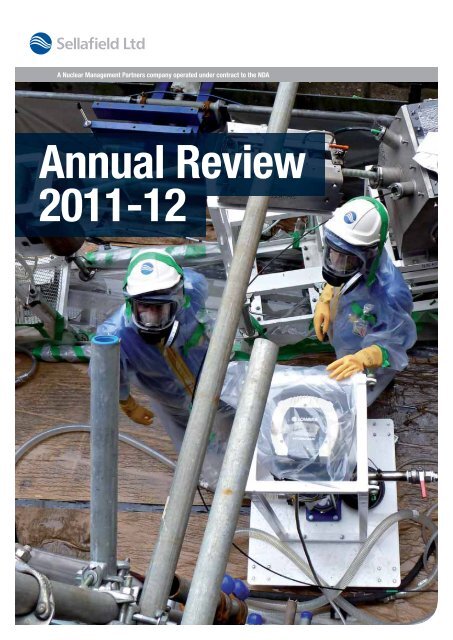

Annual Review 2011-12 - Sellafield Ltd

Annual Review 2011-12 - Sellafield Ltd

Annual Review 2011-12 - Sellafield Ltd

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>At <strong>Sellafield</strong> we have one of the largestand most diverse decommissioningportfolios in the world today, with atotal value of approximately£23bn

4<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Overview: <strong>Sellafield</strong> <strong>Ltd</strong><strong>Sellafield</strong> <strong>Ltd</strong> overview<strong>Sellafield</strong> <strong>Ltd</strong> is the company responsible for safely deliveringdecommissioning, reprocessing and nuclear waste managementactivities on behalf of the Nuclear Decommissioning Authority.Now under the ownership of Nuclear Management Partners,<strong>Sellafield</strong> <strong>Ltd</strong> has the largest concentration of nuclear expertisein Europe, with over 50 years of experience.Under the ownership of NuclearManagement Partners (NMP),we are safely delivering nucleardecommissioning, waste managementand commercial operations and bycontinually raising our performancewe will achieve the NuclearDecommissioning Authority’s (NDA)vision to become the site and workforceof choice for potential new missions.With a diverse portfolio that stretches acrossthe North West of England and spans the entirehistory of the UK’s civil nuclear industry, ourchallenge is unique.Nuclear decommissioning, managing,processing and storing low, intermediate andhigh level waste and reprocessing used nuclearfuel; our ten thousand strong workforce isdelivering all of this and more at <strong>Sellafield</strong> inWest Cumbria, Capenhurst in Cheshire andRisley in Warrington.We commit to maintaining our engagementwith our employees, customers, regulators andlocal communities around our sites.The NDA selected NMP to manage <strong>Sellafield</strong>’sdiverse mission of decommissioning, and spentnuclear fuel recycling, because of its worldleadingexpertise and track record in all ofthese functions.NMP is a consortium of the world’s leadingnuclear industry experts. NMP comprises ofthree companies: nuclear clean-up projects and sites thanany other company. and project management company. programme – the industry’s model.NMP’s focus is on making<strong>Sellafield</strong> safer, cleaner, moreproductive, more cost-effective,and a better neighbour each andevery day.By doing so, NMP will make <strong>Sellafield</strong> <strong>Ltd</strong> fit forpurpose and help build the bridge to the UK’sgreen and safe energy future. Specifically, NMPfocus on the following: safety culture at <strong>Sellafield</strong> while reducingrisk to workers (through high-hazardreduction). the public and the environment bycleaning up what needs it the most first(accelerated high-hazard reduction). project management and workforcedevelopment practices from around theworld to boost productivity and acceleratethe achievement of site and projectmilestones. clean up the site and recycle fuel at thelowest cost to the UK taxpayer. accelerated clean-up and organisationalchange on workers and our hostcommunities through smart planning,pursuit of new site activities, and supportBritain’s Energy Coast Blueprint.URS manages more US government nuclear cleanupprojects and sites than any other companyAMEC is the leading UK nuclear engineeringand project management companyAREVA operates the French fuel cycleprogramme – the industry’s model

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>All our employees have a specificsafety role – helping to ensure oursafety performance is world classacross our operations and sites

