Y-TG, R-410A ZJ/ZR/ZF Series 15-25 ton, 60 Hertz - Usair-eng.com

Y-TG, R-410A ZJ/ZR/ZF Series 15-25 ton, 60 Hertz - Usair-eng.com

Y-TG, R-410A ZJ/ZR/ZF Series 15-25 ton, 60 Hertz - Usair-eng.com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

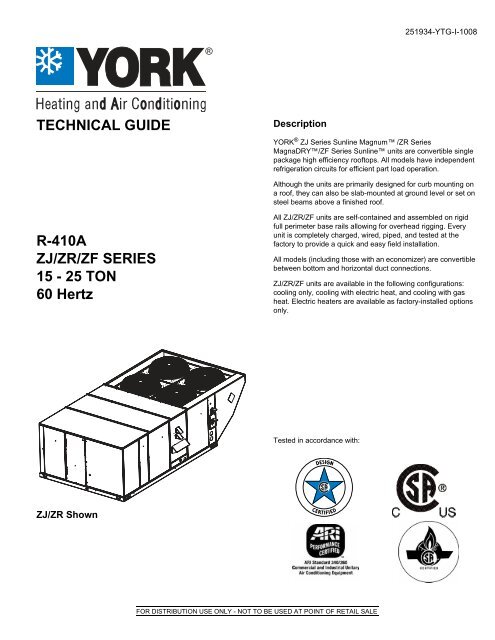

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008 TECHNICAL GUIDEDescriptionYORK ® <strong>ZJ</strong> <strong>Series</strong> Sunline Magnum /<strong>ZR</strong> <strong>Series</strong>MagnaDRY/<strong>ZF</strong> <strong>Series</strong> Sunline units are convertible singlepackage high efficiency rooftops. All models have independentrefrigeration circuits for efficient part load operation.Although the units are primarily designed for curb mounting ona roof, they can also be slab-mounted at ground level or set onsteel beams above a finished roof.R-<strong>410A</strong><strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> SERIES<strong>15</strong> - <strong>25</strong> TON<strong>60</strong> <strong>Hertz</strong>All <strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> units are self-contained and assembled on rigidfull perimeter base rails allowing for overhead rigging. Everyunit is <strong>com</strong>pletely charged, wired, piped, and tested at thefactory to provide a quick and easy field installation.All models (including those with an economizer) are convertiblebetween bottom and horizontal duct connections.<strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> units are available in the following configurations:cooling only, cooling with electric heat, and cooling with gasheat. Electric heaters are available as factory-installed optionsonly.Tested in accordance with:<strong>ZJ</strong>/<strong>ZR</strong> ShownFOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008Table of ContentsDescription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>15</strong>Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 962 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008Component Location(<strong>ZJ</strong> shown)Simplicity ® Control Board2” Disposable Filters(4” Filters Optional)Slide In/ Plug InInternal Economizer(Optional)110 Volt ConvenienceOutlet (“Powered” or“Non-Powered” Optional)Disconnect Location(Optional Disconnect Switch)Bottom Power andControl Wiring EntryPower Ventor MotorElectric Heater Location(Optional Electric/Electric Units)Copper Tube/Aluminum FinEvaporatorCoilsThermalExpansionValve1” NPTCondensate DrainFilter Drier(Solid Core)Belt DriveBlower Motor14 GaugeBase Railswith Lifting HolesLocation of VFD (Optional)Location of VFD Bypass (Optional)Copper Tube/Aluminum FinCondenser Coils4-High Efficiency Scroll CompressorsJohnson Controls Unitary Products 3

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008valve, if applicable, and the temperature limit switch ongas and electric heat units. The unit control board willalarm on ignition failures, <strong>com</strong>pressor lockouts andrepeated limit switch trips.• Nuisance Trip Protection and Strikes - To preventnuisance trouble calls, the control board uses a “threetimes, you’re out” philosophy. The high and lowpressureswitches and the freezestats must trip threetimes within two hours before the unit control board willlock out the associated <strong>com</strong>pressor.• On Board Diagnostics - Each alarm will energize atrouble light on the thermostat, if so equipped, and flashan alarm code on the control board LED. Each high andlow-pressure switch alarm as well as each freezestatalarm has its own flash code. The control board savesthe five most recent alarms in memory, and these alarmscan be reviewed at any time. Alarms and programmedvalues are retained through the loss of power.• Reliable - From the beginning - All units undergo<strong>com</strong>puter automated testing before they leave the factory.Units are tested for refrigerant charge and pressure, unitamperage, and 100% functionality. For the long term - Allunits are painted with a long lasting, powder paint thatstands up over the life of the unit. The paint used hasbeen proven by a 1000 hour salt spray test.• Full Perimeter Base Rails - The permanently attachedbase rails provide a solid foundation for the entire unit andprotect the unit during shipment. The rails offer riggingholes so that an overhead crane can be used to place theunits on a roof.• Easy Installation - Gas and electric utility knockouts aresupplied in the unit underside as well as the side of theunit. Utility connections can be made quickly and with aminimum amount of field labor. All units are shipped with2" throw-away filters installed.• Wide Range of Indoor Airflows - All supply air blowersare equipped with a belt drive that can be adjusted tomeet the exact requirements of the job. A high static driveoption is available for applications with a higher CFM and/or static pressure requirement.• Warranty - All models include a 1-year limited warrantyon the <strong>com</strong>plete unit. Compressors and electric heaterelements each carry a 5-year warranty. Aluminized steeland stainless steel tubular heat exchangers carry a 10-year warranty.Factory Installed OptionsYORK ® offers several equipment options factory installed, forthe <strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> <strong>Series</strong>.• Single Input Electronic Enthalpy Economizers -Includes a slide-in / plug-in damper assembly with fullymodulating spring-return motor actuator capable ofintroducing up to 100% outdoor air with nominal 1%leakage type dampers.The enthalpy system contains one sensor that monitorsthe outdoor air and determines when the air is coolenough and dry enough to provide free cooling.The rainhood is painted to match the basic unit and mustbe field-assembled before installing.• BAS-Ready Economizer - Includes a slide-in / plug-indamper assembly with fully modulating spring-returnmotor actuator with zero to 95-degree rotation capable ofintroducing up to 100% outdoor air with nominal 1%leakage type dampers.Actuator requires 2-10 VDC input from an external source,such as a field-installed or factory-installed BAScontroller. BAS-ready actuators have an adjustableauxiliary end-switch for optional power exhaust control.For units with optional VAV or Simplicity® Intelli-Comfort control, a factory-installed, dry bulb sensordetermines if outdoor air temperature is low enough toprovide free-cooling operation. (Field-installed humiditysensors for either outdoor air or outdoor & return airstreams are available for single enthalpy and differentialenthalpy configurations, respectively).The rainhood is painted to match the basic unit and mustbe field-assembled before installing.• Power Exhaust - Our economizer options are availablewith power exhaust. Whenever the outdoor air intakedampers are opened for free cooling, the exhaust fan willbe energized to prevent the conditioned space from beingover-pressurized during economizer operation.The exhaust fan, motor and controls are installed andwired at the factory. The rain hood must be assembledand installed in the field.The power exhaust option can only be used on bottomduct configurations.• Motorized Outdoor Air Intake Damper - Includes aslide-in / plug-in damper assembly with a 2- position,spring return motor actuator which opens to a pre-setposition whenever the supply air blower is operating andwill drive fully closed when the blower unit shuts down.The rain hood is painted to match the basic unit and mustbe field assembled before installing.• Barometric Relief Damper - This damper option can beused to relieve internal building air pressure on units withan economizer without power exhaust. This accessoryincludes a rain hood, a bird screen and a fully assembleddamper. With bottom duct connections, the dampershould be mounted over the opening in the return airpanel. With horizontal ductwork, the accessory should bemounted on the return air duct.• Phenolic Coated Evaporator And Condenser Coils -Special coating process that utilizes Technicoat 10-1"processes. Coating is applied by total immersion of the<strong>com</strong>plete coil for maximum protection.• Electric Heaters - wired for single point power supply.These nickel chromium heater elements are provided withlimit and automatic reset capability to prevent operation atexcessive temperatures.