STK Series - PMC Group

STK Series - PMC Group

STK Series - PMC Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

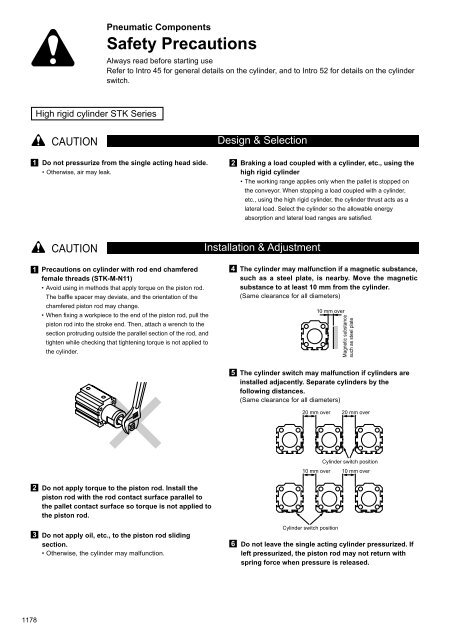

Pneumatic ComponentsSafety PrecautionsAlways read before starting useRefer to Intro 45 for general details on the cylinder, and to Intro 52 for details on the cylinderswitch.High rigid cylinder <strong>STK</strong> <strong>Series</strong>CAUTIONDesign & Selection1 Do not pressurize from the single acting head side.• Otherwise, air may leak.2 Braking a load coupled with a cylinder, etc., using thehigh rigid cylinder• The working range applies only when the pallet is stopped onthe conveyor. When stopping a load coupled with a cylinder,etc., using the high rigid cylinder, the cylinder thrust acts as alateral load. Select the cylinder so the allowable energyabsorption and lateral load ranges are satisfied.CAUTIONInstallation & Adjustment1Precautions on cylinder with rod end chamferedfemale threads (<strong>STK</strong>-M-N11)• Avoid using in methods that apply torque on the piston rod.The baffle spacer may deviate, and the orientation of thechamfered piston rod may change.• When fixing a workpiece to the end of the piston rod, pull thepiston rod into the stroke end. Then, attach a wrench to thesection protruding outside the parallel section of the rod, andtighten while checking that tightening torque is not applied tothe cylinder.4The cylinder may malfunction if a magnetic substance,such as a steel plate, is nearby. Move the magneticsubstance to at least 10 mm from the cylinder.(Same clearance for all diameters)10 mm overMagnetic substancesuch as steel plate5The cylinder switch may malfunction if cylinders areinstalled adjacently. Separate cylinders by thefollowing distances.(Same clearance for all diameters)20 mm over 20 mm overCylinder switch position10 mm over 10 mm over2Do not apply torque to the piston rod. Install thepiston rod with the rod contact surface parallel tothe pallet contact surface so torque is not applied tothe piston rod.3Do not apply oil, etc., to the piston rod slidingsection.• Otherwise, the cylinder may malfunction.6Cylinder switch positionDo not leave the single acting cylinder pressurized. Ifleft pressurized, the piston rod may not return withspring force when pressure is released.1178