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 9Overview: DeliveryRisk & Hazard ReductionNuclear MaterialsThe Nuclear DecommissioningAuthority’s Strategy, approved by theSecretary of State for Energy andScottish Ministers in March <strong>2011</strong> hasat its heart the priority of reducingrisk and hazard and to deliver theclean-up mission cost-effectively.Spent Fuel ManagementSpent Fuel Management at <strong>Sellafield</strong>includes the reprocessing ofspent Magnox nuclear fuel fromstations across the UK and also thereprocessing of spent oxide fuel fromoverseas customers.DecommissioningFloc Storage TanksPile Fuel Storage PondFirst Generation MagnoxStorage PondMagnox Swarf Storage SilosPile Fuel Cladding SiloHAL WorkstreamPCM Treatment and StorageWindscaleMagnox ReprocessingOngoing Receipt of AGR FuelThorp ReprocessingWet Inlet Facility (WIF)Nuclear materials are safely used andstored at the <strong>Sellafield</strong> site.Waste ManagementWe deliver an integrated nuclearwaste management programmewhich seeks to reduce wastevolumes arising as part of ourcurrent activities as well as historicoperations, ensuring that waste isstored safely, minimising the risk tothe public and environment.FunctionsOverseas Pu ReturnEffluent ManagementILW Treatment and StorageLLW and Sub LLW TreatmentFunctions include those areas which support the operational andclean-up work at <strong>Sellafield</strong>. They include support services such asenvironment, health and safety (EHS&Q), human resources, financeand communications. The strategic objective for all functions is toprovide effective functional support in the most cost-efficient manner.End StatesThe Decommissioning Programmecovers a group of facilities across<strong>Sellafield</strong> where decommissioningis currently being carriedout. It excludes the specificdecommissioning of all futurefacilities, facilities which are currentlyoperational and facilities which aresubject to retrievals operations.<strong>Sellafield</strong> SiteDecommissioningThe land and groundwaterremediation programme is anextensive piece of work whichstretches out over the next 110 years.Ultimately the programme will deliverthe clean-up of the <strong>Sellafield</strong> site tothe agreed end-state as stated in theNuclear Decommissioning Authority(NDA) StrategyLand and GroundwaterRemediationSocio-economicWe are committed to delivering the mission of our customer, the NDAwhich is to deliver a world-class programme of safe, cost-effective,accelerated and environmentally responsible decommissioning of theUK civil nuclear legacy in an open and transparent manner and withdue regard to the impact on communities affected by our operations.The <strong>Sellafield</strong> PlanFurther information on progress at<strong>Sellafield</strong> <strong>Ltd</strong> can be found on:www.sellafieldsites.com

<strong>12</strong><strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionPile Fuel StoragePond reprocessing intermediate level waste (ILW) and low level waste (LLW)

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 13Risk & Hazard Reduction: Pile Fuel Storage PondOverviewThe Pile Fuel Storage Pond at <strong>Sellafield</strong>is one of the site’s four Legacy Pond andSilo facilities. We are focused on safelydecommissioning these buildings as part ofour hazard and risk reduction programme.Delivery <strong>2011</strong>/<strong>12</strong>: out of pond installation of the sludgeretrieval hood complete transferred to pond corral retrieved from pond the Local Sludge TreatmentPlantAn important step has been takentowards decommissioning the 60year-old storage pond, by retrieving thevery first nuclear fuel out of the pondsince the 1960s. The programme wentahead five years ahead of previousexpectations.The machine known as the sludge retrievalhood has been designed and built in orderto retrieve the sludge from the floor of theopen air pond. It is deployed and operatedremotely so that the sludge can then betransferred into a sludge corral.80 fuel skips have been washed and thesludge transferred to the pond corral, anda total of 43 out of 186 empty skips havenow been exported.In addition, the plant also safely retrieved20 tonnes of contaminated waste from thepond which was transferred to the LowLevel Waste Repository.The construction of the Pile Fuel StoragePond’s Local Sludge Treatment Plant hasbeen completed and is now in its inactivecommissioning phase.Strategic Objectives:1. Safe stewardship of nuclear material2. Restore the basic condition of the asset3. Reduce risk associated with the storageof nuclear material4. Prepare plant for retrievals5. Retrieve the waste6. Decommission all of the facilities andreduce the pond to base slab20 tonnes of contaminated waste has beenretrieved from the Pile Fuel Storage Pond andwill be exported for either disposal as Low LevelWaste or for metal clean-up and recyclingA sludge retrieval hood has been installed intothe pond. Together with other equipment thehood will help with sludge retrieval operationsThe 1st nuclear fuel retrieved out of the Pile FuelStorage Pond for 60 years was transported byflask to an interim storage pond

14<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard Reduction Magnox Storage Pond reprocessing intermediate level waste (ILW) and low level waste (LLW)material

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 15Risk & Hazard Reduction: Overview Pond at <strong>Sellafield</strong> is one of the site’s fourLegacy Pond and Silo facilities. We arefocused on safely decommissioningthese buildings as part of our hazardand risk reduction programme.Delivery <strong>2011</strong>/<strong>12</strong>: developed to remove hazard used to survey pond successfully moved underown power Vessel assembled developed in order to safely removea significant hazard associated with manipulator arm firstly removedredundant pipework, and has now beenused to clean and seal the pond wall.Remotely operated vehicles, also knownas mini submarines have also been usedto survey the contents of the pond.The Skip Handler Machine which is aspecially designed crane, was successfullymoved under its own power for the firsttime in over 10 years.A major step forward has been reachedwith the completion of the assembly <strong>Sellafield</strong> Sludge Plant 1 project, which willhydraulically receive legacy sludge from theFirst Generation Magnox Storage Pond.Strategic Objectives:1. Maintain safe storage of the radioactivewaste inventory2. Retrieve sludge3. Export and immobilise sludge4. Retrieve solids5. Passivate solids6. Decommission all facilities anddemolish the pond to base slabA unique powered remote manipulator armremoved redundant pipework and has nowbeen used to clean and seal the pond wallA specially designed crane, called a skip handlermachine was successfully moved under its ownpower for the first time in over 10 yearsConstruction of a new waste plant has taken amajor step forward by completing assembly ofthe first Buffer Storage Vessel for the <strong>Sellafield</strong>Sludge Packaging Plant project