• Variable Air Volume (VAV) - A factory-installed variablefrequency drive (VFD), mounted in the Blower Access<strong>com</strong>partment, is used to control the speed of the indoorblower motor in order to maintain a constant static6 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008Control Options• BAS - Building Automation System Controls(available on two-system cooling product only).Simplicity INTELLI-Comfort Control - The York ®Simplicity INTELLI-CO 2 sensor to perform DifferentialDemand Ventilation. It uses a Patented ComfortVentilation algorithm to provide <strong>com</strong>fortable ventilation airtemperature. The patented economizer-loading algorithmwill protect the equipment when harsh operatingconditions exist. Humidity in the occupied space or returnduct can be monitored and controlled via humidity sensorsand the on-board connection for hot gas re-heat system. Ituses the INTELLI-Start algorithm to maximize energysavings by recovering the building from the UnoccupiedSetpoints to the Occupied Setpoints just in time for theOccupied Time Period to begin. The SimplicityINTELLI-Comfort balances space temperature,ventilation air temperature, CO 2 and humidity for ultimate<strong>com</strong>fort.Simplicity INTELLI-Comfort with ModLINCControl - The York® Simplicity INTELLI-Comfort withModLINC control is factory installed. It includes all thefeatures of the INTELLI-Comfort control with anadditional control to translate <strong>com</strong>munications fromMODBUS to the BACnet MSTP protocol.Novar® BAS Control - The Novar® building automationsystem controller is factory installed. Incudes supply airsensor, return air sensor, dirty filter indicator switch, andair proving switch.Johnson Controls BAS Control - The Johnson ControlYK-UNT-1126 building automation system controller isfactory installed. Includes supply air sensor, return airsensor, dirty filter indicator switch, and air proving switch.CPC BAS Control - The Computer Process ControlsModel 810-30<strong>60</strong> ARTC Advanced Rooftop buildingautomation system controller is factory installed. Includessupply air sensor, return air sensor, dirty filter indicatorswitch and air proving switch.Honeywell BAS Control - The Honeywell W7750Cbuilding automation system controller is factory installed.Includes air supply sensor, return air sensor, dirty filterindicator switch, and air proving switch.Field Installed AccessoriesYORK ® offers several equipment accessories for fieldinstallation, for the <strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> <strong>Series</strong>.• Single Input Electronic Enthalpy Economizers -Includes a slide-in / plug-in damper assembly with fullymodulating spring-return motor actuator capable ofintroducing up to 100% outdoor air with nominal 1%leakage type dampers.The enthalpy system contains one sensor that monitorsthe outdoor air and determines when the air is coolenough and dry enough to provide free cooling.The rainhood is painted to match the basic unit and mustbe field-assembled before installing.• Motorized Outdoor Air Intake Damper - Includes aslide-in / plug-in damper assembly with a 2-position,spring return motor actuator which opens to some pre-setposition whenever the supply air blower is operating andwill drive fully closed when the blower unit shuts down.The rain hood is painted to match the basic unit and mustbe field assembled before installing.• Roof Curbs - Fourteen-inch high roof curbs provide awater-tight seal between the unit and the finished roof.These full perimeter curbs meet the requirements of theNational Roofing Contractors Association (NRCA) and areshipped knocked-down for field assembly.They're designed to fit inside the base rails of the unit andinclude both a wood nailing strip and duct hanger supports.• High Altitude Natural Gas - Burner orifices and pilotorifices are provided for proper furnace operation ataltitudes up to 6,000 feet.• Propane - Burner orifices, pilot orifices and gas valve partsare provided to convert a natural gas furnace to propane.• High Altitude Propane - Burner orifices and pilot orificesare provided for proper furnace operation at altitudes upto 6,000 feet. This accessory supplements the basicpropane conversion kit.• Side Duct Flanges - One-inch flanges replace the supplyand return air panels on the rear of the unit to ac<strong>com</strong>modatehorizontal duct connections. These flanges can also be usedindividually for bottom supply / horizontal return or horizontalsupply/bottom return. They cannot be used on units withpower exhaust.• Barometric Relief Damper - This damper accessory canbe used to relieve internal building air pressure on unitswith an economizer without power exhaust. Thisaccessory includes a rain hood, a bird screen and a fullyassembled damper. With bottom duct connections, thedamper should be mounted over the opening in the returnair panel. With horizontal ductwork, the accessory shouldbe mounted on the return air duct.• High Static Drive - May include a belt, blower pulley,motor pulley or a motor change to enhance blowerperformance.• Enthalpy Accessory Control Kit - This kit contains therequired <strong>com</strong>ponents to convert a single enthalpyeconomizer to dual enthalpy.• Burglar Bars - Mount in the supply and return openingsto prevent entry into the duct work.• Flue Exhaust Extension Kit - In locations with wind orweather conditions which may interfere with properexhausting of furnace <strong>com</strong>bustion products, this kit can beinstalled to prevent the flue exhaust from entering nearbyfresh air intakes.• Wood Skid - Allows unit to be handled with 90" forks.• CO 2 Sensor - Senses CO 2 levels and automaticallyoverrides the economizer when levels rise above thepresent limits.• Coil Guard - Customers can purchase a coil guard kit toprotect the condenser coil from damage. This is not a hailguard kit.8 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008• Phase Monitors - Designed to prevent unit damage. Thephase monitor will shut the unit down in an out-of phasecondition.Guide SpecificationsGeneralUnits shall be manufactured by Johnson Controls UnitaryProducts in an ISO 9001 certified facility.York's <strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong> units are convertible single package units. <strong>ZJ</strong>models have four independent refrigerant circuits and <strong>ZR</strong>/<strong>ZF</strong>models have dual independent refrigerant circuits for efficientpart load operation and maximum <strong>com</strong>fort control. Although theunits are primarily designed for curb mounting on a roof, theycan also be slab-mounted at ground level or set on steel beamsabove a finished roof. Cooling only, cooling with gas heat andcooling with electric heat models are available with a widevariety of factory-mounted options and field-installedaccessories to make them suitable for almost every application.All units are self-contained and assembled on full perimeterbase rails with holes in the four corners for overhead rigging.Every unit is <strong>com</strong>pletely piped, wired, charged and tested at thefactory to simplify the field installation and to provide years ofdependable operation. All models (including those with aneconomizer) are suitable for either bottom or horizontal ductconnections. Models with power exhaust are suitable for bottomduct connections only. For bottom duct, remove the sheet metalpanels from the supply and return air openings through thebase of the unit. For horizontal duct, replace the supply andreturn air panels on the rear of the unit with a side duct flangeaccessory. All supply air blowers are equipped with a belt drivethat can be adjusted to meet the exact requirements of the job.A high static drive option is available for applications with ahigher CFM and/or static pressure requirement.<strong>ZJ</strong>/<strong>ZR</strong> models have 4 condenser fan motors and <strong>ZF</strong> modelshave 2 condenser fan motors. All <strong>com</strong>pressors includecrankcase heat and internal pressure relief. Every refrigerantcircuit includes an expansion valve, a liquid line filter-drier, adischarge line high pressure switch and a suction line with afreezestat and low pressure/loss of charge switch. The unitcontrol circuit includes a 75 VA transformer, a 24-volt circuitbreaker and a relay board with two <strong>com</strong>pressor lockout circuits,a terminal strip for thermostat wiring, plus an additional set ofpin connectors to simplify the interface of additional fieldcontrols. All units have long lasting powder paint cabinets with1000 hour salt spray test approval under ASTM-B117procedures. All models are CSA approved. All models include a1-year limited warranty on the <strong>com</strong>plete unit. Compressors andelectric heater elements carry an additional 4-year warranty.Aluminized steel tubular heat exchangers carry an additional 9-year warranty.Description<strong>ZJ</strong> units shall be factory-assembled, single packaged, <strong>ZJ</strong>***NElectric Cooling/Gas Heat, <strong>ZJ</strong>***C/E Electric Cooling/OptionalElectric Heat, designed for outdoor mounted installation. The <strong>15</strong><strong>ton</strong> unit shall have a minimum EER rating of 12.4. The 17.5 <strong>ton</strong>unit shall have a minimum EER rating of 12.1. The 20 <strong>ton</strong> unitshall have a minimum EER rating of 11.6. The <strong>25</strong> <strong>ton</strong> unit shallhave a minimum EER rating of 10.4.<strong>ZR</strong> units shall be factory-assembled, single packaged, <strong>ZR</strong>***NElectric Cooling/Gas Heat, <strong>ZR</strong>***C/E Electric Cooling/OptionalElectric Heat, designed for outdoor mounted installation. The <strong>15</strong><strong>ton</strong> unit shall have a minimum EER rating of 11.6. The 20 <strong>ton</strong>unit shall have a minimum EER rating of 12.1. The <strong>25</strong> <strong>ton</strong> unitshall have a minimum EER rating of 10.5.