures are excessive.Other intake air sensor strategies include:• Ambient air pressure sensor (barometricpressure sensor) for altitude compensation.• Intake manifold temperature sensor. This isdata is used to modify fuel timing/injection ratesto minimize emissions and is monitored by theengine protection system in the event of excessintake temperature• Turbocharger boost pressure sensor; data usedto adjust fuel rates and sense engine load.Moisture & Dirt Removal From Intake<strong>Air</strong>Intake systems can be designed a number ofways to minimize the entry of moisture and dirtentry into the air induction system.A frontal intake system alone with inlets closeto the ground will results in more ingestion ofroad salt and water into the air intake. Waterwill dissolve the salt and allow it to passthrough the induction system causing corrosionto components like the aluminium intercoolerand eventually cylinder component damage.Below: frontal air intake system withinduction passage through the hood.Note the dirt-air drainAbove: Side mounted intake systemseliminate more moisture and dirtaspiration than frontal systemsbutlose the “Ram <strong>Air</strong>” effect

air deflected by the windshield to push air intothe induction piping. The use of the optionalwinter/summer intake allows warmer air to bedrawn from under the hood where it is lesslikely to be moisture or snow contaminated.Snow-plow trucks are especially suited torequire this configuration.Above: Ram air inductionAn intake that is located in the side or top of aAbove: <strong>Air</strong> Intakes with optionalsummer or winter air inlets. Note flapin top picture.In some applications, the entry to the airinduction system is located high to avoid roadspray. The above Freightliner uses the force ofhood will result in less water/dirt ingestion intothe air intake since the air can change directionmore quickly than the dirt/water.PrecleanersPrecleaners remove as much as 90% of dirt andcontaminants from the incoming air often usingcentrifugal force.

Filter ElementsA number of filter media are used to removeparticle contamination from the air inductionsystem. While paper-cellulose elements are themost popular, felt, foam, oil soaked paper foam,and synthetic glass fibres (microglass) are alsoused. None of these will effectively removesome contaminants such as cement dust that canbe so small that it will pass through many mediatypes. Electrostatic filtration is often used inindustrial applications. Also, road salt dissolvedin water will also pass through many mediatypes causing contamination and corrosion of airinduction/cylinder components.Dry <strong>Air</strong> CleanersPaper filters are made from compressedcellulose fibers. The spaces between these fibersprovide microscopic holes the air must passthrough. As dirty air flows through one by one,these holes become plugged with dirt and dustparticles. Once a hole becomes plugged, the airmust find an alternate route through themedium. It should be noted that the larger holestend to plug up faster since greater air volumeswill flow through those channels. Since thereare generally more smaller holes in the filtermedia, these will plug up later. Thisphenomenon will result in better filtration (i.e.more particles are blocked) as the filter loadswith contamination. Over servicing of filtersshould be avoided to obtain the best filtrationsince a new filter will pass more dirt than a usedone. However, it should also be noted that asthe filter collects more dirt, its resistance to airflow increases because there are fewer andfewer holes are left open and as resistance orrestriction to airflow goes up. Eventuallyhorsepower and fuel economy decrease. Ideally,the paper must be thick and/or the fibers mustbe tightly compressed and dense to load asmuch dirt and obtain effective filtration.Paper filter elements are made from treatedpaper (to resist water damage which causes thepores to close) and pleated to form “V’s”. Thepleating will allow more surface area to pass airand greater dirt loading capacity before the filterbecomes restricted. In some filter models, thispleated paper element can be opened to a fulllength of 12 to 18 m (40 to 60 ft). The chemicalsused to treat the paper can be dissolved throughthe use of solvents found in cleaners used towash filters.FilterFibersMediaThe paper element is surrounded and protectedby a perforated steel mesh screen (shell). Insidethe filter, the mesh can actas a flame retarder inthe event of engine backfire. On the outside itfunctions to smooth out turbulence in the airstream.‣Trucks used in applications such asconstruction will use a primary and secondaryfilter arrangement. The inner filter may have a

separate/integral restriction gauge or indicator toprevent over servicing.In composite filters, dirty air enters through theinlet opening, where it travels through a plasticring of vanes (called a pre-cleaner) around theoutside of the element. These vanes aredesigned to create a cyclonic twist to the air tothrow the heavier dust and dirt particles outwardagainst the filter housing walls by centrifugalforce and downward into the dust cup.Above: Two stage – primary &secondary filter used in “dump truckapplicationComposite FilterFilter EfficiencyA filters effectiveness must be stated as the % ofdirt trapped at a particular micron size. Typicalnumbers for paper element filters are 40%efficiency at 10 microns, 60% at 20 microns,93% at 30 microns, and 97% at 40 microns

Power Core FiltersUsing a new design and material, Donaldson hasintroduced a new filter technology using apolymer (Plastic) type filtration media. Powercore filters use a layered type fluted cells. Thefluted channels are alternately sealed allowingair to enter through an open flute and forcing itto exit out an adjacent flute.Advantages claimed by the manufacturerinclude:• Improved efficiency:Power Core is 10 times more efficient thanaverage conventional filtersGain over 100% more dust holding capacity in agiven volume.• Improved engine protection:No media movement, expansion, contraction orbunching, with less dust and dirt passed on tothe engine

• Improved contaminant encapsulation:Dust and dirt won’t dislodge during servicing• Improved handling and maintenance:Lighter and smaller, changing filters is a snap• Improved disposal ease:No metal, incinerableThe other major benefit is the filter usessignificantly less space, this allowsmanufacturers the freedom to design uniqueconfigurations to fit tight spots, and overalldesign simplicityHeavy Equipment <strong>Air</strong> IntakesTo improve the pre-cleaner efficiency of someHD diesels in off-road applications, the velocityof exhaust gases is used to clean the pre-filter.A venturi like device is used at the exhaustoutlet to draw dust and contaminants out of thefilter housing pre-cleaner trap or bowl.