16<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionMagnox SwarfStorage Silos (Magnox swarf and miscellaneous intermediate levelwaste)

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard Reduction: Magnox Swarf Storage SilosOverviewThe Magnox Swarf Storage Silos at<strong>Sellafield</strong> is one of the site’s four LegacyPond and Silo facilities. We are focusedon safely decommissioning thesebuildings as part of our hazard and riskreduction programme.Delivery <strong>2011</strong>/<strong>12</strong>: (LAR) Programme removed Machine manufacture two compartments Plant to be built programme exceeded its stretchtarget of 320m 3 removed from the facility to date.Completion of the Silo Emptying Machine2 mobile cave manufacture has takenplace and has now been handed over forcommissioning. This is the first of threemobile caves that will be used for theretrieval of intermediate level waste.Two routine cooling systems have beenreinstated to compartments in the 1st and3rd extensions of the facility.A multi million pound Nitrogen Plant isbeing installed at the Magnox SwarfStorage Silos replacing a 30 year oldexisting facility. It is the largest taskmanaged as part of the Asset RestorationProject and enables the continuation of thenitrogen inerting system.Strategic Objectives:1. Maintain continued safe storage of theradioactive waste inventory2. Restore asset and systems to fit forpurpose state3. Prepare the asset and install retrievalsequipment4. Retrieve inventory5. Process and immobilise inventory in theSilos Direct Encapsulation Plant6. Decommissioning of all facilitiesConstruction of the Box Transfer Facility at<strong>Sellafield</strong> is under wayCompletion of the Silo Emptying Machine 2mobile cave manufacture has been completedand handed over for commissioningA multi million pound Nitrogen Plant is beinginstalled at the Magnox Swarf Storage Silos,replacing a 30 year old existing facility

18<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionPile FuelCladding Silo for intermediate level waste (ILW) to be constructed at<strong>Sellafield</strong> operations ceased enable the building to continue to store waste safely.The next task in the programme is to safely retrieve thewaste and store it in compact concealed units

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 19Risk & Hazard Reduction: Pile Fuel Cladding SiloOverviewThe Pile Fuel Cladding Silo at <strong>Sellafield</strong>is one of the site’s four Legacy Pond andSilo facilities. We are focused on safelydecommissioning these buildings as part ofour hazard and risk reduction programme.Delivery <strong>2011</strong>/<strong>12</strong>: for three waste retrievalcontracts constructed to the 10.46metre level design detail complete.£160 million has been awarded for threewaste retrieval contracts, the contractsare for the design and manufacture ofthe specialised waste retrieval modulesand for constructing and manufacture ofthe Waste Retrieval Facility (WRF).This contract will also include the buildingand operation of a 63 tonne semi goliathcrane which will handle the wastepackages.The WRF superstructure construction hasreached the 10.46 metre level. The WRFis being built on the side of the existingstructure and will also house the semigoliath crane.The retrieval access penetration designdetail has also been completed for theWRF.Strategic Objectives:1. Maintain continued safe storage of theradioactive waste inventory2. Prepare for retrievals3. Retrieve inventory for interim storageprior to treatment4. Build treatment plant to immobilise thewaste5. Immobilise inventory ready for longterm storage6. Decommission the facilities£160 million contract was awarded for three wasteretrieval contracts to design and manufacturethe specialised waste retrieval modules and forconstructing the Waste Retrieval Facility (WRF)The Waste Retrieval Facility (WRF) superstructureto retrieve waste from the Pile Fuel CladdingSilo has reached the 10.46 metre level in itsconstruction programmeA artist’s impression of the Waste RetrievalFacility which is being constructed opposite thePile Fuel Cladding Silo

20<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionHALWorkstream reprocessing irradiated nuclear fuel called vitrification vitrified residue is returned to the country of origin

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 21Risk & Hazard Reduction: HAL WorkstreamOverview high level waste and is a by-product ofreprocessing spent nuclear fuel. It is treatedat <strong>Sellafield</strong> in the vitrification plant whereit is converted into a solid stable form fortransport and long term storage.Delivery <strong>2011</strong>/<strong>12</strong>: to serviceThe Waste Vitrification line 3 hassuccessfully returned to servicefollowing all delivery of the enhancedsafety measures.This enabled the Higher Active Liquor Plant to process 2,329teU (tonnesequivalent uranium)Strategic Objectives:1. Maintain safe operation of all facilities2. Receive, process and store HAL3. Processing the legacy HAL stocks tobuffer levels by 20144. Design, construct and operateadditional evaporative capacity5. Vitrify the HAL into solid waste6. Safely store vitrified HAL7. Export vitrified HAL to overseascustomers8. Remove tanks heels/Post OperationalClean Out (POCO)of Highly Activefacilities9. Export vitrified (UK origin) HAL to anational Geological Disposal Facility10. Decommission the Highly ActivefacilitiesVitrified high level waste is stored in the VitrifiedProduct Store at <strong>Sellafield</strong>Historic construction of the HAL evaporation and storage facilities at <strong>Sellafield</strong>