<strong>ZF</strong> units shall be factory-assembled, single packaged, <strong>ZF</strong>***NElectric Cooling/Gas Heat, <strong>ZF</strong>***C/E Electric Cooling/OptionalElectric Heat, designed for outdoor mounted installation. The <strong>15</strong>and 17.5 <strong>ton</strong> units shall have a minimum EER rating of 11.0.The 20 and <strong>25</strong> <strong>ton</strong> units shall have a minimum EER rating of 10.They shall have built-in field convertible duct connections fordown discharge supply/return or horizontal discharge supply/return, and be available with factory installed options or fieldinstalled accessories. The units shall be factory wired, piped,charged with R-<strong>410A</strong> refrigerant and factory tested prior toshipment. All unit wiring shall be both numbered and colorcoded. All units shall be manufactured in a facility certified toISO 9001 standards and the cooling performance shall be ratedin accordance with DOE and ARI test procedures. Units shallbe CSA listed, classified to ANSIZ21.47 standards, UL 1995/CAN/CSA No. 236-M90 conditions.Unit CabinetUnit cabinet shall be constructed of galvanized steel, withexterior surfaces coated with a non-chalking, powdered paintfinish, certified at 1000 hours salt spray test per ASTM-B117standards. Indoor blower section shall be insulated with aminimum 1/2" thick insulation, coated on the airside. Aluminumfoil faced insulation shall be used in the furnace <strong>com</strong>partmentand be fastened with ridged fasteners to prevent insulation fromentering the air stream. Cabinet panels shall be "large" size,easily removable for servicing and maintenance. Full perimeterbase rails shall be provided to assure reliable transit ofequipment, overhead rigging and proper sealing on roof curbapplications. Disposable 2" filters shall be furnished and beaccessible through a removable access door, sealed airtight.Units filter track shall be designed to ac<strong>com</strong>modate either 1" or2" filters. Fan performance measuring ports shall be providedon the outside of the cabinet to allow accurate airmeasurements of evaporator fan performance without removingpanels or creating air by-pass of the coils. Condensate panshall be internally sloped and conform to ASHRAE 62-89 selfdrainingstandards. Condensate connection shall be a minimumof 1" I.D. female and be a ridged mount connection. Unit shallincorporate a fixed outdoor air damper with an outdoor airintake opening covered with a bird screen and a rain hoodpainted to match the exterior of the unit.Indoor (Evaporator) Fan AssemblyFan shall be a belt drive assembly and include an adjustablepitchmotor pulley. Job site selected (B.H.P.) brake horsepowershall not exceed the motors nameplate horsepower rating, plusJohnson Controls Unitary Products 9

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008the service factor. Units shall be designed not to operate aboveservice factor. Fan wheel shall be double-inlet type withforward-curved blades, dynamically balanced to operatesmoothly throughout the entire range of operation. Airflowdesign shall be constant air volume.A variable air volume (VAV) option using a variable frequencydrive (VFD) is available for applications requiring a constantsupply duct static pressure. Units equipped for VAV shall becontrolled by a duct pressure transducer with a 0 - 5” WCpressure range. The pressure transducer shall provide a 0 - 5VDC output signal to a VAV control board which, in turn shallprovide a 2 - 10 VDC speed reference signal to the VFD. TheVAV control board shall operate using factory-installed SupplyAir, Return Air and Outside Air Temperature Sensors. Unitsequipped with VFD’s shall have factory-installed manual bypassas an option.Outdoor (Condenser) Fan AssemblyThe outdoor fans shall be of the direct-driven propeller type,discharge air vertically, have aluminum blades riveted tocorrosion resistant steel spider brackets and shall bedynamically balanced for smooth operation. The 4 outdoor fanmotors shall be totally enclosed with permanently lubricatedbearings, internally protected against overload conditions andstaged independently.Refrigerant ComponentsCompressors:a. Shall be Scroll <strong>com</strong>pressors internally protected withinternal high-pressure relief and over temperatureprotection.b. Shall have internal spring isolation and sound muffling tominimize vibration and noise, and be externally isolatedon a dedicated, independent mounting.Coils:a. Evaporator and condenser coils shall have aluminumplate fins mechanically bonded to seamless internallyenhanced copper tubes with all joints brazed. SpecialPhenolic coating shall be available as a factory option.b. Evaporator and Condenser coils shall be of the directexpansion, draw-thru, design.Refrigerant Circuit and Refrigerant Safety Components shallinclude:a. Balance-port thermostatic expansion valve withindependent circuit feed system.b. Filter drier/strainer to eliminate any moisture or foreignmatter.c. Accessible service gage connections on both suctionand discharge lines to charge, evacuate, and measurerefrigerant pressure during any necessary servicing ortroubleshooting, without losing charge.d. The refrigeration system shall provide at least <strong>15</strong>° F ofsub-cooling at design conditions.e. All models shall have four independent circuits.f. Hot gas bypass option shall be factory-installed on<strong>com</strong>pressor #1 discharge line to provide cooling in lowloadapplications. HGBP shall be a standard feature onVAV models and an optional feature on CV models.Unit Controlsa. Unit shall be <strong>com</strong>plete with self-contained low-voltagecontrol circuit protected by a resettable circuit breaker onthe 24-volt transformer side.b. Unit shall incorporate a lockout circuit which providesreset capability at the space thermostat or base unit,should any of the following standard safety devices tripand shut off <strong>com</strong>pressor.c. Loss-of-charge/Low-pressure switch.1. High-pressure switch.2. Freeze-protection thermostat, evaporator coil. If any ofthe above safety devices trip, a LED (light-emittingdiode) indicator shall flash a diagnostic code thatindicates which safety switch has tripped.d. Unit shall incorporate "AUTO RESET" <strong>com</strong>pressor overtemperature, over current protection.e. Unit shall operate with conventional thermostat designsand have a low voltage terminal strip for easy hook-up.f. Unit control board shall have on-board diagnostics andfault code display.g. Standard controls shall include anti-short cycle and lowvoltage protection, and permit cooling operation down to0 °F.h. Control board shall monitor each refrigerant safety switchindependently.i. Control board shall retain last 5 fault codes in non volatilememory, which will not be lost in the event of a powerloss.Gas Heating Section (<strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong>***N Models)Shall be designed with induced draft <strong>com</strong>bustion with post purgelogic and energy saving direct spark ignition, redundant main gasvalve. Ventor wheel shall be constructed of stainless steel forcorrosion resistance. The heat exchanger shall be of the tubulartype, constructed of T1-40 aluminized steel for corrosionresistance and allowing minimum mixed air entering temperatureof <strong>25</strong> °F. Burners shall be of the in-shot type, constructed ofaluminum coated steel and contain air mixture adjustments. Allgas piping shall enter the unit cabinet at a single location througheither the side or curb, without any field modifications. Anintegrated control board shall provide timed control of evaporatorfan functioning and burner ignition. Heating section shall beprovided with the following minimum protection:a. Primary and auxiliary high-temperature limit switches.b. Induced draft motor speed sensor.c. Flame roll out switch (automatic reset).d. Flame proving controls. Unit shall have two independentstages of capacity.10 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008Electric Heating (<strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong>***C/E Models)Nickel chromium electric heating elements shall be provided asrequired by the application with 1 or 2 stage control, asrequired, from 13.5 KW to 72 KW capacities. The heatingsection shall have a primary limit control(s) and automatic resetto prevent the heating element system from operating at anexcessive temperature. Units with Electric Heating shall bewired for a single point power supply with branch circuit fusing(where required).Unit Operating CharacteristicsUnit shall be capable of starting and running at 1<strong>25</strong>° F outdoortemperature, exceeding maximum load criteria of ARI Standard340/3<strong>60</strong>. The <strong>com</strong>pressor, with standard controls, shall becapable of operation down to <strong>25</strong>° F outdoor temperature.Accessory low ambient kit shall be available for operation to 0°F. Unit shall be provided with fan time delay to prevent cold airdelivery before heat exchanger warms up (Gas heat only).Electrical RequirementsAll unit power wiring shall enter unit cabinet at a single factoryprovided location and be capable of side or bottom entry, tominimize roof penetrations and avoid unit field modifications.Separate side and bottom openings shall be provided for thecontrol wiring.Standard Limited Warranties• Compressor 5 Years• Heat Exchanger 10 Years• Electric Heat Element 5 Years• Other Parts 1 YearOptional Outdoor Air (Shall be made available by either/or):• Electronic Enthalpy Automatic Economizer - Outdoorand return air dampers that are interlocked and positionedby a fully-modulating, spring-return damper actuator. Themaximum leakage rate for the outdoor air intake dampersshall not exceed 2% when dampers are fully closed andoperating against a pressure differential of 0.5 IWG. Aunit-mounted potentiometer shall be provided to adjustthe outdoor and return air damper assembly to take inCFM of outdoor air to meet the minimum ventilationrequirement of the conditioned space during normaloperation. During economizer operation, a mixed-airtemperature control shall modulate the outdoor and returnair damper assembly to prevent the supply airtemperature from dropping below 55°F. Changeover from<strong>com</strong>pressor to economizer operation shall be provided byan integral electronic enthalpy control that feeds input intothe basic module. The outdoor intake opening shall becovered with a rain hood that matches the exterior of theunit. Water eliminator/filters shall be provided.Simultaneous economizer/<strong>com</strong>pressor operation is alsopossible. Dampers shall fully close on power loss.