The Best of Both Worlds: Hybrid Ship Hulls Use Composites & Steel

The Best of Both Worlds: Hybrid Ship Hulls Use Composites & Steel

The Best of Both Worlds: Hybrid Ship Hulls Use Composites & Steel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

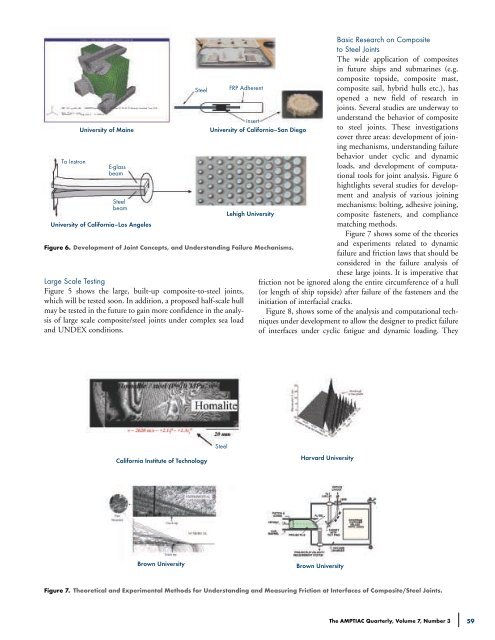

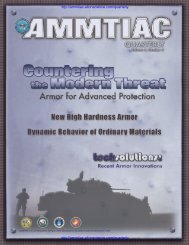

To InstronUniversity <strong>of</strong> MaineE-glassbeam<strong>Steel</strong>beamUniversity <strong>of</strong> California–Los AngelesFigure 6. Development <strong>of</strong> Joint Concepts, and Understanding Failure Mechanisms.<strong>Steel</strong>Large Scale TestingFigure 5 shows the large, built-up composite-to-steel joints,which will be tested soon. In addition, a proposed half-scale hullmay be tested in the future to gain more confidence in the analysis<strong>of</strong> large scale composite/steel joints under complex sea loadand UNDEX conditions.FRP AdherentBasic Research on Compositeto <strong>Steel</strong> Joints<strong>The</strong> wide application <strong>of</strong> compositesin future ships and submarines (e.g.composite topside, composite mast,composite sail, hybrid hulls etc.), hasopened a new field <strong>of</strong> research injoints. Several studies are underway tounderstand the behavior <strong>of</strong> compositeto steel joints. <strong>The</strong>se investigationscover three areas: development <strong>of</strong> joiningmechanisms, understanding failurebehavior under cyclic and dynamicloads, and development <strong>of</strong> computationaltools for joint analysis. Figure 6hightlights several studies for developmentand analysis <strong>of</strong> various joiningmechanisms: bolting, adhesive joining,composite fasteners, and compliancematching methods.Figure 7 shows some <strong>of</strong> the theoriesand experiments related to dynamicfailure and friction laws that should beconsidered in the failure analysis <strong>of</strong>these large joints. It is imperative thatfriction not be ignored along the entire circumference <strong>of</strong> a hull(or length <strong>of</strong> ship topside) after failure <strong>of</strong> the fasteners and theinitiation <strong>of</strong> interfacial cracks.Figure 8, shows some <strong>of</strong> the analysis and computational techniquesunder development to allow the designer to predict failure<strong>of</strong> interfaces under cyclic fatigue and dynamic loading. <strong>The</strong>yinsertUniversity <strong>of</strong> California–San DiegoLehigh UniversityCalifornia Institute <strong>of</strong> Technology<strong>Steel</strong>Harvard UniversityBrown UniversityBrown UniversityFigure 7. <strong>The</strong>oretical and Experimental Methods for Understanding and Measuring Friction at Interfaces <strong>of</strong> Composite/<strong>Steel</strong> Joints.<strong>The</strong> AMPTIAC Quarterly, Volume 7, Number 3 59