22<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionPCM Treatment& Storage a result of a range of operations maintenance and decommissioning <strong>Sellafield</strong> is stored in steel drums in modern engineereddrum stores

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 23Risk & Hazard Reduction: PCM Treatment & StorageOverview with plutonium during operations areclassed as being ‘plutonium contaminatedmaterials’. These are treated at <strong>Sellafield</strong> asa form of intermediate level waste and assuch are grouted in cement which makes thematerial suitable for long term storage.Delivery <strong>2011</strong>/<strong>12</strong>: Accident for PlutoniumContaminated MaterialTeam Contaminated Material(PCM) processed passivatedThe PCM programme operatorscelebrated the achievement of reaching5 years without a Lost Time Accident by North West Air Ambulance.The PCM programme for the last twoconcurrent years has successfullyprocessed in excess of 2,000 drumsannually, which means that in last twoyears over 25% of the plant’s total lifetimethroughput has been processed.A record of 40kg of plutonium has beenpassivated in one year through the plantfeed which has focused onto higherhazard drums in the store.Strategic Objectives:1. Maintain safe operation of allassociated facilities2. Maximise the utilisation of existingtreatment capability3. Ensure adequate storage capacity andtreatment capability for the lifetimeof plutonium contaminated materialarising4. Transfer historical plutoniumcontaminated material to moderncontainment5. Ensure all waste products aredisposable6. Optimise waste packing fractions inorder to minimise volumes for storageand disposal7. Decommission all facilitiesThe Plutonium Contaminated Material programmeoperators safely reached 5 years without a singlelost time accident and donated a cheque for£2,000 to the North West Air AmbulanceA plutonium contaminated material waste drumbeing loaded into an assay monitorPlutonium contaminated material drums beingtransported by rail

24<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Risk & Hazard ReductionWindscale reducing the hazard associated with the building allowing us to transfer resources to high hazard work

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 25Risk & Hazard Reduction: WindscaleOverviewWindscale was historically a separatelicensed site located on the <strong>Sellafield</strong>site. On 1 April 2008 the site licence forWindscale was transferred to <strong>Sellafield</strong> <strong>Ltd</strong>,integrating the Windscale and <strong>Sellafield</strong>sites. It comprises three reactors, two of in 1981. Decommissioning activities beganin the mid 1980s.Delivery <strong>2011</strong>/<strong>12</strong>: cooled Reactor completelydecommissioned agreed for WindscaleTrenches Chimney filter gallerydecommissioningDecommissioning of the Windscale reached a significant milestone as itcomes to the end of its 20 years ofdecommissioning. The final section ofthe membrane was safely removed fromthe reactor’s concrete bioshield, markingthe successful completion of the finalreactor decommissioning campaign.The Best Available Techniques wasagreed at a workshop involving key localstakeholders, the environment agency andthe Office for Nuclear Regulation, whichwill be used for controlling the contentsof the Windscale Trenches until finalremediation takes place to the meet theend state of the site.Work has also restarted on thedecommissioning of the Pile Chimney filtergallery which will see the top filter gallerycompleted removed.Strategic Objectives:1. Maintain safe operation of all facilities2. Operate Active Handling Facility fuelelement facilities3. Decommission facilitiesDecommissioning under way inside theWindscale Advanced Gas-cooled ReactorThe view of the pile chimney cappedafter being dismantledThe Best Available Techniques were agreed forthe controlling the contents of the WindscaleTrenches until final remediation can take place

26<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Spent Fuel ManagementMagnoxReprocessing and plutonium components of spent Magnox fuel from

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Spent Fuel Management: Magnox ReprocessingOverviewThe Magnox Reprocessing plant at <strong>Sellafield</strong>reprocesses spent nuclear fuel from Magnoxnuclear power stations across the country –including <strong>Sellafield</strong>’s Calder Hall station.Delivery <strong>2011</strong>/<strong>12</strong>: remains to be processed Calder Hall and reprocessedMagnox reprocessing has passedthe milestone of 4,000 tonnes offuel remaining to process and hassuccessfully decanned and reprocessed603 tonnes of fuel which is the highestyearly total since 2004.Calder Hall commenced its defuellingprogramme and also celebrated sevenyears or 1.3 million man hours ofoperations without a lost time accident.To mark the occasion, NuclearManagement Partners (NMP) donatedcheques of £1,000 each to two charities ofthe workforce’s choice.Strategic Objectives1. Maintain continued safe storage of fuel,products and radioactive material2. Maintain safe operation of all facilities3. Receive, store and reprocess ~4,400teMagnox fuel in line with MagnoxOperating Programme4. Decommission all facilitiesWe will safely reprocess spent Magnox fuel,supporting the defuelling of the Magnox powerstations. We will also safely manage the wastegenerated (above)Removal of ducts from the Calder Hall reactorsat <strong>Sellafield</strong>Magnox Reprocessing will support the defuellingoperations at the Calder Hall station at <strong>Sellafield</strong>