• Motorized Outdoor Air Dampers - Outdoor and returnair dampers that are interlocked and positioned by a 2-position, spring-return damper actuator. The maximumleakage rate for the outdoor air intake dampers shall notexceed 2% when dampers are fully closed and operatingagainst a pressure differential of 0.5 IWG. A unit-mountedpotentiometer shall be provided to adjust the outdoor andreturn air damper assembly to take in the design CFM ofoutdoor air to meet the ventilation requirements of theconditioned space during normal operation. Whenever theindoor fan motor is energized, the dampers open up toone of two pre-selected positions - regardless of theoutdoor air enthalpy. Dampers return to the fully closedposition when the indoor fan motor is de-energized.Dampers shall fully close on power loss.Other Pre-<strong>eng</strong>ineered Accessories Available• Roof Curb - 14" high, full perimeter curb with wood nailer(shipped knocked-down).• 100% Barometric Relief Damper - Contains a rain hood,air inlet screen, exhaust damper and mounting hardware.Used to relieve internal air pressure through the unit.• Propane Conversion Kit - Contains new orifices and gasvalve parts to convert from natural to L.P. gas. One perunit required.• High Altitude - Natural Gas - Contains orifices requiredfor applications between 2000 and <strong>60</strong>00 feet altitude.• High Altitude - Propane Gas - Contains orifices requiredfor applications between 2000 and <strong>60</strong>00 feet altitude.Must be used with propane conversion kit.• Burglar Bars - Designed to work with above roof curbs,depending on unit model. Fits duct openings of curbsupply and return air openings.• Side Duct Flange - Supply and return air duct flanges forside duct applications. Do not use on units with powerexhaust.• High Static Drive - May include a belt, blower pulley,motor pulley or a motor change to enhance blowerperformance.• Wood Skid - Allows unit to be handled with 90" forks.• Economizer/motorized Damper Rain Hood(<strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong>N/E/C300 only) - Contains all hood panels andthe hardware for assembling.• Anti-Recycle Timer - Assures 5-minute off time between<strong>com</strong>pressor cycles.• Low Ambient Kit - Provides unit cooling operation downto 0 °F.• Coil Guard Kit - Guard for cooling coil.OTHER FACTORY INSTALLED OPTIONS• Power Exhaust Option - To work in conjunction witheconomizers.• Stainless Steel Heat Exchanger• Stainless Steel Drain Pan• Technicoat Phenolic Coated Condenser AndEvaporator Coil• Electronic Single Enthalpy EconomizerJohnson Controls Unitary Products 11

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008Reheat Control BoardRY1P4Y2GK1W1W2K2OCCCK4K3COM`P6P5P3HGRRHGRHUMMODESELECTIONJUMPERDEHUMIDISTATHARNESSCONNECTIONReheat Controls - Part 1Johnson Controls Unitary Products 13

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008UCBUNIT CONTROLBOARDRHBREHEAT CONTROLBOARDHUMHUMIDIFYTERMINALRHRREHEATRELAYRHTBREHEATTERMINALBLOCKReheat Controls - Part 2REHEATSOLENOID 1REHEATSOLENOID 3REHEATSOLENOID 2UCBUNIT CONTROLBOARDRHBREHEATCONTROLBOARD14 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>180-300 Physical DataComponentModels<strong>ZF</strong>180 <strong>ZF</strong>210 <strong>ZF</strong>240 <strong>ZF</strong>300Nominal Tonnage <strong>15</strong> 17.5 20 <strong>25</strong>ARI COOLING PERFORMANCEGross Capacity @ ARI A point (K Btu) 181 208 <strong>25</strong>9 279ARI net capacity (K Btu) 174 203 <strong>25</strong>0 270EER 11.0 11.0 10.0 10.0SEER - - - -IPLV 12.9 12.77 11.5 11Nominal CFM <strong>60</strong>00 7000 8000 10000System power (KW) <strong>15</strong>.8 18.5 <strong>25</strong>.0 27.0Refrigerant type R-410a R-410a R-410a R-410aRefrigerant charge (lb-oz)System 1 20-8 23-8 22 22System 2 20-8 23-8 23 23-4ARI HEATING PERFORMANCEHeating model 24 32 24 32 24 32 24 32Heat input (K Btu) 300 400 300 400 300 400 300 400Heat output (K Btu) 240 320 240 320 240 320 240 320AFUE% - - - - - - - -Steady state efficiency (%) 80 80 80 80 80 80 80 80No. burners 6 8 6 8 6 8 6 8No. stages 2 2 2 2 2 2 2 2Temperature Rise Range (ºF) 20-50 30-<strong>60</strong> 20-50 30-<strong>60</strong> 20-50 30-<strong>60</strong> 20-50 30-<strong>60</strong>Gas Limit Setting (ºF) 195 195 195 195 195 195 195 195Gas piping connection (in.) 1 1 1 1 1 1 1 1DIMENSIONS (inches)L<strong>eng</strong>th 1<strong>25</strong>-1/4 136-1/4 136-1/4 136-1/4Width 92 92 92 92Height 48-5/8 52-5/8 52-5/8 52-5/8OPERATING WT. (lbs.) 1870 <strong>25</strong>33 2006 <strong>25</strong>97COMPRESSORSType Scroll Scroll Scroll ScrollQuantity 2 2 2 2Unit Capacity Steps (%) 50 / 100 50 / 100 50 / 100 50 / 100CONDENSER COIL DATAFace area (Sq. Ft.) 36.0 43.3 43.3 43.3Rows 3 3 3 3Fins per inch 13.5 <strong>15</strong> <strong>15</strong> <strong>15</strong>Tube diameter (in.) 3/8 3/8 3/8 3/8Circuitry Type Split-face Split-face Split-face Split-faceEVAPORATOR COIL DATAFace area (Sq. Ft.) <strong>15</strong>.5 <strong>25</strong> 20 <strong>25</strong>Rows 4 4 4 4Fins per inch 13.5 13.5 13.5 13.5Tube diameter 3/8 3/8 3/8 3/8Circuitry Type Intertwined Split-face Intertwined Split-faceRefrigerant control TXV TXV TXV TXVJohnson Controls Unitary Products 19

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>180-300 Physical Data (Continued)ComponentModels<strong>ZF</strong>180 <strong>ZF</strong>210 <strong>ZF</strong>240 <strong>ZF</strong>300Nominal Tonnage <strong>15</strong> 17.5 20 <strong>25</strong>CONDENSER FAN DATAQuantity 2 2 2 2Fan diameter (Inch) 24 24 30 30Type Prop Prop Prop PropDrive type Direct Direct Direct DirectNo. speeds 1 1 1 1Number of motors 2 2 2 2Motor HP each 1.<strong>25</strong> 1.<strong>25</strong> 1.<strong>25</strong> 1.<strong>25</strong>RPM 1140 1140 1140 1140Nominal total CFM 5765 7000 7000 7000BELT DRIVE EVAP FAN DATAQuantity 1 1 1 1Fan Size (Inch) <strong>15</strong> X <strong>15</strong> 18 X <strong>15</strong> 18 X <strong>15</strong> 18 X <strong>15</strong>Type Centrifugal Centrifugal Centrifugal CentrifugalMotor Sheave 1VP65 1VP65 1VP<strong>60</strong> 1VP<strong>60</strong> 1VP<strong>60</strong> 1VP<strong>60</strong> 1VP<strong>60</strong> 1VP75X 1VP75XBlower Sheave BK110 BK090 BK110 BK090 BK110 BK090 1B5V94 1B5V110 1B5V94Belt BX85 BX81 BX78 BX75 BX78 BX75 BX78 5VX840 5VX8<strong>60</strong>Motor HP each 5 5 5 7.5 5 7.5 7.5 10 <strong>15</strong>RPM 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong> 17<strong>25</strong>Frame size 184T 184T 184T 213T 184T 213T 213T 2<strong>15</strong>T <strong>25</strong>4TFILTERSQuantity - Size- 4 - 16 x <strong>25</strong> x 2 4 - 16 x <strong>25</strong> x 2 4 - 16 x <strong>25</strong> x <strong>25</strong> - 18 x 24 x 2 4 - 16 x 20 x 2 4 - 16 x 20 x 2 4 - 16 x 20 x 2<strong>ZJ</strong>/<strong>ZR</strong>/<strong>ZF</strong>180-300 Unit LimitationsSize(Tons)180(<strong>15</strong>)210(17.5)240(20)300(<strong>25</strong>)Unit VoltageUnit LimitationsApplied VoltageOutdoor DB TempMin Max Max (°F)208/230-3-<strong>60</strong> 187 <strong>25</strong>2 1<strong>25</strong>4<strong>60</strong>-3-<strong>60</strong> 432 504 1<strong>25</strong>575-3-<strong>60</strong> 540 630 1<strong>25</strong>208/230-3-<strong>60</strong> 187 <strong>25</strong>2 1<strong>25</strong>4<strong>60</strong>-3-<strong>60</strong> 432 504 1<strong>25</strong>575-3-<strong>60</strong> 540 630 1<strong>25</strong>208/230-3-<strong>60</strong> 187 <strong>25</strong>2 1<strong>25</strong>4<strong>60</strong>-3-<strong>60</strong> 432 504 1<strong>25</strong>575-3-<strong>60</strong> 540 630 1<strong>25</strong>208/230-3-<strong>60</strong> 187 <strong>25</strong>2 1<strong>25</strong>4<strong>60</strong>-3-<strong>60</strong> 432 504 1<strong>25</strong>575-3-<strong>60</strong> 540 630 1<strong>25</strong>20 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>180-300 Cooling Capacities<strong>ZF</strong>180 (<strong>15</strong> Ton)Air onEvaporator CoilCFM375045005<strong>25</strong>0<strong>60</strong>0067507500375045005<strong>25</strong>0<strong>60</strong>0067507500WB(°F)TotalCapacity 1(MBh)SensibleTemperature of Air on Condenser CoilTotalCapacity (MBh) Total TotalSensible Capacity (MBh)(kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 65InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)75°F 85°F77 236.7 12.4 97.3 80.1 63.0 - - - 223.9 13.0 91.7 74.8 58.0 - - -72 216.0 11.9 124.5 107.3 90.2 73.1 - - 204.1 