28<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Spent Fuel ManagementOngoing Receipt into the Fuel Handling Plant at <strong>Sellafield</strong> it for interim storage and reprocessing in line withcontractual commitments stored in the Thorp Receipt and Storage pond pending Disposal Facility

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 29Spent Fuel Management: Overview Fuel Handling Plant at <strong>Sellafield</strong>. The fuel isdismantled and consolidated to prepare it forinterim storage and reprocessing.Delivery <strong>2011</strong>/<strong>12</strong>: The Managing Director’s overall award Improvement Team.The team showed great commitment inexecuting work in any operational arearanging from manufacturing through toservice provision.Strategic Objectives:1. Maintain safe operation of all facilities2. Receive and prepare AGR fuel forreprocessing or interim storage in linewith contractual commitments3. Make fuel available to Thorp forreprocessing4. Provide enough pond storage to allowcontinued receipt of AGR fuel5. Provide safe interim storage of AGRfuel pending decision to package fordisposal6. Condition and export fuel to theGeological Disposal Facility whenavailable7. Decommission all facilitiesThe Overall Managing Director’s BusinessExcellence Award went to the AGR DismantlingThroughput Improvement Team for great workcommitmentWhen delivered to the <strong>Sellafield</strong> site, spent AGRfuel is dismantled in the fuel handling plantSpent nuclear fuel is kept in storage ponds onthe <strong>Sellafield</strong> site for a period of cooling

30<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Spent Fuel ManagementThorp Reprocessing engineering projects employing up to 5,000 contractorson site and supporting a further 10,000 with suppliersand subcontractors Separation plants in 1985

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 31Spent Fuel Management: Thorp ReprocessingOverviewThe Thermal Oxide Reprocessing Plant(Thorp) at <strong>Sellafield</strong> combines all of thefacilities needed to reprocess spent oxide and foreign spent fuel.Delivery <strong>2011</strong>/<strong>12</strong>: target of 419 tonnes implemented – 52 transfer racksremoved– 104 Multi Element off site for disposal Examination materialsreceived into ThorpThorp achieved its best shearingperformance since 2004 and sheared430 tonnes against a year end target of419 tonnes.A major achievement for Thorp in theenhancement of contamination controlwhen the radiological rollback programmewas rolled out in Thorp.The ongoing pond refurbishmentprogramme has celebrated successfullyremoving 52 transfer racks from Thorppond along with 104 Multi Element Bottles.A further 54 bottles have been despatchedoff the site for final disposal.Thorp received the first Post-IrradiationExamination materials into the receipt andstorage area in readiness of support to thehigh level hazard reduction programme forthe Pile Fuel Storage Pond.Strategic Objectives:1. Maintain safe operation of all facilities2. Reprocess all contracted overseasOxide fuel3. Reprocess the contracted amount ofAGR fuel4. Reprocess sufficient AGR fuel to allowcontinued receipt of fuel from the AGRstations5. Long term safe storage of UK-deriveduranium and return of overseasuranium to customers6. Decommission all facilitiesOnce inside Thorp Receipt and Storage the fuel isremoved from its transport flaskA £20m project was completed to install areplacement Medium Active Salt Free Evaporator(MASFE) into Thorp. This was a predicted activityin the plant designThe vitrification plant at <strong>Sellafield</strong> processes thehigh level waste produced in Thorp and turns itinto a solid stable form

32<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Spent Fuel ManagementThe Wet InletFacility (WIF) on behalf of our customers on site used to manage our customers’ fuel

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 33Spent Fuel Management: The Wet Inlet Facility (WIF)OverviewThe Wet Inlet Facility is one of our storageponds on the <strong>Sellafield</strong> site used to manageshort to medium term storage of ourcustomers’ fuel.Delivery <strong>2011</strong>/<strong>12</strong>: transfersThe Wet Inlet Facility (WIF) hasexceeded the target number of internalfuel transfers and enabled the transferof Post-Irradiation Examination (PIE)materials from the Active HandlingFacility.Strategic Objectives:1. Safely store customer fuel andcomponents2. Store fuel and components in the FirstGeneration Oxide Fuel Storage Pond3. Transfer customer fuel and componentsfrom the First Generation Oxide FuelStorage Pond to the WIF4. Complete specific activities as requiredby customers to support their strategicobjectives5. Receive into the WIF fuel delivered fromoff site6. Maintain customers’ external flasksand flask ancillaries in ‘ready to deploystate’7. Export fuel for final treatment anddisposal8. All facilities in the above programmewill be decommissioned postoperationsAn elevated view of the WIFThe Flask Maintenance Facility supportsboth Magnox and Thorp reprocessing aswell as the defuelling of Magnox stations

34<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Decommissioning<strong>Sellafield</strong> SiteDecommissioning facilities across <strong>Sellafield</strong> where decommissioning iscurrently being carried out for future decommissioning but excludes the specificdecommissioning of:– All future facilities– Facilities which are currently operational– Facilities subject to retrievals operations

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 35Decommissioning: <strong>Sellafield</strong> Site DecommissioningOverviewOnce buildings are no longer operational theygo through a process called decommissioningwhich includes decontamination anddemolition. The Decommissioning Programmeat <strong>Sellafield</strong> completes the decommissioningof some key non operational buildings anduses the learning from this to set the strategyfor the future decommissioning for theremaining facilities on the site.Delivery <strong>2011</strong>/<strong>12</strong>: completed on theSeparation Area Ventilation(SAV) project manufacturing plantdecommissioned demolished begins in legacy storeThe Separation Area Ventilation Stackhas seen three major milestonescompleted with the construction ofthe Control Room and Fan Plant Roomtaking place and also the construction The decommissioning of a redundant fuelmanufacturing plant, which producedfuel for the Prototype Fast Reactor hasalso been safely completed along witha series of redundant historic plutoniumcontaminated material buildings.The Hurricane Run buildings have alsobeen successfully and safely demolishedwhich were originally constructed toprocess plutonium solutions into solidmetal as part of the Hurricane Run for the1st atomic test in 1952.A new overbuilding has allowed retrievalsof storage cell lids to begin along withthe inspection of waste in a legacy wastestorage facility.Strategic Objectives1. Safe decommissioning of facilities2. Develop and coordinate long termdecommissioning strategyThe Hurricane Run buildings have been safelydemolished which were originally constructedto process plutonium solutions into solid metalas part of the Hurricane Run for the 1st AtomicTest in 1952Decommissioning of a redundant fuelmanufacturing plant safely completeThe Separation Area Ventilation (SAV) projectreached another milestone with the testing ofthe ventilation stack monitoring equipment

36<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Nuclear MaterialsOverseasPu Return fabricated into new fuel following reprocessing

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Nuclear Materials: Overseas Pu ReturnOverviewThe Overseas Pu Returns programme allowshighly active waste to be returned to thecustomer in accordance with contractual contracts for reprocessing signed with returned to the customer of origin.Delivery <strong>2011</strong>/<strong>12</strong>: shipment to JapanIn August <strong>2011</strong> the NuclearDecommissioning Authority announcedthe closure of the <strong>Sellafield</strong> MOX Plantdue to the impact on the Japanese The three transport flasks, containing76 canisters of Highly Active Waste wastransported to Japan by a purpose builtvessel called the Pacific Grebe. Returns has been successfully shippedback to Japan.Strategic Objectives:1. Decommission facilities76 canisters of Highly Active Waste (HAW) wassuccessfully shipped back to Japan in threetransport flasks. This was the 2nd shipment tobe returned in the Vitrified Residue ReturnsThe <strong>Sellafield</strong> MOX plant converted overseasplutonium derived from reprocessing into newfuel for export to customersThe specially designed vessel, the Pacific Grebetransporting the highly active waste

38<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Waste ManagementManagement from <strong>Sellafield</strong> operations reprocessing and decommissioning Exchange Plant

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 39Waste Management: OverviewAt <strong>Sellafield</strong> an integrated nuclear wastemanagement programme is in place whichseeks to reduce waste volumes arising aspart of current activities as well as historicoperations. It ensures that waste is storedsafely, minimising the risk to the public andthe environment.Delivery <strong>2011</strong>/<strong>12</strong>: Organisation of NuclearOperators visitA successful WANO visit took placewithin the facility, where the team wererecognised as striving for excellence inall areas of operations.Strategic Objectives:1. Maintain safe operations2. Provision of adequate low and mediumactive effluent management capability3. Provision of adequate solvent managementcapability4. Ensure continuous provision of effluentmanagement capability to support hazardreduction activities5. Provision of adequate solid waste storagecapacity to support ongoing effluentabatement arisings from risk and hazardreduction activities6. Develop a process to retrieve and exportsludge and sand/clinoptilolite from the SiteIon Exchange Plant bulk storage tanks7. Retrieve and export sludge and sand/clinoptilolite from the Site Ion ExchangePlant bulk storage tanks8. Maintain the assets and ensure thecontinued safe storage of the radioactivewaste inventory9. The removal of residual and potentiallymobile activity using existing installedequipment and operations staff, or bymaking small modifications, typicallyincluding deployment of small new tools toremove liquor heels and solids and somedecontamination activities10. To safely decommission the effluent facilitiesafter Post Operational Clean Out (POCO) to anagreed end-state11. Monitor effluent management performanceagainst the guidelines of UK Governmentpolicy and the UK Regulatory FrameworkThe Site Ion Exchange Effluent Plant helps tomaintain thermal conditions of the fuel handlingplant (above)A successful World Organisation of NuclearOperators (WANO) visit took place in the effluentdirectorate, where the team were recognised asstriving for excellence