12.8 119.4 102.5 85.7 68.8 - -67 195.4 11.5 <strong>15</strong>1.7 134.6 117.4 100.3 83.1 - 184.4 12.7 147.0 130.2 113.3 96.5 79.7 -62 178.4 11.3 178.4 164.0 142.0 124.9 107.7 90.6 168.9 12.4 168.9 161.1 137.2 120.3 103.5 86.677 245.7 12.5 107.4 88.5 69.5 - - - 232.3 13.1 101.7 82.8 63.9 - - -72 224.3 12.0 137.4 118.5 99.5 80.6 - - 211.9 12.9 132.2 113.3 94.5 75.6 - -67 202.8 11.6 167.4 148.5 129.6 110.6 91.7 - 191.4 12.7 162.7 143.9 1<strong>25</strong>.0 106.1 87.2 -62 185.2 11.3 185.2 175.6 <strong>15</strong>6.7 137.8 118.8 99.9 175.3 12.5 175.3 170.1 <strong>15</strong>1.2 132.4 113.5 94.657 236.4 10.9 236.4 231.9 213.0 194.0 175.1 <strong>15</strong>6.2 201.8 12.3 201.8 199.2 180.3 161.4 142.6 123.777 <strong>25</strong>4.6 12.5 117.5 96.8 76.0 - - - 240.8 13.2 111.7 90.8 69.9 - - -72 232.5 12.1 <strong>15</strong>0.3 129.6 108.9 88.2 - - 219.6 13.0 145.1 124.2 103.3 82.4 - -67 210.3 11.6 183.2 162.5 141.7 121.0 100.3 - 198.4 12.8 178.4 <strong>15</strong>7.5 136.6 1<strong>15</strong>.7 94.8 -62 192.0 11.4 192.0 187.2 171.4 <strong>15</strong>0.7 129.9 109.2 181.7 12.6 181.7 179.1 165.3 144.4 123.5 102.657 245.1 10.9 245.1 242.8 232.9 212.2 191.4 170.7 209.1 12.4 209.1 207.8 197.1 176.2 <strong>15</strong>5.3 134.477 263.6 12.6 127.6 105.1 82.6 - - - 249.3 13.2 121.7 98.8 75.9 - - -72 240.7 12.2 163.3 140.7 118.2 95.7 - - 227.3 13.1 <strong>15</strong>7.9 135.0 112.1 89.1 - -67 217.7 11.7 198.9 176.4 <strong>15</strong>3.9 131.4 108.8 - 205.4 12.9 194.1 171.2 148.3 1<strong>25</strong>.3 102.4 -62 198.8 11.5 198.8 198.8 186.1 163.6 141.0 118.5 188.1 12.7 188.1 188.1 179.4 <strong>15</strong>6.5 133.6 110.657 <strong>25</strong>3.7 11.0 <strong>25</strong>3.7 <strong>25</strong>3.7 <strong>25</strong>2.8 230.3 207.8 185.3 216.5 12.4 216.5 216.5 213.9 191.0 168.0 145.172 246.2 12.1 172.9 148.2 123.5 98.8 - - 231.1 13.1 168.9 144.1 119.2 94.4 - -67 222.7 11.7 213.3 185.4 1<strong>60</strong>.7 136.0 111.3 - 208.8 12.9 203.2 182.6 <strong>15</strong>7.7 132.9 108.0 -62 203.4 11.5 203.4 203.4 197.0 172.3 147.6 122.9 191.2 12.7 191.2 191.2 186.9 162.0 137.2 112.357 <strong>25</strong>9.3 11.0 <strong>25</strong>9.3 <strong>25</strong>9.3 <strong>25</strong>8.8 234.1 209.4 184.7 220.1 12.5 220.1 220.1 218.8 193.9 169.1 144.272 <strong>25</strong>1.8 12.1 182.6 <strong>15</strong>5.7 128.8 101.9 - - 234.9 13.1 180.0 <strong>15</strong>3.2 126.4 99.6 - -67 227.8 11.7 227.8 194.4 167.5 140.6 113.7 - 212.2 12.9 212.2 194.0 167.2 140.4 113.6 -62 208.0 11.4 208.0 208.0 208.0 181.1 <strong>15</strong>4.2 127.3 194.3 12.7 194.3 194.3 194.3 167.5 140.7 113.957 264.8 11.0 264.8 264.8 264.8 237.9 211.0 184.2 223.7 12.5 223.7 223.7 223.7 196.9 170.1 143.395°F 105°F77 211.0 13.6 86.1 69.5 53.0 - - - 197.0 <strong>15</strong>.4 81.3 67.6 51.0 - - -72 192.2 13.7 114.2 97.7 81.1 64.6 - - 179.3 <strong>15</strong>.4 111.5 94.9 78.3 61.7 - -67 173.4 13.8 142.4 1<strong>25</strong>.8 109.3 92.7 76.2 - 161.6 <strong>15</strong>.3 141.8 122.2 105.6 88.9 72.3 -62 <strong>15</strong>9.3 13.6 <strong>15</strong>9.3 <strong>15</strong>8.2 132.3 1<strong>15</strong>.8 99.2 82.7 148.6 <strong>15</strong>.1 148.6 144.5 120.5 103.9 87.3 70.677 219.0 13.7 96.0 77.2 58.4 - - - 204.0 <strong>15</strong>.5 93.6 74.8 56.0 - - -72 199.5 13.8 127.0 108.2 89.4 70.6 - - 185.7 <strong>15</strong>.4 123.6 104.8 86.0 67.2 - -67 180.0 13.9 <strong>15</strong>8.0 139.2 120.4 101.6 82.8 - 167.4 <strong>15</strong>.4 <strong>15</strong>3.5 134.7 1<strong>15</strong>.9 97.1 78.3 -62 165.4 13.7 165.4 164.6 145.8 127.0 108.2 89.4 <strong>15</strong>3.9 <strong>15</strong>.2 <strong>15</strong>3.9 <strong>15</strong>1.2 132.4 113.5 94.7 75.957 167.1 13.7 167.1 166.4 147.6 128.8 110.0 91.2 <strong>15</strong>7.6 <strong>15</strong>.2 <strong>15</strong>7.6 <strong>15</strong>7.3 139.5 120.7 101.9 83.177 227.0 13.8 105.9 84.9 63.8 - - - 211.0 <strong>15</strong>.5 106.0 82.0 61.0 - - -72 206.7 13.9 139.8 118.7 97.7 76.6 - - 192.0 <strong>15</strong>.5 135.6 114.6 93.6 72.6 - -67 186.5 14.0 173.7 <strong>15</strong>2.6 131.5 110.5 89.4 - 173.1 <strong>15</strong>.4 165.2 147.2 126.2 105.3 84.3 -62 171.4 13.8 171.4 171.0 <strong>15</strong>9.3 138.2 117.1 96.1 <strong>15</strong>9.1 <strong>15</strong>.2 <strong>15</strong>9.1 <strong>15</strong>7.8 144.2 123.2 102.2 81.<strong>25</strong>7 173.2 13.8 173.2 172.8 161.3 140.2 119.1 98.1 163.0 <strong>15</strong>.3 163.0 162.8 <strong>15</strong>2.0 131.0 110.0 89.077 234.9 13.8 1<strong>15</strong>.9 92.5 69.2 - - - 217.9 <strong>15</strong>.6 118.4 89.2 66.0 - - -72 214.0 13.9 <strong>15</strong>2.6 129.3 105.9 82.6 - - 198.4 <strong>15</strong>.5 147.7 124.5 101.3 78.1 - -67 193.1 14.1 189.3 166.0 142.7 119.3 96.0 - 178.8 <strong>15</strong>.5 177.0 <strong>15</strong>9.8 136.6 113.4 90.2 -62 177.4 13.8 177.4 177.4 172.8 149.4 126.1 102.8 164.4 <strong>15</strong>.3 164.4 164.4 <strong>15</strong>6.0 132.9 109.7 86.557 179.3 13.9 179.3 179.3 174.9 <strong>15</strong>1.6 128.3 104.9 168.4 <strong>15</strong>.3 168.4 168.4 164.4 141.3 118.1 94.972 216.0 14.0 165.0 140.0 114.9 89.9 - - 200.1 <strong>15</strong>.5 <strong>15</strong>9.0 134.2 109.5 84.7 - -67 194.8 14.1 193.0 179.8 <strong>15</strong>4.8 129.8 104.8 - 180.4 <strong>15</strong>.5 179.5 170.1 147.6 122.8 98.1 -62 179.0 13.9 179.0 179.0 176.7 <strong>15</strong>1.7 126.7 101.7 165.9 <strong>15</strong>.3 165.9 165.9 161.7 136.9 112.1 87.457 180.9 13.9 180.9 180.9 178.8 <strong>15</strong>3.7 128.7 103.7 169.9 <strong>15</strong>.4 169.9 169.9 167.9 143.1 118.4 93.672 217.9 14.0 177.4 <strong>15</strong>0.6 123.9 97.2 - - 201.9 <strong>15</strong>.6 170.4 144.0 117.6 91.3 - -67 196.6 14.1 196.6 193.6 166.9 140.2 113.5 - 182.0 <strong>15</strong>.5 182.0 180.5 <strong>15</strong>8.6 132.2 105.9 -62 180.7 13.9 180.7 180.7 180.7 <strong>15</strong>4.0 127.3 100.5 167.3 <strong>15</strong>.3 167.3 167.3 167.3 140.9 114.6 88.<strong>25</strong>7 182.6 14.0 182.6 182.6 182.6 <strong>15</strong>5.9 129.2 102.4 171.4 <strong>15</strong>.4 171.4 171.4 171.4 145.0 118.6 92.3Johnson Controls Unitary Products 41

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>180 (<strong>15</strong> Ton) (Continued)SensibleAir onTemperature of Air on Condenser CoilEvaporator Coil Total TotalCapacity (MBh) Total TotalSensible Capacity (MBh)CFMWB Capacity 1 InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)(°F) (MBh) (kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 651<strong>15</strong>°F 1<strong>25</strong>°F77 182.9 17.2 76.5 65.8 49.1 - - - 168.9 19.0 74.3 63.9 47.1 - - -375072 166.4 17.0 108.9 92.2 75.5 58.8 - - <strong>15</strong>3.5 18.6 106.2 89.4 72.6 55.9 - -67 149.8 16.8 141.2 118.6 101.9 85.2 68.5 - 138.0 18.3 138.0 114.9 98.2 81.4 64.6 -62 137.8 16.6 137.8 130.9 108.7 92.0 75.3 58.6 127.1 18.1 127.1 117.2 96.9 80.1 63.4 46.677 188.9 17.2 91.3 72.5 53.7 - - - 173.9 19.0 91.3 70.1 51.3 - - -72 171.8 17.0 120.1 101.3 82.5 63.7 - - <strong>15</strong>8.0 18.6 116.7 97.9 79.1 <strong>60</strong>.3 - -4500 67 <strong>15</strong>4.7 16.8 149.0 130.2 111.4 92.6 73.8 - 142.1 18.3 142.1 1<strong>25</strong>.7 106.9 88.1 69.3 -62 142.3 16.6 142.3 137.7 118.9 100.1 81.3 62.5 130.8 18.1 130.8 124.3 105.5 86.7 67.8 49.057 148.1 16.7 148.1 148.1 131.4 112.6 93.8 75.0 138.6 18.2 138.6 138.6 123.3 104.5 85.7 66.977 194.9 17.3 106.1 79.2 58.3 - - - 178.9 19.0 108.3 76.3 55.5 - - -72 177.3 17.1 131.4 110.5 89.6 68.7 - - 162.6 18.6 127.3 106.4 85.6 64.8 - -5<strong>25</strong>0 67 <strong>15</strong>9.7 16.8 <strong>15</strong>6.8 141.9 121.0 100.1 79.1 - 146.2 18.3 146.2 136.5 1<strong>15</strong>.7 94.9 74.0 -62 146.9 16.7 146.9 144.6 129.1 108.2 87.3 66.4 134.6 18.1 134.6 131.3 114.0 93.2 72.3 51.557 <strong>15</strong>2.8 16.7 <strong>15</strong>2.8 <strong>15</strong>2.8 142.7 121.7 100.8 79.9 142.7 18.2 142.7 142.7 133.3 112.5 91.7 70.877 201.0 17.3 120.9 85.9 62.9 - - - 184.0 19.0 1<strong>25</strong>.2 82.6 59.7 - - -72 182.8 17.1 142.7 119.7 96.7 73.7 - - 167.2 18.6 137.8 114.9 92.1 69.2 - -<strong>60</strong>00 67 164.6 16.9 164.6 <strong>15</strong>3.5 130.5 107.5 84.5 - <strong>15</strong>0.4 18.3 <strong>15</strong>0.4 147.3 124.4 101.6 78.7 -62 <strong>15</strong>1.4 16.7 <strong>15</strong>1.4 <strong>15</strong>1.4 139.3 116.3 93.2 70.2 138.4 18.1 138.4 138.4 122.5 99.7 76.8 53.957 <strong>15</strong>7.5 16.8 <strong>15</strong>7.5 <strong>15</strong>7.5 <strong>15</strong>3.9 130.9 107.9 84.9 146.7 18.2 146.7 146.7 143.4 120.5 97.7 74.872 184.3 17.1 <strong>15</strong>3.1 128.5 104.0 79.5 - - 168.5 18.7 147.1 122.8 98.6 74.3 - -675067 166.0 16.9 166.0 1<strong>60</strong>.5 140.4 1<strong>15</strong>.9 91.4 - <strong>15</strong>1.6 18.3 <strong>15</strong>1.6 <strong>15</strong>0.8 133.2 108.9 84.7 -62 <strong>15</strong>2.7 16.7 <strong>15</strong>2.7 <strong>15</strong>2.7 146.6 122.1 97.6 73.0 139.5 18.1 139.5 139.5 131.6 107.3 83.0 58.757 <strong>15</strong>8.9 16.8 <strong>15</strong>8.9 <strong>15</strong>8.9 <strong>15</strong>7.1 132.5 108.0 83.5 147.9 18.3 147.9 147.9 146.2 121.9 97.7 73.472 185.9 17.2 163.4 137.4 111.3 85.3 - - 169.8 18.7 <strong>15</strong>6.5 130.8 105.0 79.3 - -750067 167.4 17.0 167.4 167.4 <strong>15</strong>0.3 124.3 98.2 - <strong>15</strong>2.8 18.4 <strong>15</strong>2.8 <strong>15</strong>2.8 142.0 116.3 90.6 -62 <strong>15</strong>4.0 16.8 <strong>15</strong>4.0 <strong>15</strong>4.0 <strong>15</strong>4.0 127.9 101.9 75.9 140.6 18.2 140.6 140.6 140.6 114.9 89.2 63.557 1<strong>60</strong>.2 16.9 1<strong>60</strong>.2 1<strong>60</strong>.2 1<strong>60</strong>.2 134.2 108.1 82.1 149.0 18.3 149.0 149.0 149.0 123.3 97.6 71.91. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.4<strong>15</strong> x kW. Refer to the appropriate BlowerPerformance Table for the kW of the supply air blower motor.2. These ratings include the condenser fan motors (total 1 kW) and the <strong>com</strong>pressor motors but not the supply air blower motor.42 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>210 (17.5 Ton)Air onEvaporator CoilCFM43755<strong>25</strong>061<strong>25</strong>70007875875043755<strong>25</strong>061<strong>25</strong>700078758750WB(°F)TotalCapacity 1(MBh)SensibleTemperature of Air on Condenser CoilTotalCapacity (MBh) Total TotalSensible Capacity (MBh)(kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 65InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)75°F 85°F77 266.4 14.9 105.7 87.4 69.1 - - - <strong>25</strong>2.5 16.1 104.8 86.2 67.5 - - -72 246.6 14.5 139.2 120.9 102.6 84.2 - - 233.7 <strong>15</strong>.7 137.6 118.9 100.2 81.6 - -67 226.7 14.0 172.7 <strong>15</strong>4.4 136.0 117.7 99.4 - 2<strong>15</strong>.0 <strong>15</strong>.4 170.3 <strong>15</strong>1.6 133.0 114.3 95.6 -62 209.7 14.0 209.7 194.9 165.5 147.2 128.9 110.5 198.6 <strong>15</strong>.2 198.6 191.2 163.3 144.6 126.0 107.377 276.8 14.8 119.5 97.9 76.4 - - - 261.8 16.1 117.3 95.7 74.2 - - -72 <strong>25</strong>6.2 14.4 <strong>15</strong>6.5 135.0 113.4 91.9 - - 242.4 <strong>15</strong>.7 <strong>15</strong>3.3 131.7 110.1 88.5 - -67 235.5 14.0 193.5 172.0 <strong>15</strong>0.5 129.0 107.4 - 223.0 <strong>15</strong>.4 189.3 167.7 146.1 124.5 102.9 -62 217.8 13.9 217.8 207.9 183.1 161.5 140.0 118.5 205.9 <strong>15</strong>.2 205.9 201.0 179.4 <strong>15</strong>7.8 136.2 114.657 219.1 13.8 219.1 216.4 189.4 167.9 146.3 124.8 205.8 <strong>15</strong>.1 205.8 204.4 182.8 161.2 139.6 118.077 287.1 14.8 133.2 108.5 83.7 - - - 271.2 16.1 129.9 105.3 80.8 - - -72 265.7 14.4 173.8 149.1 124.3 99.6 - - <strong>25</strong>1.1 <strong>15</strong>.7 169.1 144.5 120.0 95.5 - -67 244.3 14.0 214.4 189.7 164.9 140.2 1<strong>15</strong>.4 - 231.0 <strong>15</strong>.4 208.3 183.7 <strong>15</strong>9.2 134.7 110.2 -62 2<strong>25</strong>.9 13.9 2<strong>25</strong>.9 221.0 200.7 175.9 <strong>15</strong>1.2 126.4 213.3 <strong>15</strong>.2 213.3 210.9 195.5 171.0 146.5 122.057 227.3 13.8 227.3 2<strong>25</strong>.9 207.6 182.8 <strong>15</strong>8.1 133.3 213.1 <strong>15</strong>.2 213.1 212.5 199.2 174.7 <strong>15</strong>0.2 1<strong>25</strong>.777 297.5 14.7 147.0 119.0 91.1 - - - 280.6 16.1 142.4 114.9 87.5 - - -72 275.3 14.3 191.1 163.2 135.2 107.2 - - <strong>25</strong>9.8 <strong>15</strong>.7 184.8 <strong>15</strong>7.4 129.9 102.5 - -67 <strong>25</strong>3.1 13.9 235.3 207.3 179.4 <strong>15</strong>1.4 123.4 - 239.0 <strong>15</strong>.4 227.2 199.8 172.3 144.9 117.4 -62 234.1 13.9 234.1 234.1 218.3 190.3 162.3 134.4 220.7 <strong>15</strong>.2 220.7 220.7 211.7 184.2 <strong>15</strong>6.8 129.357 235.4 13.8 235.4 235.4 2<strong>25</strong>.7 197.8 169.8 141.8 220.5 <strong>15</strong>.2 220.5 220.5 2<strong>15</strong>.7 188.2 1<strong>60</strong>.8 133.372 278.8 14.5 203.0 173.1 143.2 113.3 - - 262.4 <strong>15</strong>.8 195.7 166.4 137.2 107.9 - -67 <strong>25</strong>6.4 14.1 247.5 219.9 190.0 1<strong>60</strong>.1 130.2 - 241.4 <strong>15</strong>.5 235.5 211.2 182.0 <strong>15</strong>2.7 123.4 -62 237.1 14.0 237.1 237.1 229.2 199.3 169.4 139.5 222.9 <strong>15</strong>.3 222.9 222.9 218.4 189.1 <strong>15</strong>9.8 130.657 238.5 13.9 238.5 238.5 233.6 203.7 173.8 143.9 222.7 <strong>15</strong>.3 222.7 222.7 220.3 191.0 161.7 132.572 282.4 14.6 214.9 183.1 <strong>15</strong>1.3 119.4 - - 264.9 <strong>15</strong>.9 206.6 175.5 144.4 113.3 - -67 <strong>25</strong>9.6 14.2 <strong>25</strong>9.6 232.5 200.7 168.8 137.0 - 243.7 <strong>15</strong>.6 243.7 222.6 191.6 1<strong>60</strong>.5 129.4 -62 240.1 14.1 240.1 240.1 240.1 208.2 176.4 144.6 2<strong>25</strong>.0 <strong>15</strong>.4 2<strong>25</strong>.0 2<strong>25</strong>.0 2<strong>25</strong>.0 194.0 162.9 131.857 241.5 14.0 241.5 241.5 241.5 209.6 177.8 146.0 224.9 <strong>15</strong>.3 224.9 224.9 224.9 193.8 162.7 131.695°F 105°F77 238.5 17.2 104.0 84.9 65.9 - - - 222.3 19.0 92.0 77.9 59.4 - - -72 220.9 17.0 135.9 116.9 97.9 78.9 - - 205.9 18.7 128.5 110.0 91.5 73.0 - -67 203.4 16.7 167.9 148.9 129.9 110.9 91.9 - 189.4 18.4 165.0 142.1 123.6 105.1 86.6 -62 187.5 16.4 187.5 187.5 161.1 142.1 123.1 104.1 177.4 18.2 177.4 176.9 148.8 130.3 111.8 93.377 246.9 17.3 1<strong>15</strong>.2 93.6 71.9 - - - 230.2 19.0 108.4 86.8 65.3 - - -72 228.7 17.0 <strong>15</strong>0.1 128.5 106.8 85.1 - - 213.2 18.7 143.7 122.1 100.6 79.0 - -67 210.5 16.7 185.0 163.4 141.7 120.0 98.4 - 196.2 18.4 179.0 <strong>15</strong>7.4 135.9 114.3 92.7 -62 194.1 16.5 194.1 194.1 175.8 <strong>15</strong>4.1 132.4 110.8 183.7 18.2 183.7 183.4 163.5 141.9 120.4 98.857 192.5 16.5 192.5 192.5 176.2 <strong>15</strong>4.6 132.9 111.3 182.2 18.2 182.2 182.2 164.7 143.1 121.6 100.077 <strong>25</strong>5.3 17.3 126.5 102.2 77.9 - - - 238.2 19.0 124.7 95.7 71.1 - - -72 236.5 17.1 164.3 140.0 1<strong>15</strong>.7 91.4 - - 220.6 18.7 <strong>15</strong>8.8 134.2 109.6 85.0 - -67 217.7 16.8 202.1 177.8 <strong>15</strong>3.5 129.2 104.9 - 203.0 18.4 192.9 172.7 148.1 123.5 98.9 -62 200.7 16.5 200.7 200.7 190.4 166.1 141.8 117.5 190.1 18.2 190.1 189.9 178.2 <strong>15</strong>3.6 129.0 104.457 199.0 16.5 199.0 199.0 190.9 166.6 142.3 118.0 188.5 18.2 188.5 188.5 179.5 <strong>15</strong>4.9 130.3 105.777 263.7 17.4 137.8 110.8 83.9 - - - 246.1 19.1 141.1 104.6 77.0 - - -72 244.3 17.1 178.5 <strong>15</strong>1.5 124.6 97.7 - - 227.9 18.7 174.0 146.3 118.7 91.0 - -67 224.9 16.8 219.2 192.2 165.3 138.4 111.4 - 209.7 18.4 206.9 188.0 1<strong>60</strong>.4 132.7 105.1 -62 207.3 16.6 207.3 207.3 205.1 178.1 <strong>15</strong>1.2 124.2 196.4 18.2 196.4 196.4 192.9 165.3 137.6 110.057 205.6 16.6 205.6 205.6 205.6 178.7 <strong>15</strong>1.7 124.8 194.8 18.2 194.8 194.8 194.3 166.7 139.0 111.472 245.9 17.2 188.3 <strong>15</strong>9.7 131.1 102.4 - - 229.0 18.8 182.2 <strong>15</strong>3.3 124.5 95.6 - -67 226.4 16.9 223.5 202.5 173.9 145.3 116.6 - 210.7 18.5 209.3 196.1 168.2 139.3 110.4 -62 208.7 16.6 208.7 208.7 207.5 178.9 <strong>15</strong>0.3 121.7 197.3 18.3 197.3 197.3 195.6 166.7 137.8 108.957 206.9 16.6 206.9 206.9 206.9 178.3 149.7 121.0 195.7 18.3 195.7 195.7 195.5 166.6 137.7 108.872 247.5 17.2 198.2 167.9 137.5 107.2 - - 230.1 18.9 190.5 1<strong>60</strong>.4 130.3 100.2 - -67 227.8 16.9 227.8 212.8 182.5 <strong>15</strong>2.2 121.8 - 211.7 18.6 211.7 204.2 176.0 145.9 1<strong>15</strong>.8 -62 210.0 16.7 210.0 210.0 210.0 179.7 149.4 119.1 198.2 18.4 198.2 198.2 198.2 168.1 138.0 107.957 208.2 16.7 208.2 208.2 208.2 177.9 147.6 117.3 196.6 18.4 196.6 196.6 196.6 166.5 136.4 106.3Johnson Controls Unitary Products 43

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>210 (17.5 Ton) (Continued)SensibleAir onTemperature of Air on Condenser CoilEvaporator Coil Total TotalCapacity (MBh) Total TotalSensible Capacity (MBh)CFMWB Capacity 1 InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)(°F) (MBh) (kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 651<strong>15</strong>°F 1<strong>25</strong>°F77 206.1 20.8 80.0 70.9 52.9 - - - 190.0 22.6 66.6 63.7 46.3 - - -437572 190.8 20.5 121.1 103.1 85.1 67.1 - - 175.7 22.2 113.6 96.1 78.7 61.2 - -67 175.5 20.2 162.1 135.3 117.3 99.3 81.3 - 161.5 21.9 1<strong>60</strong>.3 128.5 111.0 93.5 76.0 -62 167.3 20.0 167.3 166.3 136.4 118.4 100.5 82.5 <strong>15</strong>7.2 21.8 <strong>15</strong>7.2 <strong>15</strong>5.7 124.1 106.6 89.1 71.677 213.6 20.8 101.5 80.1 58.6 - - - 196.9 22.5 94.7 73.3 51.9 - - -72 197.7 20.5 137.2 1<strong>15</strong>.8 94.3 72.8 - - 182.2 22.2 130.8 109.4 88.0 66.7 - -5<strong>25</strong>0 67 181.8 20.1 172.9 <strong>15</strong>1.5 130.0 108.5 87.1 - 167.5 21.8 166.9 145.5 124.2 102.8 81.4 -62 173.3 20.0 173.3 172.7 <strong>15</strong>1.2 129.8 108.3 86.9 163.0 21.7 163.0 162.0 139.0 117.6 96.3 74.957 172.0 20.0 172.0 172.0 <strong>15</strong>3.1 131.7 110.2 88.7 161.7 21.8 161.7 161.7 141.6 120.2 98.8 77.577 221.1 20.7 123.0 89.2 64.3 - - - 203.9 22.4 122.7 82.9 57.5 - - -72 204.6 20.4 <strong>15</strong>3.4 128.4 103.5 78.6 - - 188.7 22.1 147.9 122.7 97.4 72.2 - -61<strong>25</strong> 67 188.2 20.1 183.7 167.6 142.7 117.8 92.9 - 173.4 21.8 173.4 162.6 137.3 112.1 86.9 -62 179.4 19.9 179.4 179.1 166.0 141.1 116.2 91.3 168.7 21.6 168.7 168.3 <strong>15</strong>3.8 128.6 103.4 78.