40<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Waste ManagementILW Treatmentand Storage radioactive sludge historical operations and risk and hazard reduction work to ensure that <strong>Sellafield</strong> has the necessary buildings toprocess and provide interim storage for ILW

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 41Waste Management: ILW Treatment and StorageOverviewThere are three types of nuclear waste;low level, intermediate level and high levelwaste. This programme covers the treatmentand storage of intermediate level nuclearwaste at <strong>Sellafield</strong>.Delivery <strong>2011</strong>/<strong>12</strong>: in Encapsulation Product without a lost time accidentThe Encapsulation Product Storesexceeded all their commitments, withrecord breaking imports from the its dismantling program while net The Miscellaneous Beta Gamma WasteStore celebrated a total of 15 years ofsafety without a lost-time accident.Strategic Objectives:1. Provide safe storage capability tosupport hazard reductionand clean-up2. Provide adequate treatment capabilityto support hazard reduction andclean-up3. Ensure delivery of key projects withinprogramme to support hazard reductionand clean-up (eg the Combined Importand Export Facility and the 3m 3 BoxProject)4. Ensure that waste will be suitable fordisposal to the Geological DisposalFacility5. Decommission facilitiesOperations under way inside the WasteEncapsulation PlantThe excellent safety record at the MiscellaneousBeta Gamma Waste Store (MBGWS) continuedwhen the teams celebrated reaching 15 yearswithout a lost time accident

42<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Waste ManagementLLW and SubLLW Treatment waste and is only slightly radioactive building fabric, metal and concrete the remaining clean material to be reused and then sent to Low Level Waste Repository (LLWR) for disposal

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 43Waste Management: LLW and Sub LLW TreatmentOverviewLow level waste (LLW) makes up the largestphysical volume of radioactive waste and isonly slightly radioactive. We are committedto safely managing low level waste andprocessing it to reduce the volume of wastewhich needs to be disposed of at the LowLevel Waste Repository (LLWR).Delivery <strong>2011</strong>/<strong>12</strong>: exceeded by Low LevelWaste Programme recycledThe Low Level Waste Programmehas exceeded all key programmecommitments across the year. Thisincludes the Waste Monitoring andCompaction Plant continuing tocompact all the <strong>Sellafield</strong> site andexternal consignors arisings priorto disposal at the Low Level WasteRepository.Overall the volume of waste disposedfrom <strong>Sellafield</strong> <strong>Ltd</strong> to the LLWR hascontinued on a four year downward trenddue to better avoidance, minimisation,segregation and recycling.Metal recycling has been very successfulacross the year with a total of 1429 tonnesof metal recycled from active operationson the site.Strategic Objectives:1. Maintain safe operations2. Support delivery of UK Nuclear IndustryLLW Strategy3. Optimise the use of the planned UK LLWdisposal capacity4. Where practicable, avoid the generationof waste5. Characterise, sort and segregate LLWand where possible maximise theuse of exemption orders and enhancein-house capability for sorting andsegregation6. Continue to use existing authorisedwaste routes including specified landfill7. Continue to operate existing wasteinfrastructure efficiently and effectively8. Explore opportunities and make bestuse of the supply chain (both nationallyand internationally) for waste treatmentand disposal9. Work with the national low level wastecontractor at the Low Level WasteRepository to integrate solutions,develop business cases and ensurestrategic fit with UK Nuclear IndustryLLW strategy10. Decommission all facilitiesOur focus is on safely managing low level nuclearwaste while implementing new technology (suchas the wheelabrator seen here) to reduce thevolumes of waste which needs to be disposed ofThe site’s wheelabrator facilities remove surfacecontamination

44<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>End States Remediation an extensive piece of work which stretches out over thenext 110 years the <strong>Sellafield</strong> site to the agreed end-state as stated inthe Nuclear Decommissioning Authority (NDA) Strategy

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 45End States: OverviewRainfall/RechargeRainfall/RechargeSurfaceRunoffMade GroundIrishSeaBeachEhenSpitRiverAnthropogenicRechargeUnsaturatedZoneBeachSpringsPercolationDisposalTrenchWater TableDriftExchange with RiversPerched GroundwaterDrift Groundwater FlowBoreholesUpper GroundwaterContaminantPlumeSandstoneSaline InterfaceOur land and groundwater remediationprogramme will deliver clean-up of the<strong>Sellafield</strong> site to the agreed end-state ofpartial remediation, followed by indefiniteinstitutional control.Regional Groundwater FlowBuriedChannelDelivery <strong>2011</strong>/<strong>12</strong>: Management SystemselectedInformed Solutions has been selectedto provide a Land Quality DataManagement System to enhancethe site’s ground contaminationmanagement programme.The programme will bring together over40 years of contaminated land andgroundwater data into one location.Strategic Objectives:1. Demonstrate compliance withauthorisations, consents and permitsthrough monitoring and assessment2. Develop conceptual models for land andgroundwater remediation on the site3. Mitigate leaks to ground by providing a‘line of control’ around the separationarea4. Remediate contaminated land andgroundwater5. Provide a land characterisation servicefor projects at <strong>Sellafield</strong><strong>Sellafield</strong> <strong>Ltd</strong> purchased a Land Quality DataManagement System to enhance the site’sground contamination management programmeLand and groundwater monitoring is done on andoff the <strong>Sellafield</strong> siteEvery year we publish a groundwater monitoringreport which is available on the <strong>Sellafield</strong> <strong>Ltd</strong>website

46<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>FunctionsFunctions operational and clean-up work at <strong>Sellafield</strong> health and safety (EHS&Q), human resources, financeand communications capability also provide services to other sites in theNDA’s estate effective functional support in the most cost-efficientmanner

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>FunctionsOverviewThe Functional Portfolio provides support tothe site mission, ensuring that site activities Functions scope of work covers these areas:Engineering, Quality, Transformation, EHS&Q,HR, Communications and Commercial andContract Management.Delivery <strong>2011</strong>/<strong>12</strong>: without a lost time accident Nuclear Power Operators)International Programme Alliance Frameworkcontract agreed programme completed project completedA multi million pound contract for apprentice training for approximately 80young people a year, further and highereducation courses, such as foundationdegrees in a number of nucleardisciplines and short courses rangingfrom safety to technical subjects.The Functions Directorate has alsocelebrated 3.7 million man hours with asingle lost time accident.The ACEMAN programme was rolled out bythe Transformation directorate to implementa line of sight tool. It provides a platform tofix the barriers which prevent the delivery ofexcellence in the business.As well as being members of the WorldAssociation of Nuclear Operators (WANO)for the last six years, <strong>Sellafield</strong> <strong>Ltd</strong> had nowbecome the latest nuclear company to jointhe Institute of Nuclear Power Operators(INPO) International programme.The Design Services Alliance Frameworkcontract, known as the Design ServicesAlliance, is projected to extend for 15 yearsand is the first of its kind for <strong>Sellafield</strong> <strong>Ltd</strong>.The £1.5 billion is the first of an anticipated£9 billion worth of long-term contractswhich will be let by <strong>Sellafield</strong> <strong>Ltd</strong> over thenext two years under a new approach tosubcontracting.The beach monitoring programme wassuccessfully completed, achieving its targetof 150 hectares. Additionally programmes ofseabed sediment grab sampling work weresuccessfully delivered which is helping tocharacterise the seabed.The successful completion of the Hypalonreplacement project took place with amulti-disciplined team led by the TechnicalDirectorate and two major worldwide glovesuppliers. They assessed new materialsand carried out testing in order to seekapproved alternatives for continuous glovebox operations.A multi million pound contract was awarded approximately 80 young people a yearThe functions directorate celebrated more than accident<strong>Sellafield</strong> <strong>Ltd</strong> has now become the latest nuclearcompany to join the Institute of Nuclear PowerOperators (INPO) International Programme

48<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong>Socio-economicSocio-economic Energy Coast Masterplan and Communities that Work development and social planning, these strategies willdeliver a positive future for West Cumbria partners Nuclear Management Partners and the NuclearDecommissioning Authority, is committed to supportingthe West Cumbrian economic development agenciesand local authorities in delivering their vision

<strong>Annual</strong> <strong>Review</strong> <strong>2011</strong>/<strong>12</strong> 49Socio-economicOverviewThe <strong>Sellafield</strong> site has evolved over the pasteight decades. It has served many purposes,from supporting the war effort to helping Delivery <strong>2011</strong>/<strong>12</strong>: took part in scienceworkshops Scheme deliveredsuccessfully Technology, Engineering andMathematics programme(STEM)More than 4,000 primary age childrentook part in science related workshopswithin the <strong>Sellafield</strong> and Risley areas.The very 1st Government Pilot Schemefor the National Citizen Service wascompleted through the BusinessImprovements team who worked with year10/11 students to deliver the scheme.The STEM programme reached its 10year anniversary, with over 250 activeambassadors from <strong>Sellafield</strong> <strong>Ltd</strong> workingwith local schools.Strategic Objectives:1. Act as a responsible employer aligningstaffing levels and skills to the futurework programme of the site2. Align NDA, NMP and <strong>Sellafield</strong> <strong>Ltd</strong>socio-economic investment3. Channel the majority of socio-economicinvestment through Britain’s EnergyCoast4. Through Britain’s Energy Coast wewill support local regeneration anddevelopment projects5. Maintain our role as corporate partnersto the West Cumbrian community –supporting local authorities as theydeliver their vision for the areaMore than 4,000 primary aged children took partin science related workshops within the <strong>Sellafield</strong>and Risley areasOur employees are very much part of thecommunity, undertaking key roles such ascouncillors, school governors and rescuevolunteersOur STEM ambassadors are inspiring rolemodels for school children