<strong>25</strong>7 178.0 20.0 178.0 178.0 168.1 143.2 118.3 93.3 167.5 21.7 167.5 167.5 <strong>15</strong>6.7 131.5 106.2 81.077 228.5 20.7 144.5 98.4 70.1 - - - 210.9 22.4 <strong>15</strong>0.7 92.5 63.1 - - -72 211.5 20.4 169.5 141.1 112.7 84.4 - - 195.1 22.0 165.0 135.9 106.8 77.7 - -7000 67 194.5 20.1 194.5 183.8 <strong>15</strong>5.4 127.1 98.7 - 179.4 21.7 179.4 179.4 <strong>15</strong>0.5 121.4 92.3 -62 185.5 19.9 185.5 185.5 180.8 <strong>15</strong>2.4 124.1 95.7 174.5 21.6 174.5 174.5 168.7 139.6 110.5 81.457 184.0 19.9 184.0 184.0 183.1 <strong>15</strong>4.7 126.3 97.9 173.2 21.6 173.2 173.2 171.8 142.7 113.6 84.572 212.1 20.5 176.1 147.0 117.9 88.7 - - 195.2 22.1 170.0 140.6 111.3 81.9 - -787567 195.0 20.1 195.0 189.7 162.5 133.4 104.2 - 179.4 21.7 179.4 179.4 <strong>15</strong>6.8 127.4 98.0 -62 185.9 20.0 185.9 185.9 183.6 <strong>15</strong>4.5 1<strong>25</strong>.4 96.2 174.6 21.6 174.6 174.6 171.7 142.3 112.9 83.557 184.5 20.0 184.5 184.5 184.0 <strong>15</strong>4.9 1<strong>25</strong>.8 96.6 173.3 21.7 173.3 173.3 172.6 143.2 113.8 84.472 212.6 20.5 182.7 <strong>15</strong>2.9 123.0 93.1 - - 195.2 22.2 175.0 145.4 1<strong>15</strong>.7 86.0 - -875067 195.6 20.2 195.6 195.6 169.6 139.7 109.8 - 179.4 21.8 179.4 179.4 163.1 133.4 103.8 -62 186.4 20.0 186.4 186.4 186.4 <strong>15</strong>6.6 126.7 96.8 174.7 21.7 174.7 174.7 174.7 145.0 1<strong>15</strong>.3 85.757 185.0 20.1 185.0 185.0 185.0 <strong>15</strong>5.1 1<strong>25</strong>.2 95.3 173.3 21.7 173.3 173.3 173.3 143.7 114.0 84.31. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.4<strong>15</strong> x kW. Refer to the appropriate BlowerPerformance Table for the kW of the supply air blower motor.2. These ratings include the condenser fan motors (total 1 kW) and the <strong>com</strong>pressor motors but not the supply air blower motor.44 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>240 (20 Ton)Air onEvaporator CoilCFM5000<strong>60</strong>00700080009000100005000<strong>60</strong>0070008000900010000WB(°F)TotalCapacity 1(MBh)SensibleTemperature of Air on Condenser CoilTotalCapacity (MBh) Total TotalSensible Capacity (MBh)(kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 65InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)75°F 85°F77 316.2 19.7 123.8 103.9 84.0 - - - 308.3 21.7 123.2 102.8 82.4 - - -72 295.9 19.3 163.9 144.1 124.2 104.3 - - 286.8 21.2 162.0 141.7 121.3 100.9 - -67 275.6 18.8 204.1 184.2 164.4 144.5 124.6 - 265.2 20.8 200.9 180.5 1<strong>60</strong>.1 139.7 119.4 -62 <strong>25</strong>2.4 18.5 <strong>25</strong>2.4 212.9 195.5 175.6 <strong>15</strong>5.8 135.9 244.3 20.4 244.3 216.0 193.9 173.5 <strong>15</strong>3.1 132.777 330.2 19.8 137.5 114.8 92.2 - - - 320.1 21.7 136.2 113.1 90.0 - - -72 309.0 19.4 181.6 <strong>15</strong>8.9 136.3 113.6 - - 297.7 21.3 178.6 <strong>15</strong>5.5 132.4 109.3 - -67 287.7 18.9 2<strong>25</strong>.7 203.0 180.3 <strong>15</strong>7.7 135.0 - 275.4 20.8 221.0 198.0 174.9 <strong>15</strong>1.8 128.7 -62 263.6 18.6 263.6 237.2 214.6 191.9 169.2 146.5 <strong>25</strong>3.7 20.4 <strong>25</strong>3.7 234.8 211.7 188.6 165.5 142.457 <strong>25</strong>6.7 18.4 <strong>25</strong>6.7 <strong>25</strong>5.3 231.7 209.0 186.4 163.7 248.4 20.3 248.4 247.7 224.6 201.5 178.4 <strong>15</strong>5.377 344.3 19.9 <strong>15</strong>1.3 1<strong>25</strong>.8 100.3 - - - 331.9 21.8 149.2 123.4 97.6 - - -72 322.1 19.4 199.3 173.8 148.3 122.9 - - 308.7 21.3 195.2 169.4 143.6 117.8 - -67 299.9 19.0 247.3 221.8 196.3 170.9 145.4 - 285.5 20.9 241.2 2<strong>15</strong>.4 189.6 163.8 138.0 -62 274.8 18.6 274.8 261.6 233.6 208.1 182.7 <strong>15</strong>7.2 263.1 20.5 263.1 <strong>25</strong>3.6 229.5 203.7 177.9 <strong>15</strong>2.<strong>15</strong>7 267.6 18.5 267.6 266.9 <strong>25</strong>2.3 226.8 201.3 175.8 <strong>25</strong>7.5 20.4 <strong>25</strong>7.5 <strong>25</strong>7.2 243.5 217.7 191.9 166.177 358.3 19.9 165.1 136.8 108.5 - - - 343.7 21.8 162.2 133.7 105.2 - - -72 335.2 19.5 217.0 188.7 1<strong>60</strong>.4 132.1 - - 319.7 21.4 211.8 183.3 <strong>15</strong>4.7 126.2 - -67 312.1 19.1 268.9 240.6 212.3 184.0 <strong>15</strong>5.8 - 295.7 21.0 261.4 232.8 204.3 175.8 147.3 -62 286.0 18.7 286.0 286.0 <strong>25</strong>2.7 224.4 196.1 167.8 272.4 20.5 272.4 272.4 247.4 218.8 190.3 161.857 278.5 18.6 278.5 278.5 272.8 244.5 216.2 188.0 266.7 20.4 266.7 266.7 262.4 233.9 205.4 176.972 337.9 19.7 241.5 205.3 169.0 132.8 - - 321.5 21.5 230.8 196.7 162.6 128.5 - -67 314.6 19.2 293.0 <strong>25</strong>9.9 223.7 187.5 <strong>15</strong>1.2 - 297.3 21.1 280.2 248.8 214.7 180.6 146.5 -62 288.2 18.9 288.2 288.2 268.7 232.4 196.2 1<strong>60</strong>.0 273.9 20.6 273.9 273.9 2<strong>60</strong>.0 2<strong>25</strong>.9 191.8 <strong>15</strong>7.757 280.7 18.7 280.7 280.7 277.9 241.6 205.4 169.1 268.2 20.5 268.2 268.2 266.1 232.0 197.9 163.872 340.5 19.8 266.1 221.8 177.6 133.4 - - 323.3 21.6 249.9 210.2 170.5 130.8 - -67 317.0 19.4 317.0 279.3 235.1 190.9 146.7 - 299.0 21.2 299.0 264.8 2<strong>25</strong>.1 185.5 145.8 -62 290.5 19.0 290.5 290.5 284.7 240.5 196.3 <strong>15</strong>2.1 275.5 20.8 275.5 275.5 272.6 232.9 193.2 <strong>15</strong>3.557 283.0 18.9 283.0 283.0 283.0 238.7 194.5 <strong>15</strong>0.3 269.7 20.7 269.7 269.7 269.7 230.0 190.3 <strong>15</strong>0.795°F 105°F77 300.4 23.6 122.6 101.7 80.9 - - - 280.0 26.0 1<strong>15</strong>.7 95.0 74.3 - - -72 277.6 23.2 1<strong>60</strong>.1 139.3 118.4 97.5 - - 2<strong>60</strong>.0 <strong>25</strong>.4 <strong>15</strong>3.5 132.7 112.0 91.3 - -67 <strong>25</strong>4.9 22.7 197.7 176.8 <strong>15</strong>5.9 135.0 114.1 - 239.9 24.9 191.2 170.5 149.7 129.0 108.2 -62 236.3 22.2 236.3 219.1 192.2 171.3 <strong>15</strong>0.4 129.6 221.9 24.4 221.9 213.1 183.2 162.4 141.7 120.977 310.0 23.7 134.9 111.4 87.8 - - - 289.0 26.0 127.8 104.4 81.0 - - -72 286.5 23.2 175.6 <strong>15</strong>2.1 128.6 105.1 - - 268.3 <strong>25</strong>.4 169.0 145.6 122.1 98.7 - -67 263.0 22.8 216.4 192.9 169.4 145.9 122.3 - 247.6 24.9 210.1 186.7 163.3 139.8 116.4 -62 243.8 22.3 243.8 232.3 208.8 185.3 161.8 138.3 229.0 24.4 229.0 223.2 199.7 176.3 <strong>15</strong>2.9 129.457 240.0 22.2 240.0 240.0 217.5 194.0 170.4 146.9 227.7 24.5 227.7 227.6 204.6 181.2 <strong>15</strong>7.8 134.377 319.6 23.7 147.1 121.0 94.8 - - - 297.9 26.0 139.9 113.8 87.7 - - -72 295.4 23.2 191.1 165.0 138.8 112.7 - - 276.6 <strong>25</strong>.4 184.5 <strong>15</strong>8.4 132.3 106.1 - -67 271.1 22.8 235.1 209.0 182.8 <strong>15</strong>6.7 130.6 - <strong>25</strong>5.3 24.9 229.1 203.0 176.8 <strong>15</strong>0.7 124.6 -62 <strong>25</strong>1.3 22.3 <strong>25</strong>1.3 245.6 2<strong>25</strong>.4 199.3 173.1 147.0 236.1 24.4 236.1 233.2 216.3 190.2 164.1 137.957 247.4 22.2 247.4 247.4 234.8 208.6 182.5 <strong>15</strong>6.3 234.7 24.5 234.7 234.7 221.6 195.5 169.4 143.277 329.2 23.7 <strong>15</strong>9.4 130.6 101.8 - - - 306.9 26.0 <strong>15</strong>2.0 123.2 94.4 - - -72 304.2 23.3 206.6 177.8 149.1 120.3 - - 284.9 <strong>25</strong>.4 200.0 171.2 142.4 113.6 - -67 279.3 22.8 <strong>25</strong>3.9 2<strong>25</strong>.1 196.3 167.5 138.8 - 262.9 24.9 248.0 219.2 190.4 161.6 132.8 -62 <strong>25</strong>8.9 22.3 <strong>25</strong>8.9 <strong>25</strong>8.9 242.0 213.3 184.5 <strong>15</strong>5.7 243.2 24.4 243.2 243.2 232.9 204.1 175.3 146.457 <strong>25</strong>4.9 22.3 <strong>25</strong>4.9 <strong>25</strong>4.9 <strong>25</strong>2.1 223.3 194.5 165.7 241.8 24.5 241.8 241.8 238.6 209.8 180.9 <strong>15</strong>2.172 305.1 23.4 220.2 188.2 <strong>15</strong>6.2 124.3 - - 285.0 <strong>25</strong>.5 212.1 180.4 148.7 116.9 - -67 280.1 22.9 267.4 237.7 205.8 173.8 141.8 - 263.0 <strong>25</strong>.0 <strong>25</strong>5.5 230.5 198.8 167.0 135.3 -62 <strong>25</strong>9.7 22.4 <strong>25</strong>9.7 <strong>25</strong>9.7 <strong>25</strong>1.2 219.3 187.3 <strong>15</strong>5.4 243.3 24.5 243.3 243.3 238.1 206.4 174.7 142.957 <strong>25</strong>5.6 22.4 <strong>25</strong>5.6 <strong>25</strong>5.6 <strong>25</strong>4.2 222.3 190.3 <strong>15</strong>8.4 241.8 24.5 241.8 241.8 240.2 208.5 176.8 145.172 306.1 23.5 233.7 198.6 163.4 128.3 - - 285.0 <strong>25</strong>.6 224.2 189.5 <strong>15</strong>4.9 120.3 - -67 281.0 23.0 281.0 <strong>25</strong>0.4 2<strong>15</strong>.2 180.1 144.9 - 263.0 <strong>25</strong>.1 263.0 241.7 207.1 172.5 137.9 -62 2<strong>60</strong>.4 22.5 2<strong>60</strong>.4 2<strong>60</strong>.4 2<strong>60</strong>.4 2<strong>25</strong>.3 190.2 <strong>15</strong>5.0 243.3 24.6 243.3 243.3 243.3 208.7 174.1 139.457 <strong>25</strong>6.4 22.4 <strong>25</strong>6.4 <strong>25</strong>6.4 <strong>25</strong>6.4 221.3 186.1 <strong>15</strong>1.0 241.9 24.6 241.9 241.9 241.9 207.2 172.6 138.0Johnson Controls Unitary Products 45

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>240 (20 Ton) (Continued)SensibleAir onTemperature of Air on Condenser CoilEvaporator Coil Total TotalCapacity (MBh) Total TotalSensible Capacity (MBh)CFMWB Capacity 1 InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)(°F) (MBh) (kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 651<strong>15</strong>°F 1<strong>25</strong>°F77 <strong>25</strong>9.6 28.3 108.9 88.3 67.7 - - - 239.1 30.7 99.0 81.5 61.1 - - -500072 242.3 27.7 146.8 126.2 105.6 85.0 - - 224.6 30.0 140.1 119.7 99.2 78.8 - -67 2<strong>25</strong>.0 27.1 184.8 164.2 143.6 122.9 102.3 - 210.0 29.3 178.3 <strong>15</strong>7.8 137.4 116.9 96.5 -62 207.6 26.7 207.6 207.2 174.1 <strong>15</strong>3.5 132.9 112.3 193.3 28.9 193.3 193.3 165.0 144.6 124.1 103.777 267.9 28.3 120.8 97.4 74.1 - - - 246.8 30.6 113.8 90.5 67.2 - - -72 <strong>25</strong>0.0 27.7 162.3 139.0 1<strong>15</strong>.6 92.3 - - 231.8 29.9 <strong>15</strong>5.7 132.4 109.2 85.9 - -<strong>60</strong>00 67 232.2 27.1 203.9 180.5 <strong>15</strong>7.2 133.8 110.5 - 216.8 29.2 197.6 174.4 <strong>15</strong>1.1 127.8 104.6 -62 214.3 26.6 214.3 214.0 190.6 167.3 143.9 120.6 199.5 28.8 199.5 199.5 181.6 <strong>15</strong>8.3 135.0 111.757 2<strong>15</strong>.4 26.7 2<strong>15</strong>.4 2<strong>15</strong>.1 191.8 168.4 145.1 121.7 203.0 29.0 203.0 202.7 179.0 <strong>15</strong>5.7 132.4 109.177 276.2 28.2 132.7 106.6 80.5 - - - <strong>25</strong>4.5 30.5 128.5 99.4 73.4 - - -72 <strong>25</strong>7.8 27.6 177.9 <strong>15</strong>1.8 1<strong>25</strong>.7 99.6 - - 239.0 29.8 171.3 145.2 119.1 93.0 - -7000 67 239.4 27.0 223.0 196.9 170.8 144.7 118.6 - 223.5 29.1 217.0 190.9 164.8 138.7 112.7 -62 220.9 26.6 220.9 220.8 207.2 181.1 <strong>15</strong>5.0 128.9 205.7 28.7 205.7 205.7 198.1 172.0 145.9 119.857 222.0 26.7 222.0 221.9 208.4 182.3 <strong>15</strong>6.2 130.1 209.3 28.9 209.3 209.2 195.3 169.2 143.1 117.077 284.5 28.2 144.7 1<strong>15</strong>.8 86.9 - - - 262.2 30.4 143.3 108.4 79.5 - - -72 265.6 27.6 193.4 164.6 135.7 106.9 - - 246.3 29.7 186.8 <strong>15</strong>7.9 129.0 100.1 - -8000 67 246.6 27.0 242.2 213.3 184.5 <strong>15</strong>5.6 126.8 - 230.3 29.1 230.3 207.4 178.5 149.7 120.8 -62 227.6 26.5 227.6 227.6 223.7 194.9 166.0 137.2 212.0 28.6 212.0 212.0 212.0 185.7 <strong>15</strong>6.8 127.957 228.7 26.6 228.7 228.7 2<strong>25</strong>.1 196.2 167.4 138.5 2<strong>15</strong>.7 28.8 2<strong>15</strong>.7 2<strong>15</strong>.7 211.6 182.7 <strong>15</strong>3.8 124.972 264.8 27.7 204.0 172.5 141.1 109.6 - - 244.6 29.8 195.9 164.7 133.5 102.2 - -900067 245.9 27.1 243.6 223.2 191.7 1<strong>60</strong>.3 128.8 - 228.7 29.1 228.7 216.0 184.7 <strong>15</strong>3.5 122.2 -62 226.9 26.6 226.9 226.9 2<strong>25</strong>.0 193.5 162.0 130.5 210.5 28.7 210.5 210.5 210.5 180.6 149.3 118.<strong>15</strong>7 228.0 26.7 228.0 228.0 226.2 194.7 163.2 131.8 214.2 28.9 214.2 214.2 212.2 180.9 149.7 118.572 263.9 27.8 214.6 180.5 146.4 112.3 - - 242.9 29.9 205.1 171.5 137.9 104.3 - -1000067 245.1 27.2 245.1 233.1 199.0 164.9 130.8 - 227.2 29.2 227.2 224.5 190.9 <strong>15</strong>7.3 123.7 -62 226.2 26.7 226.2 226.2 226.2 192.1 <strong>15</strong>8.0 123.9 209.1 28.8 209.1 209.1 209.1 175.5 141.9 108.357 227.3 26.8 227.3 227.3 227.3 193.2 <strong>15</strong>9.1 1<strong>25</strong>.0 212.8 29.0 212.8 212.8 212.8 179.2 145.6 112.01. These capacities are gross ratings. For net capacity, deduct air blower motor, MBh = 3.4<strong>15</strong> x kW. Refer to the appropriate BlowerPerformance Table for the kW of the supply air blower motor.2. These ratings include the condenser fan motors (total 1 kW) and the <strong>com</strong>pressor motors but not the supply air blower motor.46 Johnson Controls Unitary Products

<strong>25</strong>1934-Y<strong>TG</strong>-I-1008<strong>ZF</strong>300 (<strong>25</strong> Ton)Air onEvaporator CoilCFM6<strong>25</strong>0750087501000011<strong>25</strong>01<strong>25</strong>006<strong>25</strong>0750087501000011<strong>25</strong>01<strong>25</strong>00WB(°F)TotalCapacity 1(MBh)SensibleTemperature of Air on Condenser CoilTotalCapacity (MBh) Total TotalSensible Capacity (MBh)(kW) 2 90 85 80 75 70 65 (MBh) (kW) 2 90 85 80 75 70 65InputReturn Dry Bulb (°F)Capacity 1 InputReturn Dry Bulb (°F)75°F 85°F77 368.2 22.7 163.8 139.5 1<strong>15</strong>.2 - - - 335.6 23.9 144.4 118.0 91.7 - - -72 343.8 21.9 213.3 189.1 164.8 140.5 - - 312.8 23.2 190.6 164.2 137.8 111.5 - -67 319.5 21.0 262.9 238.6 214.3 190.0 165.7 - 290.0 22.6 236.7 210.4 184.0 <strong>15</strong>7.6 131.3 -62 296.8 20.6 296.8 296.8 273.1 248.8 224.5 200.2 268.9 22.1 268.9 268.6 231.3 204.9 178.5 <strong>15</strong>2.277 379.3 22.6 176.4 148.7 120.9 - - - 352.1 24.0 <strong>15</strong>8.7 129.4 100.2 - - -72 354.3 21.8 227.4 199.7 171.9 144.2 - - 328.2 23.3 209.1 179.9 <strong>15</strong>0.7 121.4 - -67 329.3 20.9 278.5 <strong>25</strong>0.7 223.0 195.2 167.5 - 304.3 22.6 <strong>25</strong>9.6 230.3 201.1 171.9 142.7 -62 305.9 20.5 305.9 305.9 284.5 <strong>25</strong>6.8 229.1 201.3 282.2 22.2 282.2 282.0 <strong>25</strong>2.8 223.6 194.3 165.<strong>15</strong>7 295.4 20.5 295.4 295.4 281.6 <strong>25</strong>3.9 226.1 198.4 276.0 22.1 276.0 276.0 <strong>25</strong>2.6 223.4 194.2 165.077 390.5 22.5 189.0 <strong>15</strong>7.8 126.6 - - - 368.7 24.0 172.9 140.8 108.7 - - -72 364.7 21.7 241.5 210.3 179.1 147.9 - - 343.6 23.3 227.7 195.6 163.5 131.4 - -67 339.0 20.8 294.0 262.8 231.6 200.4 169.2 - 318.6 22.7 282.4 <strong>25</strong>0.3 218.2 186.2 <strong>15</strong>4.1 -62 3<strong>15</strong>.0 20.4 3<strong>15</strong>.0 3<strong>15</strong>.0 296.0 264.8 233.6 202.4 295.5 22.2 295.5 295.4 274.3 242.2 210.1 178.057 304.0 20.4 304.0 304.0 292.7 261.5 230.3 199.1 289.0 22.1 289.0 289.0 274.1 242.1 210.0 177.977 401.6 22.4 201.6 167.0 132.3 - - - 385.3 24.1 187.2 <strong>15</strong>2.2 117.3 - - -72 375.2 21.6 <strong>25</strong>5.6 220.9 186.3 <strong>15</strong>1.6 - - 359.1 23.4 246.2 211.3 176.3 141.4 - -67 348.8 20.7 309.6 274.9 240.2 205.6 170.9 - 332.9 22.7 305.3 270.3 235.4 200.4 165.5 -62 324.0 20.3 324.0 324.0 307.5 272.8 238.2 203.5 308.8 22.3 308.8 308.8 295.8 2<strong>60</strong>.9 2<strong>25</strong>.9 191.057 312.6 20.3 312.6 312.6 303.7 269.1 234.4 199.8 302.0 22.2 302.0 302.0 295.6 2<strong>60</strong>.7 2<strong>25</strong>.7 190.872 372.4 21.4 275.6 234.4 193.1 <strong>15</strong>1.9 - - 354.6 23.3 263.4 222.6 181.8 141.0 - -67 346.2 20.6 326.6 290.4 249.2 207.9 166.7 - 328.7 22.6 314.9 283.5 242.7 201.9 161.1 -62 321.6 20.1 321.6 321.6 313.4 272.1 230.9 189.6 304.9 22.1 304.9 304.9 298.4 <strong>25</strong>7.6 216.8 176.057 310.4 20.2 310.4 310.4 305.9 264.7 223.4 182.2 298.2 22.1 298.2 298.2 295.0 <strong>25</strong>4.2 213.4 172.672 369.6 21.3 295.6 247.8 200.0 <strong>15</strong>2.2 - - 350.1 23.1 280.6 234.0 187.4 140.7 - -67 343.6 20.4 343.6 305.9 <strong>25</strong>8.1 210.3 162.5 - 324.5 22.5 324.5 296.7 <strong>25</strong>0.1 203.4 <strong>15</strong>6.8 -62 319.2 20.0 319.2 319.2 319.2 271.4 223.6 175.8 301.0 22.0 301.0 301.0 301.0 <strong>25</strong>4.4 207.7 161.<strong>15</strong>7 308.1 20.1 308.1 308.1 308.1 2<strong>60</strong>.3 212.4 164.6 294.4 21.9 294.4 294.4 294.4 247.8 201.1 <strong>15</strong>4.595°F 105°F77 303.0 <strong>25</strong>.1 1<strong>25</strong>.0 96.6 68.2 - - - 287.2 27.1 <strong>15</strong>4.1 129.0 101.8 - - -72 281.7 24.6 167.8 139.3 110.9 82.5 - - 267.0 26.8 184.2 <strong>15</strong>7.0 129.7 102.5 - -67 2<strong>60</strong>.4 24.1 210.5 182.1 <strong>15</strong>3.7 1<strong>25</strong>.3 96.8 - 246.8 26.5 214.3 184.9 <strong>15</strong>7.7 130.4 103.2 -62 241.1 23.7 241.1 230.8 189.5 161.0 132.6 104.2 232.0 26.0 232.0 226.9 192.4 165.1 137.9 110.777 3<strong>25</strong>.0 <strong>25</strong>.3 140.9 110.2 79.5 - - - 305.7 27.2 173.9 144.2 114.6 - - -72 302.1 24.8 190.8 1<strong>60</strong>.1 129.4 98.7 - - 284.2 26.9 206.1 176.4 146.7 117.1 - -67 279.3 24.3 240.7 210.0 179.3 148.6 117.9 - 262.6 26.6 238.3 208.6 178.9 149.2 119.6 -62 <strong>25</strong>8.5 23.9 <strong>25</strong>8.5 <strong>25</strong>1.7 221.0 190.3 <strong>15</strong>9.6 128.9 246.9 26.2 246.9 243.4 218.4 188.7 <strong>15</strong>9.0 129.357 <strong>25</strong>6.6 23.6 <strong>25</strong>6.6 <strong>25</strong>4.4 223.7 193.0 162.3 131.6 245.1 26.2 245.1 244.0 218.5 188.8 <strong>15</strong>9.1 129.577 346.9 <strong>25</strong>.5 <strong>15</strong>6.8 123.8 90.9 - - - 324.2 27.4 193.8 <strong>15</strong>9.5 127.3 - - -72 322.5 <strong>25</strong>.0 213.8 180.8 147.9 114.9 - - 301.3 27.0 228.0 195.9 163.8 131.6 - -67 298.1 24.5 270.8 237.8 204.9 171.9 138.9 - 278.5 26.7 262.3 232.3 200.2 168.1 135.9 -62 276.0 24.1 276.0 272.6 <strong>25</strong>2.6 219.6 186.6 <strong>15</strong>3.7 261.7 26.3 261.7 2<strong>60</strong>.0 244.4 212.2 180.1 147.957 274.0 23.8 274.0 272.9 <strong>25</strong>5.6 222.6 189.7 <strong>15</strong>6.7 <strong>25</strong>9.9 26.3 <strong>25</strong>9.9 <strong>25</strong>9.3 244.6 212.5 180.3 148.277 368.9 <strong>25</strong>.7 172.7 137.4 102.2 - - - 342.6 27.5 213.6 174.7 140.1 - - -72 343.0 <strong>25</strong>.2 236.8 201.6 166.3 131.1 - - 318.5 27.2 <strong>25</strong>0.0 2<strong>15</strong>.4 180.8 146.2 - -67 317.0 24.7 300.9 265.7 230.5 195.2 1<strong>60</strong>.0 - 294.3 26.9 286.3 <strong>25</strong>6.0 221.5 186.9 <strong>15</strong>2.3 -62 293.5 24.3 293.5 293.5 284.1 248.9 213.6 178.4 276.6 26.4 276.6 276.6 270.4 235.8 201.2 166.657 291.3 24.0 291.3 291.3 287.5 <strong>25</strong>2.3 217.1 181.8 274.6 26.5 274.6 274.6 270.7 236.1 201.5 166.972 336.7 <strong>25</strong>.1 <strong>25</strong>1.2 210.9 170.5 130.2 - - 311.7 27.4 261.2 224.8 184.6 144.3 - -67 311.3 24.6 303.2 276.6 236.3 195.9 <strong>15</strong>5.6 - 288.0 27.1 284.0 264.4 226.2 186.0 145.7 -62 288.2 24.1 288.2 288.2 283.5 243.1 202.8 162.4 270.7 26.7 270.7 270.7 267.6 227.3 187.1 146.857 286.0 23.9 286.0 286.0 284.1 243.8 203.4 163.1 268.7 26.7 268.7 268.7 266.8 226.5 186.3 146.072 330.5 <strong>25</strong>.0 265.7 220.2 174.7 129.2 - - 304.9 27.6 272.5 234.3 188.4 142.5 - -67 305.5 24.5 305.5 287.6 242.1 196.6 <strong>15</strong>1.1 - 281.8 27.3 281.8 272.8 231.0 185.1 139.2 -62 282.8 24.0 282.8 282.8 282.8 237.3 191.9 146.4 264.8 26.9 264.8 264.8 264.8 218.9 173.0 127.<strong>15</strong>7 280.7 23.8 280.7 280.7 280.7 235.3 189.8 144.3 262.9 26.9 262.9 262.9 262.9 217.0 171.1 1<strong>25</strong>.2Johnson Controls Unitary Products 47